Research Article Open Access

Synthesis of Carbon Nanotubes for Oil-water Interfacial Tension Reduction

Soleimani H1*, Yahya N1, Baig MK1, Khodapanah L2, Sabet M3, Burda M4, Oechsner A5 and Awang M6

1Department of Fundamental and Applied Sciences, Universiti Teknologi PETRONAS, Bandar Seri Iskandar, 32610 Tronoh, Perak, Malaysia

2Faculty of Environmental Studies, Universiti Putra Malaysia, Serdang, Malaysia

3Department of Petroleum and Chemical Engineering, Jalan Tungku Link, Gadong BE1410, Institute Teknologi Brunei (ITB), Darussalam, Brunei

4Department of Materials Science and Metallurgy, University of Cambridge 27 Charles Babbage Road, Cambridge CB3 0FS, USA

5School of Engineering, Griffith University, Gold Coast Campus Queensland 4222, Australia

6Petroleum Engineering Department, Universiti Teknologi PETRONAS, Bandar Seri Iskandar, 31750 Tronoh, Perak, Malaysia

- *Corresponding Author:

- Soleimani H

Department of Fundamental and Applied Sciences

Universiti Teknologi Petronas, Bandar Seri Iskandar

32610 Tronoh, Perak, Malaysia

Tel: +6053688000

E-mail: Hassan.soleimani@petronas.com.my

Received date: September 16, 2015; Accepted date: October 28, 2015; Published date: November 05, 2015

Citation: Soleimani H, Yahya N, Baig MK, Khodapanah L, Sabet M, et al. (2015) Synthesis of Carbon Nanotubes for Oil-water Interfacial Tension Reduction. Oil Gas Res 1:104. doi: 10.4172/2472-0518.1000104

Copyright: © 2015 Soleimani H, et al. This is an open-access article distributed under the terms of the Creative Commons Attribution License, which permits unrestricted use, distribution, and reproduction in any medium, provided the original author and source are credited.

Visit for more related articles at Oil & Gas Research

Abstract

A conventional recovery method has an adverse effect towards unconventional reservoir production. A nanoparticle leads as a primary candidate to develop the unconventional reservoir and it is considered as one of the latest technology in oil and gas industry. Therefore this research is intended to study the effects of Carbon Nanotubes (CNT) towards interfacial tension. Practically MWCNTs were successfully synthesized using CVD technique by pyrolizing toluene and ferrocene in inert gas environment and characterized using X-ray diffraction (XRD) and Transmission Electron Microscope (TEM) in order to understand its structure, shape, size and morphology. The characterization results show the CNTs are in cylindrical shape and well aligned. After characterization, a pendant drop experiment was carried out to further understand the effect of Carbon Nanotubes on Interfacial Tension (IFT). Since the Carbon Nanotubes are very “cloudy” the drop phase could not be identified and the Interfacial Tension was not calculated by the software. Due to this major setback, the Surface Tension was calculated with different concentration.

Keywords

Carbon nanotubes (CNT); Interfacial tension; Enhanced oil recovery (EOR); Nanofluid

Introduction

Carbon nanotubes were first discovered in 1952 by Radushkevich and Lukyanovich [1] Carbon nanotubes have unique mechanical, electrical, magnetic, optical, and thermal properties. Another excellent use of nanotubes is in microelectronics [2]. Application of nanotechnology in the oil and gas industry is just emerging. Recent Research projects have shown that nanotechnology has the potential to solve several problems in the oil and gas industry. One of the speculated areas of application is in Enhanced Oil recovery (EOR). In general EOR methods such as chemical flooding, nano flooding and thermal recovery, they rely on altering the mobility ratio and interfacial tension (IFT) between the displacing and displaced fluids to improve recovery efficiency [3]. Among the various EOR methods nano flooding is most promising and cost effective method. According to current researches and technical literature, the new generation nano-agents should both affect the properties of the injected fluid, in terms of viscosity, density, thermal conductivity and specific heat and modify the fluid-rock interaction properties, for example in terms of wettability and interfacial tension. The reduction of IFT between oil and water is very important and it will lead to the reduction of capillary pressure within the pores, thus allowing the recovery of oil trapped in small pores. By adding CNTs based nanofluid, IFT between oil and water can be reduced [4]. Recovery factor of oil reservoir plays important role in production. A reservoir with very low recovery factor is considered not profitable and feasible. But this mind set has been overtaken by the advancement in production technology and reservoir engineering. It is understand that, if the present global recovery factor could be enhanced compared to present limit, it would solve certain issues in regards to global energy supply [5]. This recovery factor is assumed to be lower in future due to the daily production of oil comes from mature or maturing oil fields. In global scale the average recovery factor of hydrocarbon reservoir stands at 30 percent approximately. This situation creates an opportunity for the advancement in secondary recovery or even in tertiary recovery (EOR) to turn around this position [6]. The CNTs containing high surface charge reduces the IFT between oil-water interface and adsorption at the rock surface changes the wettability from oil wet to water wet.

