Research Article Open Access

Technological Processing of Oil Waste

Senkevich I*, Grigorov BA, Mardupenko AAPolytechnical Institute, Department of Technology of Processing of Oil, Gas and Solid Fuel, National Technical University, Kharkov, Kharkov, Ukraine.

- *Corresponding Author:

- Senkevich I

Polytechnical Institute

Department of Technology of Processing of Oil

Gas and Solid Fuel

National Technical University

Kharkov, Kharkov, Ukraine

Tel: +972-8-648-2255

E-mail: sf_lskatkov@bezeqint.net

Received Date: July 03, 2016; Accepted Date: July 18, 2016; Published Date: July 31, 2016

Citation: Senkevich I, Grigorov BA, Mardupenko AA (2016) Technological Processing of Oil Waste. Oil Gas Res 2:115. doi: 10.4172/2472-0518.1000115

Copyright: © 2016 Senkevich I, et al. This is an open-access article distributed under the terms of the Creative Commons Attribution License, which permits unrestricted use, distribution, and reproduction in any medium, provided the original author and source are credited.

Visit for more related articles at Oil & Gas Research

Abstract

Since oil waste is one of the most dangerous component of natural environment, the great attention should be paid for the problem of its keeping and processing. Oil waste may be processed in thermal, physical, chemical and biological ways. Present article describes the processing of oil waste by light thermal cracking. Products of thermal cracking of oil waste, due to their properties, may be widely used in motor oil and other kinds of fuel production.

Keywords

Oil waste; Collector; Refinery; Gasoline; Diesel; Kerosene

Introduction

Quick increase of the scientific and technological revolution temps and influence of human on the nature becomes more and more powerful each year. A numerous toxic substances are emitted into the biosphere and that leads to undesirable effects [1]. Every year about 30 billion tons of fossil fuels are extracted for satisfying of human needs, at the same time about 100-150 billion tons of subsoil are moved. During the further recovery processes the substation part of extracted fuels which are not the part of economic goods, becomes a waste. Although in XX century the negative influence of the waste on biosphere was smoothed by nature processes, in last decades the size of human activity leads to the edge of ecological disaster. One of the most polluting branches is petrochemical industry. That’s why, the recovery of oil waste is one of the most actual ecological problems Oil waste is one of the most dangerous component of natural environment. Oil waste is a strong polydisperse system that is formed as a product of oil, water and mechanical admixtures interaction. An oxidation of organic part of the waste by the oxygen of air and catalityc action of metals of this oxidation have a great impact on the formation of such system and lead to formation of resinous substances. The average oil waste consists of oil component (35-45%), mechanical admixtures (under 35%) and water (20-30%). The composition of oil waste may be various and depends on place and period of its formation. This circumstance may strongly complicate the problem of waste utilization. Considering all main world tendencies in petrochemical industry, it should be mentioned that Ukrainian oil refineries realize the closed cycle principle which means using waste as a raw in technological process. This way allows to create a technology with the least amount of waste and decrease the negative influence of waste on the environment and produce the great amount of secondary raw as well. All kinds of oil wastes at the oil refineries are traditionally collected and kept in the special vessels, which are called waste collectors (or slurry tanks), and are divided into three layers: the upper one is emulsion, the middle is waste water and the lower is a sediment with a big amount of mechanical admixtures. These collectors occupy the large territory, which is completely excluded from the agriculture. The technologies, which are used for oil waste processing, can be divided into the following groups:

• Thermal: Burning in the different types of ovens, formation of asphalt residue;

• Physical: Saving into the deep geological repository, separation in the centrifugal field, vacuum filtration and filtration under the pressure;

• Chemical: Extraction by solvents (solidification by using cement, glass or clay) or organic additions (epoxy or polystyrene resin etc.)

• Physical and Chemical: Using special reagents that change physical and chemical properties with further processing on the appropriate facilities;

• Biological: Microbiological decomposition in the ground directly in the place of keeping and biothermical decomposition;

Difficulty of oil waste recovery is determined by the following factors:

- Oil waste is a hardly-separated emulsion;

- Oil waste has its own features about the environmental safety;

- Oil waste provokes corrosion and this circumstance requires using high-quality sorts of metal for equipment production.

