Review Article Open Access

The Preparation of Silk Fibroin Modified Pbt-Co-Pbs/Peg Composite Films and their Effects on Clinical Human Salivary Epithelial Cells Transplantation

Jie Zhu1*, Yueming Zhang1, Zhicheng Tao1, Nanwei Xu2, Liqun Wang1* and Xiaolin Zhu1

1School of Pharmaceutical Engineering & Life Science, Changzhou University, Changzhou 213164, China

2Department of Orthopaedics, Changzhou No.2 People’s Hospital, Changzhou 213003, China

- Corresponding Authors:

- Jie Zhu

School of Pharmaceutical Engineering & Life Science

Changzhou University, Changzhou 213164, China

Tel: 86-519-86334597

Fax: 86-519-86334597

E-mail: zhujie_cczu@yahoo.com

- Liqun Wang

School of Pharmaceutical Engineering & Life Science

Changzhou University, Changzhou 213164, China

E-mail: wlq@cczu.edu.cn

Received date April 23, 2013; Accepted date July 08, 2013; Published date July 16, 2013

Citation: Zhu J, Zhang Y, Tao Z, Xu N, Wang L, et al. (2013) The Preparation of Silk Fibroin Modified PBT-co-PBS/PEG Composite Films and their Effects on Clinical Human Salivary Epithelial Cells Transplantation. J Biomim Biomater Tissue Eng 18:107. doi: 10.4172/1662-100X.1000107

Copyright: © 2013 Zhu J, et al. This is an open-access article distributed under the terms of the Creative Commons Attribution License, which permits unrestricted use, distribution, and reproduction in any medium, provided the original author and source are credited.

Visit for more related articles at Journal of Biomimetics Biomaterials and Tissue Engineering

Abstract

We reported the preparation of surface modified poly(butylene terephthalate)-co-poly(butylene succinate)-bpoly( ethylene glycol) (i.e. PBT-co-PBS/PEG) films by three methods: silk fibroin coating, SO2 plasma treatment and silk fibroin anchoring. The obtained composite films were named SF/(PBT-co-PBS/PEG), SO2/(PBT-co-PBS/PEG) and SF/ SO2/(PBT-co-PBS/PEG), respectively. Their surface properties were characterized by contact angles, surface energies and XPS. The biocompatibility of the films were further evaluated by in vitro and in vivo tests including the morphology, attachment, proliferation and viability of human salivary epithelial cells (HSG cells) and the following histological observation of the films implanting in Sprague Dawley rattus norregicus (SD rat). Results revealed that SF/SO2/(PBTco- PBS/PEG) possessed the high surface free energy (59.67 mJ/m2) and could immobilize a great amount of fibroin (SF surface coverage: 26.39 wt%), which attributed to the formation of such polar groups as hydrosulfide group, sulfonic group, carboxyl and carbonyl ones in the process of SO2 plasma treatment. The tests in vitro and in vivo suggested that the silk fibroin anchoring could significantly enhance the biocompatibility of PBT-co-PBS/PEG, which implied the potential application of fibroin modified PBT-co-PBS/PEG for clinical HSG cells transplantation in artificial salivary gland constructs.

Keywords

Poly(butylene terephthalate)-co-poly(butylene succinate)-b-poly(ethylene glycol); SO2 anchoring; Surface modification; Human salivary epithelial cell line; Biocompatibility

Introduction

Mammal’s salivary gland, an exocrine one composed of acinous cells and duct cells, has the main function of saliva secretion. In clinic, both the radiation treatment to the tumor on one’s head or neck, and Sjogren’s syndrome will cause the damage to the salivary gland irreversibly [1-3]. One of the therapeutic strategies is to develop a tissue-engineered salivary gland and transplant it to the oral mucous membrane, in which the artificial salivary gland will realize the saliva secretion. Wang et al. [4] seeded human salivary epithelial cells (HSG cells) in the lining of the rat trachea and then observed the cell growth and differentiation, which confirmed it feasible to use natural and synthetic biomaterials to prepare the artificial salivary gland.

At present, poly(hydroxy esters) including poly(glycolic acid) (PGA), poly(lactic acid) (PLA) and their co-polymer poly(lactic-co-glycolic acid) (PLGA), are commonly used synthetic polymers in tissue engineering owing to their good biodegradable properties and the fact that they are approved by the US Food and Drug Administration for clinical use [5]. Larsen et al. [6,7] cultured adult mouse submandibular salivary gland (SMG) ductal epithelial cells on PLGA nanofiber scaffold and observed their continuous proliferation on it.

