Research Article Open Access

The Study of Sustainable Green HVAC Systems in Health Care Facilities

Abdul FSM, Mofarhi S, Abdulwahab Y, Ali Z, ElBorombali H and Milyani H*Architecture Student, Effat University, Saudi Arabia

- *Corresponding Asuthor:

- Milyani H

Architecture Student, Effat University

Jeddah 22332, Saudi Arabia,

Tel: +966 2 636 4300

E-mail: eng.hadeelmilyani@gmail.com

Received date: December 09, 2015; Accepted date: February 11, 2016; Published date: March 15, 2016

Citation: Abdul FSM, Mofarhi S, Abdulwahab Y, Ali Z, ElBorombali H, et al. (2016) The Study of Sustainable Green HVAC Systems in Health Care Facilities. J Archit Eng Tech 5:160. doi:10.4172/2168-9717.1000160

Copyright: © 2016 Abdul FSM, et al. This is an open-access article distributed under the terms of the Creative Commons Attribution License, which permits unrestricted use, distribution, and reproduction in any medium, provided the original author and source are credited.

Visit for more related articles at Journal of Architectural Engineering Technology

Abstract

The amount of energy used up in healthcare buildings by traditional types of Heating, Ventilating and Air Conditioning systems is about 40% of the total building energy consumption. It also accounts for a large number of harmful emissions released into the environment. Therefore, we need to implement the use of green systems that will help in not only improving indoor comfort and quality but also in reducing energy consumptions and harmful CO2 emissions. HVAC is defined as a system that is responsible for controlling and maintaining the thermal comfort of indoor rooms.

The purpose of this research paper is to identify sustainable Heating, Ventilating and Air Conditioning systems that can be used in healthcare facilities. The research also focuses on identifying different methods and technologies to help understand how they can be used with maximum efficiency.

First we discuss types of heating ventilation and air conditioning systems and their manufacturing process. Then we analyze the different criteria and technologies for systems specific to healthcare facilities and green technologies. The final process of this research paper involves the study of different case studies where we use several assessments to confirm the most appropriate type of green systems to be used for healthcare buildings. In conclusion, every healthcare building has a different set of requirements but new and green technologies are the most environmentally and economically beneficial.

This paper is divided into six main parts: (i) Introduction (ii) Literature Review (iii) Manufacturing Process (iv) New Systems and Technology (v) Green HVAC Systems and (vi) Conclusion.

Hence, by identifying the several types of green HVAC systems in this paper, we will now be able to understand the most appropriate and efficient type that we can use in health care facilities. This will allow for a great reduction in energy consumption, harmful emissions and provide a more thermally comfortable environment for patients.

Keywords

Sustainable; HVAC; Manufacturing; Green; Healthcare buildings

Introduction

Heating ventilating and air conditioning (HVAC) is the technology that provides environmental comfort inside of a building. However, in hospitals they have numerous functions, including: improving the indoor air quality, maintaining diseases from transmission, conserving energy that also leads to controlling energy costs, providing life safety, low maintenance requirements and meeting safety standards. Maintaining disease transmission is what the American Society of Heating, Refrigerating and AirConditioning Engineers' calls infection control. An example would be, places that deal with substances that are hazardous to our health, such as pharmacies and laboratories. They require specific air distribution systems that will ensure the protection of people and medicines. It not only has to follow the ASHRAE criteria for infection control but it also has to be of good quality and be sustainable. The newly released ASHRAE criteria manual describes how to meet the standards and details how and why engineers and hospital owners may want to design systems that exceed the standards. This is why hospital HVAC systems are different from all others where environmental comfort is the predominant and usually sole objective [1-5].

Hospital buildings are one of the few types of building that run at full scale twenty-four hours a day. Unlike other buildings, HVAC in hospitals require not only comfort but also safety and hygiene. Hospitals need to maintain the temperature, air quality, air flow, and humidity to create the most comfortable environment possible for the patients. Ventilation in hospitals also work to control hazards, because there are frequently fumes and chemicals in the air that could cause harm if not properly dealt with. Different areas of a hospitals have different air conditioning systems, depending on the function. Different parts of a hospital have different needs an operating room may need to be colder than a lobby for example and a morgue may have specific ventilation needs from a ward. Hospital ventilation also needs to account for infection control, because there are so many pathogens in the air. Additionally, since the systems are running around the clock, it is necessary to make sure the systems are energy efficient.

With the many requirements of hospitals, which also include energy and costsaving concerns, sustainable HVAC systems that are most suitable for hospital buildings will be discussed in this paper. Possible alternate energy sources to power large scale systems, along with the different methods of implementing these systems to benefit from maximum efficiency, will also be addressed. Thus this paper will explore the research questions of “What heating ventilation air conditioning systems are most suitable for hospitals and how can they be used in the best, most sustainable way?” The significance of this research is to gain a cohesive understanding and spread awareness about HVAC systems, how they are manufactured, and the best options for hospitals that allow them to run smoothly, efficiently and sustainably twenty-four hours a day in order to keep patients comfortable and sensitive medical equipment operating correctly at all times.

Healthcare building HVAC system requirements

Heating, ventilating, and air conditioning system have a very important role in health care facilities. They not only maintain good air quality and create comfortable atmospheres for the patients, but they also help staff members remain productive at all times. It is very critical for an HVAC system to be flexible to all the different needs in a healthcare facility such as; operating rooms, patient rooms, administrative offices, meeting rooms, etc. Healthcare building specifically require these systems to be able to filter the air coming in and out of it from airborne contaminants along with bacteria to prevent infections spreading or harming patients. Those systems should also meet the minimum standards for healthcare ventilation, air changes, temperature, humidity, filtration and design. The most important HVAC system needs in hospitals include: design, size, and energy efficiency.

HVAC systems should create quiet environments for patients and minimize disruptions. The design of the system has to have a different environment inside the building as critical care spaces, operating rooms, recovery rooms, and intensive care units all have different atmospheres and each environment should be controlled separately according to its temperature and humidity requirements. According to studies, patients are proven to show slower recovery in uncontrolled environments opposed to controlled environments. Its size must be of enough functional capacity to meet the needs of heating, cooling and ventilation in the building. Moreover, it must be consistently good in quality and performance not to breakdown and endanger the health and safety of the patients. It should be easily accessible for routine maintenance to achieve achieving maximum productivity with minimum wasted effort or expense. Hospitals are working 24 hours a day which means HVAC systems are constantly consuming energy. Therefore, energy efficient system are especially important in such facilities [6-10].

