Research Article Open Access

Understanding the Estimation and Improvement of Recovery Rate for OilShale In situ Processing

Wang Yiwei*, Su Jianzheng, Wang Youping, Meng Xiang Long and Ma ZhongliangPetroleum Exploration and Production Research Institute of SINOPEC, Beijing 100083, China

- *Corresponding Author:

- Wang Yiwei

Petroleum Exploration and Production Research Institute of SINOPEC, Beijing, China

Tel: + 86-10-82312089

E-mail: wangyw.syky@sinopec.com

Received Date: May 18, 2017; Accepted Date: May 25, 2017; Published Date: May 31, 2017

Citation: Yiwei W, Jianzheng S, Youping W, Long MX, Zhongliang M (2017) Understanding the Estimation and Improvement of Recovery Rate for Oil Shale in situ Processing. Oil Gas Res 3: 140. doi: 10.4172/2472-0518.1000140

Copyright: © 2017 Yiwei W, et al. This is an open-access article distributed under the terms of the Creative Commons Attribution License, which permits unrestricted use, distribution, and reproduction in any medium, provided the original author and source are credited.

Visit for more related articles at Oil & Gas Research

Abstract

Oil shale in situ processing research booms in recent years because it innovate the method of oil shale exploitation and enable to develop deep oil shale. But commercialization of oil shale in situ processing staggered due to uncertainty of recovery rate which closely related to profit. Considering amount of oil generated in situ and amount of oil flow to the surface during the oil shale in situ processing operation, this study analyse the recovery rate and effect factors based on experiments, the permeability and pressure variation under high temperature also were discussed. The result shows that recovery rate can be influenced by formation pressure, moisture content and heating rate. The total recovery rate is about 60.5% of Fischer Assay based on experiments. To improve the recovery rate, some measurement including gas injection, temperature optimization and stimulation were suggested

Keywords

Oil shale; in situ processing; Recovery rate; Estimation

Introduction

Oil shale is a great potential alternative resource which attracted many researchers and investors thanks to rich organic content and abundant reserve. The total organic carbon of oil shale with high quality can reach 50% [1,2]. There is 411 billion tons of equivalent oil of oil shale in the world according to recent statistics [3]. The surface retorting was widely applied in the past few decades to get oil from the oil shale by mining and heating oil shale in the retort furnace. However, it bring environment pollution and unable to utilize deep oil shale. A new technology called oil shale in situ processing appeared in recent years which typically involved retorting oil shale without removing the oil shale from underground by mining [4]. Various approach of oil shale in situ processing were proposed and tested in the field such as in situ Conversion Process (ICP), Electrofrac, Conduction, Convection and Reflux (CCR) and so on. ICP pilot test in green river oil shale deposit, operated by Shell, got great success which indicate the oil shale in situ is technical feasible, meanwhile, the other technique of in situ processing pilot test were carried out in USA, Israel, Jordan and China [4-8]. Actually, the profit always plays important role to technology development, the main factor affecting profit is the final recovery rate and energy input for specific oil shale deposit. There are many literature addressed about heating method to save energy input to minimize the cost. But little literature was addressed about recovery rate estimation. Estimation of recovery rate mainly involved how much oil and gas can be generated in place from organic material pyrolysis and how much oil and gas can be lifted up to the surface. Although a lot of work have done to examine oil yield from kerogen pyrolysis, Fischer Assay method, for example, was extensively used for estimating oil content of oil shale pyrolysis, but it is not accurate to assess oil yield for oil shale in situ processing because the reaction condition which change dynamically during the operation process was different [9-11]. in situ process includes heating, pyrolysis and flow. Not only the pyrolysis but also temperature distribution, pressure distribution, products composition and properties, porosity and permeability change must be considered [12-15]. In terms of pyrolysis, some mechanism of in situ processing is still unclear partly because the molecular structure of kerogen is in largely unknown and condition varies complicatedly and quickly. This paper discusses the challenges of oil recovery estimation and dominant factors including pyrolysis feature, porosity, permeability and pressure based on laboratory research. The methods of improving recovery rate for in situ processing also were suggested.

