Short Communication Open Access

Value Added Biomaterials via Laccase-Mediated Surface Functionalization

Mark D Cannatelli 1 and Arthur J Ragauskas 2*1School of Chemistry & Biochemistry, Renewable Bioproducts Institute, Georgia Institute of Technology, Atlanta, GA 30332, USA

2Department of Chemical & Biomolecular Engineering, Department of Forestry, Wildlife & Fisheries, University of Tennessee, Knoxville, TN 37996, USA

- Corresponding Author:

- Arthur J Ragauskas

Department of Chemical & Biomolecular Engineering

Department of Forestry, Wildlife & Fisheries

University of Tennessee, Knoxville

TN 37996, USA

E-mail: Art.Ragauskas@rbi.gatech.edu

Received date: January 30, 2015; Accepted date: April 16, 2015; Published date: April 22, 2015

Citation: Cannatelli MD, Ragauskas AJ (2015) Value Added Biomaterials via Laccase-Mediated Surface Functionalization. J Biotechnol Biomater 5:175. doi:10.4172/2155-952X.1000175

Copyright: © 2015 Ragauskas AJ et al. This is an open-access article distributed under the terms of the Creative Commons Attribution License, which permits unrestricted use, distribution, and reproduction in any medium, provided the original author and source are credited.

Visit for more related articles at Journal of Biotechnology & Biomaterials

Short Communication

As we delve deeper into the 21st century, concerns regarding the current state of the environment and the future of the planet continue to rise. In response, companies and organizations from a broad spectrum of industries are increasing their involvement in joining the worldwide effort to incorporate sustainability into existing operations.

The implementation of the biorefining concept, whose mission is to maximize the use of all constituents of biomass, including pulp and paper, lumber and the biofuels sectors has increased the sustainability of these industries as well as provided an avenue for the production of extensive amounts of biomaterials [1]. Nowadays, biomass derived materials are incorporated into a wide array of consumer products, ranging from sophisticated biomedical devices to the plastic bottles that contain our beverages. These bio products not only provide the advantages of being renewable, sustainable, and biodegradable compared to synthetic materials, but they can be of lower cost and non-toxic. For the most part, biomaterials are mainly derived from woody and plant biomass, which comprise of three main biopolymers: cellulose, hemicellulose, and lignin. Whilst cellulose has many uses (paper products and conversion to ethanol to name a couple), the conversion of lignin into valuable products is far less established and thus has become is a growing research direction within the biorefinery committee [2].

One strategy aimed at adding value to lignocellulosic biomass is by functionalizing the surface of these materials via chemical grafting thereby creating materials with improved properties such as strength, antimicrobial resistance, and water resistance. This grafting procedure can be achieved either chemically or enzymatically. Compared to chemical methods, the enzymatic approach allows for the production of functionalized biomaterials in an eco-friendly manner as the reaction conditions are frequently much milder, renewable and based on the use of biodegradable enzymes frequently accomplished in an aqueous system.

Laccases (benzenediol:oxygen oxidoreductase EC 1.10.3.2) are a class of multicopper oxidases that are found in a variety of fungi, bacteria, plants, algae, and insects [3]. They catalyze the four electron reduction of O2 to two H2O coupled to the oxidation of four substrate molecules, making them a “green” catalyst of choice for a variety of oxidative processes ranging from pulp delignification to the synthesis of fine chemicals. Given that lignin is a natural laccase substrate, it is logical that these enzymes have been increasingly employed in the past two decades to functionalize lignocellulosic fibers [4,5]. The novel biomaterials created exhibit improved antimicrobial, hydrophobic, and strength properties.

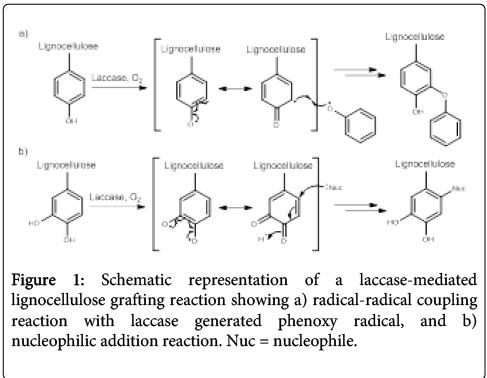

Surface functionalization can be achieved in a number of ways, one of which is by covalently linking small molecules onto the surface exposed lignin units. Thus, it is largely the properties of the grafted molecules that determine the properties of the newly formed material. Mechanistically, this grafting can occur via a radical-radical coupling reaction or a nucleophilic addition (Figure 1). The reactions can be conducted both in the presence or absence of a laccase-mediator – a small molecule that, when oxidized by laccase, can go on to oxidize other substrates.

