Research Article Open Access

Using X-Ray Fluorescence to Examine Ancient Extractive Metallurgy Practices: A Case Study from Iron Age Khirbat al-Jariya, Jordan

Liss B* and Levy TECUCSD Levantine and Cyber-Archaeology Lab, University of California, San Diego, USA

- *Corresponding Author:

- Brady Liss

UCSD Levantine and Cyber-Archaeology Lab

University of California, San Diego, USA

Tel: 203-482-0050

E-mail: bradyjliss@gmail.com

Received Date: December 29, 2015; Accepted Date: January 12, 2016; Published Date: January 20, 2016

Citation:Liss B, Levy TE (2016) Using X-Ray Fluorescence to Examine Ancient Extractive Metallurgy Practices: A Case Study from Iron Age Khirbat al-Jariya, Jordan. J Powder Metall Min 4:140. doi:10.4172/2168-9806.1000140

Copyright: © 2016 Liss B, et al. This is an open-access article distributed under the terms of the Creative Commons Attribution License, which permits unrestricted use, distribution, and reproduction in any medium, provided the original author and source are credited.

Visit for more related articles at Journal of Powder Metallurgy & Mining

Abstract

The first industrial revolution to appear in the southern Levant (Israel, Jordan, Palestine, Lebanon, southern Syria and the Sinai Peninsula) occurred during Iron Age (ca. 1200-500 BCE) when large scale copper smelting occurred. The hub of this technological development occurred in the Faynan region of Southern Jordan, which is home to the largest copper ore deposits in the southern Levant. Throughout history, these abundant ores were exploited by local populations with copper production reaching an industrial scale in the 10th and 9th centuries BCE. The evidence for this massive production remains visible on the surface throughout Faynan at ancient smelting sites populated with large heaps of industrial copper slag. Khirbat al-Jariya (KAJ), one such copper smelting center, was the focus of renewed excavations by the Edom Lowlands Regional Archaeology Project in the summer of 2014. In order to investigate the history of metal production at KAJ, a test probe was excavated into one of the site’s slag mounds. The 1×1 meter sounding was excavated to bedrock to provide a complete representation of copper smelting activities during the site’s history. To supplement excavations, our team collected geo-referenced slag samples from stratigraphically controlled contexts within the probe and from several other slag mounds around the site at KAJ. These samples were subsequently the focus of post-season X-Ray Fluorescence (XRF) analysis to provide insight beyond the visible record. By combining the XRF results with the chronological framework provided by archaeological excavation, it is possible to examine diachronic changes in the elemental compositions of the slag samples. In turn, the elemental contents of the slag can be used as a proxy for evaluating the extractive metallurgy practices of the ancient metalworkers. Thus, this paper presents the results of the XRF analyses and the possible conclusions to be drawn concerning ancient copper smelting at Khirbat al-Jariya.

Keywords

Ancient extractive metallurgy; Archaeometallurgy; X-Ray fluorescence; Copper smelting; Faynan

Introduction

Archaeology is paradoxically rooted in the past but dependent on the future. Modern advancements in the hard sciences and technologies have provided archaeologists with new and insightful ways to investigate the material culture of previous generations. This “marriage” of archaeology and science/engineering, now termed cyberarchaeology, created a new tool box for the modern archaeologist [1]. One such tool, X-Ray Fluorescence (XRF), allows archaeologists to ‘dig’ into individual artifacts and go beyond the visible record. Its elemental vision and (in some cases) non-destructive methodology made XRF immediately appealing to archaeological research, and it has since became a popular instrument for cyber-archaeologists [2]. In particular, using XRF has become a regular practice in investigating metallurgical remains and artifacts (i.e., archaeometallurgy) both in the field and in the lab. As such, archaeological investigations in the Faynan region of southern Jordan, one of the largest copper ore deposits in the eastern Mediterranean, have integrated XRF into the cyber-archaeology work flow.

