Research Article Open Access

The Creation of the Russian Production of Metal Powders as a Basic Element Additive Technology

Bogdanov SV*

State University of Management, Moscow, Russia

- *Corresponding Author:

- Bogdanov SV

State University of Management, Moscow, Russia

Tel: +7-915-330-57-65

E-mail: bsv-29@yandex.ru

Received Date: November 16, 2016; Accepted Date: December 26, 2016; Published Date: January 30, 2017

Citation: Bogdanov SV (2016) The Creation of the Russian Production of Metal Powders as a Basic Element Additive Technology. J Powder Metall Min 6: 148. doi:10.4172/2168-9806.1000148

Copyright: © 2016 Bogdanov SV. This is an open-access article distributed under the terms of the Creative Commons Attribution License, which permits unrestricted use, distribution, and reproduction in any medium, provided the original author and source are credited.

Visit for more related articles at Journal of Powder Metallurgy & Mining

Abstract

Presents the results of the development of technology and equipment for the production of granules that get on the plasma-centrifugal atomization with the guidance of the liquid bath of the melt in a rotating crucible with a skull. This technology and equipment are a promising and commercially attractive in the perspective of experimental-industrial production of pellets intended for the manufacture of monolithic products, methods of compaction and 3-D technology

Keywords

Granules; Greenhouse environment; Composite material; Metal powder

Introduction

Additive technology based on the principle of concept formation and summation of the positive merits of different technological solutions in the life cycle of the receipt of the product, are becoming more widespread in the twenty-first century. The methodology of this process is based on the use of digital technologies and on the basis of 3-D computer models of real parts. The loop starts from the idea of designing and manufacturing a prototype and then creates the production and its disposal after use. It can radically reduce the time and cost of producing complex functional parts and products with unique properties. Also provides reduced energy costs in the production of marketable products of a given quality and reduces greenhouse gas emissions, improves the environment for running industrial enterprises.

Materials and Methods

In the production of metal products with the use of additive technologies are widely used metal powders (granules) of a certain chemical and fractional composition. Currently known technology of production of articles by methods of moulding, sintering, cold and hot extrusion or layer-by-layer synthesis using digital technologies allow to apply a systematic synergistic approach to obtaining the end products of the specified quality. This approach aims at a comprehensive study of the possibility of new properties of products made of complex metal composite materials at all stages of the technological production cycle, which allows to obtain a finished marketable products a unique quality.

The use of the proposed Haken of ideas about the order parameters and the principle of subordination in synergistic systems help to make the conclusion that the properties of the metal powders can be a sort of basic control parameters achieve the quality indicators of finished products derived from these materials. It is known that if the system consists of a large number of parts, the state vector q=q(x,t), describing the whole system at the micro - or mesoscopic levels can to satisfy the equation of  (where x - the spatial coordinate; N - a nonlinear function of q; α - the control parameter; F(t) is a fluctuating function [1,2]. For products produced using additive technologies based on the use of powdered granular materials, the most important indicator is the shape of the particles, their density, microhardness, structural and chemical homogeneity of the matrix solid-phase composition, providing the desired properties of the final marketable products. Valid density of the powder particles largely depends on the availability of the various impurities of closed pores, lattice defects and other reasons which cause the difference of the actual density of the material from the theoretical. The microhardness of powder particles characterizes the ability of deformation, which also largely depends on the content of impurities in the powder particle and crystal lattice defects. The high crystallization rate of sputtering of the molten metal allows not only to grind formed during the crystallization of grain, but also provide the most effective grain-boundary and bulk hardening of the most solid spheroidizing particles and composite materials made of pellets by known methods of compaction.

(where x - the spatial coordinate; N - a nonlinear function of q; α - the control parameter; F(t) is a fluctuating function [1,2]. For products produced using additive technologies based on the use of powdered granular materials, the most important indicator is the shape of the particles, their density, microhardness, structural and chemical homogeneity of the matrix solid-phase composition, providing the desired properties of the final marketable products. Valid density of the powder particles largely depends on the availability of the various impurities of closed pores, lattice defects and other reasons which cause the difference of the actual density of the material from the theoretical. The microhardness of powder particles characterizes the ability of deformation, which also largely depends on the content of impurities in the powder particle and crystal lattice defects. The high crystallization rate of sputtering of the molten metal allows not only to grind formed during the crystallization of grain, but also provide the most effective grain-boundary and bulk hardening of the most solid spheroidizing particles and composite materials made of pellets by known methods of compaction.

