The Implementation of Floating Fuel Terminal in Maritime Case Study (Saudi Ports)

Received: 02-May-2023 / Manuscript No. JMSRD-23-101975 / Editor assigned: 05-May-2023 / PreQC No. JMSRD-23-101975(PQ) / Reviewed: 19-May-2023 / QC No. JMSRD-23-101975 / Revised: 02-Jun-2023 / Manuscript No. JMSRD-23-101975(R) / Published Date: 30-Jun-2023 DOI: 10.4172/2155-9910.1000402

Abstract

The Floating Storage Reorganization Unit (FSRU) is a vital component required during transit and transportation of LPG, in addition to it is one of the magic solutions to overcome many maritime transport problems in terms of increasing the production capacity of marine ports, especially in the kingdom of Saudi Arabia and the optimal use of infrastructure available as well as increasing the absorptive capacity of classic ports such as Jeddah Islamic port (due to the limited expansion of the presence of the population blocks surrounding the port) in addition to adhering to the requirements of the international maritime organization in terms of the level of carbon emissions to about half a pal cent by the year 2020 due to the transformation processes of ships from heavy fuel to supply liquefied natural gas and this can be a special kind of unity of ships used to transport Liquefied Natural Gas (LPG) or floating terminal in the territorial waters of the port area. Since LPG, which is highly applicable and environmentally friendly, is an essential component of fuel for commercial ships, especially during the next ten years and for the application of paper there are many requirements given that errors in this area can lead to the loss of precious lives and valuable fuel, not to mention the further deterioration of the system surrounding environment.

Keywords: Fuel; Terminal; Implementation; Floating; Maritime

Keywords

Fuel; Terminal; Implementation; Floating; Maritime

Introduction

Liquefied petroleum gas needs a special technique to deal with ships in general in return. It is imperative to heat the LPG fuel that is transported in a soft semi-cooled state of -160°C to the desired destination and then return it to its original gas state. By performing a reheating before pumping the gas into its storage systems. The whole process of freezing and reheating fuel is expensive, not to mention time consuming as well. Hence, the solution resulting from this time consuming process is the floating terminal with the resettlement unit. LPG is one of the cleanest fuels available today with low sulfur content. It will also be considered the best way to ship fuel operations in terms of saving and reducing vessel consumption. The main advantage of LPG as fuel when burning in the engine is the production of low levels of nitrogen oxides and less carbon dioxide compared to other marine fuels and provides a significant reduction in all other pollutants (including spills during transportation) that are caused by the use of fuel conventional marine such as Heavy Fuel Oil (HFO), Marine Diesel Fuel (MDO) and Marine Gas Oil (MGO) [1]. LPG has become a technical and economical option as an alternative fuel for marine shipping. LPG is also more stringent to reduce or control conventional air emissions. The International Maritime Organization (IMO) has adopted emission standards through Annex VI to the international convention for the prevention of pollution from ships (MARPOL).

Case Presentation

The emissions regulations in Annex VI include, among other requirements, a multi-level compliance system that provides stricter restrictions on emissions of Sulfur Oxide (SOx), Nitrogen Oxide (NOx) and Particulate Matter (PM). In addition to the global requirements that include stringent emissions. With the IMO introducing a new 0.5% sulfur cap as of 2020, demand for LPG fuel fuels is expected to increase, given that LPG provides an almost complete reduction in sulfur oxide emissions and a very significant reduction in emissions of nitrogen oxides and dioxide carbon [2].

At the same time, the main economic drivers are the availability of high LPG storage fuel and the comparative competitiveness of LPG prices. Thus, according to the circumstances, LPG could be the most cost-effective option, taking into account the establishment of a global network of LPG storage bases in order to further strengthen the LNG ships and the actions that must be taken, in order to paving the way to take follow-up on marine routes, which is what the current paper allows to make the best use of the benefits of LPG as fuel for marine transport ships [3].