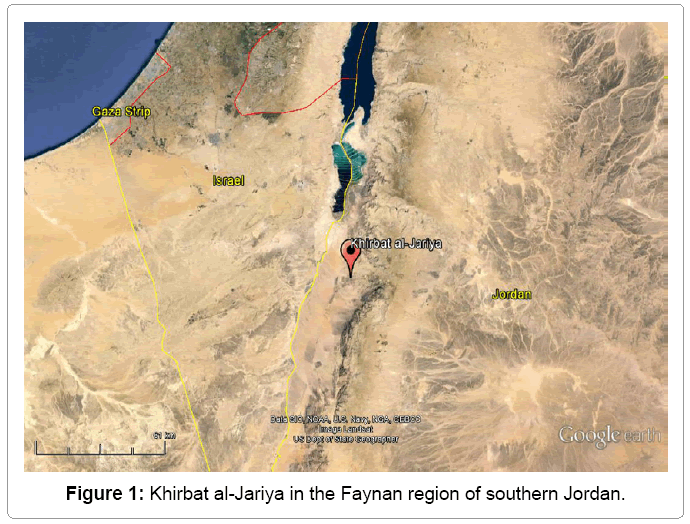

Since 1997, the University of California, San Diego Edom Lowlands Regional Archaeology Project (ELRAP) has been surveying and excavating in Faynan [3]. Throughout history, the region’s abundant ores were exploited by local populations with copper production reaching an industrial scale in the Iron Age (ca. 10th and 9th centuries BCE) [3,4]. The evidence for this massive production remains visible on the surface throughout Faynan at ancient smelting sites populated with large heaps of copper slag. Khirbat al-Jariya (KAJ), one such copper smelting center, was the focus of renewed excavations by the ELRAP in the summer of 2014 (Figure 1). In order to investigate the history of metal production at KAJ, a 1×1 meter test probe was excavated into one of the site’s slag mounds. The sounding was excavated to bedrock to provide a complete representation of copper smelting over the site’s history. In addition, researchers collected slag samples from controlled contexts within the probe and from several other slag mounds at KAJ. These samples were subsequently the focus of post-season XRF analysis. By combining the XRF results with the chronological scaffolding provided by archaeological excavation, it is possible to examine diachronic changes in the compositions of the slag samples. The elemental contents of the slag can then be used as a proxy for evaluating the extractive metallurgy practices of the ancient metalworkers [4]. Thus, this paper presents the results of the XRF analyses and the possible conclusions to be drawn concerning ancient copper smelting at Khirbat al-Jariya.

Geological considerations

The copper ores of Faynan formed through a series complex geological processes and mineralizations [5]. The richest deposits of these ores are found in the Cambrian Dolomite-Limestone Shale (DLS) formation (also known as the “Burj Formation”) [5]. Within Faynan, this geological unit ranges in thickness from 20-40 meters, but the richest copper mineralizations are found in the top layers in a shale unit between 1-1.5 meters thick [5]. Uniquely, the copper ores of the DLS are characterized by a significant presence and intergrowth of manganese ores (to be discussed further below) [5]. These copper and manganese mineralizations can be found in Faynan above the dark outcrops and terraces of dolomites and limestone in the DLS [5]. The exposed layers of the DLS provided an accessible and principal ore source for copper smelting by local populations in antiquity [5]. In addition, as will be seen, the exploitation of these ores left an important mark on the archaeological record.

Khirbat al-Jariya (KAJ)