Methodology

Chemical Vapor Deposition (CVD) is a simple and economic technique for synthesizing CNTs at low temperature and ambient pressure [7]. In this work a solution of ferrocene, Fe(C5H5)2 in toluene (in a suitable ratio) was injected into a two-stage furnace whose reaction zone was maintained at 760°C. Argon is used as the carrier gas and its flow rate is adjusted in such a manner that the maximum quantity of precursor is consumed in the reaction zone. The first stage of the furnace is maintained at around 200°C to ensure that the solution is vaporized as soon as it is injected (the vaporization temperature of ferrocene and toluene are 175°C and 110°C, respectively). MWCNTs grow predominantly in the centre of the quartz reaction tube, which are then scraped out after cooling the reaction tube to room temperature [8,9]. The effect of these MWCNTs on interfacial tension reduction between oil and water investigated using pendant drop method.

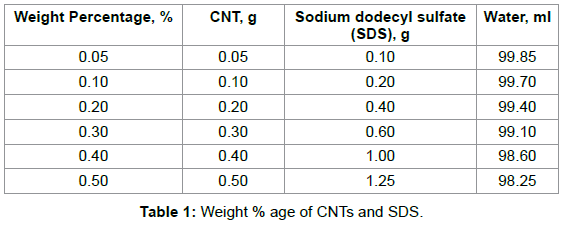

Nanofluid preparation

CNTs were dispersed in distilled water which acts as the base fluid and magnetically stirred for an hour to form a homogenous dispersion. Then, CNT nanofluid undergoes ultrasonic agitation in order to break any nanotubes agglomeration and produce highly uniform dispersion. The solution was prepared as stated in Table 1 Sodium dodecyl sulfate (SDS) used as a surfactant for nanofluid preparation.

Pendant drop experiment

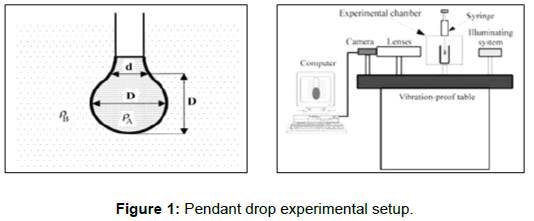

Pendant drop method generally used to measure the Interfacial Tension (IFT) between two immiscible liquids. It involves determination of drop profile of one liquid suspended to another liquid at mechanical equilibrium. This profile is determined with the aide of gravity and surface forces. The interfacial tension (γ) equation as follows:

(1)

(1)

Where

D = drop diameter

H = correction factor related to shape of pendant drop

Δρ = density difference between solution and crude oil

In general, pendant drop equipment consists of three parts which are a viewing system, an illuminating and an experimental cell. The main function of the viewing system is to visualize the drop and the data acquisition system to measure the interfacial tension from the drop profile as shown in Figure 1. A pendant drop test was carried out to study the effects of Carbon Nanotubes (CNT) on Interfacial Tension (IFT) reduction [10].

Results and Discussions

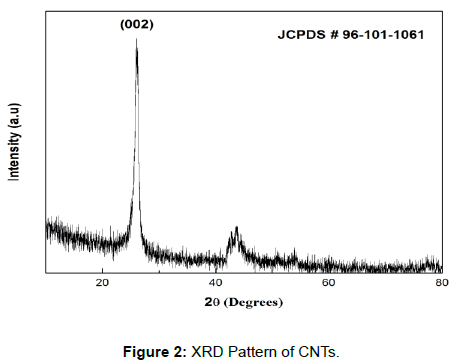

XRD pattern

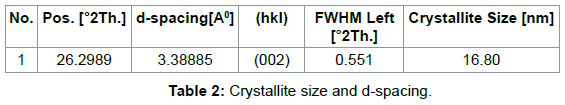

X-ray diffraction (XRD) measurements were performed to determine structural properties using a Bruker D8 advance X-ray diffractometer and Cu-Kα radiation with an accelerating voltage of 40 kV. Figure 2 shows the XRD profiles of the MWCNTs. The strongest and sharpest diffraction peak at around 2θ = 26.3° could be indexed as the C (002) reflection of graphite. The sharpness of the C (002) peak indicates that the graphite structure of MWCNTs [11]. XRD was used to measure the crystal size and interlayer spacing. Due to the CNT’s intrinsic nature, the main features of the X-ray diffraction pattern of CNTs are close to those of graphite, as shown in Figure 2 [12]. Measurements of crystal size (d) can be achieved from this peak (Table 2) and the Scherrer equation (Equation 2). As mentioned below, the average crystallite size of the CNTs was determined using the XRD patterns, via the well-known Scherrer equation:

