Research Article Open Access

Understanding the Problems and Challenges of Polymer Flooding Technique

Jie Xiao*, Guibiao QiaoHolding Energy Petroleum Engineering,(BeiJing)Co., Ltd, China

- *Corresponding Author:

- Jie Xiao

Consultant, Holding Energy Petroleum Engineering

(BeiJing) Co., Ltd, China

Tel: + 010-88593266-817

E-mail: info@smartpetrochem.com

Received Date: December 16, 2016; Accepted Date: December 22, 2016; Published Date: January 02, 2017

Citation: Xiao J, Qiao G (2017) Understanding the Problems and Challenges of Polymer Flooding Technique. Oil Gas Res 3: 126. doi: 10.4172/2472-0518.1000126

Copyright: © 2017 Xiao J, et al. This is an open-access article distributed under the terms of the Creative Commons Attribution License, which permits unrestricted use, distribution, and reproduction in any medium, provided the original author and source are credited.

Visit for more related articles at Oil & Gas Research

Abstract

Polymer flooding has been widely used to address the problems of high mobility ratio or high reservoir heterogeneity in water flooding operations. It reduces the surface tension between oil and water and release trapped oil and makes oil easier to produce. However, polymers tend to reside in formation due to precipitation, adsorption, mechanical entrapment, or even degradation. This study analyzed those formation damage problems in polymer flooding and provided suggestions on how to design an effective polymer flooding treatment to minimize the potential formation damage issues. Results show that the polymer solution (polymer and brine) can affect the nature of strain in different systems and thus influence regains permeability. To minimize the damage effect of polymer retention or polymer plugging, core flow tests should be designed to incorporate the effect of different parameters

Keywords

Polymer flooding; Formation damage; Regained permeability; EOR

Introduction

The nature of polymer flooding is to use polymer agent to be function as a mobility control agent to provide better displacement and volumetric sweep efficiencies during flooding treatments. The efficiency of polymer flood is believed to be in the range of 0.7-1.75 lb polymer per bbl of incremental oil production. The target zone of polymer flooding is the remaining oil saturation above the residual oil saturation [1-5]. Polymer flooding has been successfully applied in all different types of reservoirs and provides huge amount of recovered oil production in petroleum industry. It is simple and efficient, compared with other enhanced oil recovery techniques [6,7]. It can be also applied in some special cases, such as heavy oil reservoir with low viscosity where steam assisted gravity drainage is not suitable. To be able to fully understand the problems and challenges during polymer flooding, this study presents its intrinsic properties, effective strategies to design optimal parameters, associated formation damage and polymer plugging problems, and injection issues in polymer flooding [8-12].

Properties of Polymer Flooding

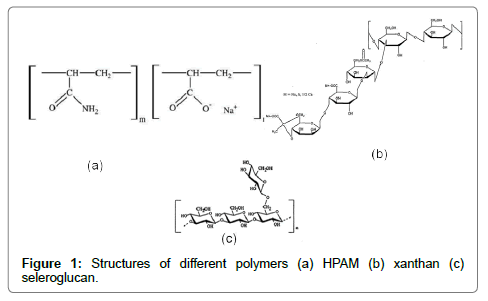

It is widely believed that polymer solution behaves as pseudoplastic fluids at intermediate shear rates while behave like Newtonian fluids at low or high shear rates. As in the high shear rate, all the macromolecules are oriented along the flow direction and thus reduce the viscosity. Figure 1 provides the structure of three typical polymers used in polymer flooding. In the field, synthetic polymers or biopolymers are used in polymer flooding. Polymer flooding is generally applied in reservoir with oil viscosity below 150 cp (preferable 10-100 cp) or API gravity above 15 [13]. The matrix permeability should be above 10 md. Reservoir temperature is in the range of 176 to 210°F. The clay content in the reservoir should be low. Low salinity of the injection and reservoir brines are favorable for higher recovery factor. In the field, back produced water is usually used for preparation of polymer solution as far as the water can satisfy water quality specifications after chemical treatment. However, one should note that potential damage may rise due to the re-injected waters [14-17].

Problems Associated with Polymer Flooding

In polymer flooding, polymer can be retained in porous media through precipitation, adsorption, or mechanical entrapment. As a result, formation damage can occur. Therefore, core flow tests should be conducted to examine the potential formation damage problems during polymer flooding processes prior to field application [18,19]. The adsorption in polymer flooding can be severe, as it is irreversible and the adsorbed polymer occupies a large pore volume. In this case, it is hard to recover a considerable amount of oil and the formation permeability is decreased, leading to less recovery factor. The stability of polymer solution during polymer flooding has been a issue due to its degradation. It can be chemical degradation through oxidation or effect of ionic ions. Mechanical degradation refers to the macromolecules are sheared at high flow rate, close to wall region. Biological degradation commonly occurs in biopolymers, for example, HPAM is the nutrition source for SRB. Additionally, some polymers will change their volume ratio or viscosities under different reservoir conditions [20-22]. As a result of high rock retention, problem of formation damage can be severe. The flow region is restricted, leading to high increase in external viscosity. This further increase formation damage issues and make it is hard to displace those retented polymer out of formation. Filtration of gel from unfiltered polymer solution can also cause potential formation damage problems as a slim skin is formed. According to experimental studies, this filtration effect will reach equilibrium even after a continuous increase of the pressure differential pressure [23-25].