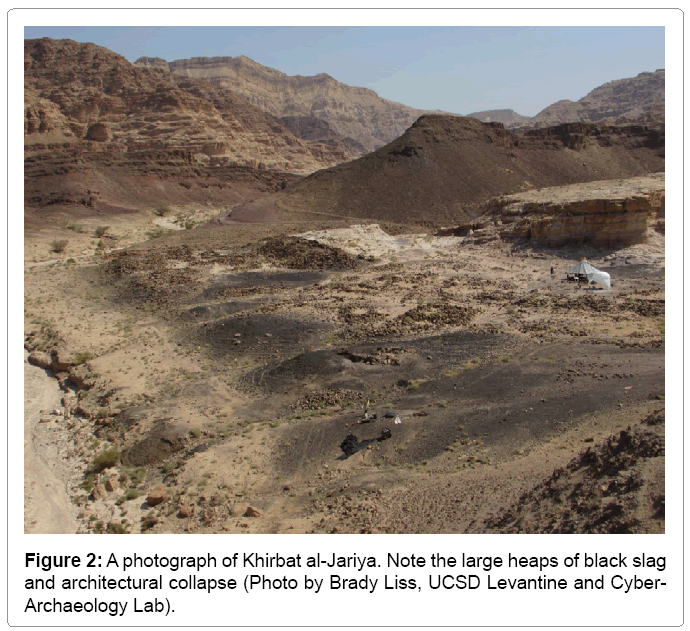

KAJ is one of the largest copper smelting centers in the Iron Age industrial landscape of Faynan (Figure 2). Located among the local monzogranite mountains, with the exception of natural formation processes of erosion, KAJ was primarily undisturbed since its Iron Age abandonment, leaving a relatively pristine record for archaeological research. The site covers an area of roughly 7 hectares, stretching across both sides of the seasonal riverbed (Wadi al-Jariya) that runs through its central portion [6]. The material remains at KAJ are primarily architecture (identifiable by heaps of stone collapse) and large mounds of copper slag still visible on the surface. These mounds distributed across the site contain an estimated 15,000-20,000 tons of slag attesting to the significance of production [5]. Archaeological investigations prior to the 2014 season included surveys and limited excavations in the southern part of the site [4-8]. These projects dated the site to the early Iron Age (the 11th and 10th centuries BCE) based on ceramics, technical ceramics, radiocarbon dates, and a geomagnetic intensity study [5-7]. However, the localized and small-scale nature of previous excavations by our team warranted renewed investigations by the ELRAP in 2014 to further explore additional areas of KAJ.