Poly(ether ester), another type of synthetic polymer, combines aliphatic and aromatic units in the same polyester chain. It has been envisaged for a long time as an attractive approach to obtain novel products encompassing suitable biodegradable and mechanical properties by changing the ratios of aliphatic units to aromatic ones [8,9]. Two important aliphatic-aromatic copolyesters, poly(butylene succinate-co-terephthalate) (PBST) and poly(ethylene glycol terephthalate)-poly(butylene terephthalate) (PEGT/PBT), were investigated intensively in the past years for the application on tissue engineering [10-12]. Furthermore, Feng et al. [13] found that the incorporation of aliphatic unit poly(butylene succinate) (PBS) in PEGT/PBT copolymer will increase its flexibility and hydrophilicity, and accelerate its degradation rate as well. The obtained copolyester was named poly(butylene terephthalate)-co-poly(butylene succinate)- b-poly(ethylene glycol), i.e., PBT-co-PBS/PEG.

To develop tissue-engineered products, it is important to mimic key features of the normal cellular microenvironment including extracellular matrix (ECM) structure and its chemical composition, which are involved in survival, spread, and proliferation of the cells. Although synthetic polymers possess some advantages mentioned above, they lack cell recognition signals and their hydrophobic nature will hinder cell seeding. In general, a higher surface energy (hydrophilic) material typically results in a higher number of attached cells, with a spread out and polygonal shape; in contrast, a lower surface energy (hydrophobic) material reduces cell attachment and leads to a rounded morphology [14,15]; Meanwhile, cell recognition signals on material surface are conducive to create cell-biomaterial interfaces that elicit controlled cell adhesion and maintain differentiated phenotypic expression [16]. So, it is essential for synthetic polymers to carry on some surface modifications when they are used in cell seeding. Such modifications generally involve enriching the substrates with ECM molecules and their derivatives, such as collagen, chitosan and gelatin, as surface modifiers, which have been found to significantly improve the cytocompatibility of polyesters [17].

Silk fibroin (SF), a structural protein without physiological activity, is composed of 17 amino acids and its main components are weak polar ones (alanine, glycine and serine residues). Fibroin is considered to possess the excellent biocompatibility as the same as that of ECM molecules [18,19] and its excellent biocompatibility has attracted researchers’ significant attentions in recent years to prepare some artificial tissues such as skin, blood vessel and cornea [20-23]. Fibroin modified synthetic polymer will merge the advantages of two materials. In this scheme, the synthetic polymer is the main provider of the profile due to its good mechanical and biodegradable property; and the silk fibroin is the main contributor to realize the cell attachment and spreading due to its excellent biocompatibility. Yao et al. [24] prepared silk fibroin modified poly(D,L-lactic acid) film and the studies indicated that fibroin modification could improve osteoblasts viability and differentiated cell function significantly on poly (D,L-lactic acid) film.

Previously, ECM molecules modified biomaterials could be realized by either physical coating, or chemical crosslinking. In spite of some advantages such as safety and convenience, the physical coating is easy to wash away from the surface due to their weak affinity. On the contrary, although the ECM molecules can be tightly immobilized onto the surface by the method of chemical crosslinking, the preparation process involved some coupling agents such as glutaraldehyde, which is harmful to the health of human and will cause some environmental problems.

ECM anchoring, a convenient and efficient surface modification method with a combination of plasma treatment and physical coating, can be used for the purpose of resolving the disadvantages of traditional methods. Low-temperature plasma treatment is regarded as a green and effective one for modifying the surface properties or introducing desired chemical groups at the surface of a material without affecting its bulk properties [25]. By choosing an appropriate plasma source, diverse functional groups could be introduced to the surface to improve biocompatibility or to allow subsequent covalent immobilization of various bioactive molecules [5,26]. Chen et al. [5] prepared the cationized gelatin (CG) modified poly(lactic acid) (PLLA) nanofibers (NF) (CG-PLLA NFM) with the method of CG anchoring and the studies indicated the superior ability of PLLA NFM after surface modification with CG to support chondrocyte proliferation, differentiation and cartilaginous matrix biosynthesis.

In this work, silk fibroin was anchored onto SO2 plasma treated PBT-co-PBS/PEG film and the synthesized composite was named SF/ SiO2/(PBT-co-PBS/PEG). PBT-co-PBS/PEG is selected as the substrate because it is an elastomeric material which has the good properties on swelling, degradability and mechanical strength. These properties make it suitable as the scaffold for the artificial soft tissues, such as the glands, blood vessels and derma [13]. The performance of surface modified PBT-co-PBS/PEG films here was evaluated by analyzing the culture of HSG cells in vitro and their implantation in vivo for the purpose of investigating the potential application in artificial salivary gland.

Experimental

Materials

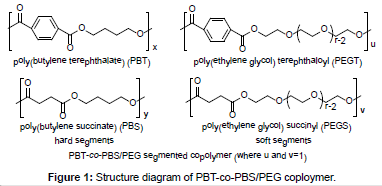

PBT-co-PBS/PEG is a gift of Prof. Zengguo Feng from the school of materials, Beijing Institute of Technology and its molecular structure is shown in Figure 1. In this work, the molecular weight of the starting PEG blocks used in the copolymerization was 1000 Da. The molar fractions of PBS, PBT and soft segment in the copolymer are 20%, 60% and 20%, respectively. The total molecular weight of PBT-co-PBS/PEG copolymer is approximately 6.6×104 Da.