Improving the antimicrobial properties of lignocellulosic material is of interest for medical and hygiene applications as well as food packaging and other material applications. It has been demonstrated that laccases can be used to functionalize kraft linerboard fibers with a variety of phenolic compounds (e.g. p-hydroxybenzoic acid, caffeic acid), resulting in an enhanced bactericidal effect [6]. The new material may be a viable alternative for food packaging as it may prevent food deterioration, increase shelf-life, and ultimately reduce the amount of preservatives that are added to food. A similar improvement in antimicrobial properties with the incorporation of phenols was also observed for flax fibers, which are a non-woody form of lignocellulosic biomass [7]. Very recently, Catel-Ferreira et al. developed a novel method for the production of antiviral Kimwipes® [8]. The wipes, which are made of cellulosic fibers, can be functionalized with the polyphenol catechin employing laccase as the grafting agent. The new wipes showed antiviral activity and can potentially be used as antiviral wipes or in face masks.

Attributing to their capacity for hydrogen bonding, lignocellulosic fibers are inherently hydrophilic, rendering them impractical for use in applications where waterproofing and adhesion with hydrophobic materials are required. Thus, converting lignocellulosic fibers into a hydrophobic material has been of interest to researchers for an extended time period. For example, in order to increase the hydrophobicity of beech veneers, laccases were employed to graft fluorophenols onto the surface of the veneers [9]. The increased hydrophobicity is important for protecting construction wood from weathering and biodegradation. A common hydrophobizing agent is lauryl gallate. Due to its long alkyl side chain, it has been used in conjunction with laccases to functionalize a variety of lignocellulosic fibers. Garcia-Ubasart et al. demonstrated that this technology could be used on hardwood kraft pulp to reduce water penetration and wettability of the resulting handsheets [10], while another study used the process on jute fibers to develop a material that was more compatible with hydrophobic resins and could therefore be used as reinforcement in composites [11]. The protection of wood against microbial and fungal activity has also been advanced by employing an innovative laccase-catalyzed iodination of the wood [12] or phenolics [13]. Laccase catalyzed generation of iodo-phenolics, such as iodovanillin and iodo-ethyl vanillin, has been shown to have substantial growth inhibitory effects on several wood degrading fungal species.

Strength properties, such as wet and dry tensile strength, tear, and burst, are of great importance in the manufacturing of paper products. These stringent property standards must be maintained so that paper and packaging products meet the quality needs of their applications. Previous research within our group has showed that laccase-assisted grafting of amino acids onto the surface of high-lignin content softwood kraft pulp can yield handsheets with improved wet and dry tensile strength as well as improved tear resistance [14]. It is believed that the increase in strength properties may be due to an increase in anionic charge of the fibers introduced by the carboxylate groups of the amino acids grafted onto the fibers via laccase. Similar increases in these strength properties were also obtained by using laccases to graft gallic acid onto the surface of a similar softwood kraft pulp [15].

The field of lignocellulosic fiber modification to create value added biomaterials has not only provided an avenue for the productive use of lignin while further establishing the biorefinery, but has also engineered some truly remarkable materials with widespread, practical applications. Combined with the use of laccases as the grafting agents, this biotechnological approach is sustainable and garnering greater scientific effort [16,17]. Furthermore, this biotechnology platform is not only limited to lignocellulosic biomass, as it has also been used to functionalize chitosan [18]. Thus, it will be interesting to witness in the years ahead not only the types of novel biomaterials that can be made from lignocellulosic biomass, but also what other types of biopolymers can be modified and the corresponding new materials that are generated.

References

- Ragauskas AJ, Williams CK, Davison BH, Britovsek G, Cairney J, et al. (2006) The path forward for biofuels and biomaterials. Science 311: 484-489.