The 2014 slag mound excavation

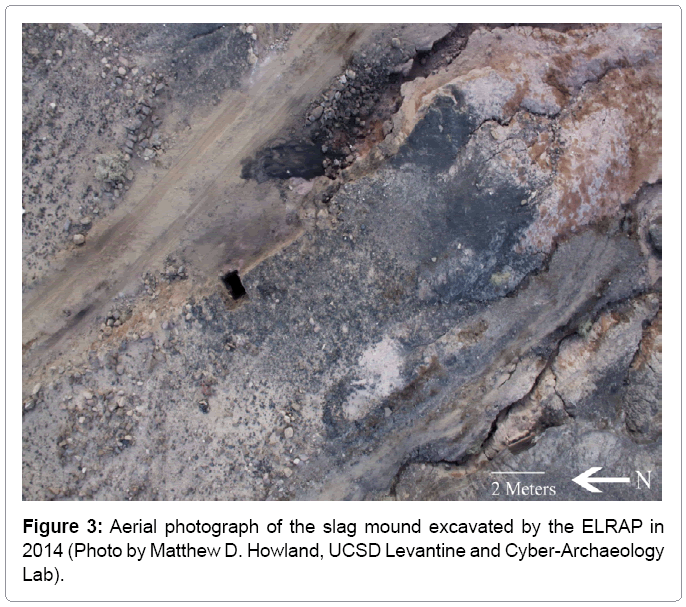

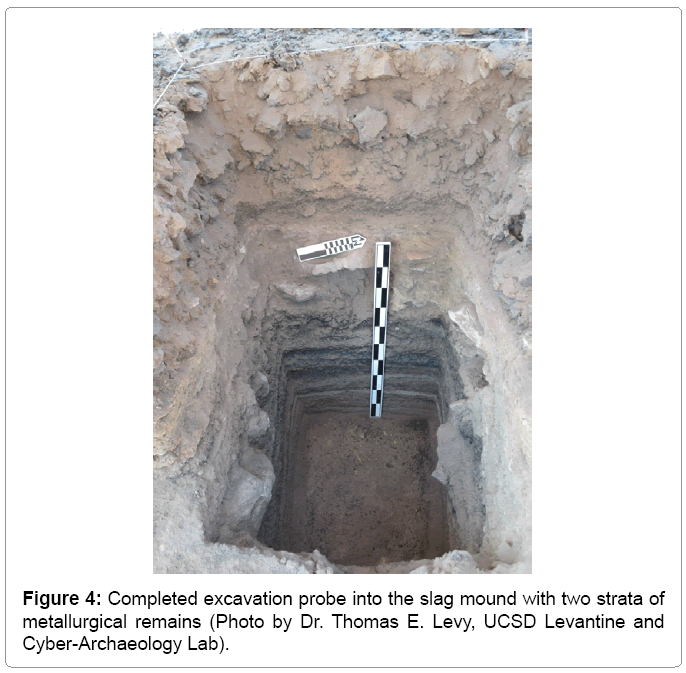

As part of the 2014 excavations, a slag mound at KAJ was selected for a test probe to explore its contents, and in turn, the history of metal production in this part of the site. This particular mound is located on the southeastern outskirts, and it was identified by the presence of broken slags on the surface (Figure 3). The slag heap was cut on its northeast and southwest edges by modern mining roads that run along the eastern extent of KAJ, exposing additional metallurgical remains beneath the surface. The 1 × 1 meter sounding was systematically excavated to the site’s bedrock at a depth of about 1.75 meters (Figure 4). Excavations revealed three distinct layers with unique collections of artifacts. The first approximately 50 centimeters of excavated material consisted almost entirely of large slag fragments (5-25 centimeters in diameter), probably representing the major copper production phase at KAJ. Beneath this stratum, the material culture drastically changed in a layer representing a possible habitation phase; there were almost no metallurgical materials collected. Finally, the last roughly 80 centimeters of the slag mound was entirely crushed slag above bedrock (slag was crushed to extract copper prills and bits trapped in its matrix). To summarize, the slag mound probe revealed two strata associated with copper smelting separated by a layer that appears to be related to habitation/domestic functions. The crushed slag at the bottom represents an early phase of production at the site; its location directly above bedrock reiterates the site was established for copper smelting [6]. The second phase on the surface associated with large fragments of slag was probably the main and final period of copper production prior to the site’s abandonment.

In order to supplement this somewhat static interpretation, the ELRAP also collected slag samples from both the probe and additional slag mounds at KAJ for XRF analysis. Representative geo-referenced samples were collected from both slag layers visible in the mound sounding including two large slag fragments and a selection of crushed slag (Figure 5). While the sample size is admittedly small, slag samples sufficiently representative of their respective contexts were selected to facilitate generalizable conclusions. Furthermore, six additional samples were assembled from other mounds of crushed slag found at KAJ for comparison. These small mounds were sectioned to look for possible variations through their contents, and samples were collected based on such or at arbitrary distances through the cross-section. All of the samples were returned to the University of California, San Diego Levantine and Cyber-Archaeology Lab for preparation and analysis.

Methods

Ancient slags are inherently heterogeneous in content. The extractive metallurgy of the past often resulted in bits and prills of copper entrapped in the slag’s matrix. As such, using a XRF instrument with a small spot of analysis can result in drastically different compositional outcomes based on the selected location of analysis. For example, if the instrument’s beam partially or wholly included one of these bits of copper, the results will be an unrepresentative elemental composition of the slag with disproportionate copper content. In order to address this possible inaccuracy in the data, the slag samples were crushed into a fine powder. In doing so, the samples are relatively homogenized to produce a more accurate representation of its elemental composition. A small sledge hammer was used to break down larger pieces into manageable bits, and a mortar and pestle were used in following to grind the material into a powder with sub-millimeter grain size. The slag was then collected in sample cups with a thin-film base (four microns thick) allowing the material to sit flush against the instrument without inhibiting analysis. Each cup included approximately two centimeters of material to prevent X-rays from passing through the sample.

