Research Article Open Access

Synchrotron Powered Transmission X-ray Micro-tomography System in Shale Gas Micro-structural Characterisation

Marek S Zbik1,2*, Trzcinski JT1, Williams DJ2, Song YF3, Wang ChC3 and Frost RL Ray4*

1Faculty of Geology, Institute of Hydrogeology and Engineering Geology, University of Warsaw, Zwirki i Wigury 93, Warsaw, 02-089, Poland

2Geotechnical Engineering Centre, The University of Queensland, Brisbane, Australia

3National Synchrotron Radiation Research Center, 101 Hsin-Ann Road, Hsinchu Science Park, Hsinchu 30076, Taiwan, R.O.C

4Faculty of Science and Engineering, Queensland University of Technology, Brisbane, Australia

- *Corresponding Author:

- Marek SZ

Faculty of Geology, Institute of Hydrogeology and Engineering Geology

University of Warsaw, Zwirki, Poland

E-mail: marek.zbik@uw.edu.pl

- Ray LF

Faculty of Science and Engineering

Queensland University of Technology, Brisbane, Australia

E-mail: hsy@knu.ac.kr

Received date: November 16, 2015; Accepted date: December 31, 2015; Published date: February 05, 2016

Citation: Zbik MS, Trzcinski JT, Williams DJ, Song YF, Wang ChC, et al. (2016) Synchrotron Powered Transmission X-ray Micro-tomography System in Shale Gas Micro-structural Characterisation. Oil Gas Res 2:109. doi: 10.4172/2472-0518.1000109

Copyright: © 2016 Zbik MS, et al. This is an open-access article distributed under the terms of the Creative Commons Attribution License, which permits unrestricted use, distribution, and reproduction in any medium, provided the original author and source are credited.

Visit for more related articles at Oil & Gas Research

Abstract

The shale gas renaissance was brought about by improved methods of well drilling and completion by hydraulic cracking technology. It has become increasingly urgent to developed new method of 3-D characterisation of potential rocks collectors. Release of gas from compacted shales needs new aproach to void promoting and increasing technology and new monitoring characterisation. In present study the transmission x-ray microscope (TXM) method was validated in microstructural study of mudstone shale sample. High structural complexity was observed. Initial structure displays anisotropic aggregate network with highly elongated voids 0.2 to 1.5 μm in diameter and the bulk porosity about 12-20% and pore average diameter vary between 125 to 283 nm. Texture of this rock is laminar and two distinctive lamellas direction was observed with angle between them about 20º. The average distances measured between mine stream lamellas was around 400 nm which is twice than average voids dimension. It was noticed that ultrasonic action on the shale rock has significant influence altering it microstructure. Voids becoming larger after ultrasonic treatment with porosity system increased in value above 30%, pushing up the rock permeability.

