Technology Assisted Reconstructive Surgery - A Case Report

Received: 14-Feb-2017 / Accepted Date: 06-Mar-2017 / Published Date: 31-Mar-2017 DOI: 10.4172/2572-4835.1000117

241158Introduction

Recent advancements in science and technology have resulted in important changes in the medical field. Three dimensional (3D) printing is a good example of such developments and has already achieved a considerable level of technical development in many industrial fields. Use of this innovative manufacturing technique is gradually expanding in the medical field.

3D printing or additive manufacturing is a process of making three dimensional solid objects from a digital file. The creation of a 3D printed object is achieved using additive processes. In an additive process an object is created by laying down successive layers of material until the object is created. Each of these layers can be seen as a thinly sliced horizontal cross-section of the eventual object (Figure 1).

Subperiosteal implants are placed under the gums above the jawbone. This type of implants may be used in patients who have a shallow jaw bone.

Subperiosteal implants comes in various shapes and sizes. This case presented, posts a challenge of a non-uniformly attired alveolar bone, hence a patient specific customized 3D printed implant had to be made.

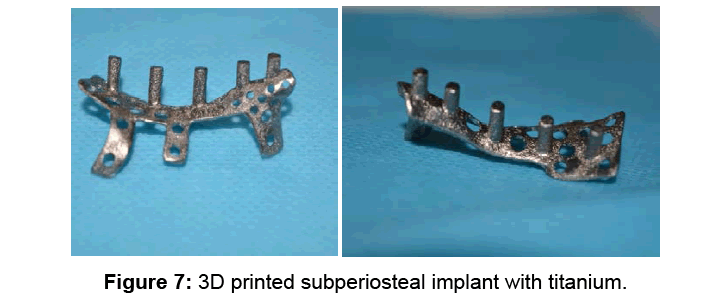

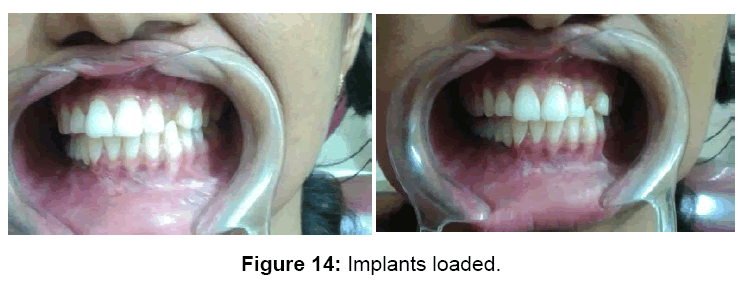

The subperiosteal implant is a framework 3D printed with surgical Titanium with a CT scan generated model avoiding the direct bone impression step. It is inserted directly on the bone, under the periosteum. The increased surface area of this custom design act and function much like a “snow shoe on snow”, by dissipating the forces over a large area. The supra-structures to be used on the posts of a circumferential subperiosteal are generally cemented fixed partial dentures.