Silk fibroin was prepared according to the reference [22]. Specifically, raw silk was degummed twice with 0.5 % (w/w) NaHCO3 solution at 100°C for 1 h and washed with distilled water. Degummed silk was then dissolved in the mixture solution of CaCl2, H2O and ethanol at the molar ratio of 1:8:2. After dialysis against distilled water for 3 days and the following degradation of the gross fibroin with NaOH (0.2 mol/L) at a temperature of 85°C for 30 min, we obtained the fibroin product with the molecular weight about 30 kDa.

PBT-co-PBS/PEG film preparation and its surface modification

PBT-co-PBS/PEG was dissolved in chloroform (A.R, Sinopharm, China), in which the concentration of PEOT/PBT was kept fixed at 0.03 g/mL. This solution was then transferred to a 60 mm diameter glass plate to form films by evaporation.

Three treatment methods for PBT-co-PBS/PEG surface modification were used in this study. The first one was a physical method, SF coating, in which the silk fibroin was directly coated on the surface of PBT-co- PBS/PEG film. Specifically, the prepared PBT-co-PBS/PEG film was impregnated in the fibroin solution for 2 h. After washing the film with distilled water 3 times and then drying overnight, the modified film was prepared. This sample was named SF/(PBT-co-PBS/PEG).

The second one was SO2 plasma treatment, in which the prepared PBT-co-PBS/PEG film was grafted with sulfur functionalities by SO2 glow discharges with the plasma treatment apparatus (HD-1A, Zhongke Changtai plasma Tech, Changzhou, China) under the atmosphere of SO2. The reaction conditions were as follows: SO2 flow rate 20 ml/min; working pressure 20 Pa; discharge power 30W and the treatment time 5 min. This prepared sample was named SO2/(PBT-co-PBS/PEG).

The final one was fibroin anchoring, which combined SO2 plasma treatment with fibroin coating. Specifically, the surface of PBT-co-PBS/ PEG film was firstly grafted with sulfur functionalities by SO2 glow discharges. The obtained SO2/(PBT-co-PBS/PEG) sample was then coated with SF. The experimental conditions in the preparation process were the same as the above two treatments. The final sample prepared was SF/SO2/(PBT-co-PBS/PEG).

All the samples above were preserved in the desiccator and sterilized under the ultraviolet light for 3 h prior to cells seeding on them.

Characterization of the surface

Contact angles of water and diiodomethane on the material surface were determined using the sessile drop method and an image analysis system on HARRE-SPCA contact angle analyzer.

Element distribution and binding energy analysis of PBT-co-PBS/PEG film before and after surface modification were performed using Perkin Elmer PHI 5300 X-ray photoelectron spectroscopy (XPS).

Cell culture and cell morphology

HSG cells were cultured at 37°C, in a humidified atmosphere of a 5% CO2 in air, in 50 cm2 flasks containing 5 ml Dulbecco’s Modified Eagle Medium (DMEM, Hyclone, USA), 10% fetal bovine serum (FBS, Tianhang Biotech, China). The cells used in this work were all between passages 10 and 20. The morphology of the cells cultured on the films was examined by Opton 405M fluorescence inverted microscope. Scanning electron images of the cells on the prepared films were recorded using a JEOL JSM-6360 LA scanning electron microscope.

Cell attachment

The film samples were completely filled the bottom of the well in a 24-well plate (Nunclon Inc, Denmark). HSG cells were then seeded onto the film at a density of about 1.0×105 cells/mL. The blank well without any films acted as the control. The cells were allowed to attach onto the film undisturbed in a humidified incubator (37°C and 5% CO2) for 2, 4, 6 and 8 h, respectively. At each time interval, the quantity of floating cells in culture suspension was counted using a light microscope to determine adherent ones on the film. Cell attachment rate (R) was calculated by the expression (1) as follows:

(1)

(1)

where Cs is the initial cell density seeding on the samples; Cu is that of floating cell density in suspension after cultivation.

Cell proliferation and viability

The MTT (Sigma) assay was used as a measure of relative cell quantity and viability. Specifically, HSG cells were cultured on the film samples with 1 mL cell suspension at the density of about 1.0×104 cells/ mL in 24-well plate (Nunclon Inc, Denmark) for 5 days. The culture medium was refreshed every 2 days. Assay was performed at 1, 3 and 5 days, respectively. At each time interval, the cell proliferation and viability was evaluated using the MTT assay, in which 100 ml of MTT (5 mg/ml) was added to the medium and incubated at 37°C for 4 h. At the end of the assay, the blue formazan reaction product was dissolved by adding 0.5 ml DMSO and transferred to a 96-well plate (Nunclon Inc, Denmark). The absorbance was measured at 570 nm using a Bio- Rad 550 spectrophotometric microplate reader.