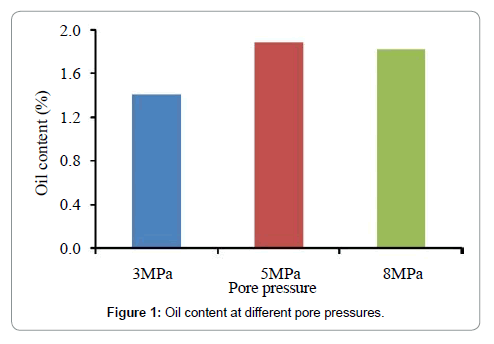

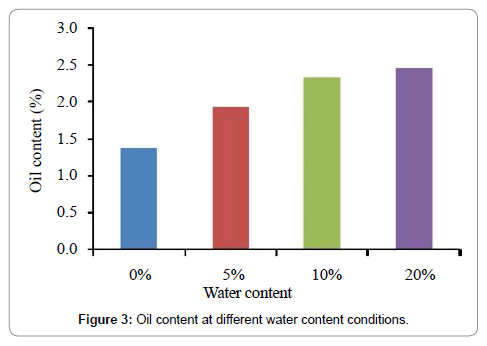

Estimation of Oil Yield in situ

Oil shale rock is composed of a solid, insoluble organic kerogen and other inorganic matter. It was acceptable that Kerogen began to convert into bitumen, oil, gas and coke when temperature reaches curtain magnitude by heating [16-21]. There are three kind of reactions during oil shale in situ processing include decomposition, cracking and coking reactions which dominant the amount of oil and gas generated [9,10]. Pressure is important factor of estimation of oil yield in situ. Typically, the oil shale layer was buried several hundred meters below the surface. Oil generation, degradation and other reaction occurring during pyrolysis of oil shale over a specified history of temperature and hydrostatic pressure [13-15]. Using core samples with original oil content of 6.5% of Fischer Assay, taken from oil shale deposit in southern of China, the pyrolysis experiment were conducted to study effect of pressure on oil yield at heating rate of 20°C/h, the final temperature is 350°C and duration time is 2880 min. The result indicates that composition of products generated in a pyrolysis temperature range depend on operation pressure. The oil yield increase when temperature increases from 3 MPa to 5 Mpa and drop when temperature continues to increase up to 8 MPa. While the total HC gas decease continuously with the pressure increase from 3 MPa to 8 MPa. It can be interpreted that high pressure can inhibit the reaction process which causes gas result in system volume increase. Furthermore, restrain of gas generation is helpful to increase oil amount under relatively low pressure because the reaction of oil converting to gas slow down. However, the whole reaction would be inhibited when pressure increase to certain magnitude (Figures 1 and 2). Using core sample from same layer, the pyrolysis experiment were conducted to study effect of water content on oil yield at same heating procedure. The results shows that hydrous pyrolysis can get more oil and gas than pyrolysis without water, oil yield increase with the moisture content increase based on experiment of hydrous pyrolysis with tem (Figure 3), however, more water content will consume more energy. According to calculation combined by laboratorial data, oil shale formation with about 10 wt% moisture content would be ideal target for in situ retorting. The heating rate related to residence time, final temperature and products distribution, is a factor of major importance to oil yield in situ oil shale processing. For in situ processing, samples are not powders or small particles any more but huge continue sedimentary rock which need heating for about several month or several years due to slow the heating rate of about 1°C per day [17-19]. A number of investigators have attempted to get the regulation, results reveal that less oil yield would be obtained at low heating rate, for example, at a heating rate of 2°C/h, 83% of Fischer Assay oil is collected whereas at a rate of 180°C/h the yield is 99% based on Lawrence Livermore Laboratory work [20]. It indicates that oil yield might be far less than 83% of Fischer assay oil at heating rate of 1°C/day. The liberated shale oil can be degraded are cracking and coking reaction. So, the in-place oil is subjected to two competing process oil degradation and oil removal. The degradation reaction will be more preponderant than oil removal at low heating rate which lead to less oil yield. The yield was determined by the timetemperature history of liberated oil and not by the thermal history of the kerogen. API gravity of generated hydrocarbons increase at lower heating rate which means the oil quality is better for in situ processing [4].

