Research Article Open Access

The Parametric survey on the nano particles performance for treating of industrial wastewater

Abdolrahim Zarei and Farshad Farahbod*

Department of Chemical Engineering, Sirjan Branch, Islamic Azad University, Sirjan, Iran

- *Corresponding Author:

- Farshad Farahbod

Department of Chemical Engineering

Islamic Azad University

Firoozabad, Iran

Tel: +98 47352110

E-mail: mf_fche@iauf.ac.ir

Received Date: December 26, 2016; Accepted Date: January 02, 2017; Published Date: January 12, 2017

Citation: Zarei A, Farahbod F (2017) The Parametric Survey on the Nano Particles Performance for Treating of Industrial Wastewater. Oil Gas Res 3:129. doi: 10.4172/2472-0518.1000129

Copyright: © 2017 Zarei A, et al. This is an open-access article distributed under the terms of the Creative Commons Attribution License, which permits unrestricted use, distribution, and reproduction in any medium, provided the original author and source are credited.

Visit for more related articles at Oil & Gas Research

Abstract

The techniques of wastewater treatment have been considered, recently. The performance of usage of nano ferric oxide and aluminum oxide as coagulant is evaluated in this work, experimentally. The experiments were conducted to measure the important parameters in quality of treatment by addition of four different amounts of nano two metal oxides 1, 1.5, 2 and 2.5 gr. The value of pH, color, color/color0, zeta potential, slug volume index, total dissolved solids conductivity, turbidity, ammonia, sulfide, heavy metals, phenol, oil and grease is investigated. The results show the better performance of nano ferric oxide in coagulation and flocculation by lower amount of zeta potential, ammonia, phenol and sulfide and oil, grease elimination than aluminum oxide. However the value of slug volume index in treated wastewater by nano ferric oxide is higher than that is obtained with nano aluminum oxide

Keywords

Pretreatment reactor; Sea ecosystem; Softening process; Wastewater treatment; Desalination; Total hardness; Nano coagulants

Introduction

Totally, the published researches about the pretreatment of exit wastewater from desalination units are rare. Nowadays, lake of potable water, development of industries and population growth, extend desalination units [1-3]. Although desalination units have been grown up, but exit brine stream is usually drained into the sea ecosystem. Moreover, annually a large quantity of concentrated brine is discharged into the sea [4,5]. By treatment of this saline wastewater, it is possible to eliminate the hazardous effects of salinity on sea ecosystem. Additionally two valuable matters, salt and sweet water can be produced. Total hardness and turbidity of wastewater must be reduced during pretreatment process of wastewater to produce Sodium Chloride salt [3,6]. Coagulants are the matters used to decrease total hardness of wastewater. The pretreatment process includes 3 steps: coagulation, flocculation and sedimentation. Improving the efficiency of pretreatment process depends on water specifications and also the operating parameters [7-9]. The optimum mixing rate of first pretreatment reactor, type of coagulant, ratio of sodium carbonate to coagulant and sodium hydroxide to coagulant are some of the important factors in operating conditions. Polyelectrolytes or mixture of coagulants can be used to improve the efficiency of total hardness removal [10,11]. In this research various binary mixtures of three mineral coagulants were investigated quantitatively and qualitatively. The optimum amounts of Sodium Carbonate to coagulant ratio and Sodium Hydroxide to coagulant ratio were studied for each coagulant individually. This shows that the best ratio for Sodium Carbonate to coagulant is three and for Sodium Hydroxide to coagulant are four [12].

Materials and Methods

Materials

Experiments are managed for the brine wastewater of Tehran petroleum refinery which exits from desalination unit.

Method

The purposes of this study is finding the optimum speed of mixer in the coagulation step when mixtures of nano coagulants are used and also reaching the best type of coagulant which results in the higher efficiency in the softening process. A sample of wastewater is fed to the first pretreatment reactor; the proper amounts of Sodium Carbonate and Sodium Hydroxide, and also one type of nano coagulant are added to the first pretreatment reactor in each run. The mixer speed in the first pretreatment reactor is set for 160 rpm in 120 second as time interval. The constant condition for second reactor is 45 rpm in 10 minutes as time interval. The amount of Sodium Hydroxide and Sodium Carbonate is 600 and 450 ml, respectively. Coagulation step is occurred in the first pretreatment reactor, in this step configuration of coagulants are broken and permanent and temporary hardness can be attached to coagulants and make tiny scales. The experiments are handled by three values of speed of mixer for this step and the speed is 120 rpm. After 120 seconds the valve 2 is opened and wastewater with the suspended sediments is drained to the second pretreatment reactor. The speed of mixer in this reactor adjusted on 45 rpm for helping the flocculation of the tiny scales. After 10 minutes the mixer turns off and the suspension drained to a baker and let be rest for more than 1 hr. In this sedimentation step, larger floc precipitated and separated from the clarified soft water. If the size of floc is large enough, the last sedimentation step may take less than 45 minutes, approximately.