Implantation in vivo and histological observation

Sprague Dawley rattus norregicus (SD rat), the experimental animal in this work, was provided by Experimental Animal Center of China Agricultural University. The sample of SF/SO2/(PBT-co-PBS/PEG) film were cut to the blocks with the size of 1 cm ×1 cm. After 60Co radiation with the dose of 200 million Rad, the blocks were implanted into the subcutaneous tissue of the SD rats. 8 weeks later, the blocks and the tissues around them were taken out to make the slices with H-E stain. Histological observation was carried out to evaluate the histocompatibility of SF/SO2/(PBT-co-PBS/PEG).

Statistical analysis

Experiments were run in 4 duplicates per sample. All data were expressed as means ± standard deviation (SD) for n=4; Single factor analysis of variance (ANOVA) technique was used to evaluate the statistical significance of results. Multiple comparison tests were performed using Student’s t-test. P values <0.05 were considered significant.

Results and Discussion

Characterization of films

Water contact angle and surface free energy analysis: Water contact angle (WCA) and the calculated surface free energy were usually employed to evaluate the hydrophobicity or hydrophilicity of one material surface, with more hydrophilic surface having the smaller water contact angle and the higher surface free energy.

According to the mathematical model proposed by Owens [27,28], the surface free energy is composed of dispersion and polar components (γd and γp). On a solid-liquid interface, the surface free energy of the solid (γs) can be calculated by the expression “γs d+γs p”, and that of the liquid (γl) has the similar expression “γl d+γl p”.

Combining Young equation, the relationship between the surface energy and the contact angle can be expressed as the equation (2):

(2)

(2)

Equation (2) indicated that the surface energy of one solid material including dispersion and polar components could be calculated if only contact angles of two different test liquids on the solid surface were measured in the experiment. In this study, water and diiodomethane were employed to calculate the surface energy of the samples. Based on the reference [29], the dispersion/polar components (γl d/γl p) of water and diiodomethane are 22.1/50.7 mJ/m2 and 44.1/6.7 mJ/m2, respectively.

| Sample | Water contact angle a (°) | Surface free energy b, c(mJ/m2) | ||||

|---|---|---|---|---|---|---|

| θ H2O | θ CH2I2 | γ | γ d | γ p | X p | |

| A: PEOT/PBT | 81 ± 4 | 59 ± 3 | 34.13 | 22.12 | 12.01 | 0.35 |

| B: SF/(PEOT/PBT) | 68 ± 5 | 43 ± 2 | 45.07 | 28.22 | 16.85 | 0.38 |

| C: SO2/(PEOT/PBT) | 42 ± 2 | 18 ± 3 | 63.06 | 34.45 | 28.61 | 0.45 |

| D: SF/SO2/(PEOT/PBT) | 48 ± 3 | 21 ± 2 | 59.67 | 34.18 | 25.49 | 0.43 |

Note: (a) average ± standard deviation (n=4) (b) γ: total surface free energy; γ=γd + γp γd: dispersion component of the surface free energy; γp: polar component of the surface free energy; Xp: percentage of the polar component in total surface free energy, γp/γ. (c) Surface free energy calculated with the average contact angles of the samples.

Table 1: The surface wettability of PBT-co-PBS/PEG copolymers before and after surface modification (n=4).

| Sample | C (wt %) | O (wt %) | N (wt %) | S (wt %) |

|---|---|---|---|---|

| A: PBT-co-PBS/PEG | 81.74 | 18.26 | - | - |

| B: SO2/(PBT-co-PBS/PEG) | 74.08 | 24.37 | - | 1.55 |

| C: SF/(PBT-co-PBS/PEG) | 78.31 | 18.13 | 3.28 | 0.27 |

| D: SF/SO2/(PBT-co-PBS/PEG) | 70.71 | 21.59 | 6.73 | 0.97 |

| E: pure SF | 41.82 | 43.12 | 15.06 | - |

Table 2: Elements composition on the surface of the materials before and after surface modification.

| Functional group | -S-H | -SO3H | |

|---|---|---|---|

| Binding energy (ev) | 165.03 | 169.60 | 170.43 |

| Sulfur distribution (wt%) | 26.71 | 41.13 | 32.16 |

Table 3: Sulfur composition on the surface of PBT-co-PBS/PEG copolymer after the surface modification with SO2 plasma treatment.

| Functional group | -N-H | -C(=O)-N-H |

|---|---|---|

| Binding energy (ev) | 398.9 | 399.7 |

| Nitrogen composition (wt %) | 36.30 | 63.70 |

Table 4: Nitrogen composition on the surface of PBT-co-PBS/PEG copolymer after the surface modification with silk fibroin anchoring.

Contact angles of modified surfaces via three methods and their calculated surface energies as well as the control were shown in Table 1. It indicated that the hydrophilicity of PBT-co-PBS/PEG film increased greatly after its surface modification including SF coating, SO2 plasma and SF anchoring (WCA: pAB, pAC and pAD<0.01). So, the surface modifications with three methods could all cause the amelioration of PBT-co-PBS/PEG biocompatibility. It was noted that among the samples, SO2/(PBT-co-PBS/PEG) has the highest surface energy due to the strong polarity produced via SO2 plasma treatment, which was proved by a higher percentage of polar component (Xp) on SO2/(PBT-co- PBS/PEG) (0.45) than that on PBT-co-PBS/PEG (0.35). However, because of the weak polarity of alanine, glycine and serine, which are the main compositions of silk fibroin, the method of SF coating could not increase PBT-co-PBS/PEG surface energy to the same extent as SO2 plasma treatment did.