- Ragauskas AJ, Beckham GT, Biddy MJ, Chandra R, Chen F, et al. (2014) Lignin valorization: improving lignin processing in the biorefinery. Science 344: 1246843.

- Dwivedi UN, Singh P, Pandey VP, Kumar A (2011) Structure–function relationship among bacterial, fungal and plant laccases. J MolCatal B: Enzym 68: 117-128.

- Kudanga T, Nyanhongo GS, Guebitz GM, Burton S (2011) Potential applications of laccase-mediated coupling and grafting reactions: a review. Enzyme MicrobTechnol 48: 195-208.

- Kalia S, Thakur K, Kumar A, Celli A (2014) Laccase-assisted surface functionalization of lignocellulosics. J MolCatal B: Enzym 102: 48-58.

- Elegir G, Kindl A, Sadocco P, Orlandi M (2008) Development of antimicrobial cellulose packaging through laccase-mediated grafting of phenolic compounds. Enzyme MicrobTechnol 43: 84-92.

- Schroeder M, Aichernig N, Guebitz GM, Kokol V (2007) Enzymatic coating of lignocellulosic surfaces with polyphenols. Biotechnol J 2: 334-341.

- Catel-Ferreira M, Tnani H1, Hellio C, Cosette P, Lebrun L (2015) Antiviral effects of polyphenols: development of bio-based cleaning wipes and filters. J Virol Methods 212: 1-7.

- Kudanga T, Prasetyo EN, Widsten P, Kandelbauer A, Jury S, et al. (2010) Laccasecatalyzed covalent coupling of fluorophenols increases lignocellulose surface hydrophobicity. BioresourTechnol 101: 2793-2799.

- Garcia-Ubasart J, Colom JF, Vila C, Gómez Hernández N, Roncero MB, et al. (2012) A new procedure for the hydrophobization of cellulose fibre using laccase and a hydrophobic phenolic compound. BioresourTechnol 112: 341-344.

- Dong A, Yu Y, Yuan J, Wang Q, Fan X (2014) Hydrophobic modification of jute fiber used for composite reinforcement via laccase-mediated grafting. Appl Surf Sci 301: 418-427.

- Schubert M, Engel J, Thöny-Meyer L, Schwarze FW, Ihssen J (2012) Protection of wood from microorganisms by laccase-catalyzed iodination. Appl Environ Microbiol 78: 7267-7275.

- Ihssen J, Schubert M, Thöny-Meyer L, Richter M1 (2014) Laccasecatalyzed synthesis of iodinated phenolic compounds with antifungal activity. PLoS One 9: e89924.

- Witayakran S, Ragauskas AJ (2009) Modification of high-lignin softwood kraft pulp with laccase and amino acids. Enzyme MicrobTechnol 44: 176-181.

- Chandra RP, Lehtonen LK, Ragauskas AJ (2004) Modification of high lignin content kraft pulps with laccase to improve paper strength properties. 1. Laccase treatment in the presence of gallic acid. Biotechnol Prog 20: 255-261.

- Kalia S, Thakur K, Kumar A, Celli A (2014) Laccase-assisted surface functionalization of lignocellulosics. J Mol Catal B: Enzym 102: 48-58.

- Kudanga T, Nyanhongo GS, Guebitz GM, Burton S (2011) Potential applications of laccase-mediated coupling and grafting reactions: a review. Enzyme MicrobTechnol 48: 195-208.

- Yu C, Pei J, Zhang F (2014) Heterogeneous method for grafting of syringaldehyde onto chitosan by laccase oxidation. Appl Mech Mater 477-478: 1340-1344.

Relevant Topics

- Agricultural biotechnology

- Animal biotechnology

- Applied Biotechnology

- Biocatalysis

- Biofabrication

- Biomaterial implants

- Biomaterial-Based Drug Delivery Systems

- Bioprinting of Tissue Constructs

- Biotechnology applications

- Cardiovascular biomaterials

- CRISPR-Cas9 in Biotechnology

- Nano biotechnology

- Smart Biomaterials

- White/industrial biotechnology

Recommended Journals

Article Tools

Article Usage

- Total views: 16486

- [From(publication date):

April-2015 - Jul 11, 2025] - Breakdown by view type

- HTML page views : 11779

- PDF downloads : 4707