In a hospital environment, large amounts of harmful microorganisms tend to cluster. The most important rule of hospital design from an infection control point of view is not to expose the patient to harmful infections while in the hospital. Hygiene, reliability, safety and energyrelated are some unique technical demand issues.

Contact transmission is the most crucial and common type of infections transmission (nosocomial). It is further subcategorized into direct and indirect contact transmissions. Directcontact transmission happens by direct contact between two bodies that transfer the micro-organisms from the infected body to the other. However, Indirect-contact transmission transfers microorganisms from a person to another through instruments.

Droplet transmission take place when an infected person makes droplets containing microorganisms which are transferred at a short distance within air and lands on the conjunctivae, nasal mucosa or mouth of a host. Droplets do not stay hanging in the air, therefore no particular air handling and ventilation are needed to stop droplet transmission. They are generated by coughing, sneezing and talking.

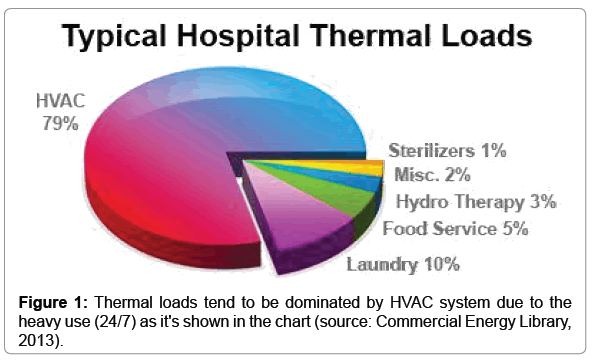

Airborne transmission occurs when either airborne droplet nuclei or dust particles disseminate infectious agents. Droplet happens through nuclei or dust. Nuclei smaller droplets of bacteria or viruses caused by the high velocity with which coughing and sneezing. In this case the control of ventilation and air handling is very needed to prevent nosocomial airborne transmission of microorganisms (Figure 1).

Types of HVAC systems

The Four HVAC System Types include:

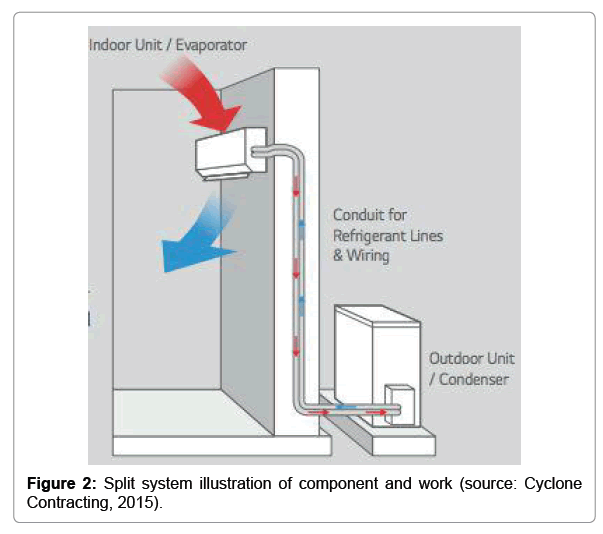

Heating and air conditioning split system: The most traditional and most used system it has parts both inside and outside the building and mainly would include (Figure 2):

• An air conditioner that cools the refrigerant,

• Furnaces and a fan or evaporator coil to convert the refrigerant and circulate the air,

• Ducts that carry air all through your building,

• A control panel/thermostat to manage the system,

• The occasional optional accessories for quality indoor air such as air cleaners, purifiers, humidifiers, UV lamps and so on.

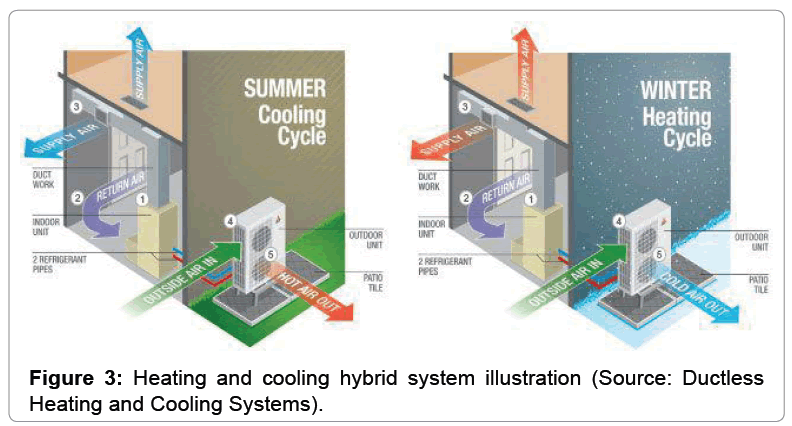

Hybrid heat split system: This system is an advanced and more energy efficient version of the traditional HVAC split system. A Heat pump addition to this system will allow it to become an electrically fueled HVAC (Figure 3). An ideal hybrid heat split system that is cost effective will have:

• A heat pump that heats or cools the refrigerant

• Furnaces plus the evaporator coil for conversion of the refrigerant and circulation of air

• The ducts to channel the air around your building

• Your interface for adjusting and controlling the system

• Optional accessories for more quality indoor air

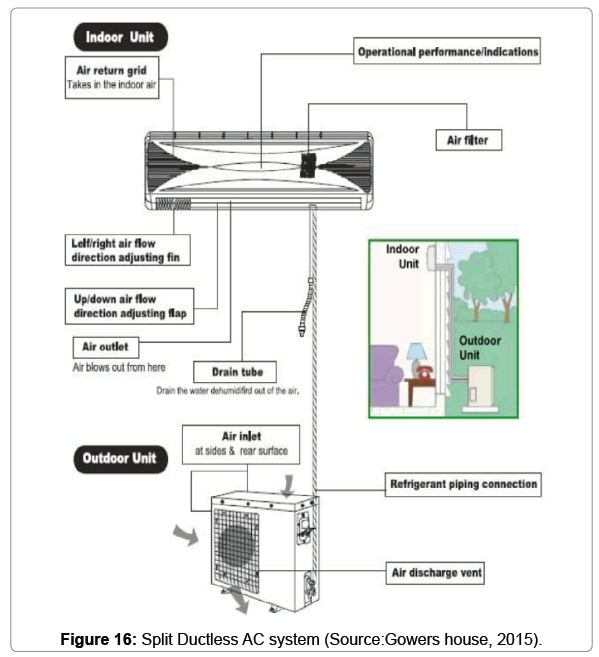

Duct Free split heating and air conditioning system: A ductfree HVAC is easy to install for places that conventional systems with ducts can’t fit into. These systems also complement the existing ducted types of HVAC systems. Ductfree systems will have the following;