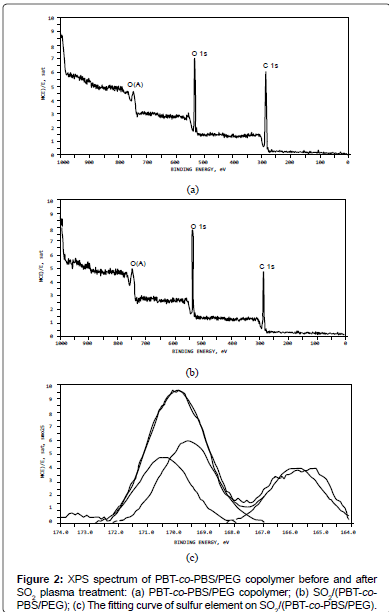

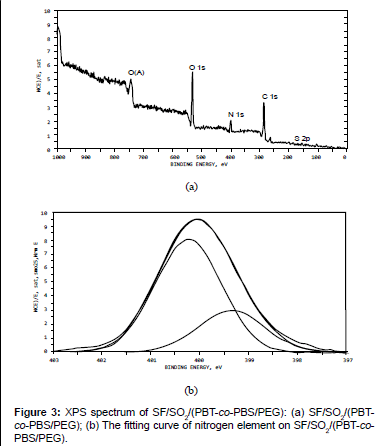

XPS analysis: Element compositions and functional group properties on PBT-co-PBS/PEG film before and after surface modifications had been analyzed by XPS and the results were shown in Tables 2-4 and Figures 2 and 3.

Compared with original film, the obtained SO2/(PBT-co-PBS/PEG) after SO2 plasma treatment owned about 1.55 wt% sulfur element on its surface (Table 2, Figure 2a and 2b). Through the further fitting to the XPS spectrum line of sulfur element (Figure 2c), the sulfuric functional groups on the surface were composed of hydrosulfide group (-SH) and sulfonic group (-SO3H), which have the characteristic binding energies at 165.03 ev, 169.6 ev and 170.43 ev, respectively. The sulfur percent in hydrosulfide group accounted for 26.71 wt% of the total sulfur element and sulfonic group for 73.29 wt%, which implied that sulfonic group was the main existence form of sulfur element on the surface (Table 2). It was just the strong polarities of two sulfuric functional groups that caused the great increase on PBT-co-PBS/PEG surface energy, thereafter ameliorating its biocompatibility. Meanwhile, the comparatively higher ratio of oxygen to carbon (O/C=0.33) on SO2/(PBT-co-PBS/PEG) than that on PBT-co-PBS/PEG (O/C=0.22) hinted the occurrence of surface oxidation in the process of SO2 plasma treatment, which caused the increase of the content on the groups involving carbon-oxygen bonds such as carboxyl and carbonyl one. This is another possible reason that caused the increase of the surface energy.

In addition, the surface modifications of SF coating and SF anchoring both caused the increase of nitrogen percent on the materials. However, compared with SF/(PBT-co-PBS/PEG), SF/SO2/(PBT-co- PBS/PEG) owned the higher nitrogen percent (about 6.73 wt%), more than two times of SF/(PBT-co-PBS/PEG) (only 3.28 wt%) (Table 2), which indicated that the fibroin fixed on the surface by the method of SF anchoring is more efficient than the direct SF coating. It could be explained that a great amount of polar groups such as hydrosulfide group, sulfonic group, carboxyl and carbonyl ones on the surface of SO2/(PBT-co-PBS/PEG) would help to immobilize the fibroin by the coformation of hydrogen bonds. The fibroin surface coverage (η) can be further calculated in equation (3):

(3)

(3)

where N/C is the mass ratio of nitrogen to carbon on the sample surface, i represents the sample with surface modification, SF is the pure fibroin.

Based on Table 2, N/C in pure fibroin, SF/(PBT-co-PBS/PEG) and SF/SO2/(PBT-co-PBS/PEG) were 0.36, 0.042 and 0.095, respectively. So, the SF surface coverage on SF/(PBT-co-PBS/PEG) and SF/SO2/ (PBT-co-PBS/PEG) was equal to 11.67% and 26.39%. Since SF could enhance the growth of anchorage dependent mammalian cells as the substratum, as that of collagen did [30], a large amount of SF on SF/ SO2/(PBT-co-PBS/PEG) sample might be favorable for the interaction with the negative charged surface of cell film. Through the further analysis on the fitting curve of nitrogen element (Table 4 and Figure 3b), the nitrogenous functional groups on the surface was mainly composed of the amine groups (-NH2) and amide groups (-CONH) with the characteristic binding energies at 398.9 ev and 399.7 ev, which was in accordance with the molecular structure of SF.