Results and Discussion

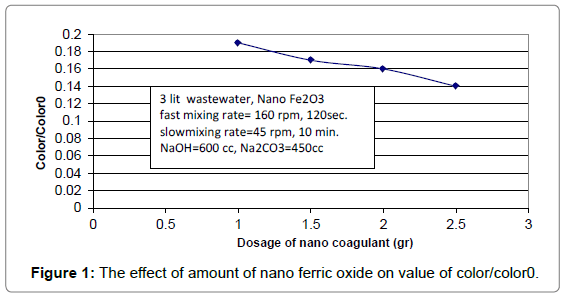

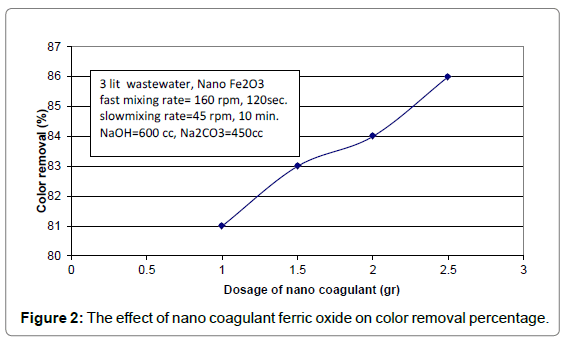

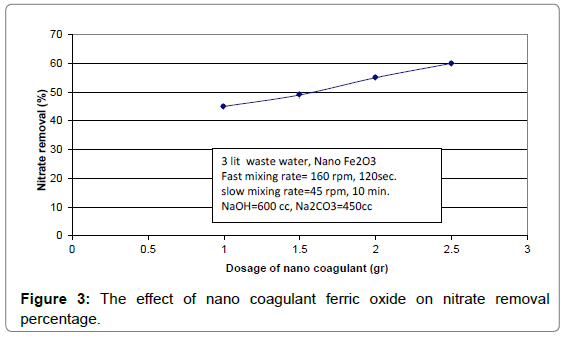

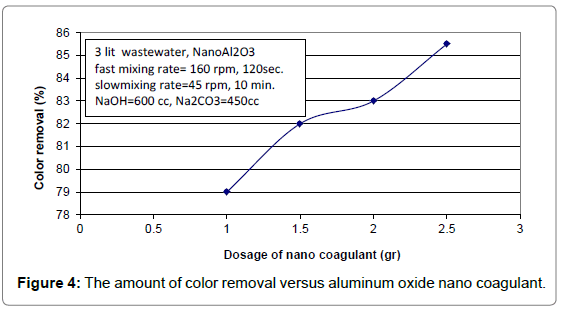

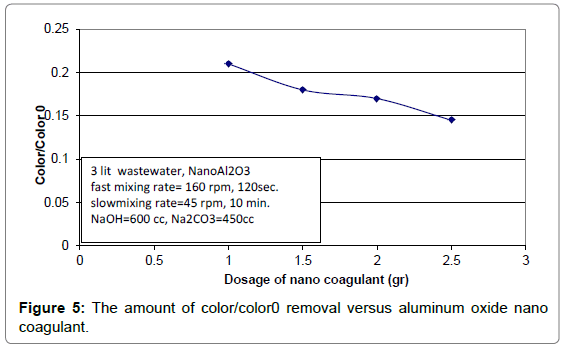

Important parameters in pretreatment of wastewater to drain into the environment are investigated in this experimental work. So, different ranges of both nano ferric and aluminum oxide are used to find the proper operation conditions in pretreatment of wastewater. Figure 1 shows the effect of usage of nano ferric oxide on the fraction of color/color0. This is one factor to show the quality of clearance of wastewater. The increase in the coagulant dosage decreases this value. This shows the power of coagulant in elimination of component which makes turbidity. The increase from 1 g to 2.5 g of coagulant decreases this fraction from 0.19 to 0.14. The increase in the amount of nano ferric oxide increases the amount of color removal percentage. The Figure 2 shows this effect and indicates on the results in the previous experiments. The color removal percentage decreases from 81% to 86%. This depends on the amounts of all factors of turbidity. These factors are examined in the following results. Figure 3 illustrates the effect of dosage of nano coagulant on the nitrate removal. The amount of nano coagulant changes from 1 g to 2.5 g and the effect of nano ferric oxide augmentation on the removal percentage of nitrate. The nitrate removal percentage increases from 45% to 60%. The nitrate compounds can bond with coagulant or trapped in the flocs. In addition, the results show the positive effect in removal of BOD amount. The values of BOD removal percentage change from 21% to 44%. Usage of nano ferric oxide as 1 g and 1.5 g shows 8% and 10% better performance in removing biological oxygen demands than usage of the same amount of aluminum oxide. Although the results show the better ability of aluminum oxide in BOD removal than ferric oxide with usage of 2 g and 2.5 g of each coagulant. The Figure 4 shows the effect of nano aluminum oxide usage on the value of color. The usage of 1 g to 2.5 g of nano aluminum oxide changes the value of color removal from 79% to 86%. Due to the results, usage of nano ferric oxide show the better results than usage of nano aluminum oxide in all amounts. Initialization of 1 g, 1.5 g, 2 g and 2.5 g of nano ferric oxide coagulant shows the 2.5%, 1.2%, 1.2% and 0.05% more improvement in color removal than usage of nano aluminum oxide, respectively. The Figure 5 shows the effect of nano aluminum oxide on the value of color/clolor0. This ratio decreases from 0.21 to 0.14 using 1 g to 2.56 g of nano aluminum oxide. Comparing these result with those is obtained for using of nano ferric oxide show the higher performance of nano ferric oxide about 10%. 0.5%, 0.6% and 0.4% in ratio of color/color 0 than aluminum oxide. Nitrate removal is shown in Figure 6 usage of nano aluminum oxide in pretreatment process. Values of Nitrate removal percentage increase from 40% to 51%. Comparison of results from addition of ferric oxide with those are from aluminum oxide show the higher values of nitrate elimination percentage about 12%, 17%, 12% and 15%, respectively.