In the technology of powder metallurgy are widely used granules of one particular chemical composition. Much less for compaction products use granules of materials of different composition. The use of different methods of mixing of pellets of different fractional composition, as a rule, does not produce satisfactory uniformity of the chemical composition and properties of finished products formed from these granules. Performed by Russian authors for the design of composite materials from metals, alloys, intermetallic phases, carbides using plasma atomization technology showed the promise of obtaining high-density, structurally homogeneous, solid materials in industrial conditions [3-5]. In the modern method, plasma-centrifugal atomization of a spherical particle provides for the application of plasma as a heating source for melting raw materials and its use for the formation of a liquid bath in a rotating crucible with a skull. During cooling drops from the rotating crucible provides a high speed of crystallization of the melt sprayed in the working chamber (in the range of 103-106 °C/s). This allows you to grind formed during the crystallization of grain in the spheroids provides the most effective grain boundary and volumetric hardening the formed solid pellet, and those composite materials that are produced from them by known methods of compaction or methods layer-by-layer synthesis products.

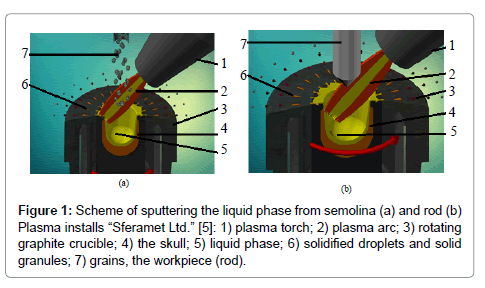

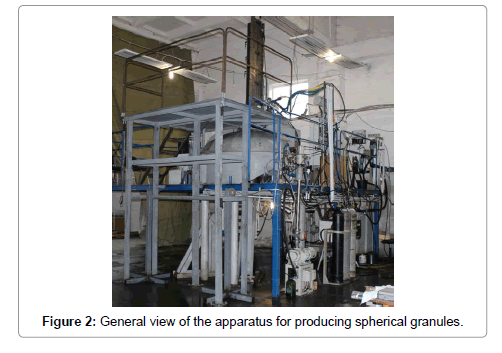

In Russia there is a technology of plasma-centrifugal atomization pellets and suitable equipment for centrifugal spraying of the liquid phase obtained from the melt of bulk raw materials, nibs or workpiece. The schematic diagram of the sputtering process in a rotating crucible with skull shown in Figure 1. General view of pilot plant is shown in Figure 2.

A method of producing granules is implemented in drip or jet-droplet mode. This excludes the capture of the inert gas and the formation of internal voids in the formed spherical granule. The design of the system and elements of the technological process of obtaining her solid granules of a certain chemical and granulometric composition of the patented [6].

Process spheroidizing of the liquid phase occurs on the edge of the skull in a rotating crucible under a plasma arc. At the edge of the skull crucible, the melt accumulated in this volume, which further ensures the formation of stable drops. After separation from the edge of the skull this drop in flight takes a spherical shape without the seizure of an inert gas. Elements of the technology for stable drop formation and spheroidizing in plasma-arc process of melting of the feedstock needs to be strictly synchronized. Otherwise, the edges of the crucible dispersion of droplets passes into the jet-droplet mode and formed long solid threads, which is unacceptable. Processing methods produce solid granules of spherical shape at the facility are elements of the “know-how”. On the installation were obtained spherical granules of the following materials: carbon and high-chromium steel, nickel and titanium alloys, titanium metal, tungsten carbide, alloys based on intermetallic compounds (TiAl, Ti2AlNb).

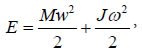

Below are the results of the preliminary analysis of the kinetic characteristics of the formation of drops from a steel melt in a rotating crucible. Full kinetic energy (�) spherical drops at the time of its separation from a rotating surface of a melt in the skull crucible can be estimated from the equation:

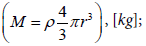

where M – the drop mass

w – speed of rotation of the crucible [m/s];

J – the moment of inertia drops, [kg•m2];

ω – angular speed of rotation drops, [rad.];

ρ – the density of the melt [kg/m3].

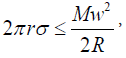

Until the moment of separation of the drop of kinetic energy of motion equal to zero and the conditions of separation drops from the surface of the melt is determined mainly by the kinetic energy of its motion. The conditions of separation droplet radius (r) from the surface of the melt obtained from the expression:

where σ – the surface tension of the melt [n/m];

R – the radius of the edge of a melt in the skull crucible, [m].

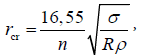

For calculations for practical purposes, the resulting formula by which it is possible to estimate the critical size of the radius of the droplet (rcr, [m]) at the time of its separation from the surface of the melt:

where n – the rotational speed of the crucible with the melt in revolutions per minute [rpm].