Since the outermost surface of biomaterials directly interfaces with the tissue or cells, the surface modification to PBT-co-PBS/PEG will change its surface properties, thereafter affecting the cell-material biocompatibility, which could be evaluated by some tests including the morphology, attachment, proliferation and viability of HSG cells in vitro and the implantation in vivo.

Cell attachment and morphology

To assess cellular attachment, the control and the PBT-co-PBS/PEG films before and after surface modifications were seeded with HSG cells (about 1.0×105 cells/mL), which had been cultivated in a period of 8 h. The results were shown in Figure 4.

Generally, HSG cells attaching to the surface modified PBT-co-PBS/ PEG samples were significantly higher than that found on original PBT-co- PBS/PEG (pBA, pCA and pDA<0.05) at all the time points. For example, the number of adherent cells on SF/SO2/(PBT-co-PBS/PEG) reached about (0.92 ± 0.06)×105 cells/mL after cultivation of 8 h, which was the highest one in all samples. The attachment rate (R) on it was calculated to be 92.0 ± 6.0 wt%, great more than that on the original film at the same time point (only 43.0 ± 3.5 wt%). It indicated the efficiency of surface modifications with silk fibroin and SO2 plasma treatment. The result was in agreement with the increase of PBT-co-PBS/PEG surface energy after modification. It was noted that although the surface energy of SO2/(PBT-co-PBS/PEG) was the highest in the samples (Table 1) which implied its best hydrophilic property, the quantities of HSG cells attaching on its surface were significantly less than that on SF/SO2/(PBT-co-PBS/PEG) (pDC<0.05) at all the time points. It could be explained that the cell attachment depends not only on the surface hydrophilicity, but also the ECM molecules which could be recognized by the cells to attachment. Hence, the fibroin anchoring on the surface would help HSG cells adherence to the surface as same as ECM did. In addition, compared to the blank well in the 24-well culture plate, SF/ SO2/(PBT-co-PBS/PEG) possesses the better attachment property at all the time points (pDN<0.05 or pDN<0.01), which displayed its potential advantages in biomaterials.

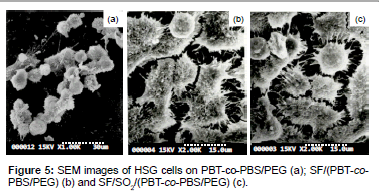

Figure 5 shows the morphology of HSG cells cultured on original PBT-co-PBS/PEG, SO2/(PBT-co-PBS/PEG) and SF/SO2/(PBT-co-PBS/ PEG) after 2 h. Obvious differences in morphology were observed between the cells grown on PBT-co-PBS/PEG films before and after surface modification. HSG cells were smooth and rounded on the original film (Figure 5a), which hinted their weak attachment; On the contrary, after surface modification, cells attaching on SO2/(PBT-co- PBS/PEG) and SF/SO2/(PBT-co-PBS/PEG) samples (Figures 5b and 5c) spread outward to form the irregular shape with a great amount of filopodia, which suggested the excellent cell attachment property on the sample surface.

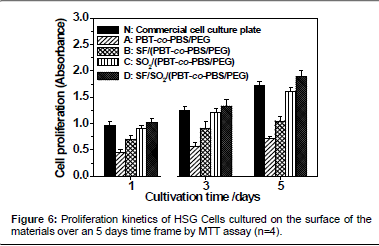

Cell proliferation and viability

As shown in Figure 6, the quantity of HSG cells on film samples increased with the cultivation going on, which exhibited the cell proliferation occurring on all films. Compared to the original PBT-co- PBS/PEG sample, HSG cells proliferation on surface modified ones was significantly higher than the former (pBA, pCA and pDA<0.01) at the whole period of cultivation, which further confirmed the efficiency of surface modification by the methods of SO2 plasma treatment and fibroin coating. This result was the same as that on cell attachment test. Meanwhile, the highest cell proliferation on SF/SO2/(PBT-co-PBS/PEG) samples in each time point also indicated that the method of fibroin anchoring possesses the obvious advantages to enhance the biocompatibility of PBT-co-PBS/PEG over the other two methods.