(2)

(2)

where β is the full width at half maximum (FWHM), θ is the diffraction angle, λ is the X-ray wavelength (1.54 Å), D is the particle (crystallite) size, and k is the Scherrer constant (0.91). The Scherrer equation derived from Bragg’s law and it is limited to nano scale particles only. It is known that a decrease in the order of crystallinity in carbon materials will make the XRD peaks broader.

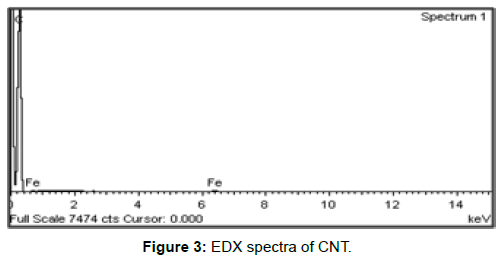

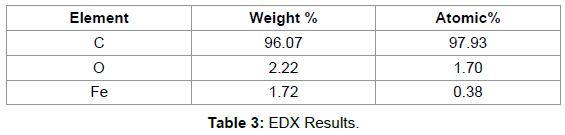

EDX results

Energy Dispersive X-ray spectroscopy was used to investigate the presence of elements in the sample and their chemical composition.

The Figure 3 shows the EDX spectra of CNT sample. The Table 3 reveals the presence of carbon in the synthesized sample.

The final sample composed of approximately 96% of carbon and remaining composed of Iron (Fe) and Oxygen (O) as shown in Table 3. Iron used as catalyst in the synthesis for growth of CNTs.

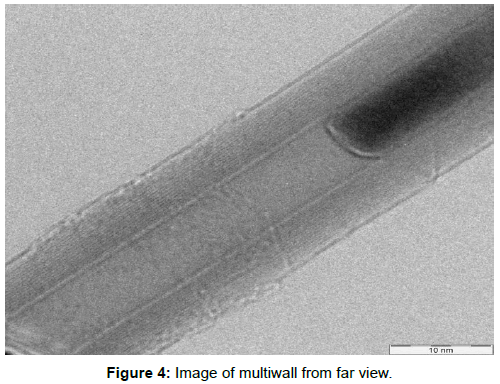

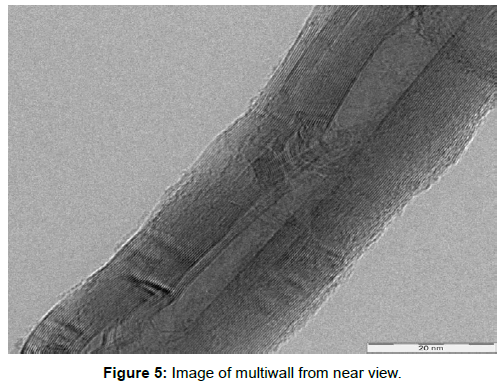

Transmission Electron Microscope (TEM) results

Transmission Electron Microscope (TEM) provides information on micro texture and nanostructure of specimens. This particular TEM shows the Carbon Nanotube is a multiwall CNT (MWCNT).

TEM image clearly shows the partition or the existence of the wall [13]. The outer diameter is in the range of 30 to 180 nm. The average pore volume was found to be around 0.103266 cm3/g, with a narrow low BET surface area of 29.6354 m2/g. There are three obvious partitions present in the image captured using TEM for CNT sample as shown in Figures 4 and 5.

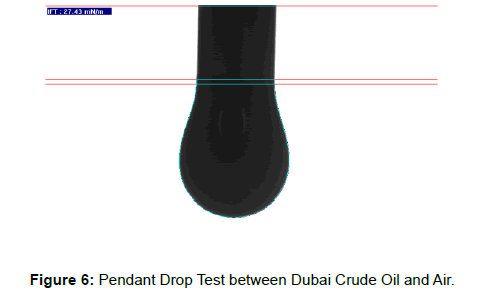

Pendant drop test

A pendant drop test was carried out to find the Interfacial Tension (IFT) of the liquids. Firstly, a Dubai crude oil was tested for IFT with air as shown in Figure 6. The figure below shows the pendant drop test result. The Surface Tension for this case is 27.43 mN/m.