• The heat pump or an air conditioner to heat\cool the refrigerant

• A fan coil that is compact

• Wires and tubing for the refrigerant, connecting the outdoor unit to the fan coil

• The thermostat or control panel

• Optional accessories to clean the air and make it more pleasant before its distribution through the house

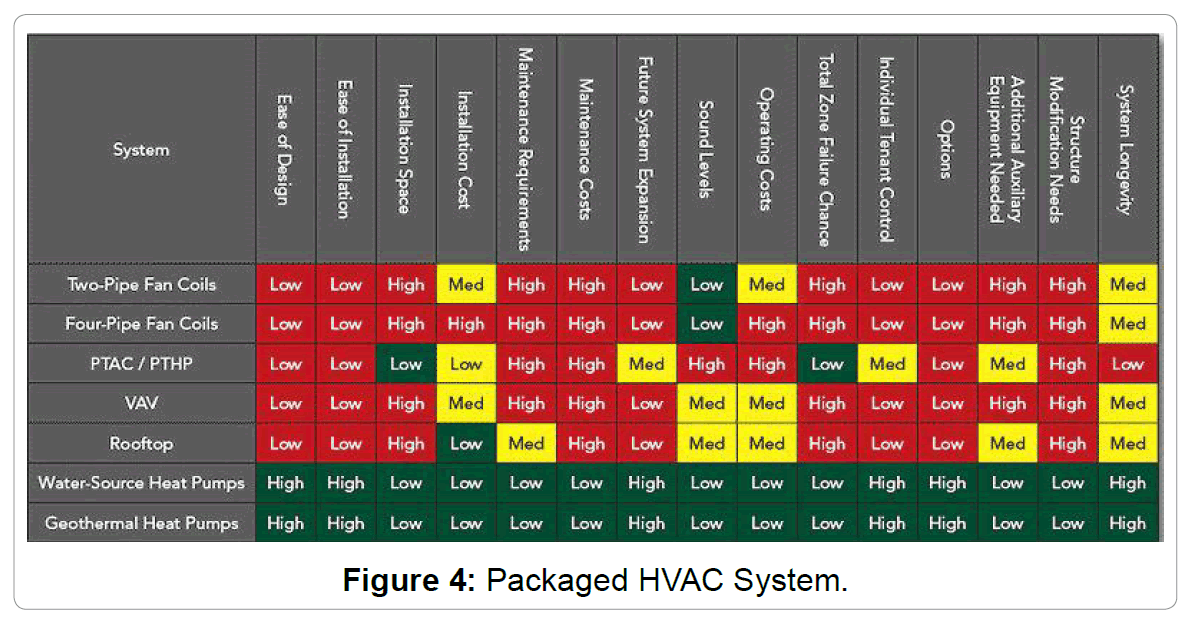

Packaged heating and air conditioning system: A packaged HVAC system is for smaller homes and offices that don't have the space for the split units (Figure 4). Packaged heating and air conditioning systems will sort out confined spaces that range from entire homes to the one-roomed units, all in one package. Packaged HVAC systems will contain:

• The air conditioner/heat pump together with the evaporator/fan coil in one unit

• Thermostat/control interface for a complete control of the system

• Optional air quality improvers. Things like the air purifiers, cleaners, ventilators or UV lamps, which gear towards making the air extra clean before it circulates your home or office.

Manufacturing Process

Ventilation types

Methods for ventilating a building may be divided into mechanical/ forced, natural and mixed types. A building ventilation system that uses powered fans or blowers to provide fresh air to rooms when the natural forces of air pressure and gravity are not enough to circulate air through a building.

Mechanical ventilation is used to control indoor air quality, excess humidity, odours, and contaminants can often be controlled via dilution or replacement with outside air. However, in humid climates specialised ventilation systems can remove excess moisture from the air (Figure 5).

Ceiling fans are commonly seen as ventilation systems as they are usually the most visible mechanical system in a building; however ceiling fans do not provide real ventilation, as there is no introduction of fresh air. Ceiling fans only circulate air within a room for the purpose of reducing the perceived temperature by method of evaporation of perspiration on the skin of the occupants. Also hot air rises therefore; ceiling fans may be used to keep a room warmer in the winter by circulating the warm from the ceiling to the floor [11-13].

Types of mechanical ventilation

1. Window AC, Split AC, Packaged AC, Central AC

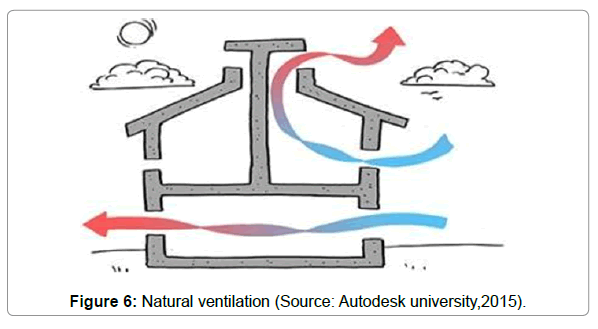

2. Natural Ventilation

It is the ventilation of a building with outside air without using fans or other mechanical systems. It is normally openings being positioned strategically around the space in order to produce a healthy air flow.

The plans, cross sections and pictures below provide insight into four styles of natural ventilation. The blue ribbons represent fresh airflow whilst the red represents the stagnant air. In order to be successful natural ventilation must take some key factors into consideration (Figure 6).

• Passive Cooling

• Shading of the building

• Geometry of the building

How HVAC is made

High quality HVAC systems are high in demand in not only healthcare but almost all buildings nowadays. Air conditioning manufacturing companies play a significant role in making AC units more affordable by enhancing efficiency, improving components, and technology. With demands increasing, competition is rising between different companies to provide the best quality yet most affordable AC units and systems.