Estimation of Oil Yield on Surface

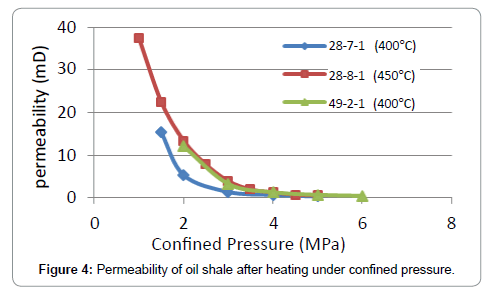

Oil yield on surface strongly depend on permeability, residual oil saturation and the pressure difference. The permeability varies with the temperature rising due to thermal expansion and pyrolysis which caused pore structure change. Unfortunately, there is almost no effective approach and apparatus to measure permeability data directly during pyrolysis under high temperature as at least 300°C and under overburden pressure as several million Pascal. The makeshift experimental method of for measuring permeability for in situ processing was proposed by some scholars. The procedure of experiment can be separated into two steps. First the initial permeability is evaluated at room temperature, and then the sample is heated to pyrolysis temperatures and then cooled to room temperature to measure the permeability again after retorting. The results show there is much difference between oil shale from different region by using makeshift experiment. Typically, with the temperature rising, the permeability increase slightly at first and then decrease sharply to a minimum value followed by continues increase phenomenon link to pore change and fluid phase change. The stress affects the permeability dramatically. It is well known that oil shale is characteristic of bedding which caused the fracture penetrating along direction of bedding. Permeability experiments show the strong stress sensitivity due to weak shear stress in oil shale rock. The preexisting fractures and fractures generated in the heating begin to close when confined pressure subjected on the sample. The magnitude of permeability can get about 10 mD after heating in 400°C and 450°C under 3 MPa confined pressure (Figure 4). Actually, well testing is a reliable way to estimate the permeability if pilot test was carried out in the field. The oil shale formation in green river can provide enough permeability and conductivity to ensure fluid flowing into producing well according to shell filed test. This conclusion may not be suitable for other type of oil shale result from different mineral composition, mechanical properties, pores structure and stress status etc. How much oil generated would detain in formation depend on residual oil saturation which involve wettability, capillary force and properties of fluid. The experiments shows that oil shale wettability can change gradually from water-wet under original condition to oilwet when oil release due to organic pyrolysis. Residual oil saturation can be determined from the relative permeability curve by Mercury injection and other experiment. Unfortunately, it is not easy to get the permeability curve data because the wettability and capillary pressure change result from fluid composition and pore structure change when the pyrolysis are in progress during the heating process. The oil and gas produced from oil shale retorting area to wellbore of production well at above 300°C temperature. There is no method to get high temperature relative permeability curve data so far, but the residual saturation value is relatively high which is not helpful to improve the recovery rate for shale formation. The pressure difference between external fluid and internal fluid experiment was conducted to estimate the pressure increase during the heating process using core sample. With the temperature rise, the pore pressure increase. The pressure jump high when temperature reach above 330°C due to organic materials began to pyrolysis to release fluid and gases. The pressure increases consecutively from original 2 MPa to 8 MPa.

Recovery Rate and Improvement for in situ Processing

Recovery rate depend on both oil amount generated in situ and oil amount can flow into surface. Estimation of recovery rate for specific oil shale deposit need comprehensive study on oil content, mineral composition, pore structure, well-pattern and heating design. Theoretically, the residual oil saturation of shale is generally much large which indicates low recovery rate for oil shale processing, but the traditional experiment did not reflect the characteristic of oil shale under high temperature and dynamic properties of formation. In addition, fractures and fissure generated by heating would change the pore structure which lead to different relative permeability behaviour. In order to evaluate the final recovery rate of in situ processing, simulation experiments using core samples in close system were conducted at heating rate of 20°C/h and final temperature is 500°C. 4.72% oil of sample weight was collected at the end of experiments, which indicates the final recovery rate for oil shale processing is about 60.5% of Fischer Assay oil yield. The recovery rate for oil shale in field might be less than experimental data for same oil shale layer. Some countermeasures may be taken to improve the recovery rate for oil shale in situ processing. By optimizing the temperature of pyrolysis zone of oil shale, Pressure within the formation can be controlled to vary the composition of the produced fluids to allow hydrocarbons materials to be more easily removed from sedimentary formation. Well pattern design is needed to improve volumetric heating efficiency and sweep efficiency. Gas can be injected to formation in the late stage to provide drive energy as well as can remove liberated oil as soon as possible to reduce the degradation reaction. A kind of reducing agent provided to the formation may react with hydrocarbon fragments for form selected products or inhibit the production of non-selected products. Stimulation operation might be applied in produce well to provide high conductivity to allow the relatively vicious oil flow into wellbore.

Conclusion

1. The amount of oil generated in situ is sensitive to pressure, moisture content, heating rate for oil shale processing. The appropriate pressure, moisture and high heating rate tend to increase the oil yield in place.

2. Porosity and permeability will increase dramatically with the temperature rise which is helpful to improve the recovery rate. But the magnitude of improvement is different from deposit to deposit because of different kerogen type, mineral composition and original pore structure.

3. The fractures occurred under high temperature may cause relative permeability feature change and most portion of oil flow out from sedimentary formation by gas phase which require less permeability. The recovery rate for in situ processing may be optimistic comparing to data based on traditional oil residual saturation experiment.