Once powdered, the slags were analyzed using a Bruker TRACeR III – V + hand-held XRF analyzer. This particular instrument is equipped with a rhodium anode to produce x-rays, and a Si-Pin detector for collecting fluorescence from the targeted sample. The X-ray beam produced is roughly 3 × 4 millimeters [9]. The Bruker S1PXRF software allows the user to control voltage (up to 40 kV) and current (between 0-60 μA) to enhance the detection of desired elements [9]. In addition, interchangeable filters and an external vacuum system are available to further refine the analysis. The filters will remove undesired radiation from reaching the sample, and the vacuum increases sensitivity to lighter elements. Thus, the XRF system can be tailored to target specific elements of interest, maximizing their detection.

For the slag samples, two different system configurations were utilized to investigate heavy and light elements independently. For heavier elements of interest (above iron on the Periodic Table of Elements), the XRF was set to 40 kV and 13 μA for an acquisition time of 300 seconds. The green filter (Aluminum, Titanium, and Copper filter) was positioned in the instrument, and the vacuum system was not employed. In the case of lighter elements (iron and below), the settings were changed to 15 kV and 35 μA with the blue filter (Titanium filter) and the vacuum system (a 300 second run time was maintained). Samples of particular interest (the ones from the slag mound probe) were analyzed for heavy elements (most importantly copper - see below) three times to produce averages and avoid anomalistic data. Based on the spectra collected using a laptop computer with S1PXRF software, the results were semi-quantified to provide photon counts of each element analyzed (i.e., the number of times the instrument measured an energy associated with a specific element can be calculated based on the area under the respective peak in the spectrum). These data can then be used for relative concentrations and comparisons.