Among all existing methods of waste recovery and utilization, the most effective are:

- Delivery of waste to the refinery, where bruiqetted fuel is produced;

- Chemical rendering harmless. In this case, petroleum substances of waste are combined by reagent (quicklime and surfactants (CaО: 92- 93%, Synthetic detergents: 7-8%)) and as a result the non-toxic product is produced and this product may be used as a construction material)

- Mechanical separation into the components: water, mechanical admixtures, petroleum products by centrifuges, separators and decanters [2].

Mechanical destruction of stable water-oil emulsions is based on technological method of artificial changing of concentration of disperse phase with further coalescence of small drops of this phase.

A great amount of technological facilities which provide the interfacial separation of oil waste have designed nowadays. These facilities include separators, centrifuges and hydro cyclones. Very often the filtration is used as an effective way to separate the inverse emulsions mechanically. The advantage of this method is the high yield of commodity oil, and the disadvantage is the high price for equipment.

The chemical way of oil emulsion separating for its regeneration and recycling of hydro carbonaceous products by direct appointment (light fractions, oil etc.) is based on using special surfactants as the demulsifying agents. The main disadvantage of this process is the cost of reagents and their high consumption by one ton of oil waste. Since practically all liquid hydrocarbons are lighter than water, the separation of oil emulsion is accompanied by forming a layer on its surface. This layer basically includes petroleum products and less than 5% of water and allows gathering those emulsion for further salvaging. Different kinds of polyelectrolytes, such as salts of highmolecular sulfonic acids may be used as the colloidal substances. It is also known, that at russian oil refineries the main way of recovery and salvaging of oil waste includes the following steps: centrifugation, extraction, electrolytical separation of heavy metals, composting or or production of waterproofing materials, salvaging on the solid wastes polygon. The disadvantages of this way are connected with the difficulty of implementation of complex-designed equipment. The most progressive technologies of oil waste recovery that are used in Russia and abroad, can be listed below [3]. Company ACS 530 (USA) developed a mobile system MTU 530 for processing and purifying of dirt-, oil- and petroleum wastes. The facility has an automobile platform mount base and is capable to separate oil waste into different phases (oil, water, solid substances) by centrifugation of heated oil waste. The water is applicable for further biological purification. Separated water may be used in different technical processes and dehydrated sediment – for producing building materials. This facility has been used in Russia for elimination of results of accident in the pipeline in Komi Republic. The productivity of construction equipment is 10 m3 per an hour at an output oil waste (oil concentration is under 65%). KHD Humboldt Wedag AG company (Germany) proposed a technology that includes the separation of oil waste with its further burning. The facility consists of waste collector, vibrosieve for separation the main amount of solid particles, three phase centrifuge, separator for purification of centrifugate and furnace. Its productivity is 15 m3 per an hour at an output oil waste. Petroleum company “Bashneft” uses the technology that includes the dissolving, heating and chemical treatment to separate water and mechanical admixtures. The derived oil goes to the further processing. At oil and gas production department “Tuimazyneft” since 1995 the equipment of “Tatoilgas” company is installed and used with providing the technology of Meiken Co. (Germany). This technology consists of following steps: oil waste heating, treatment by demulsifying agents, emulsion destruction in decanter with allotment of water and mechanical admixtures. The commodity crude oil reaches its required quality and the next technical step in vaporizer and three phase separator. Complex facility developed by Alfa Laval Oil Field, Ltd. Is especially interesting. This facility allows to process all kinds of oil wastes into the valuable commodity products. Technology provides the filtration of oil waste for solid particles consistent removing and separation in two phase decanting centrifuge. Oil waste is separated into the solid sediment and liquid, which contains oil and water. This water, in its turn, is getting to the plate centrifuge for maximum extraction of oil. Separation of oil waste solves the problem of its storage and as a result the expensive storage tanks and areas are getting free.