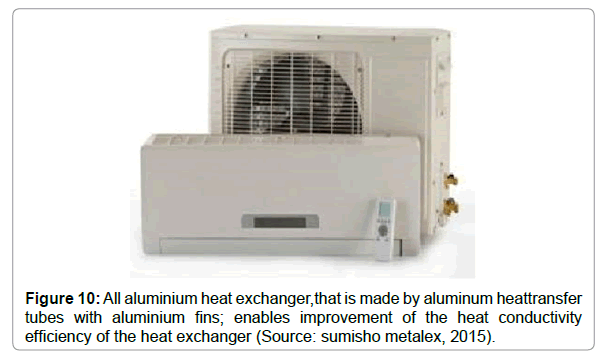

Generally in terms of raw materials, AC is composed of different types of metals, such as copper, aluminum and Finstock that are considered to be significant to create an outstanding thermal properties and a positive effect on system efficiency (Figures 7-10).

Many components or parts of AirConditioning are diverse due to the application, but usually they are composed of stainless steel and other corrosion resistant metals.

Also, Air conditioners shares basic parts which are:

1. Main parts: Compressor, Condenser, Evaporator, Fan, Expansion Valve, Refrigerant and Tubes.

2. Supporting parts: Tube insulation, Muffler, Filter, Filter dryer and receiver.

3. Control parts: Thermostat, Contactor, Damper, Humidistat and hygrometer

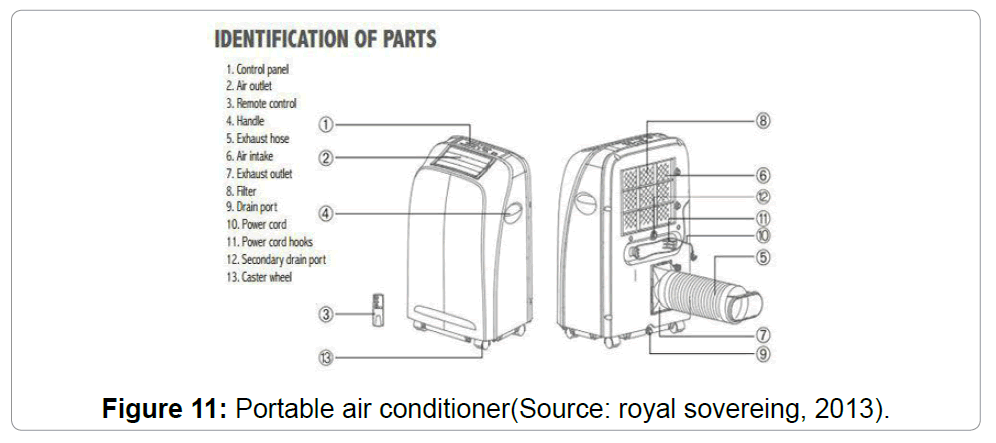

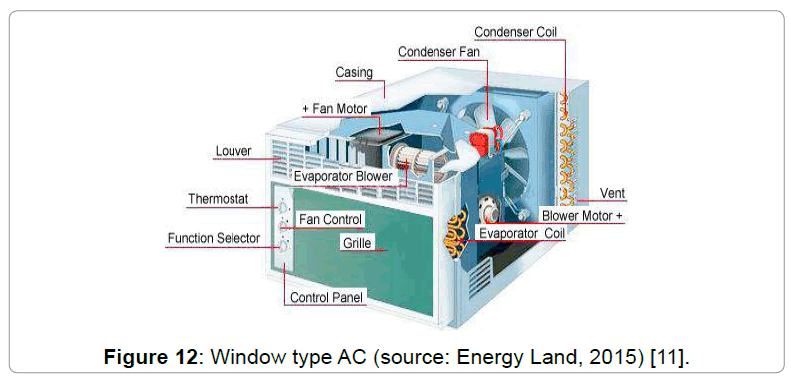

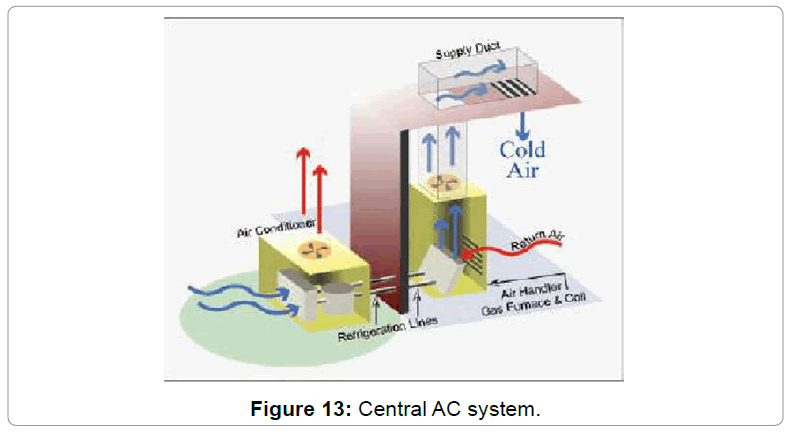

The following pictures illustrates the parts of different AC types

• Portable Air Conditioner (Figure 11)

• Window type AC (Figure 12)