Keywords

Transmission X-ray Microscope; Shale gas; Shale rocks microstructure

Introduction

Rising the oil and gas price and limited resources where these commodities can be found in prime environments for exploration; alternative sources which were overlooked previously are attracting more attention in these days. The most studied different sources are those which focus on oil and gas exploration from shale rocks. The shale is a fissile, terrigenous, sedimentary silicate rock, whose particles are mostly of silt and clay size. Until recently shale rocks reservoirs were considered unfeasible and were not suitable for exploration. The productivity of specific shale will depend on its chemical and physical properties. The chemical properties include the quantity and quality (composition and maturity) of the organic matter. The physical properties include its porosity and permeability. Fractures are the main conduit for gas flow. The shale gas renaissance was brought about by improved methods of well drilling and completion has become increasingly urgent to develop new methodology of 3-D characterisation of potential collection rocks. Release of gas from compacted shales needs new aproach to void promoting and increasing technology and new monitoring characterisation. Development in microstructural study of oil and gas reservoirs has a long history but rocks of mostly prime porosity systems were explored what did not press to look for most sophisticated method of void system characterization. Shale rocks as the oil and gas reservoirs has to be found highly anisotropic in most of the properties and much smaller in grains and voids dimension than more porous collectors. These difficulties, ignited new rush for better characterization systems in studies shale gas rocks. Good description of different method used for gas shale rocks characterization was done by Josh et al. [1]. Gas adsorption analysis has proven to be an effective method to characterize Nano pore structure explained by Karastahis and Passey [2,3] gas adsorption data indicate that the porous materials have fractal geometries. The helium porosimetry and the Mercury Injection Capillary Pressure (MICP) measurements are the standard method for characterizing pore throat size distribution in a media from the micron-scale (>1 μm) to the nano-scale (1 μm to 1 nm). In shale, mercury is able to penetrate within and between the coarse rigid grains as well as the clay intergrain areas and secondary minerals. Other methods include field emission scanning electron microscopy suggested Luffel and Sigal [4,5] and transmission electron microscopy (TEM). Different microscopy techniques were developed during recent decade or two. Most sophisticated FIB/SEM system with description of 3-D quality and quantity investigations was successfully employed in this area of study. Numbers of samples were examined on a dual-beam microscopy system (SEM-FIB) by Curtis, Loucks, Schieber, Aumbrose and Kuila [6-10] utilizing the 2-D and 3-D reconstructed submicron pore models from SEM-FIB tomography. As shown in published studies, submicron pore imaging and modeling can provide key insights into the petrophysical properties of various shale rocks, such as a pore-size histogram, porosity, tortuosity, anisotropy. This method may be adapted in many laboratories to study shale rocks in microscale because of high precision and resolution their 2-D images and computer 3-D reconstruction. Computed image is however quantified with spaces between subsequent cuts which may be as small as 50 nm. Continuous model (without cutting on different slices) can be offered by X-Ray Computer Tomography (XRCT) method. Geological applications of (XRCT) have been performed since the 1980s by Colletta and Wellington [11,12]. These investigations were on macroscale involving large shale rock specimen from core drill. High resolution micro-CT, works on the same principles of the conventional X-ray CT, but using smaller samples and a shorter distance between source and detector allows much higher resolution in scale of millimeters. The gas shale rocks however, have never been studied using X-ray CT technique with nano-scale characterization. Relatively new techniques Transmission X-Ray Microscopy (TXM) with subsequent computer reconstruction technique has been implemented for the study into the nano-material science in three dimensional space (3-D). This method is based on the synchrotron photon source. Yin and colleges reported this X-ray microscopy technique for the first time in 2006 by Yin and Attwood [13,14], Others were pioneering this method in the clay suspension nano-structure investigation since the first publication by Zbik [15]. The big advantage of the TXM tomography gave possibility to observe clay microstructure without sample pre-treatment and without drying sample in vacuum, which may cause artefact. However, one has to carry in mind that there is no artefact free computed-tomography by the very nature of its mathematical reconstruction procedure. The TXM tomography method display continuously the sample microstructure without quantified it into physically sliced sections as dual beam technique does. In the present work, TXM method was used to investigate the microstructure of gas shale sample to add new data to the studied subject and validate it potentials in shale gas area characterization and it possible alternation using external force. Because of misunderstanding between terms structure and texture in our contribution we follow the most resent definition of the term “structure” formulated by Osipov and Sokolov [16,17] as; “ Structure is a spatial organization of the entire substance of the rock described by the aggregate of morphometric, geometric, and energy characteristics, which, in their turn, are determined by the composition, quantitative proportion, and interaction of the rock components”. However, rock macroscopic physical behaviour is governed by their constitution on microscopically small scale and because our investigations were conducted on microscopically scale, in the present contribution term “microstructure” will be used.