Disadvantages and problems associated with current paper and proposed solutions

The success of establishing a floating LNG plant to make paper more successful depends on the following factors: Compliance with emissions regulations. Whereas, LPG allows ships to meet the requirements of MARPOL annex VI for both handling and operation of ships at international ports where its sulfur content is much lower than international requirements. Moreover, LPG reduces NOx emissions to levels that meet MARPOL Annex VI without the need for additional treatments [4]. Economic drivers and cost, including fuel costs, power generation, new structures, availability and LPG costs. LPG is cheaper than HSFO based on heating value. The main disadvantage of LPG is the uncertainty in the LPG price levels in the future.

The paper appeal of a LPG floating fuel station as a ship's fuel is dependent on the compatibility of each of the following factors:

The first factor: The share of the vessel's operating time, which is required for the ship to remain in the floating station.

The second factor: The price difference between LPG and HFO, LSFO, MGO.

The third factor: Investment costs for constructing floating fuel station components and the fuel system.

Results and Discussion

Proposed solution to the problem

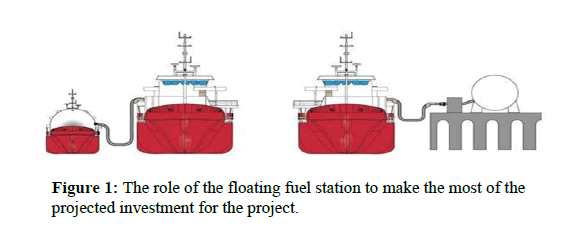

The guarantees of the flow of liquefied gas quantities are among the most important components of the success of paper and we note here to enter the kingdom of Saudi Arabia as a major producer of liquefied gas during the next short period in addition to the growth of global production of liquefied gas, where in 2017, 308 million tons, up from 305 million tons in the year 2016, an annual increase of 1.4%. LPG supplies are increasing in the wake of the increase in global production of natural gas and associated gas. Production will continue to grow mostly from the United States, while Asia will lead to an increase in demand [5]. The LPG market, as a concealed fuel, estimates that it will grow significantly over the next few years. The demand for LPG is increasing, especially in the residential and commercial sectors in developing and more developed countries. The use of cleaner liquid and gaseous fuels is expected to increase as the population grows and the total energy demand in these regions increases proportionately. At the same time, oil and gas prices have risen to improve the economies of LPG, which has led to increased transportation requirements on LPG and optimal thinking for papers in this field. With a number of LPG projects for marine infrastructure already in the planning stage, it is expected that implementation will take place. Many are in the coming years [6]. With increasing access to liquefied petroleum gas and opening markets, which will lead to the importance of the increasing role of such floating fuel stations, which in addition to its main role as a basic tributary for providing ships with this economical and environmentally friendly fuel, as already mentioned, this paper will also have an increasingly important role in the safety and overall efficiency of these projects. Today, liquefied petroleum gas is a technically feasible option as an alternative fuel for marine shipping, especially in some types of ships (Figure 1).

The figure above indicates the role of the floating fuel station to make the most of the projected investment for the project in terms of:

• The acquisition of operations that provide ships with liquefied fuel, which are the main operations of the terminal.

• Take advantage of constructions with special specifications and with an additional tributary increase to supply ships with fuel by leaving the supply ship on the floating dock and then provide other ships with their fuel needs in case other ships occupy the main terminal.

• Use the pipeline network as a third tributary to supply ships with their fuel needs and then optimize the construction and application of paper in Saudi ports.

Determinants of current paper success

• The extent of the regulatory drive's capacity towards the most stringent emission standards in place worldwide.

• Replacing old engines to comply with new regulations creates market opportunities.

• Attractive LPG price.

• The growth of the commercial and industrial market.

• Adequate supply of LPG at reasonable prices during the expected horizon.

• Increased awareness of the benefits of new technologies.

• Going toward the modifications of existing ship engines (dual engine) to suit the requirements of liquefied gas as fuel for ships.