Parameter Selection

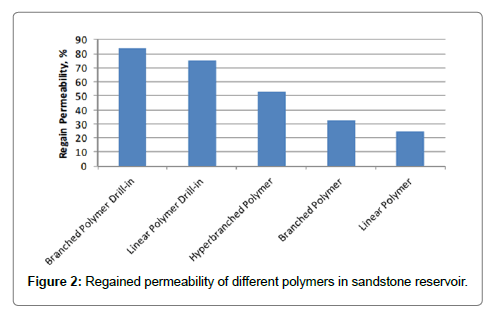

The selection of parameters for polymer flooding is critical to a successful chemical treatment. As polymer flooding is affected by many factors, various design parameters need to be designed and optimized. The parameters are affected by reservoir temperature, formation water salinity, divalent contents, clay contents, oil viscosity, formation permeability, etc. [26-28]. Take the effect of properties of formation for example, anionic polymers such as HPAM has a high adsorption rate in carbonate reservoirs, so specific polymers are only suitable for specific reservoir types. Heterogeneous carbonate reservoirs have a low permeability matrix and are unsuitable for large molecule polymers. Different polymers have different adsorption rate on different formation. Figure 2 shows the regained permeability comparison of different structures of polymers. To minimize the retention effect, selection of polymer should be based on vicosification/suspension properties. Branched polymers should be selected as they have less reduced formation damage compared with other polymers [29-32]. Sometimes, unsuitable polymer may plug the formation. To solve this problem, the selection of polymer should be based on the following factors: volume flux, core permeability, hydrodynamic size of the polymer, and core mineralogy and surface state [33].

Conclusions

Based on above discussion, the following conclusions can be drawn from this study:

1. Rheological behavior of polymer solution in shear and extensional flows affects the flow of a fluid in porous media, and thus the potential for a fluid to reduce the permeability of a formation.

2. The polymer solution (polymer and brine) can affect the nature of strain in diff erent systems and thus influence regains permeability.

3. To minimize the damage effect of polymer retention or polymer plugging, core flow tests should be designed to incorporate the effect of different parameters.

References

- He J (2011) Calcium Sulphate Formation and Mitigation When Seawater Was Used to Prepare Hcl-Based Acids. Texas AandM University.

- Audibert A, Argillier JF,Ladva HKJ, Way P,Hove AO, et al.(1999)Role of Polymers on Formation Damage Society of Petroleum Engineers.

- He J (2015) An Innovative Closed Fracture Acidizing Technique for Deep Carbonate Reservoirs Using Glda. Texas A and M University.

- Maxey JE, Van Zanten R (2012) Novel Method To Characterize Formation Damage Caused by Polymers Society of Petroleum Engineers.

- He J,Arensman D,Nasr H (2013) Effectiveness of Calcium Sulphate Scale Inhibitors in Spent Hydrochloric Acid/Seawater System. Journal of Petroleum and Environmental Biotechnology, Vol- 4.

- Omar AE (1983) Effect of Polymer Adsorption on Mobility Ratio Society of Petroleum Engineers.

- Sheng JJ,Leonhardt B,Azri N (2015) Status of Polymer-Flooding Technology Society of Petroleum Engineers.

- Jones DM, Walters K (1988) Extensional Viscosity Effects in EOR Society of Petroleum Engineers.

- He J,Arensman D, Nasr H (2013) Mitigation of Calcium Sulphate Precipitation in Spent Hydrochloric Acid/Seawater System OTC Brazil.

- He J, Mohamed IM, Nasr H (2011) Mixing Hydrochloric Acid and Seawater for Matrix Acidizing: Is It a Good Practice? In SPE European Formation Damage Conference: Society of Petroleum Engineers.

- Smalley PC, Ross AW, Brown C, Moulds TP,Smith MJ (2009) Reservoir Technical Limits: A Framework for Maximizing Recovery from Oil Fields, Society of Petroleum Engineers.

- He J, Mohamed IM, Nasr HA (2012) Mitigation of Calcium Sulphate Scale Formation When Seawater Is Used to Prepare Hcl-Based Acids In SPE International Symposium and Exhibition on Formation Damage Control: Society of Petroleum Engineers.