Results

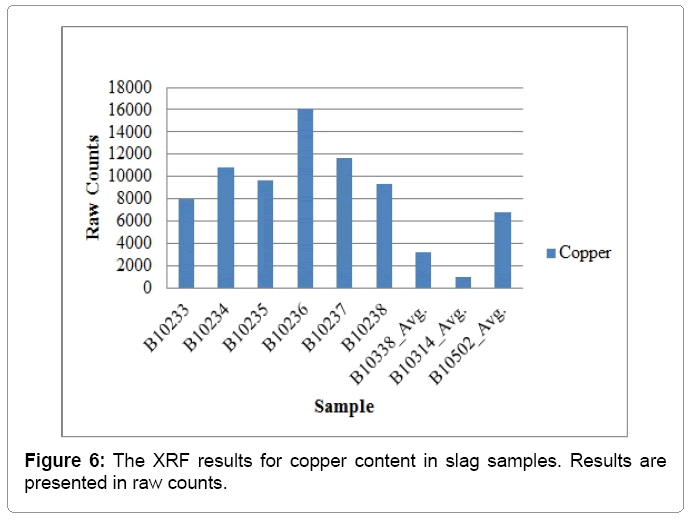

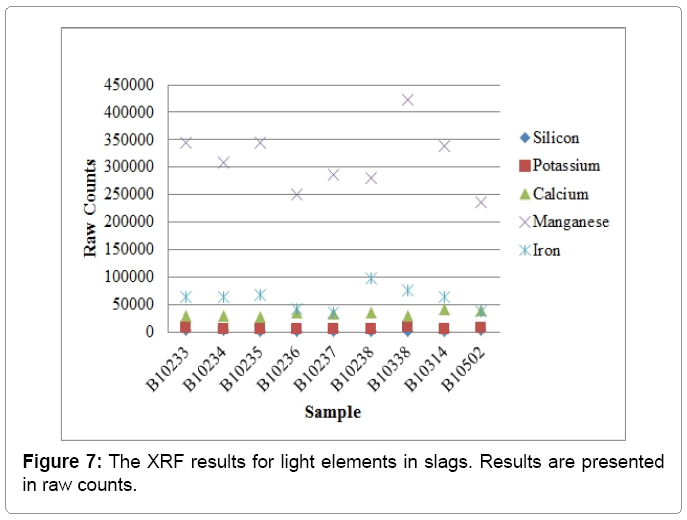

Based on the results of the XRF analyses, the remainder of this paper will focus on two elements of primary interest: manganese and copper. Manganese is important for archaeometallurgical investigations because it provides evidence for the origins of the ores. Copper is an inherent focus because it was the desired metal of the ancient metalworkers, and it is insightful towards extractive metallurgy practices. To facilitate the interpretations to be discussed in the following section, the outcomes are presented in two charts (Figures 6 and 7). The amounts of each element are provided in photon counts by respective sample. First addressing the copper, it was apparent that the amount of copper in the slags is fairly variable by sample; however, it was noticeably low in two instances [Samples B10338_Avg. and B10314_Avg.] (Figure 6). Table 1 presents the exact values of copper raw counts for each analysis and their average for samples taken from the probe. In contrast, the manganese content was strikingly high in all of the analyzed samples. To emphasize this, the manganese results were plotted against all other light elements (Figure 7). When considered against the chronological framework provided by excavation and the geology of the region, it is possible to use these results to draw archaeological conclusions otherwise unattainable through macroscopic investigations.

| Sample | Copper | |

|---|---|---|

| Second Production Phase | B10338_1 | 3111 |

| B10338_2 | 3315 | |

| B10338_3 | 3199 | |

| Average | 3208 | |

| B10314_1 | 950 | |

| B10314_2 | 845 | |

| B10314_3 | 958 | |

| Average | 917 | |

| First Production Phase | B10502_1 | 6798 |

| B10502_2 | 6664 | |

| B10502_3 | 7041 | |

| Average | 6834 |

Table 1: The XRF results for copper of each analysis of samples from the slag mound probe. Results are presented in raw counts.

Discussion

The copper content in the slags is particularly relevant because it can be used as a proxy that is representative of the sophistication of the extraction technology used to smelt the copper [4]. Copper found in the slag is metal that was lost during the smelting process, that is, it is expected that efficient smelts would result with very little copper present in the slag. With this in mind, the two slag samples with the markedly low copper are of great interest. Looking at the archaeological context of these samples, they originated in the chronologically later and main production phase discovered in the slag mound. In contrast, the examples from the bottom of the probe (and from the other crushed slag mounds) that are earlier in date based on the law of superposition contained higher copper. This suggests that from the first to second metal production phase seen in the slag mound probe there was an improvement in the technology and/or technical knowledge concerning metal extraction (conforming to a similar stratigraphic pattern seen in another slag mound excavations/analysis completed in 2006 [4]). Using an average of raw counts for copper from each layer, there is a 70% decrease in the amount of copper from the early to late phase (Table 1). The metalworkers at KAJ were more successfully/ efficiently smelting copper in this second later phase when less copper was lost in the slag.

The high manganese content of all samples provided additional insight concerning metal production at KAJ. As previously mentioned, the ores of the copper-rich DLS formation in Faynan were uniquely interspersed with manganese ores. As such, slags produced from these ores will be similarly rich in manganese [5]. Thus, the significant manganese in all samples analyzed connects them with these DLS ores. This could be expected based on the outcrops of the DLS unit in the area surrounding KAJ with evidence of exploitation in antiquity; however, the XRF results create a concrete rather than assumed connection to the mining in this area. In addition, the elevated manganese in the ores gives them a ‘self-fluxing’ quality [5]. It has been suggested that the Iron Age populations of Faynan recognized this self-fluxing advantage and deliberately selected these ores for smelting, an improved technical awareness from previous periods [5], and the XRF results conform to this hypothesis. Together, the copper and manganese values in the slags measured by the XRF investigation reveal an advanced and ever improving extractive metallurgy at KAJ connected directly to the local ores of Faynan during the Iron Age. This is especially important as the organization of extractive metallurgy can be used as a proxy for measuring ancient social organization in this formative period when the first local historical kingdoms arose in the southern Levant [10].