Experimental Details

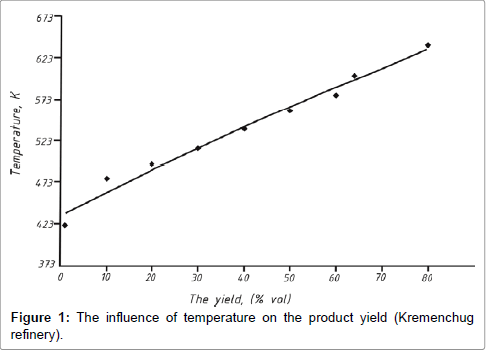

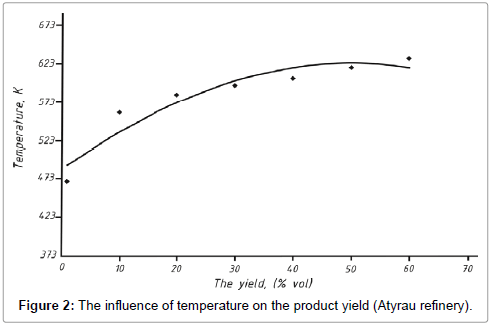

Considering the industrial volume of oil waste in current thesis it was proposed to realize technical processing by using light thermal cracking. This process can be realized directly at waste storage. In this case it is possible to decrease the expenses that are connected with waste transporting. For realization of proposed method the waste samples were taken from the settling pit at the oil refinery and previously dehydrated. Also the mechanical admixtures were removed by demulsifying agent “Proksamin” addition and further settling during 3 hours at 343 К [4]. After preparation samples are getting to light thermal cracking. The output products in this process were gas, middle distillates with boiling point about 530-650 K and coke residue. The cracking gas yield amounts to 3 vol% for oil waste taken from Kremenchug oil refinery (Ukraine, Poltava region) and 2 vol% for waste taken from Atyrau oil refinery (Atyrau, Kazakhstan). The coke residue amounts to 14% of waste from Kremenchug and 36% of waste from Atyrau. The losses amount to 1.5 and 2% respectively. Wide distillate fraction, an output product of thermal cracking, was separated into more narrow fractions according to the Ukrainian standard of petroleum fractions determination (ДСТУ 2177).