Conclusion

The performance of two nano coagulant in pretreatment of wastewater from refinery is presented in this experimental work. Refinery wastewater includes oil, grease, heavy metals, phenol, ammonia and nitrate as contaminants. The dosage of nano coagulant changes in values of 1, 1.5, 2 and 2.5 g. Both of nano ferric oxide and aluminum oxide show the positive effect in elimination of dangerous components. The increase in the amount of each nano coagulant increases the effect of them in contaminant removal. Usage of nano ferric oxide shows the higher performance of nano ferric oxide about 10%. 0.5%, 0.6% and 0.4% in ratio of color/color 0 than aluminum oxide. The results obtained from ferric oxide usage (1, 1.5, 2 and 2.5 g) show the higher value about 20%, 18%, 20% and 9.5%, respectively. The higher values of nitrate elimination percentage are obtained in usage of ferric oxide about 12%, 17%, 12% and 15%, respectively than those are obtained from aluminum oxide.

References

- Khiari R, Dridi DS, Aguir Ch, Farouk MM (2010) Experimental evaluation of eco-friendly flocculants prepared from date palm rachis. Journal of Environ Sci 22: 1539-1543.

- Gao B, Chu Y, Yue Q (2009) Purification and characterization of Al13 species in coagulant poly aluminum Chloride. Journal of Environ Sci 21: 18-22.

- Yana M, Wang D, Ni J, Qu JW (2009) Natural organic matter (NOM) removal in a typical North-China water plant by enhanced coagulation: Targets and techniques. Sep Purif Technol 68: 320-327.

- Wu Q, Hua1 T, Zhou Q (2011) Treatment and remediation of a wastewater lagoon using micro electrolysis and modified DAT/IAT methods. Journal of Environ Sci 23: 388-395.

- Setiawan A, Zhao A, Nayar CV (2009) Economic analysis and environmental considerations of mini-grid hybrid power system with reverse osmosis desalination plant for remote areas. Journal of Renew Energy 34: 374-383.

- Lee S, Maniquiz M, Kim L (2010) Characteristics of contaminants in water and sediment of a constructed. Wetland treating piggery wastewater effluent. Journal of Environ Sci 22: 940-945.

- Wang W, Li H, Wang X, Liu Y (2010) spatial variations of aluminum species in drinking water supplies in Xi'an studied applying geographic information system. Journal of Environ Sci 22: 519-525.

- Jangkorn S, Kuhakaew S, Theantanoo S, Klinla H, Sriwiriyarat T (2011) Evaluation of reusing alum sludge for the coagulation of industrial wastewater containing mixed anionic surfactants. Journal of Environ Sci 23: 587-594.

- Al-Jasser A (2011) Saudi wastewater reuse standards for agricultural irrigation: Riyadh treatment plants effluent compliance. King Saudi University- Eng Sci 23: 1-8.

- Nan J, He W, Song X, Li G (2009) Impact of dynamic distribution of floc particles on flocculation effect . Journal of Environ Sci 21: 1059-1065.

- Wang Y, Zhoua WZ, Gao BY (2009) The effect of total hardness on the coagulation performance of aluminum salts with different Al species. Sep Purif Techno 66: 457-462.

- Pa B, Roca J, Piáa AB (2009) Application of multi criteria decision analysis to jar-test results for chemicals selection in the physical-chemical treatment of textile wastewater. Journal of Hazard Mater 164: 288-295.

Relevant Topics

Recommended Journals

- Oil & Gas Research Journal

- Renewable Energy and Applications Journal

- Oceanography Journal

- Industrial Pollution Control Journal

- Coastal Zone Management Journal

- Climatology & Weather Forecasting Journal

- Geoinformatics & Geostatistics Journal

- Engineering and Technology Journal

- Petroleum & Environmental Biotechnology Journal

- Polymer Sciences Journal

Article Tools

Article Usage

- Total views: 3412

- [From(publication date):

March-2017 - Jul 13, 2025] - Breakdown by view type

- HTML page views : 2491

- PDF downloads : 921