Review Article

Design of Solar Lime Kiln

Rajaram Swaminathan* and Shikongo Tomas NadhipiteDepartment of Mechanical and Marine Engineering, Namibia University of Science and Technology, Namibia

- *Corresponding Author:

- Rajaram Swaminathan

Department of Mechanical and Marine Engineering

Namibia University of Science and Technology, Namibia

Tel: +264612072167

Fax: +264612079167

E-mail: rswaminathan@nust.na

Received date: September 15, 2017; Accepted date: September 18, 2017; Published date: September 25, 2017

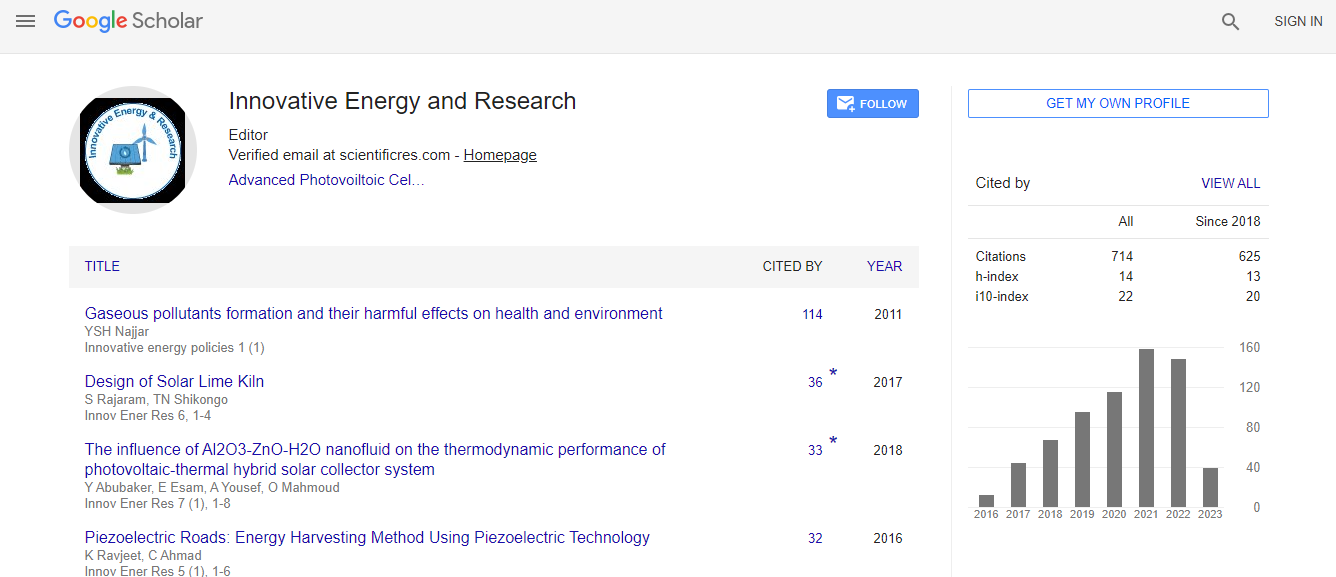

Citation: Swaminathan R, Nadhipite ST (2017) Design of Solar Lime Kiln. Innov Ener Res S1:001. doi: 10.4172/2576-1463.S1-001

Copyright: © 2017 Swaminathan R, et al. This is an open-access article distributed under the terms of the Creative Commons Attribution License, which permits unrestricted use, distribution, and reproduction in any medium, provided the original author and source are credited.

Abstract

Calcium oxide (CaO), commonly known as quicklime is a key ingredient of cement. It is produced by thermal dissociation of limestone (CaCO3) in a calcination reaction. The process of converting limestone to quicklime involves heating limestone to a temperature of 1200-1400K. This thermal dissociation reaction produces carbon dioxide (CO2). The heat required for the process is habitually supplied by the combustion of coal or, oil in the lime kiln. The combustion of these fuels produces additional CO2 emission which represents around 40% of the cement plant CO2 emissions. This emission can be reduced by switching to fuels, like natural gas, biomass or waste-derived fuels. The use of concentrated solar energy as the source of process heat is an energy efficient alternative.

This paper presents the design of a mini, scalable solar lime kiln which was designed from first principles. The kiln is designed to calcine small-grained (1-5 mm diameter) limestone particles. A solar dish collector is proposed to supply the required heat energy at the desired temperature. The heat is focussed on a heating element located centrally in a tilted rotary kiln driven by chain drive. The carbon dioxide emitted from the calcination reaction is released to prevent re-carbonation of limestone. The heating element can easily be replaced with another heat source such as electrical heating. The design procedure and design simulation are detailed in the paper.

Spanish

Spanish  Chinese

Chinese  Russian

Russian  German

German  French

French  Japanese

Japanese  Portuguese

Portuguese  Hindi

Hindi