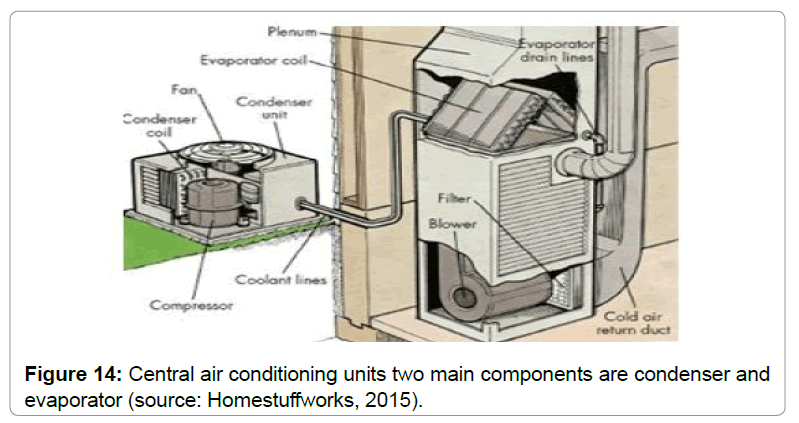

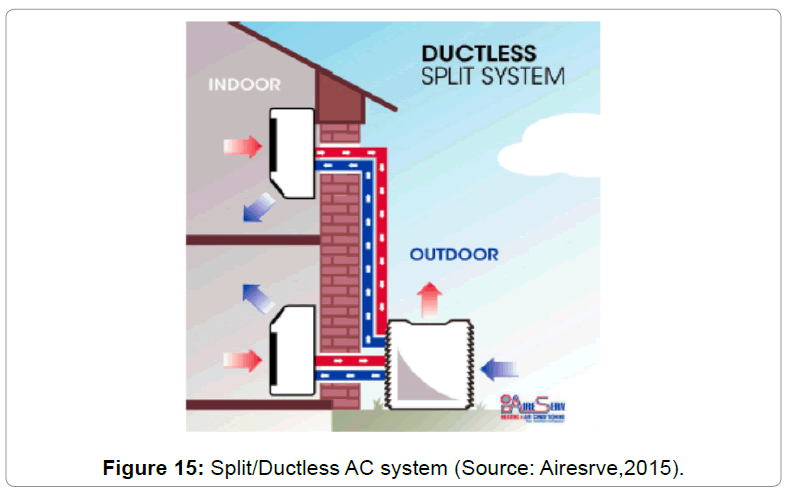

• Central AC system (Figures 13 and 14)

• Split/Ductless AC system (Figures 15 and 16)

HVAC requirements in hospitals

Before designing a proper HVAC system there are few problems that needs to be solved. we should consider whether it is planned for the isolation rooms, surgical suite, the patient rooms, or the administration offices.

First, the suitable ambient design conditions should be selected. usually, only the peak cooling design conditions are put into consideration for sizing the capacity requirements of the system. In the research of A. Bhatia about the HVAC Design for Healthcare Facilities he explains that. In the ASHRAE Handbook – Fundamentals these ambient conditions are called the drybulb temperatures with mean coincident wetbulb temperatures, representing conditions on hot, mostly sunny days. Cooling equipment such as chillers or package equipment for cooling control are sized by these conditions. This might work good on some climates, however in higher humidity climates considering only the cooling condition might not be efficient. High relative humidity and peak absolute moisture loads from the weather is the result of Extreme dewpoint temperature conditions may occur on days with moderate drybulb temperatures.

Some helpful humidity control applications values found in tables found in the Fundamentals Handbook, such as desiccant cooling and dehumidification, coolingbased dehumidification, and fresh air ventilation systems. When analyzing the behavior of cooling systems at part load conditions these values can also be used as a checklist especially for systems that are used for humidity control as a byproduct of temperature control.

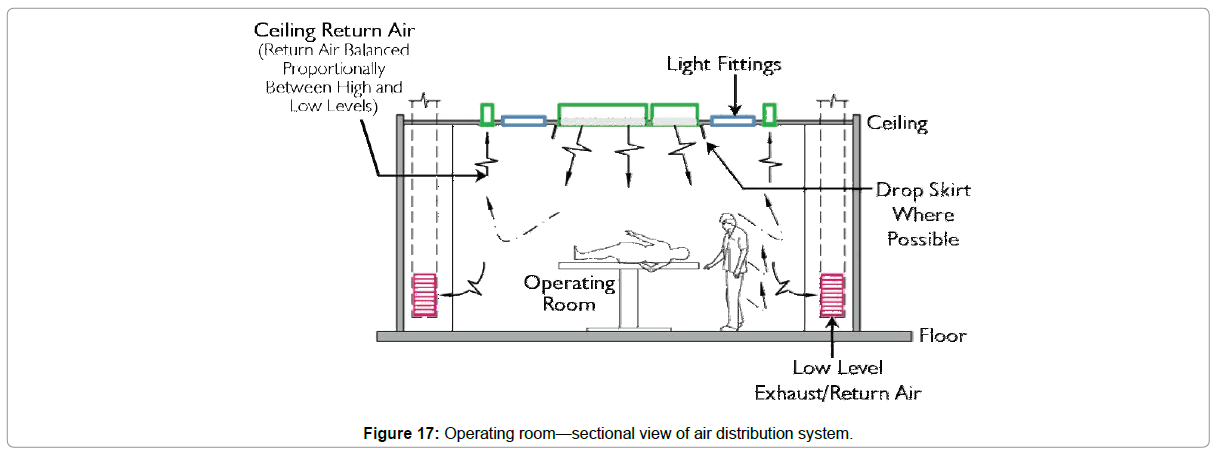

Isolation rooms and critical examination rooms

Bhatia points out in his research are For the critical areas such as isolation rooms, intensive care units and operating rooms, critical diagnostic and examination rooms, consider only the centralized HVAC system encompassing “all air systems”. In all air systems, the outdoor air enters the system via a low efficiency or "roughing" filters, which removes the large particulate matter. It is mixed with the return air and is made to pass the fine filters, which removes small size particles and many microorganisms. The air is than conditioned and delivered to each zone of the building. After the conditioned air is distributed to the designated space, it is withdrawn through a return duct system and delivered back to the HVAC unit. A portion of this "return air" is exhausted to the outside while the remainder is mixed with outdoor air and filtered for dilution and removal of contaminants” [6].

However in other critical areas HEPA filters that are located under the cooling/heating coil or at the terminal end of the duct filter the air again. All air systems can be classified as singlezone, multizone, dual-duct and reheat systems (Figure 17).

Singlezone systems: Singlezone systems work on special temperature humidity and pressure requirements for one zone. This system is very simple and basic. For this type of system to work efficiently, the load must be equal all through the zone, otherwise there may be a large temperature differences.

Multizone systems: Multizone systems are used for a small number of zones with just one central air handling unit. The air handling unit for multizone systems consists of heating and cooling coils in parallel to get a hot deck and a cold deck. This system is energy efficient because hot and cold deck temperatures are automatically changed to meet the maximum zone heating (hot deck) and cooling (cold deck) needs. Zone thermostats control mixing dampers to give each zone the right supply temperature.

Dualduct systems: Dualduct systems are similar to multizone systems, however it does not mix the hot and cold air at the air handling unit. Rather the hot and cold air are both brought by ducts to each zone where they are then mixed to meet the needs of the zone. It is usual for dualduct systems to use highpressure air distribution systems with the pressure reduced in the mixing box at each zone.

Reheat systems: Reheat systems supply cool air from a central air handler as required to meet the maximum cooling load in each zone. A heater is located in each zone’s duct that re-heat the air supply to keep the space temperature as needed.

Type of HVAC system

Normal patient care rooms administrative and noncritical areas: For the patient rooms and other nonbasic regions, any of the listed HVAC frameworks can be utilized.