LPG as a fuel for shipping, as an emerging market segment, is introducing new ship designs, technology options and operations. Driven mostly by high-risk financing/investment initiatives, LPG stocks must include customized solutions [7]. This is the case for ship designs with specific LPG fuel systems, in terms of capacity and technology. The same also applies to operations, where the need to continue shipping operations, at the same time using LPG depots, is a key component of the possibility of using the LPG fuel option on some types of ships (such as container ships or RO-PAX ferries). Note that 30% of ships currently under construction take the necessary adjustments to deal with liquefied gas as the main fuel for commercial ships [8].

LNG fuel is long-term fuel and the pace of growth is subject to various regulatory and economic challenges. Given the continued pressure on the shipping industry to improve the greenhouse gas footprint, ship owners may prefer to wait for new low-carbon options, which is what the current paper in terms of construction, especially in Saudi ports, will lead to, which also increases investment in marine transport [9].

At the same time, the main economic challenges are the infrastructure costs for LPG storage and the costs of rehabilitating traditional ships for LPG fuel use. The guidance capabilities of LNG vessels remain unlimited due to the wide global distribution of LPG storage and gas facilities [10].

Specify the advantages of the invention

Expected advantages:

• Achieve the requirements of marine environment safety and harmony with the presence of IMO2020.

• Achieving economic and parcel savings for owners, operators, designers and shipyards, especially in the kingdom of Saudi Arabia.

• The trend towards investing in supply vessels as an essential component of current paper.

• The positive implications for port equipment suppliers in general, concrete manufacturers and plastics needed to construct the floating station.

• The positives reflected on the pipe manufacturers needed for paper components and the modernization of their manufacturing technology.

• Developing the technology of manufacturing main engines for ships and the technical methods of providing ships with dual engines.

• Technical and economic benefit from increasing the availability of LPG supplies from Saudi Arabia.

• Improving the performance of Saudi ports through optimizing the available capabilities and benefiting from the kingdom's coasts.

• Developing the desires of all tenants and shippers to improve and add investments in maritime transport.

• Benefiting from the projected growth of the gas fuel fleet, which is expected to reach 250 by 2020.

• Addressing the principle of implementing paper instead of waiting and anticipating the data of the global market.

• Involve stakeholders in developing policies governing LPG storage.

• To develop the roles of a group of players who have an interest in developing LPG stocks. This includes LPG importers and international and coastal shipping companies, as well as companies with a high degree of experience in LPG storage and handling.

• Contribute to planning the liquefied petroleum gas infrastructure in a flexible manner.

• Increased dependence on the method of supplying fuel by ship to ship.

• Stimulating international cooperation in LPG supply services.

• Facilitating the harmonization of technical standards in LPG storage and benefiting from advanced technologies in this field.

• Going towards providing sufficient potential infrastructure for LPG distribution to meet potential demand on the marine market.

• Take advantage of the fluctuations in other fuel prices.

Specify the disadvantages of the paper invention

Organizational change: This category includes regulations applied by governments, for example, with respect to reducing emissions of air pollutants at sea, with emissions control areas through seaports. Whereas, the international maritime organization has adopted interim guidelines on the safety of gas-fired installations in ships. The mechanism by which these regulations will be widely accepted (for domestic deals).

Operating drivers: It is that the operational drivers cover the technological boost and ultimately save costs. The technological impulse stems from the availability of specialized engines from equipment manufacturers and ship builders who are able to install them on new or upgraded ships.

The costs: Measuring cost savings that may arise from differences in energy prices. High oil prices have prompted ship owners to consider alternative fuels to save warehouse costs compared to conventional fuels and it is the success of the current paper.

Long-term price competitiveness and regional price advantages could favor alternative strategies for investing in such papers. This also explains why LPG carriers are currently interested in using LPG payment. At least one of these new construction and updates is supported by a long-term charter for the large LPG product that will be responsible for the warehouse. Until there is an acceptable price for liquefied petroleum gas, it seems unlikely that any commercial ships operating on liquefied natural gas (of any kind) will trade in spot markets where the ship-owner is responsible for the costs of the warehouse.

