Editorial Open Access

Towards Thermoplastic Lignin Polymers: Progress in the Utilization of Kraft Lignin for the Synthesis of Heat Stable Polymer Melts

Dimitris S Argyropoulos1,2*1Department of Chemistry and Forest Biomaterials, North Carolina State University, Raleigh, NC, USA

2Center of Excellence for Advanced Materials Research (CEAMR), King Abdulaziz University, P.O. Box 80203, Jeddah 21589, Saudi Arabia

- Corresponding Author:

- Dimitris S Argyropoulos

Department of Chemistry and Forest Biomaterials

North Carolina State University

Raleigh, NC, USA

E-mail: dsargyro@ncsu.edu

Received date: September 12, 2013; Accepted date: September 13, 2013; Published date: September 19, 2013

Citation: Argyropoulos DS (2013) Towards Thermoplastic Lignin Polymers: Progress in the Utilization of Kraft Lignin for the Synthesis of Heat Stable Polymer Melts. J Biotechnol Biomater 3:e123. doi:10.4172/2155-952X.1000e123

Copyright: © 2013 Argyropoulos DS, et al. This is an open-access article distributed under the terms of the Creative Commons Attribution License, which permits unrestricted use, distribution, and reproduction in any medium, provided the original author and source are credited.

Visit for more related articles at Journal of Biotechnology & Biomaterials

Most efforts to utilize lignin have been limited by various factors that impart in it characteristics that define it as an unreliable precursor to polymer production. This is because lignin (and more specifically technical lignin) offers relatively unpredictable polymerization characteristics, depending upon its source and the degree of delignification to which the plant materials were subjected. More specifically, the highly functional character of lignin (i.e. rich in phenolic and aliphatic OH groups, as well as reactive benzylic carbons), induces a variety of potential polymerization sites and heat instability in such materials. Both factors promote gelation processes under polymerization conditions or when the temperature increases close to, and/or above the glass transition temperature (Tg). In addition, the relatively low molecular weight (a few thousands) for lignin derived from commercial pulping and biorefinery operations makes lignin unsuitable for higher end applications, such as high performance, heat stable engineering thermoplastic applications.

The work of our group at NCSU has focused at providing a detailed molecular understanding of the way the polymeric properties of kraft lignin and its derivatives are affected by their thermal treatments. This information was then correlated with the polymeric properties of the materials (glass transition temperature (Tg), molecular weight characteristics, and thermal stability), for a series of selectively and progressively derivatized softwood kraft lignin samples [1]. Softwood kraft lignin was shown to be highly susceptible to thermally induced reactions that cause its molecular characteristics to be severely altered with the concomitant formation of irreversible crosslinking with no thermoplastic processing possibilities. However, by fully methylating the phenolic OH groups [2], from within the structure of softwood kraft lignin, the thermal stability of these materials was seen to be dramatically enhanced and their Tg’s reduced [1]. Optimum thermal stability and melt cycling was observed with the fully methylated derivatives. The accumulated data is aimed at providing the foundations for a rational design of single or multi-component lignin-based thermoplastic materials with reproducible polymeric properties when thermally processed in a number of manufacturing cycles [1-3].

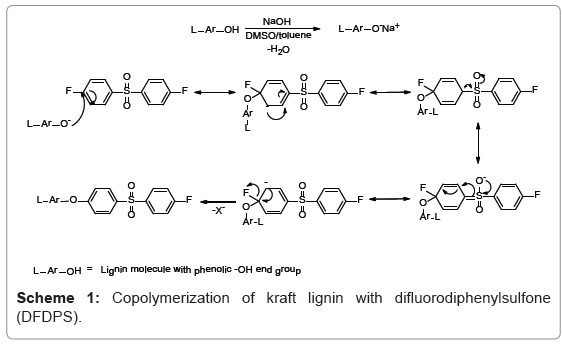

Furthermore, we have been able to create polyarylene (ether sulfone)-kraft lignin copolymers synthesized by a base catalyzed stepwise copolymerization of suitably functionalized, fractionated kraft lignin with 4,4’-Diflourodiphenyl Sulfone ( DFDPS) in an aprotic solvent at elevated temperatures (Scheme 1) [3].

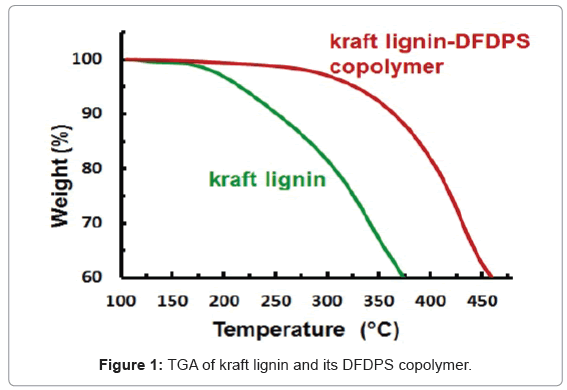

The benefits of incorporating DFDPS within kraft lignin are apparent in the TGA thermograms of the copolymer shown in Figure 1. Thermally stable polymer melts exceeding 300°C are apparently attainable [3].

Conclusions and Overall Outlook

This effort offers novel avenues at creating reactive lignin materials that are stabilized and rendered better suited for industrial applications. It provides methods for creating lignins of controlled and modulated characteristics, exhibiting thermal and polymerization stabilities. Such thermal properties and stable molecular weight distributions of lignins and copolymers produced from commercial lignins provides a means for beneficially modulating the properties of an otherwise intractable bio-polymer.

References

- Cui C, Sadeghifar H, Sen S, Argyropoulos DS (2013) Toward thermoplastic lignin polymers; Part II: Thermal and Polymer Characteristics of Kraft Lignin and Derivatives. BioResources 8: 864-886.

- Hasan S, Chengzhong C, Dimitris SA (2012) Toward thermoplastic lignin polymers. Part I. Selective Masking of phenolic hydroxyl groups in kraft lignins via methylation and oxypropylation chemistries. Ind Eng Chem Res 51:16713-16720.

- Dimitris S. Argyropoulos (2012) High value lignin derivatives. Polymers and Copolymers and Use Thereof in Thermoplastic, Thermoset and Composite Applications. US Patent Application No:61/601,181.

Relevant Topics

- Agricultural biotechnology

- Animal biotechnology

- Applied Biotechnology

- Biocatalysis

- Biofabrication

- Biomaterial implants

- Biomaterial-Based Drug Delivery Systems

- Bioprinting of Tissue Constructs

- Biotechnology applications

- Cardiovascular biomaterials

- CRISPR-Cas9 in Biotechnology

- Nano biotechnology

- Smart Biomaterials

- White/industrial biotechnology

Recommended Journals

Article Tools

Article Usage

- Total views: 15084

- [From(publication date):

August-2013 - Mar 31, 2025] - Breakdown by view type

- HTML page views : 10415

- PDF downloads : 4669