- Liu H, Wang Y,Liu YZ (2006)Mixing and Injection Techniques of Polymer Solution In Enhanced Oil Recovery-Polymer Flooding.

- Lou JH, Liu YZ,Shu P (2006)Polymer Solution Properties and Displacement Mechanisms In Enhanced Oil Recovery-Polymer Flooding.

- He J, Mohamed IM,Nasr H(2013)Potential Formation Damage Due to Preparing Hcl Acids Using Seawater Canadian Energy. Technology and Innovation Journal 1: 56-63.

- He J,Nasr H (2013)Petro chemistry and Chemical Engineering.

- Dehekker TG,Bowzer JL, Coleman RV (1986) A Progress Report on Polymer-Augmented Water flooding in Wyoming's North Oregon Basin and Byron Fields, Society of Petroleum Engineers.

- Kumar R, He J,Nasr H (2014) New Insights on the Effect of Oil Saturation on the Optimum Acid Injection Rate in Carbonate Acidizing In SPE Improved Oil Recovery Symposium,Society of Petroleum Engineers.

- Broussard L P, Hamby T W, Peterson J L (1983)SP 13 Drilling and Producing High Pressure Sour Gas Reserves World Petroleum Congress.

- Kumar RP, He J,Nasr H (2014)Effect of Oil Saturation on Acid Propagation During Matrix Acidization of Carbonate Rocks In SPE Latin America and Caribbean, Petroleum Engineering Conference: Society of Petroleum Engineers.

- Mohamed I, He J,Nasr HA (2013) Effect of Brine Composition on CO2/Limestone Rock Interactions during CO2 Sequestration. Journal of Petroleum Science Research 2:14-26.

- Mohamed IM, He J, Mahmoud M (2010) Effects of Pressure CO2 Volume and the CO2 to Water Volumetric Ratio on Permeability Change During CO2 Sequestration, In Abu Dhabi International Petroleum Exhibition and Conference: Society of Petroleum Engineers.

- Treiber L E, Yang S H (1986) The Nature of Polymer Plugging and a Wellbore Treatment To Minimize It Society of Petroleum Engineers.

- Mohamed IM, He J,Nasr HA (2011) Carbon Dioxide Sequestration in Dolomite Rock In International Petroleum Technology Conference: International Petroleum Technology Conference.

- Mohamed IM, He J,Nasr HA (2011) Permeability Change during CO2 Injection in Carbonate Aquifers: Experimental Study In SPE Americas EandP Health Safety Security and Environmental Conference: Society of Petroleum Engineers.

- Mohamed IM, He J,Nasr HA (2011)Sulphate Precipitation during CO2 Sequestration in Carbonate Rock In SPE Project and Facilities Challenges Conference at METS: Society of Petroleum Engineers.

- Mohamed IM, He J,Nasr HA (2012) Carbon Dioxide Sequestration in Sandstone Aquifers: How Does It Affect the Permeability? In Carbon Management Technology Conference: Carbon Management Technology Conference.

- Mohamed IM, He J,Nasr HA (2013) Experimental Analysis of CO2 Injection on Permeability of Vuggy Carbonate Aquifers. Journal of Energy Resources Technology 135:13-301.

- Mohamed IM, He J,Nasr HA (2012) Permeability Reduction during CO2 Injection in Sandstone Aquifers: Lab and Simulation Studies Canadian Energy. Technology and Innovation Journal 1: 36-44.

- Nasr H, Mahmoud D,Wolf CA (2012) Process to Fracture a Subterranean Formation Using a Chelating Agent In: US Patent.

- Xuejun H, He J,Tenfei S (2015a) Analysis of the Critical Buckling Loads and Contact Loads on Coiled Tubing String in a Vertical Micro hole. Chemistry and Technology of Fuels and Oils 51: 308-319.

- Xuejun H, He J,Tenfei S (2015b) Analysis on Design of Coiled Tubing Sliding Drilling Electronic Control Tractor with Hydraulic-Driven in Micro hole. Electronic Journal of Geotechnical Engineering 20: 4333-4347.

- Jiafu Y, Haiwen W,Jia He, Xiaomeng H, Huixin L(2009) Fracturing string packer packer Comparison AnalysisWell Testing 18: 6-11.

Relevant Topics

Recommended Journals

- Oil & Gas Research Journal

- Renewable Energy and Applications Journal

- Oceanography Journal

- Industrial Pollution Control Journal

- Coastal Zone Management Journal

- Climatology & Weather Forecasting Journal

- Geoinformatics & Geostatistics Journal

- Engineering and Technology Journal

- Petroleum & Environmental Biotechnology Journal

- Polymer Sciences Journal

Article Tools

Article Usage

- Total views: 10033

- [From(publication date):

March-2017 - Apr 03, 2025] - Breakdown by view type

- HTML page views : 8654

- PDF downloads : 1379