The estimated radius of the formed droplets of the melt of iron flying out of the rotating crucible with a radius of about 3 × 10-2 m is estimated at about 150 μm (σFe=1,85 n/m; ρFe=7,8 × 103 kg/m3; n=104 rpm). For melt of the titan (σTi=1,33 n/m; ρTi=4,5 × 103 kg/m3) under the same conditions of the process design value of the radius of the droplet will change slightly and will amount to a value of about 160 μm. It is known that the error in the estimates of the same diameter formed of a spherical droplet reaches 40% in comparison with the diameter of the granules obtained experimentally [7], so the estimated average diameter of iron granules can be in the range of 180-420 μm, and titanium, respectively, 255-385 μm. The calculations did not take into account the influence of many other factors: viscosity and density of the melt, the dynamic characteristics of gas-phase plasma above the melt, the instability of the process of separation of metal droplets from the melt layer on the edge of the crucible. The hyperbolic dependence of the radius of the granules from the number of revolutions of the crucible with the melt indicates that even slight braking or acceleration of the rotation of the crucible with the molten metal, can significantly affect the size of the granules. The results of the preliminary calculations showed that when the centrifugal atomization of the melt is almost possible to obtain granules in a fairly wide range of fractional composition.

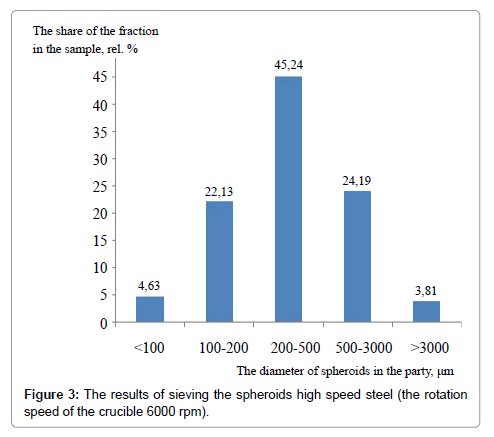

The experimental results for obtaining pellets of high-speed steel by plasma-centrifugal atomization of a melt in a graphite crucible, with advanced plasma technology with a rotating rate of 10 rpm steel rod with a diameter of 40 mm and guidance of the liquid bath of the parabolic shape in a rotating with a frequency of up to 6000 rpm crucible, confirmed the possibility of establishing a pilot production of spheroids for subsequent fabrication of monolithic composites. The results of sieving through sieves of the received batch of steel spheroids is shown in Figure 3.

Results

Figure 3 allows to make a conclusion about expediency of use of valuation techniques in calculating the amount of the solid spherical particles obtained with this apparatus. Spheroids with diameters in the range of 200-500 μm, 100-200 μm and 100 μm satisfy the requirements of the buyer. The share of steel pellets with a diameter of 500 μm was 72% (Rel.). All this stimulates the commercial attractiveness of the use of the method of producing granules on the plasma-centrifugal atomization.

References

- Haken H (1980) SynergeticsM: Mir,p:231.

- Haken G (1991) Information and self-organization: a Macroscopic approach to complex systems. The translation from English. M.: Mirp: 73.

- Kablov EN (2015) Materials and production technologies for a new generation. A solemn meeting dedicated to awarding of the International prize named after A. N. Tupolev for distinguished contribution in the field of engineering Sciences. Kazan

- Logacheva AI(2015) Technology of production of granular metal materials for additive processes. The second international technological forum "Innovation. Technology. Production". Rybinsk.

- Moskvichev Yu, Ageev SV, Panin VI, Konev AI (2013) Production of spherical granules and new composite materials. Website"Sferamet Ltd."

- AgeevSV,MoskvichevJP.Methodforproducingtungstencarbidepowder,deviceforrealizationofmethodandtungstencarbidepowder,producedusingsaidmethod. Patent RU �2301133

- Litvinenko AI, Jorda AP, White AI(2013) Analysis and kinetics of the process thermocontainer spraying of ingots of fused tungsten carbides.//Plasma-arc technology.No2. p�: 29-35.

Relevant Topics

- Additive Manufacturing

- Coal Mining

- Colloid Chemistry

- Composite Materials Fabrication

- Compressive Strength

- Extractive Metallurgy

- Fracture Toughness

- Geological Materials

- Hydrometallurgy

- Industrial Engineering

- Materials Chemistry

- Materials Processing and Manufacturing

- Metal Casting Technology

- Metallic Materials

- Metallurgical Engineering

- Metallurgy

- Mineral Processing

- Nanomaterial

- Resource Extraction

- Rock Mechanics

- Surface Mining

Recommended Journals

Article Tools

Article Usage

- Total views: 3198

- [From(publication date):

April-2017 - Jul 13, 2025] - Breakdown by view type

- HTML page views : 2348

- PDF downloads : 850