Results and Discussion

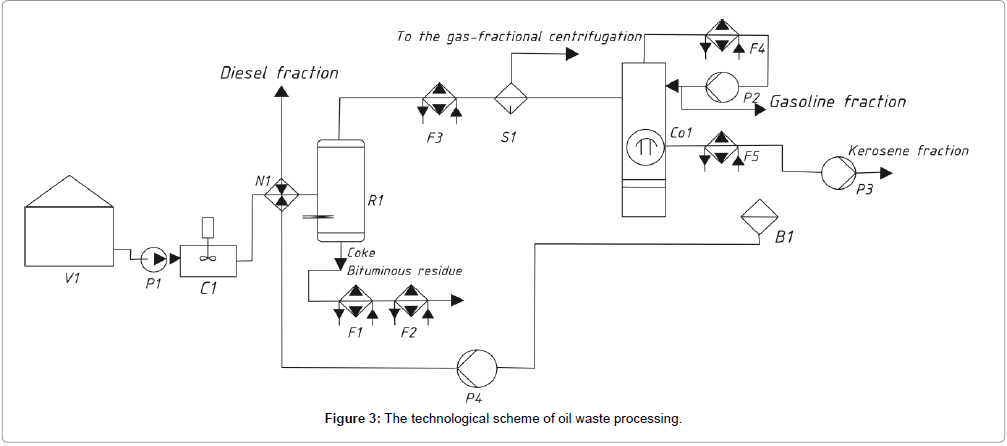

The results of determination of fractions, which were the products of waste thermal cracking from Kremenchug (Figure 1) and Atyrau (Figure 2) oil refineries, are given below. As it shown in Table 1, diesel fraction is the main output product. The amount of gasoline and gas fractions from Atyrau refinery was insignificant, these fraction have light-brown color and odor that is specific to thermal cracking products. Products of Kremenchug refinery include 26 vol% of gas fraction. A residue that has a boiling point about 633 K, was investigated as a crude for road bitumen production. A softening point of residue from Atyrau in a ring and ball apparatus is 377 K and for residue from Kremenchug it is 303 K. The results show that the molecular structure of residue of processed waste from Atyrau oil refinery is more complex that structure of residue from Kremenchug oil refinery. A narrow fraction (boiling point is about 630…690 K ) was taken for further investigations. It’s congelation point was determinated, it is about 286 and 280 K for Kremenchug and Atyrau refineries respectively [5]. The main product of waste cracking, independently of its origin, is diesel fraction. The results of investigation show that density of this fraction is about 855 kg per m3 at 273 K. A water extract of diesel has a pH approximately 5-6 and the congelation point is 291 K. A flash-point in closed cup is 348 K. The results of oil waste from Kremenchug refinery distillation are given below. Oil waste from vessel V1 gets to the centrifuge C1 by pump P1 for separation of water and mechanical admixtures. From P1 it comes to reactor R1 through the heat exchanger H1 where the dehydrated crude previously gets heat up to about 443 K. After that the crude heats up to 893 K in the thermal cracking reactor. The coke and bituminous residues get unloaded from the sump of R1. In case of producing the bituminous residue, it goes through the air F1 and water fridge and goes to the composition of commodity goods. The cracking output products are taken from R1. After that they go through fridge F3 to the separator S1, where gases are separated for futher gas fractionation. After getting from S1 the products go to the column CO1 for fractionation (Figure 3). The gasoline fraction is taken from K1 and P2 pumps it through F4, then this fraction partly returns to the column for cold irrigation and the balanced amount goes to the alkaline purification from the acidic components. During the second sampling, the kerosene fraction is taken from K1, pumped by P3 through F5 and gets unloaded from the equipment to the storage. From the bottom of CO1 the diesel fraction is derived, it is divided into two streams, one of those is pumped through the boiler B1 and returns to the CO1 for supporting the thermal balance in it. The second balance stream is pumped by P4 through the heat exchanger H1 where it heats the crude by its own heat, the crude goes to R1 for thermal cracking process.

| The name of characteristics | The yield of distillate fractions, % | |

|---|---|---|

| Atyraus refinery | Kremenchug refinery | |

| The fractional composition: | ||

| 453K | 2 | 4 |

| 453-513K | 2 | 26 |

| 513-633K | 60 | 52 |

| >633K | 36,5 | 16,5 |

| Losses, % | 1.5 | 1.5 |

Table 1: The distillated fractions yield for oil waste.

Conclusions

Products of thermal cracking of oil waste, due to their properties, may be widely used in motor oil and other kinds of fuel production. For example, the diesel fraction is a valuable component for production of commodity diesel fuel, fuel for low-speed engines of agricultural equipment, road and building vehicles.

A gasoline fraction, after it’s purification from sulphur-containing and resinous components, may be used as a component commodity gasoline compounding or in oil solvents production. A kerosene fraction, after it’s deep purification from water, sulphur-containing and resinous components, may be used in a jet fuel production and as lighting kerosene. A fuel oil or tar is completely available for boil fuel production and as a crude for motor fuel, distillate base oil, oil coke production by pyrolysis, a crude for road and building bitumen production.

References

- Karpukhin IA (2009) Oil and Gas Business8: 32-40.

- Kurochkin AK (2010) Oil and Gas Processing. Sankt-Petersburg, pp: 72-74.

- Yagafarova IA (2006) Oil and Gas Business.2: 48-61.

- Oil Refining and Marketing (2010) Construction of the Aromatics Production Center in Atyrau Refinery.

- Gron VA, Korostovenko VV,Shahray (2013)Uspehi sovremennogo estestoznaniya.9: 159-162.

Relevant Topics

Recommended Journals

- Oil & Gas Research Journal

- Renewable Energy and Applications Journal

- Oceanography Journal

- Industrial Pollution Control Journal

- Coastal Zone Management Journal

- Climatology & Weather Forecasting Journal

- Geoinformatics & Geostatistics Journal

- Engineering and Technology Journal

- Petroleum & Environmental Biotechnology Journal

- Polymer Sciences Journal

Article Tools

Article Usage

- Total views: 13455

- [From(publication date):

August-2016 - Mar 31, 2025] - Breakdown by view type

- HTML page views : 12438

- PDF downloads : 1017