Case Report

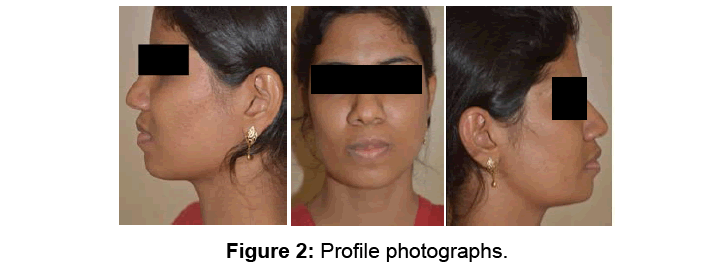

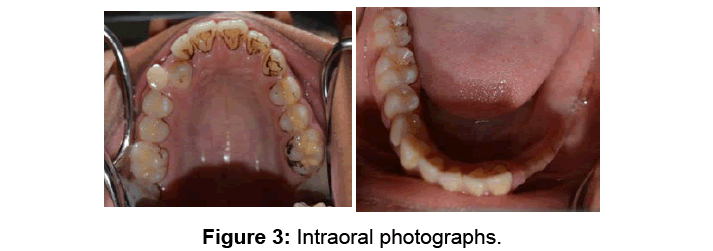

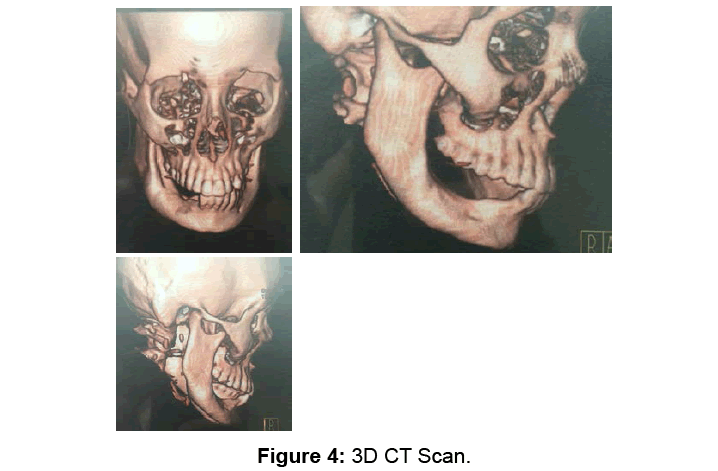

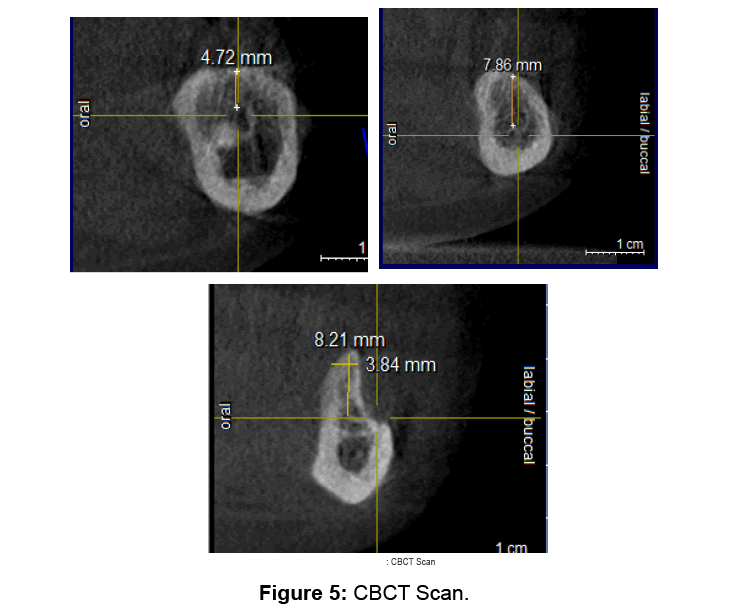

An 18 year old female patient reports to the Department of Oral and Maxillofacial Surgery with a chief complaint of replacement of missing teeth in the lower right posterior region. She presented with history of a unicystic ameloblastoma one year ago in that region for which peripheral osteotomy was done. She presents with no other relevant medical history (Figures 2-5) [1].

On examination of CBCT, it was found that the inferior alveolar nerve was close to the alveolar crest making conventional implants unfeasible.

