Research Article

Paddy Processing Mills in India: An Analysis

| Komol Singha* | ||

| Institute for Social and Economic Change, India | ||

| Corresponding Author : | Komol Singha Institute for Social and Economic Change, India Tel: +91-80-23215468 E-mail: komol@isec.ac.in |

|

| Received October 17, 2013; Accepted November 17, 2013; Published November 20, 2013 | ||

| Citation: Singha K (2013) Paddy Processing Mills in India: An Analysis. J Rice Res 1:115. doi: 10.4172/jrr.1000115 | ||

| Copyright: © 2013 Singha K. This is an open-access article distributed under the terms of the Creative Commons Attribution License, which permits unrestricted use, distribution, and reproduction in any medium, provided the original author and source are credited. | ||

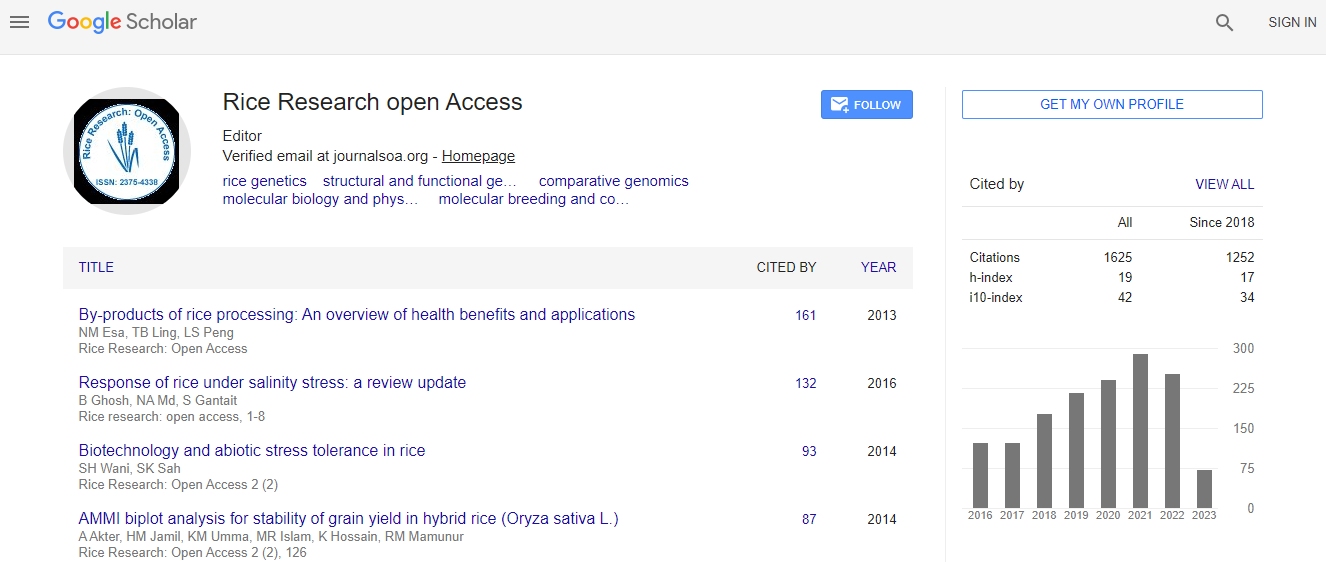

Related article at Pubmed Pubmed  Scholar Google Scholar Google |

||

Abstract

Rice (Oryza sativa L.) has been the staple food for more than half of humanity in the world. India is the second largest producer of rice in the world, consuming around 95% of what it produces. India is also the third largest exporter of rice in the world. Due to the high growth of population in recent years, there has been more pressure on arable land. This in turn has created a need for higher productivity in food crops. Concurrently, large quantities of food-grain were reported to be lost due to inefficient milling processes in the country. As such, there have been calls for better processing techniques in order to reduce processing losses. Using 442 sample mills across five major paddy producing States, the conversion ratio from paddy to polished rice was estimated and found to be around 64% for modern and 58.6% for traditional (huller) mills. The variation of conversion ratios among the States was found to be quite negligible, and fractional variation observed was due to differences in quality of the raw paddy used and infrastructure facilities available.

Spanish

Spanish  Chinese

Chinese  Russian

Russian  German

German  French

French  Japanese

Japanese  Portuguese

Portuguese  Hindi

Hindi