4. The total recovery rate can reach to 60.5% of Fischer Assay oil content based on experiment using the specific core sample gotten from wellbore of well.

5. The recovery rate can be improved by optimization of temperature pyrolysis zone, reducing agent injection which can increase the oil yield in situ. The gas injection in heating well in the late stage and stimulation operation in producing well establish high conductivity channel to allow liberated oil remove out quickly which is bound to oil yield on surface.

Acknowledgements

This study was supported by the program “Research on variation properties of oil shale during in situ heating with thermal fluids” (G5800-15-ZS-KJB026) of the Petroleum Exploration and Production Research Institute of SINOPEC, China.

References

- Zhaojun L, RongL (2005) Oil shale resource state and evaluating system. Earth Science Frontiers.

- Shaopeng L, Shixin Z, BaozhongW (2012) Relationship between industrial index and source rock evaluation parameters of oil shale. Natural Gas Geoscience.

- Dyni JR (2006) Geology and Resources of Some World Oil-Shale Deposits. Scientific Investigations Report.

- ShenC (2009) Reservoir simulation study of an in-situ conversion pilot of green-river oil shale.

- Ryan RC, Fowler TD, Beer GL, Nair V (2010) Oil shale: A solution to the liquid fuel dilemma, chapter shell's in situconversion process from laboratory to field pilots. American Chemical Society.

- Symington WA, Kaminsky RD, Meurer WP, Otten GA, Thomas MM, et al. (2010) Oil Shale: A Solution to the Liquid Fuel Dilemma, chapter ExxonMobil's ElectrofracTMProcess for in Situ Oil Shale Conversion. American Chemical Society,pp: 185-216.

- Feng XW, Chen C, Chen DY (2011) New development of oil shale in-situ technology. China Mining Magazine.

- Peng CY, Gupta R (2004) Experimental design and analysis methods in multiple deterministic modelling for quantifying hydrocarbon in-place probability distribution curve.

- Burnham AK, Braun RL (1999) Global kinetic analysis of complex materials. Energy and Fuels.

- Stainforth JG (2009) Practical kinetic modelling of petroleum g eneration and expulsion. Geol.

- Symington WA, Olgaard DL, Otten GA, Phillips TC, Thomas MM, et al. (2006) Exxonmobil'selectrofrac process for in-situ oil shale conversion. In Proceedings of the 26th Oil Shale Symposium.

- Symington WA, Spiecker PM (2008) Heat conduction modelling tools for screening in situ oil shale conversion processes. In 28th Oil Shale Symposium.

- Yang H, Gao XQ, Xiong FS, Zhang JL, Li YJ, et al. (2014) Temperature distribution simulation and optimization design of electric heater for in-situ oil shale heating. Oil Shale Symposium.

- Tanaka PL, Yeakel JD, Symington WA, Spiecker PM, Del Pico M, et al. (2011) Plan to test ExxonMobil’s in situ oil shale technology on a proposed RD&D lease. Oil Shale Symposium.

- Looney M D, Polzer R, Yoshioka K, Minnery G ( 2011) Chevron’s plans for rubblization of Green River Formation oil shale (GROS) for chemical conversion. Oil Shale Symposium.

- Iranshahr A, Voskov DV, Tchelepi HA (2010) Tie-simplex parameterization for EOS based thermal compositional simulation. SPE Journal.

- Vinegar H (2006) Shell’s in-situ conversion process for oil shale. 26th Oil Shale Symposium.

- Bauman JH, Deo MD (2010) Parameter space reduction and sensitivity analysis in complex thermal subsurface production processes. Energy and Fuels.

- Braun RL, Burnham AK (1992) A flexible model of oil and gas generation, cracking, and expulsion. Organic Geochemistry.

- Campbell JH (1978) Heating rate on oil evolution and intra-particle oil degradation. Material Science Solutions.

- DengguoL (2017) Mechanism of Kerogen pyrolysis in terms of chemical structure transformation. Material Science Solutions.

Relevant Topics

Recommended Journals

- Oil & Gas Research Journal

- Renewable Energy and Applications Journal

- Oceanography Journal

- Industrial Pollution Control Journal

- Coastal Zone Management Journal

- Climatology & Weather Forecasting Journal

- Geoinformatics & Geostatistics Journal

- Engineering and Technology Journal

- Petroleum & Environmental Biotechnology Journal

- Polymer Sciences Journal

Article Tools

Article Usage

- Total views: 3737

- [From(publication date):

August-2017 - Jul 15, 2025] - Breakdown by view type

- HTML page views : 2594

- PDF downloads : 1143