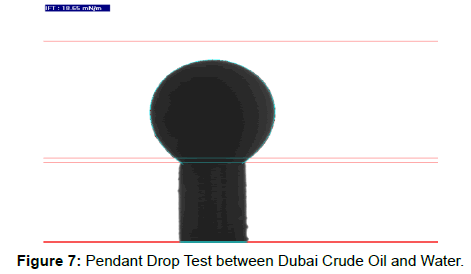

Next the IFT between Crude Oil and Water were studied. The Figure 7 shows the results obtained from pendant drop test. The Interfacial Tension for this case is 18.65 mN/m.

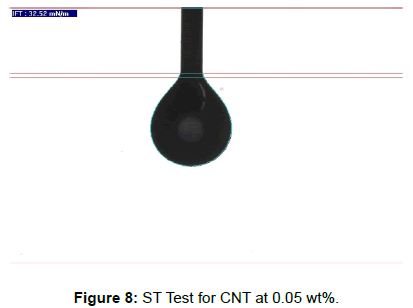

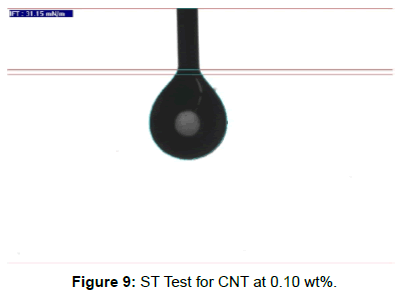

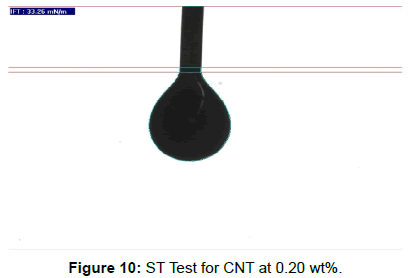

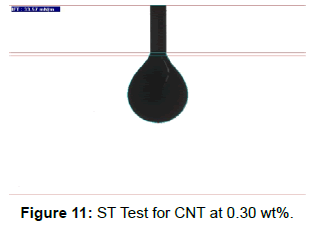

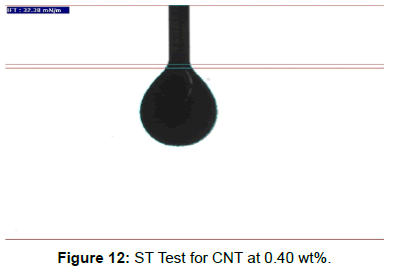

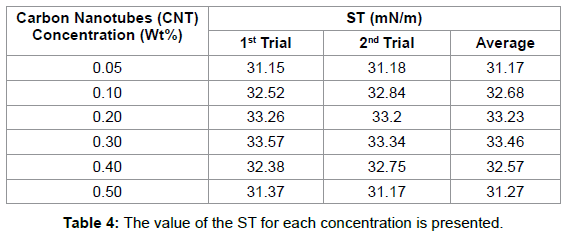

Carbon Nanotubes (CNT) is the final solution to be tested for Interfacial Tension (IFT) with Dubai crude oil. The CNT solution is black color in nature. It is known that the crude oil is in black color as well. Therefore it would be impossible to differentiate the crude oil and carbon nanotubes droplets, which results in failure of IFT calculation. Due to this major setback in calculation of Interfacial Tension (IFT) for Carbon Nanotubes (CNT), the previously mentioned methodology was altered. The Surface Tension (ST) for Carbon Nanotubes was calculated instead of Interfacial Tension (IFT) (Table 4).

Pendant drop test for carbon nanotubes (CNT)

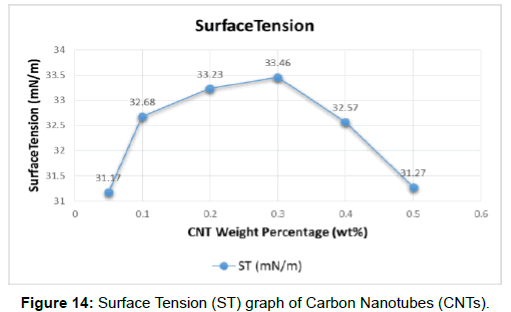

Pendant drop test for Carbon Nanotubes were carried out by using air as the second phase. This particular method was conducted since the drop phase could not be identified when the crude oil and CNTs are used. The primary objective of this test is to study the effect of concentration on Surface Tension. The Figures 8-13 shows the pendant drop images for Carbon Nanotubes at various concentrations. The value of the ST for each concentration is presented in Table 3.