• All air systems as talked about above.

• Terminal heating and cooling units, such as fan coil units or radiant ceiling panels.

• Radiant heating and cooling system.

The amount of outside air and how it is supplied to the indoor spaces would depend on the sort of HVAC framework utilized. At the point when the fan coil units or radiant ceiling panels are utilized, the rooms are conditioned by a central ventilation unit.

HVAC selection for healthcare facilities

Identifying a healthcare facility’s specific goals in patient care and energy efficiency is critical in choosing the right HVAC system.

Hospital HVAC system designs present unique challenges to facility managers due to the sensitivities of the hospital environment. The selection process is not straightforward, because in healthcare facilities there is an increased level of demand, a variety of required thermal conditions, and codes regarding reliability and hygiene. On top of that is increasing pressure to reduce energy consumption while maintaining a safe environment.

No two hospitals are alike, and while the facilities often contain the same program, varying size, location, priorities or goals can lead to completely different HVAC systems. The goal, then, is not to designate a universal HVAC system for all health care facilities, but rather to identify the various factors and general processes that need to be considered when selecting HVAC systems for health care.

• Identify project goals

• Identify program requirements

• Identify constraints.

• Identify facility desires and expectations.

• Thermal and ventilation loads.

• Identify HVAC systems.

New Systems and Technology for HVAC for Healthcare Buildings

With the continuous advances in technology, new and improved systems are being developed. This part of the study will present systems that can be applied in medical institutions.

Gatorduct ductwork system

Gatorduct is a company that has developed ducts made from a new material, called triwall, which is essentially a very strong, reinforced, corrugated cardboard. The raw materials are obtained from managed forests, so that two trees replace one that is cut down, preserving the forest environment. Triwall has been used for a while for other heavy-duty purposes but Gatorduct has combined triwall with a special coating to keep it dry and protected.

It can be flattened and packed for transportation, allowing more of it to be transported in one truck than steel ducts. This reduces energy and cost on transportation, making it environmentally friendly. In addition to this, it is about 80% lighter than traditional ducts [3], and easy to install. Gatorducts can also be relatively flat, reducing floor-to-floor height.

A school has already implemented these new duct systems with an exposed ceiling style. They have altered the colour of the material to their aesthetical preferences. The image below shows the gatorduct system in place (brown ducts).

High performance HVAC system

Generally, the heating, ventilating and air conditioning accounts for a large portion of energy consumption within a building. With the introduction of the high performance HVAC unit we will be able to save between 10% to 40% of cost and energy emissions according to Graham [8]. “Extended comfort includes employing concepts such as providing warmer, but drier air using desiccant dehumidification in summer, or cooler air with warmer windows and warmer walls in winter. In addition, highperformance HVAC can provide increased user thermal comfort, and contribute to improved indoor environmental quality (IEQ).”

The difference between a traditional hvac unit and a high performance one would be in the addition of a new discipline to the overall name and meaning which is known as, Control. This refers to the ability of providing user comfort, energy saving and consumption by the implementation of operating the HVAC unit (Figure 18).

There are specific design fundamentals to be considered in order to achieve high performance hvac. According to the Whole Building Design Guide (2014) they are as follows:

• Decide on the goals of the design as early as possible

• Select the correct size of the hvac unit for efficiency

• Take into consideration the several aspects of the building that could affect it.

• Take into account future expansion

• Think of part load performance

• Have a maintenance and operation program

• Have the hvac system commissioned.

Alternative HVAC solutions Inc units

The company, Alternative HVAC Solutions Inc provides several different types of units that are sustainable, green and energy efficient. The first one being Messana. This is a suitable system for a healthcare building as it is highly efficient, quiet and is easily attached to the ceiling. It can be easily repaired and can be used for renovations. It eliminates dust particles and provides a more clean atmosphere. This unit has the R value of 9.65 and is extremely light weight.

The second unit is the Aermec unit system. This is a reversible heat pump that produces hot water in an efficient way. It can be easily controlled using an electronic card. This system reduces cost by 30% due to its design of the heat exchange circuit. It also reduces the carbon dioxide emissions by more than 30%. This is done by the use of specific type of refrigerant that is harmless to the environment, known as R410A. This refrigerant is a thermodynamic fluid which allows the great reduction in the carbon dioxide emissions.

Finally, the third unit known as Mitsubishi Electric Heat Pump System is a highly intelligent HVAC unit. It is equipped with the technology of zoning capabilities. With this system, it can recognize different needs, occupancy, usage and parameters of solar gain. It also has the ability of measuring temperature at any location within the room which allows for a more controlled air flow. Through this system energy efficiency is achieved and the cost of air conditioning the room is heavily reduced.

Green HVAC systems

In this modern time, there is an obvious and strong focus on providing sustainable solutions. There are several HVAC systems that can be implemented in a green and sustainable way. This part of the study will present systems that are sustainable.

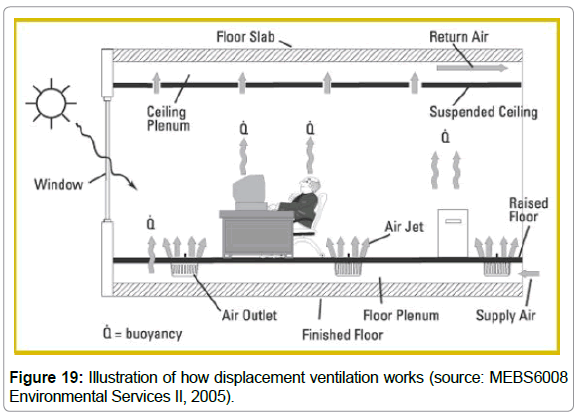

Displacement ventilation systems

Displacement Ventilation (DV) Systems are more energyfriendly alternatives to the traditional HVAC systems. They offer alternative methods to distributing air around a room. Outdoor air is cooled and pumped in at floor level at a low velocity. The cool air then warms and rises, creating convection currents within the room. It offers several advantages:

• Lower energy costs are achieved in general, although multiple factors affect this such as thermal mass, building usage etc. However, because air is pumped in at a lower velocity, there is lower pressure drop and smaller fans so less energy is required. Ventilation air change per hour (VCH) is also reduced.

• With the rising warm air, contaminants are also carried with it from heat sources, providing cleaner air. Because fresh air is supplied at floor level, contaminants like carbon dioxide, odour and such are limited from permeating throughout the space.