Conclusion

By supplementing archaeological excavation data with XRF measurements, it is possible to discern new and valuable insights concerning the ancient extractive metallurgy practices of Iron Age populations at KAJ. The slag mound test probe revealed little more than two phases of copper production waste in this area of the site. However, the results of the XRF analysis fostered an informed interpretation of the evidence by providing elemental considerations. The high manganese content of the slag samples creates a clear connection to the local ores of the DLS formation. In addition, by examining the amount of copper against the chronological framework provided by stratigraphic excavation, it was revealed that the ancient metal workers improved their technologies and/or technical knowledge over the occupational history of the site. As shown, through archaeology’s unique dependence on the future, it can more successfully reconstruct the past.

Acknowledgement

Special thanks to Dr. Mohammad Najjar, Dr. Neil G. Smith, Matthew D. Howland, Craig Smitheram, Marc Wallace, Rosemary Y. Hoshino and the local Bedouins of Qirayqira and Faynan for their assistance in the field and the lab. Graduate student work was supported by the National Science Foundation under IGERT Award #DGE-0966375, “Training, Research and Education in Engineering for Cultural Heritage Diagnostics.” Major funding came from TEL’s Norma Kershaw Chair, Department of Anthropology and Judaic Studies, UCSD. Also, thanks to Dr. Barbara Porter of the American Center of Oriental Research (ACOR) in Amman, and Dr. M. Jamhawi, Director General of the Department of Antiquities of Jordan. Thanks also to Dr. Erez Ben-Yosef for his earlier field work at KAJ that was part of his doctoral dissertation at UC San Diego. Opinions, findings, and conclusions from this study are those of the authors and do not necessarily reflect the opinions of the research sponsors.

References

- Levy T (2015) The Past Forward. Biblical Archaeology Review: Futures 40: 81-87.

- Shugar A, Mass J (2012) Studies in Archaeological Sciences. Handheld XRF for Art and Archaeology, Leuven University Press, Leuven.

- Levy T, Najjar M, Ben-Yosef E (2014) New Insights into the Iron Age Archaeology of Edom, Southern Jordan. UCLA Cotsen Institute of Archaeology Press, Los Angeles.

- Ben-Yosef E (2010) Technology and Social Process: Oscillations in Iron Age Copper Production and Power in Southern Jordan, University of California, San Diego.

- Hauptmann A (2007) The Archaeometallurgy of Copper: Evidence from Faynan, Jordan. Springer, New York.

- Ben-Yosef E, Levy T, Higham T, Najjar M, Tauxe L (2010) The beginning of Iron Age copper production in the southern Levant: new evidence from Khirbat al-Jariya, Faynan, Jordan. Antiquity 84: 724-746.

- Glueck N (1935) Explorations in Eastern Palestine, II. Annual of the American Schools ofOriental Research15: 1-288.

- Ben-Yosef E, Levy T (2014) A “Small Town” Discovered Twice: A Forgotten Report of Major H. H. Kitchener. Palestine Exploration Quarterly146: 179-184.

- Kaiser B, Wright A (2008) Draft of Bruker XRF spectroscopy user guide: spectral interpretation and sources of interference.

- Levy T, Najjar M, Higham T, Arbel Y, Muniz A, et al. (2014) Excavations at Khirbat en-Nahas 2002-2009: An Iron Age Copper Production Center in the Lowlands of Edom. New Insights into the Iron Age Archaeology of Edom, Southern Jordan,. UCLA Cotsen Institute of Archaeology Press, Los Angeles.

Relevant Topics

- Additive Manufacturing

- Coal Mining

- Colloid Chemistry

- Composite Materials Fabrication

- Compressive Strength

- Extractive Metallurgy

- Fracture Toughness

- Geological Materials

- Hydrometallurgy

- Industrial Engineering

- Materials Chemistry

- Materials Processing and Manufacturing

- Metal Casting Technology

- Metallic Materials

- Metallurgical Engineering

- Metallurgy

- Mineral Processing

- Nanomaterial

- Resource Extraction

- Rock Mechanics

- Surface Mining

Recommended Journals

Article Tools

Article Usage

- Total views: 12890

- [From(publication date):

December-2016 - Apr 07, 2025] - Breakdown by view type

- HTML page views : 11936

- PDF downloads : 954