The value of Surface Tension (ST) increases steadily up to 0.3 weight percentage of Carbon Nanotubes and falls at 0.4 wt% and 0.5 wt% as shown in Figure 14. The Sodium Dodecyl Sulphate (SDS) proportion is higher (1% and 1.25%) for 0.4 wt% and 0.5 wt% of Carbon Nanotubes [14]. Therefore it could be the reason for the drop in the ST [15].

Conclusion

Interfacial Tension (IFT) is one of the vital aspects in Enhanced Oil Recovery. By lowering the IFT, the production can be enhanced subsequently. The pendant drop test is proven to be essential in determining which concentration is able to enhance the production. Due to complication involved in determine the IFT for Carbon Nanotubes with Crude oil, the test was carried with air to calculate the Surface Tension (ST). Three cases based on the Surface Tension test were selected, which is High Case, Medium Case and Low Case. High Case provides a much better recovery compared to the other two cases. Therefore it is assumed that nanoparticles with high Surface Tension (ST) would have lower IFT value with crude oil.

Acknowledgement

The authors wish to acknowledge the project funding; FRGS research grant 0153AB-I46.

References

- Qin L(1997) CVD synthesis of carbon nanotubes. Journal of materials science letters 16: 457-459.

- Shaffer MSP (2012) CVD synthesis of carbon nanotubes. Google Patents.

- Shen P, Zhu B, Li XB, Wu YS (2006)The Influence of Interfacial Tension on Water/Oil Two-Phase Relative Permeability. SPE/DOE Symposium on Improved Oil Recovery.

- Taylor KC, Nasr-El-Din HA(1998) Water-soluble hydrophobically associating polymers for improved oil recovery: A literature review. Journal of Petroleum Science and Engineering 19: 265-280.

- Thomas S (2008) Enhanced oil recovery-an overview. Oil & Gas Science and Technology-Revue de l'IFP 63: 9-19.

- Stosur GJ (2003) EOR: Past, present and what the next 25 years may bring. SPE International Improved Oil Recovery Conference in Asia Pacific.

- Magrez A, Seo JW, Smajda R, Mionic M, Forró L (2010) Catalytic CVD synthesis of carbon nanotubes: towards high yield and low temperature growth. Materials 3: 4871-4891.

- Kumar M, Ando Y (2010) Chemical vapor deposition of carbon nanotubes: a review on growth mechanism and mass production. Journal ofNanoscience and Nanotechnology 10: 3739-3758.

- Soleimani H, Yahya N, Latiff NRA, Koziol K, Maciejewska BM, et al. (2014) Synthesis and Characterization of Mesoporous Multi-Walled Carbon Nanotubes at Low Frequencies Electromagnetic Waves. Journal of Nano Research: 117-122.

- Tao X, Zhang XB, Sun FY, Cheng JP, Fange L (2007) Large-scale CVD synthesis of nitrogen-doped multi-walled carbon nanotubes with controllable nitrogen content on a Co x Mg 1- x MoO 4 catalyst. Diamond and Related Materials 16: 425-430.

- Anjalin FM(2014) Synthesis and characterization of MWCNTs/PVDF nanocomposite and its electrical studies.Der PharmaChemica 6: 354-359.

- Khani H, Moradi O (2013) Influence of surface oxidation on the morphological and crystallographic structure of multi-walled carbon nanotubes via different oxidants. Journal of Nanostructure in Chemistry 3: 73.

- Singh DK (2010) Diameter dependence of interwall separation and strain in multiwalled carbon nanotubes probed by X-ray diffraction and Raman scattering studies. Diamond and Related Materials 19: 1281-1288.

- Lin Z, Aifen L, Haojun X, Yuli Z, Zhimei S, et al. (2012) Impact of Ultra-Low Interfacial Tension on Enhanced Oil Recovery of Ultra-Low Permeability Reservoir. Advances in Petroleum Exploration and Development 4: 49-54.

- Zhang H (2014) Enhanced oil recovery (EOR) using nanoparticle dispersions: Underlying mechanism and imbibition experiments. Energy & Fuels 28: 3002-3009.

Relevant Topics

Recommended Journals

- Oil & Gas Research Journal

- Renewable Energy and Applications Journal

- Oceanography Journal

- Industrial Pollution Control Journal

- Coastal Zone Management Journal

- Climatology & Weather Forecasting Journal

- Geoinformatics & Geostatistics Journal

- Engineering and Technology Journal

- Petroleum & Environmental Biotechnology Journal

- Polymer Sciences Journal

Article Tools

Article Usage

- Total views: 13991

- [From(publication date):

December-2015 - Jul 01, 2025] - Breakdown by view type

- HTML page views : 12863

- PDF downloads : 1128