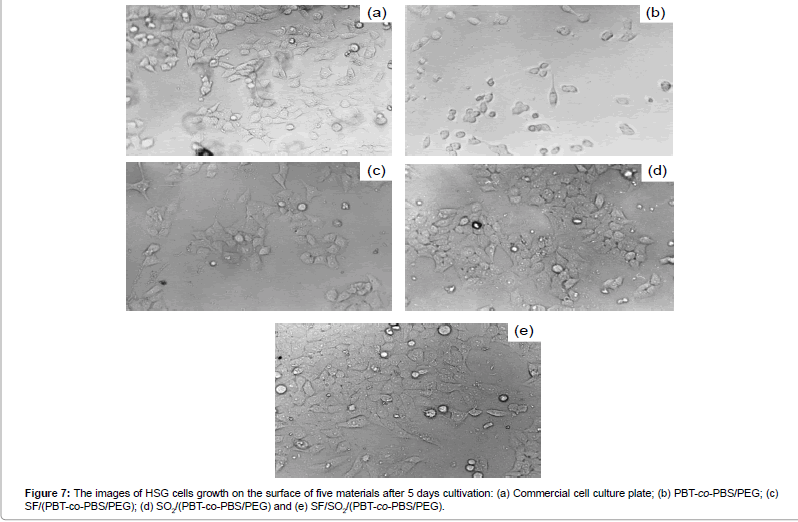

The images of HSG cells growth on surface of the samples after 5 days cultivation were shown in Figure 7. The confluent HSG cells on surface modified samples, especially on SO2/(PBT-co-PBS/PEG) and SF/SO2/(PBT-co-PBS/PEG) ones (Figures 7d and 7e) displayed “differentiated” morphological characteristics, similar to in vivo with polygonal shaped cells and fine interdigitation, which implied the cell benign proliferation on these modified surfaces due to the hydrophilicity improvement and the ECM protein anchorage. In contrast, the separated cells with the rounded shape on original film (Figure 7b) further indicated the effects of surface modification on cellmaterial biocompatibility.

In above sections, the cytocompatibility of the original film and the surface modified ones had been evaluated by some methods including cell morphology, attachment, proliferation and viability in vitro. The analysis revealed that SF/SO2/(PBT-co-PBS/PEG) obtained by fibroin anchoring possessed the excellent cytocompatibility in three modified samples. Herein, SF/SO2/(PBT-co-PBS/PEG) was further employed to assess its histocompatibility in vivo.

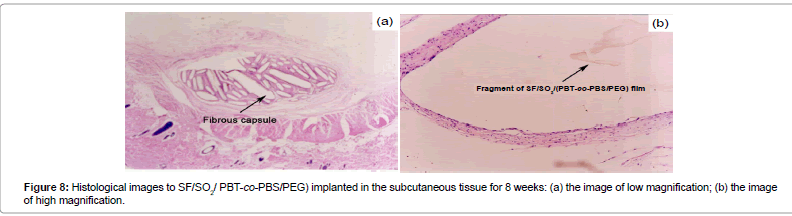

In vivo assessment of histocompatibility of SF/SO2/(PEOT/ PBT)

Histological images of SF/SO2/(PEOT/PBT) implanting in the subcutaneous tissue of SD rat for 8 weeks were shown in Figure 8. Some fibrous capsules in the image (Figure 8a) implied that SF/SO2/(PBT-co- PBS/PEG) film had begun to degrade to the fragments and the fibrous tissues grew in their gaps in vivo. Meanwhile, little inflammatory cells were found to infiltrate the tissues around the capsules and they were mainly composed of lymphocytes. Little neutrophils were found in tissues. The Histological images verified the good histocompatibility of SF/SO2/(PBT-co-PBS/PEG) (Figure 8b).

Conclusion

In this work, three surface modified PBT-co-PBS/PEG films were prepared via three different treatments: SF coating, SO2 plasma treatment and SF anchoring. By surface characterization, SF anchoring could immobilize more fibroin than the direct SF coating due to the formation of hydrogen bonds between the fibroin and polar groups on SO2/(PBT-co-PBS/PEG) surface such as hydrosulfide group, sulfonic group, carboxyl and carbonyl ones, which greatly enhanced the hydrophilic property of PBT-co-PBS/PEG. In vitro and in vivo tests including the morphology, attachment, proliferation and viability of HSG cells and the following histological observation of SF/SO2/(PBT-co- PBS/PEG) films implanting in the subcutaneous tissue of SD rat indicated that the method of SF anchoring would significantly improve the biocompatibility of PBT-co-PBS/PEG. It attributed to not only the increase of the hydrophilicity, but also the anchorage of fibroin which could be recognized by the cells to attachment. These suggest the potential application of fibroin anchored PBT-co-PBS/PEG for clinical HSG cells transplantation in the artificial salivary gland constructs.

Acknowledgements

This work is financially supported by the Natural Science Foundation of Jiangsu Higher Education Institutions (grant no. 12KJB530001).

References

- Sugihara T and Yoshimura Y (1988) Scintigraphic evaluation of the salivary glands in patients with Sjogren’s syndrome. Int J Oral Maxillofac Surg 17: 71-75.

- Sabrina L, Margherita S, Domenico L (2012) Lab Investig 92: 615.

- Meredith J, Eugene Y, John K (2012) Expert Rev Anticancer Ther 12: 359.

- Wang SL, Cukierman E, Swaim WD, Yamada KM, Baum BJ (1999) Extracellular matrix protein-induced changes in human salivary epithelial cell organization and proliferation on a model biological substratum. Biomaterials 20: 1043-1049.