• Less ductwork is needed, which can help minimize floor to floor height as well as cost.

There are some disadvantages to this system too:

• Rooms must “be higher than 9 ft for the displacement effect to take place” [4] and for DV systems to be effective. The taller the room, the better the circulation.

• Indoor temperatures tend to be warmer than if a traditional HVAC system is used. There is also a noticeable temperature difference sometimes, where below a certain height, the environment is cool and above that height it is warm. Increasing rate of air flow may help in these situations but this can also result in draughts. If colder temperatures are desired, these systems can be paired with radiant chilled ceilings, which also help balance out temperature differences. In temperate climates, DV systems are most effective.

• DV systems cannot be applied as vastly as a traditional system at the moment. Their diffusers are more expensive and supply air ducting is more complicated.

Displacement ventilation systems are great for public spaces in hospitals such as lobbies and cafeterias. They can be used in other places too such as wards and patient rooms, but if cooler temperatures are needed, they must be paired with another cooling method or system. However, overall, they still reduce energy consumption and as a result energy costs, which is doubly advantageous. Not only are they green technology but they offer the benefit of cleaner air, which is especially essential in healthcare buildings.

Desiccant-Enhanced evaporative air-conditioning systems

Desiccant-enhanced evaporative airconditioning systems, also known as DEVap Systems are currently being developed by the National Renewable Energy Laboratory (NREL) and are very promising for the energy industry. Business Insider states that DEVap systems are capable of reducing energy costs by 4080%. This efficiency is due to the relationship between the desiccant and evaporative cooler. The former dries humid air while the latter cools it simultaneously, unlike traditional systems that perform this process slower and step by step, using a dehumidifier first.

This system was initially constructed for commercial buildings (although it is starting to make an appearance in residential buildings with smallerscale systems), making it appropriate for use in both small scale healthcare facilities to larger hospitals (Figure 19).

Other benefits, according to Tucker, include:

• Removal of refrigerants that are more harmful to the atmosphere than CO2

• Temperature and humidity control are of higher standards because DEVap systems treat each of these separately

• Indoor air quality is better and spaces do not feel stuffy

Dedicated outside air systems

Dedicated Outside Air Systems (DOAS) is a new HVAC technology making waves in the industry, replacing the old system of Variable Air Volume (VAV), which was the most energy-efficient system of its time. Today, DOAS offers more potential in multiple aspects.

It works by wholly using outside air in interior spaces through a “constant-volume outside air unit” [2], recovering 100% of energy used with an enthalpy wheel that cools and dehumidifies outdoor air in hot environments. eases the outside air load on the cooling coil by up to 80% and also substantially lessens the required size of the building refrigeration plant, often by over 40%”.

This system is especially suitable for healthcare buildings because it has optimum humidity control, which as a result “nearly eradicates microbial problems and related sick-building issues” [2]. With the aid of radiant cooling ceiling panels, DOAS eliminates transfer of biological and chemical substances between different parts of a building, removing them from each individual space. Thereby, spread of any harmful substance or contaminant is prevented.

Sustainable methods

While the demand for energy-efficient systems rises and HVAC companies strive to meet demands and requirements, they cannot provide energy efficient systems to their absolute potential alone. Architectural and social techniques are required to aid systems to provide the bestquality, most sustainable environment possible. Some of these techniques are discussed below, pertaining to different situations.

General

Smart, interactive systems are becoming increasingly popular today for many building systems, including HVAC. HVAC can maintain temperature by switching on and off when needed, be remotely controlled, learn and operate according to user habits, and even make suggestions on improving energy efficiency. Each of these options can be made use of in healthcare buildings. For example, maintaining temperature by switching on and off can be used in patient rooms, while learning user habits can be implemented in offices.

Rainy, humid regions

For very rainy areas, providing some kind of rain screen or shield on the facades of buildings can aid in moisture control, which will reduce loads on HVAC systems to dehumidify air, thus saving energy. An example of this can be seen in the case study that is explored in this paper: Kiowa County Memorial Hospital.

Windy regions

If possible, the creation of wind farms near large, highly energy-consuming buildings provides a source of renewable energy that can be harnessed to power HVAC systems, as well as other electrical needs.

Sunny regions

If feasible, the use of solar panels on rooftops, facades and, recently, even as glass curtain wall panels can produce electricity to power HVAC systems, as well as serving other electrical needs.

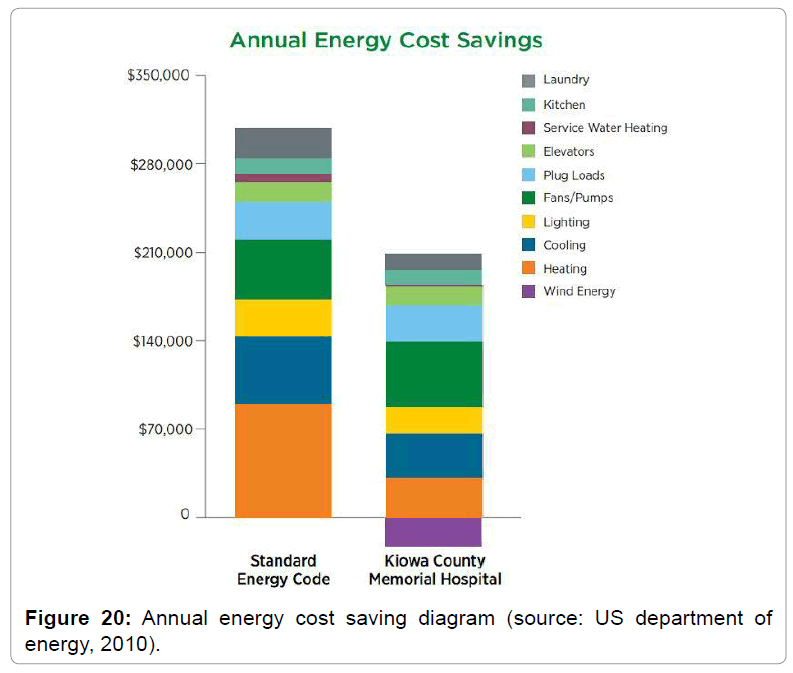

Case Study: Kiowa County Memorial Hospital

On May 4, 2007, a massive tornado destroyed or severely damaged 95% of Greensburg, Kansas. The Kiowa County Hospital got destroyed in the tornado and rebuilt sustainable. the design team of the hospital transformed one of the most energy consuming building type and turned it into an energy efficient hospital but still following the functional and safety requirements.