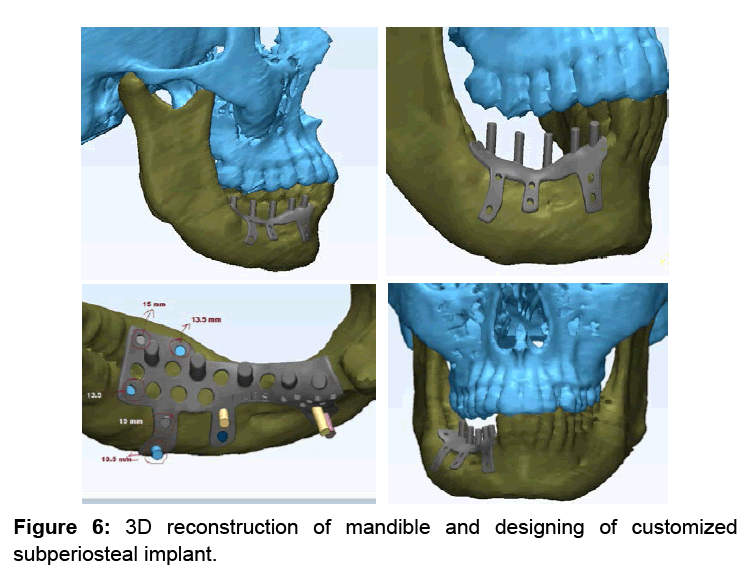

3D reconstruction of mandible was done and analyzed in mimic software. A customized subperiosteal implant was designed according to the patient’s bone topography.

Occlusal forces and stress factors on the implant were taken into consideration while designing. (Ansis software- Finite element analysis) The design was 3D printed with titanium metal in Belgium (Figures 6 and 7).

A 3D printed model of the mandible was made to check the adaptation of the implant (Figure 8).