- Chen JP and Su CH (2011) Surface modification of electrospun PLLA nanofibers by plasma treatment and cationized gelatin immobilization for cartilage tissue engineering. Acta Biomater 7: 234-43.

- Jean-Gilles R, Soscia D, Sequeira SJ, Melfi M, Gadre A, et al. (2010) Novel modeling approach to generate polymeric nanofiber scaffolds for salivary gland cells. J Nanotechnol Eng Med 1: 31008.

- Sequeira SJ, Soscia DA, Oztan B, Mosier AP, Jean-Gilles R, et al. (2012) The regulation of focal adhesion complex formation and salivary gland epithelial cell organization by nanofibrous PLGA scaffolds. Biomaterials 33: 3175-3186.

- Witt U, Müller RJ, Deckwer WD (1996) Studies on sequence distribution of aliphatic/aromatic copolyesters by high-resolution 13C nuclear magnetic resonance spectroscopy for evaluation of biodegradability. Macromol Chem Phys 197: 1525-1535.

- Müller RJ, Kleeberg I, Deckwer WD (2001) Biodegradation of polyesters containing aromatic constituents. J Biotechnol 86: 87-95.

- El-Ghalbzouri A, Lamme EN, Van Blitterswijk C, Koopman J, Ponec M (2004) The use of PEGT/PBT as a dermal scaffold for skin tissue engineering. Biomaterials 25: 2987-96.

- Malda J, Woodfield TB, van der Vloodt F, Wilson C, Martens DE, et al. (2005) The effect of PEGT/PBT scaffold architecture on the composition of tissue engineered cartilage. Biomaterials 26: 63-72.

- Luo SL, Li FX, Yu JY (2011) J Polym Res 18: 393.

- Zhang Y, Feng ZG, Liu FX, Zhang AY (2002) Acta Chimica Sinica 60: 2225.

- Lobo AO, Marciano FR, Ramos SC, Machado MM, Corat EJ, et al. (2011) Increasing mouse embryonic fibroblast cells adhesion on superhydrophilic vertically aligned carbon nanotube films. Mater Sci Eng C 31: 1505-1511.

- Moroni L, Licht R, de Boer J, de Wijn JR, Van Blitterswijk CA (2006) Fiber diameter and texture of electrospun PEOT/PBT scaffolds influence human mesenchymal stem cell proliferation and morphology, and the release of incorporated compounds. Biomaterials 27: 4911-22.

- Cui YL, Qi AD, Liu WG, Wang XH, Wang H, et al. (2003) Biomimetic surface modification of poly(L-lactic acid) with chitosan and its effects on articular chondrocytes in vitro. Biomaterials 24: 3859-68.

- Ma Z, Gao C, Gong Y, Shen J (2005) Biomaterials 26: 1253

- She RF, Deng J, Huang WL, Dong ZJ, Liu B (2012) J Tissue Eng Res 16: 455.

- Wang Q, Qi L (2012) New Chem Mater 40: 76.

- Harkin DG, George KA, Madden PW, Schwab IR, Hutmacher DW, et al. (2011) Silk fibroin in ocular tissue reconstruction. Biomaterials 32: 2445-58.

- Gobin AS, Froude VE, Mathur AB (2005) J Biomed Mater Res 74: 465.

- Hou CC, Tao SJ, Zhu Y, Xu S (2012) J Text Res 33: 27.

- Madden PW, Lai JN, George KA, Giovenco T, Harkin DG, et al. (2011) Human Corneal Endothelial Cell Growth on a Silk Fibroin Membrane. Biomaterials 32: 4076-84.

- Cai K, Yao K, Cui Y, Yang Z, LiX, et al. (2002) Influence of different surface modification treatments on poly(D,L-lactic acid) with silk fibroin and their effects on the culture of osteoblast in vitro. Biomaterials 23: 16030-11.

- Wang XF, Ding B, Yu JY, Wang MR (2011) Nano today 6: 510.

- Ding Z, Chen J, Gao S, Chang J, Zhang J, et al. (2004) Immobilization of chitosan onto poly-L-lactic acid film surface by plasma graft polymerization to control the morphology of fibroblast and liver cells. Biomaterials 25: 1059-67.

- Malda J, Woodfield TBF, Van de Vloodt F, Wilson Martens CDE, Tramper J, et al. (2005) The effect of PEGT/PBT scaffold architecture on the composition of tissue engineered cartilage. Biomaterials 26: 63-72.

- Owens DK, Wendt RC (1969) J Appl Polymer Sci 13: 1741.

- Su ZF, Zuo BQ (2011) 48: 13.

- Inouye K, Kurokawa M, Nishikawa S, Tsukada M (1998) Use of Bombyx mori silk fibroin as a substratum for cultivation of animal cells. J Biochem Biophys Methods 37: 159-164.

Relevant Topics

Recommended Journals

Article Tools

Article Usage

- Total views: 22259

- [From(publication date):

July-2013 - Apr 19, 2025] - Breakdown by view type

- HTML page views : 17645

- PDF downloads : 4614