The hospital which is 50,000 square-foot has 15 acute-care beds, rural health and specialty clinics, and emergency department with two trauma rooms, physical/occupational therapy and radiology departments, a laboratory, and other support areas (Figure 20).

The new hospital in Greensburg is expected to perform with more than 40% energy savings more than a standard code due to features such as an on-site wind turbine it is 100% renewable energy, 100% of the time.

The Kiowa County Memorial Hospital was completed in March 20120 to become the U.S. Green Building Council’s Leadership in Energy and Environmental Design (LEED®) Platinum designation.

In order to reach their LEED Platinum certification goal, the hospital design team had to put in mide and add some energy conservation and efficiency measures, which include lighting; insulation; heating, ventilation, and air conditioning (HVAC); and renewable power sources.

Air Quality and Indoor Environment

With the majority of patients, visitors, and staff inside the hospital, an environment that is safe, sanitary, and comfortable is imperative. To create this environment, the hospital utilizes a ventilation system that prevents air exchange between emergency and isolation areas and the rest of hospital, and demand-control ventilation to ensure continuous fresh air and appropriate carbon dioxide levels. Since Kansas weather can become very humid, a rain screen system on the hospital’s exterior provides moisture control. The hospital uses a filmless x-ray, which eliminates the need for dangerous chemicals, and seamless countertops and floors to help reduce infection rates.”

HVAC

1. Ultra high-efficiency magnetic bearing chiller with secondary unit reclaims waste heat for reheat and domestic water heating.

2. Ventilation air is pre-conditioned via energy recovery wheels, reducing the load on heating and cooling systems.

3. Variable air volume system provides air distribution and dynamically adjusts airflow to meet loads while maintaining pressurization.

Results

According to energy analysis modeling results, the new hospital is 32% more energy efficient than an ASHRAE-compliant building of the same size and shape. Applying the savings from the 50 kW wind generator, the hospital achieves an additional 8% in annual electrical savings for a total savings of approximately 40%.

Due to the high-efficiency HVAC and heat recovery system, the efficient building envelope, and the City of Greensburg’s 12.5 MW wind farm helping to provide power, the hospital was able to eliminate the need for an expensive boiler backup system, as well as the gas service, piping, and equipment flues associated with natural gas fired heating equipment. These savings offset the cost of the heat recovery system and high-efficiency equipment and make the hospital an electricity-only site.

Conclusion and Recommendations

HVAC systems are crucial mechanical systems in buildings, especially in a healthcare building for the following reasons:

• Healthcare buildings are first and foremost places of healing and the people within require a thermally comfortable environment to recover and function well.

• Typically, healthcare buildings have many different functions that may require different thermal environments and types of ventilation.

• Proper ventilation is very important because healthcare buildings contain people that may have contagious diseases and labs that deal with biological and chemical substances that could possibly be harmful if spread. This is why ventilation systems for healthcare buildings are designed specifically to monitor the air and control substances from spreading.

The above needs must be met but as many of these buildings are large and require HVAC systems to run around the clock, efficiency is also necessary. With today’s need for a more environmentally conscious approach to living and functioning, we are constantly striving to make our mechanical systems more environmentally friendly as well as economically and physically sustainable, which is why it is imperative to do the following:

• Architectural design is key in order to aid HVAC systems; good design and technologies such as responsive screening on facades will lessen the load on air-conditioning, thus saving energy and money. Design must be responsive to local environmental conditions.

• Healthcare buildings should make efforts to incorporate new and green technologies in their systems. Purchasing from green factories that hav sustainable practices also aids in the going green effort.

• Setting up ways to harness renewable energy for new or existing healthcare buildings will allow the building to become more energy-friendly and economically friendly in the long run.

Because each health-care building will be slightly different and thus have slightly different requirements, it is necessary to run an individual assessment for each building to understand the best HVAC options to use as well as what problems can be treated with design and what opportunities can be utilized. This can be seen in our discussion of the case study of Kiowa County Hospital. The hospital was located in a place that experienced a lot of wind and thus used this opportunity to harness wind energy as a renewable source of energy for the hospital’s HVAC system. To lessen the load on the HVAC system, a rain screen was also used on the facade to control the amount of moisture coming into the building.

In conclusion, healthcare buildings need to be individually analyzed as their functions can vary from one to the other and their locations are always different. With so many HVAC options for different requirements and environmental conditions, being developed and emerging in the market, any healthcare building can improve its HVAC efficiency, become more energy friendly and lower costs by understanding what suits their needs best. In the long-run, new and green technologies will be both environmentally and economically sustainable.

References

- Alternative HVAC Solutions Inc. (n.d.). Green HVAC Solutions.

- Arabe KC (2003) New HVAC technology to transform the industry. Industry News.

- Gatorduct (2015) Gatorduct.

- HVAC Web Connection (nd) Top 3 trends for the HVAC industry in 2015.

- Schultz RW (2012) When, where to use displacement ventilation. ConsultingSpecifying Engineer.

- Tucker E (2015) Air conditioner ready to change industry. ?National Renewable Energy Laboratory?.

- HVAC Design for Health care Facilities. Editor Bhatia A ,Continuing Education and Development, Inc.

- What Are the Different Types of HVAC Systems? (2015, September 14).

- Graham CIPE (2014) High Performance HVAC. Viridian Energy & Environmental, LLC

- Health Facilities Management, Modular services company

- HVAC systems for hospitals. Applied System Solutions.

- Making Life more comfortable. Importance of a Hospital Hvac system.

- Air conditioner. Industrial Vaccum pump 3.

Relevant Topics

- Architect

- Architectural Drawing

- Architectural Engineering

- Building design

- Building Information Modeling (BIM)

- Concrete

- Construction

- Construction Engineering

- Construction Estimating Software

- Engineering Drawing

- Fabric Formwork

- Interior Design

- Interior Designing

- Landscape Architecture

- Smart Buildings

- Sociology of Architecture

- Structural Analysis

- Sustainable Design

- Urban Design

- Urban Planner

Recommended Journals

Article Tools

Article Usage

- Total views: 23143

- [From(publication date):

March-2016 - Mar 31, 2025] - Breakdown by view type

- HTML page views : 21506

- PDF downloads : 1637