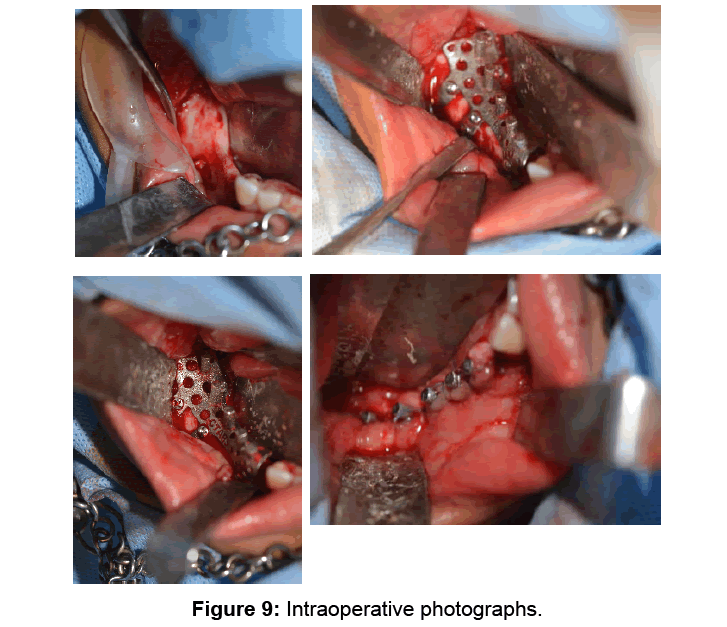

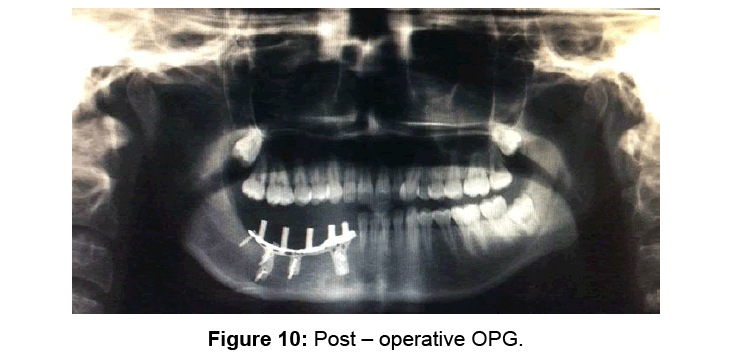

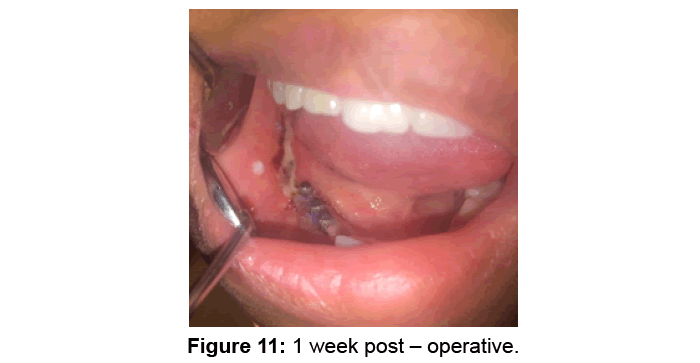

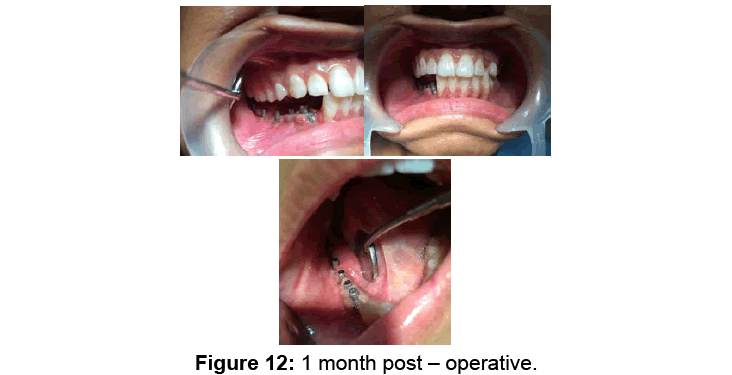

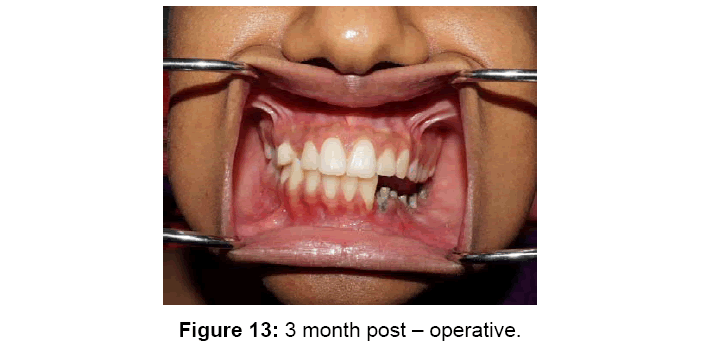

The implant was placed in the patient’s mouth under GA (Figures 9-14).

Discussion

In a place where conventional implant is not possible, customized subperiosteal implants provides a valuable solution as it avoids the need of an extra oral donor tissue/bone or the use of any allografts.

Also, by using 3D printing technology, we will be able to achieve more accurate results.

Advantages of 3D printing include:

• Greatly reduce the operating time.

• Exempt the time consuming process of bending or modifying the appliance during the surgery.

• Increased precision of the technique.

However it is not cost effective.

Conclusion

The role of 3D printing in oral and maxillofacial surgery should be a focus of interest, since the technique could offer endless developmental possibilities.

References

- Moore DJ, Hansen PA (2004) A descriptive 18-year retrospective review of subperiosteal implants for patients with severely atrophied edentulous mandibles. J Prosthet Dent 92: 145-150.

Citation: James D, Chakravarthy A, Muthusekhar MR (2017) Technology Assisted Reconstructive Surgery - A Case Report. Dent Implants Dentures 2: 117. DOI: 10.4172/2572-4835.1000117

Copyright: © 2017 James D, et al. This is an open-access article distributed under the terms of the Creative Commons Attribution License, which permits unrestricted use, distribution, and reproduction in any medium, provided the original author and source are credited.

Select your language of interest to view the total content in your interested language

Share This Article

Recommended Journals

Open Access Journals

Article Tools

Article Usage

- Total views: 4386

- [From(publication date): 0-2017 - Jul 05, 2025]

- Breakdown by view type

- HTML page views: 3433

- PDF downloads: 953