The investment levels required to implement: The current paper will contribute to developing the returns of the Saudi marine ports, especially in terms of harmony with the kingdom's vision 2030 in addition to the positive repercussions on investment in maritime transport if the application of paper and clarity of the feasibility of investment through it and the application of a clear model in one of the Saudi ports and focus on the expected revenue for paper with the optimal exploitation of the benefit from the compelling increase in the number of vessels transiting the red sea basin, in addition to attracting more frequent shipping lines to Saudi ports, in addition to focusing the current paper on integrating many media into one place (floating terminal ) and what is contained in the following components:

• The floating station

• Pipe lines network

• Storage operations and

• Clear procedures to supply ships with liquefied gas

Conclusion

The positive implications for port equipment suppliers in general, concrete manufacturers and plastics needed to construct the floating terminal. The positives reflected on the pipe manufacturers needed for paper components and the modernization of their manufacturing technology. Developing the technology of manufacturing main engines for ships and the technical methods of providing ships with dual engines. Technical and economic benefit from increasing the availability of LPG supplies from Saudi Arabia. Increased dependence on the method of supplying fuel by ship to ship due to increasing shipyard performance.

References

- Rocco MV, Lange S, Pigoli L, Colombo E, Pellegrini LA (2019) Assessing the energy intensity of alternative chemical and cryogenic natural gas purification processes in LNG production. J Cleaner Prod 208: 827-840.

- Dong DT, Cai W (2019) Life-cycle assessment of ships: The effects of fuel consumption reduction and light displacement tonnage. Proc Inst Mech Eng Part M J Eng Marit Environ 234: 143-153.

- Alkaner S, Zhou P (2006) A comparative study on life cycle analysis of molten carbon fuel cells and diesel engines for marine application. J Power Sources 158: 188-199.

- Smith L, Ibn-Mohammed T, Yang F, Reaney IM, Sinclair DC, et al. (2019) Comparative environmental profile assessments of commercial and novel material structures for solid oxide fuel cells. Appl Energy 235: 1300-1313.

- Yoo BY (2017) Economic assessment of Liquefied Natural Gas (LNG) as a marine fuel for CO2 carriers compared to Marine Gas Oil (MGO). Energy 121: 772-780.

- Thomson H, Corbett JJ, Winebrake JJ (2015) Natural gas as a marine fuel. Energy Policy 87: 153-167.

- El-Gohary MM (2012) The future of natural gas as a fuel in marine gas turbine for LNG carriers. J Eng Marit Env 226: 371-377.

- Finnveden G, Hauschild MZ, Ekvall T, Guinee J, Heijungs R, et al. (2009) Recent developments in life cycle assessment. J Eng Maritime Environ 91: 1-21.

- Levasseur A, Lesage P, Margni M, Deschenes L, Samson R (2010) Considering time in LCA: Dynamic LCA and its application to global warming impact assessments. Env Sci Technol 44: 3169-3174.

- Hwang S, Jeong B, Jung K, Kim M, Zhou P (2019) Life cycle assessment of LNG fueled vessel in domestic services. J Mar Sci Eng 7: 359.

Citation: Elentably A (2023) The Implementation of Floating Fuel Terminal in Maritime Case Study (Saudi Ports). J Marine Sci Res Dev 13: 402. DOI: 10.4172/2155-9910.1000402

Copyright: © 2023 Elentably A. This is an open-access article distributed under the terms of the Creative Commons Attribution License, which permits unrestricted use, distribution, and reproduction in any medium, provided the original author and source are credited.

Share This Article

Recommended Journals

Open Access Journals

Article Tools

Article Usage

- Total views: 1053

- [From(publication date): 0-2023 - Mar 31, 2025]

- Breakdown by view type

- HTML page views: 828

- PDF downloads: 225