Materials and Methods

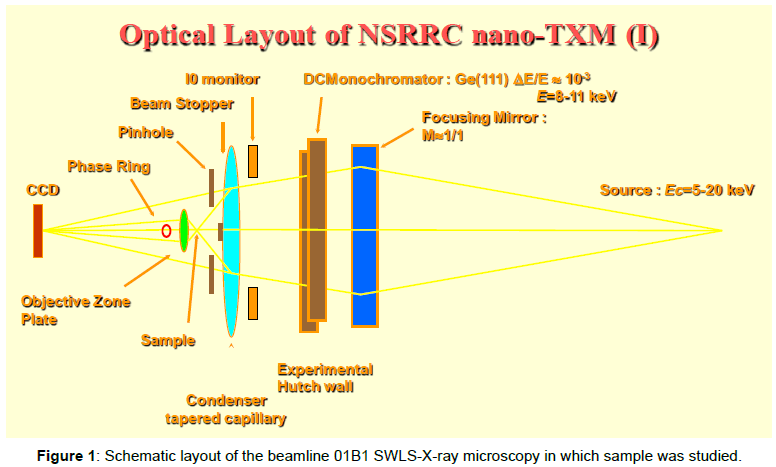

Transmission X-ray microscopy (TXM) proved to be an efficient instrument in studying internal structure of nano-material owing to its large penetration depth and superior spatial resolution. TXM, which was used in the present study, has been installed on synchrotron of NSRRC in Taiwan by Yin and Attwood [13,14]. This TXM provides two-dimensional imaging and 3D tomography at an energy of 8-11 keV, with a spatial resolution of 50-60 nm and with the Zernike-phase contrast capability for imaging light material that lacks X-ray absorption contrast. TXM allows the measurements of aqueous specimens owing to having no vacuum requirement. The photon energy of 8 keV was used to image the clay suspension for the maximum X-ray absorption. The exposure time of a 2D image is from 15 seconds to 4 minutes. By acquiring a series of 2D images with the sample rotated stepwise, 3D tomography datasets were reconstructed based on 141 sequential image frames taken in first order diffraction mode with azimuth angle rotating from -70º to + 70º for our lateral flake specimen. The TXM technique has some limitations Zbik et al. [15], in particles investigation in suspension because of particles movement during relatively long exposure time. In studies involving solid, non-moving samples like shale rocks, method give better resolution and morphology patterns are more clearly visible. Images from all microscopy studies were statistically analysed using the Statistical Image Analysing System (STIMAN) [18,19] technique, which has been adopted for the purpose of studying clay suspensions. This technique can extract integrated information on sample micro-structures, especially on total pore (void) space and the spread of micro-pore sizes. It contains a subroutine for estimating filtration properties from the void space parameters. Examples of the output parameters include: examined void number; porosity (%); total void/particle area (sq. μm); total void perimeter (μm); average diameter (μm); average perimeter (μm) and the form index (Kf) (ratio of shorter to longer particle diameter). Form index is 1 for perfectly round isometric particles and near 0 for string-like, elongated particles. In the present study, we limited use of the STIMAN technique to obtain statistical information about porosity, particle average diameter and pore distribution according to their total area from 2D micrographs. XRD patterns were recorded with a Pan alytical X’Pert Pro, a multi-purpose diffract meter using Fe filtered Ca Ka radiation, auto divergence slit, 2° anti-scatter slit and fast X’Celerator Si strip detector. The diffraction patterns were recorded in steps of 0.016° 2-theta with a 0.4 second counting time per step, and logged to data files for analysis. Electron microscope investigations were conducted using a JEOL-2100 TEM operating with a 200 kV accelerating potential. The SEM JEOL 6040 was used to investigate samples coated in platinum film with accelerating voltage 15-20 kV. The shale rock fragment was chosen arbitrary from our vast collection to conduct present validation study. This rock fragment has been collected from the Carpathian Mountains with Carpathian Flysch formation in southern Poland. During sample preparation for TXM investigation the shale rock under was gently fragmented and smallest particles were glued into the tip of glassy capillary sharpened end. Such prepared sample on top of the glassy capillary was inserted into a specimen mount and placed into the beam line (Figure 1). The low resolution 2D X-Ray micrograph was obtained for general assessment of larger scale specimen and for identification suitable spot for most detailed investigation in the micro-scale. Sample after initial TXM investigation was subjected to ultrasonic action of magnitude 50 W and duration 30 second. The TXM investigations were repeated after sonication to check influence of the external force on primary rock microstructure.

Results and Discussion

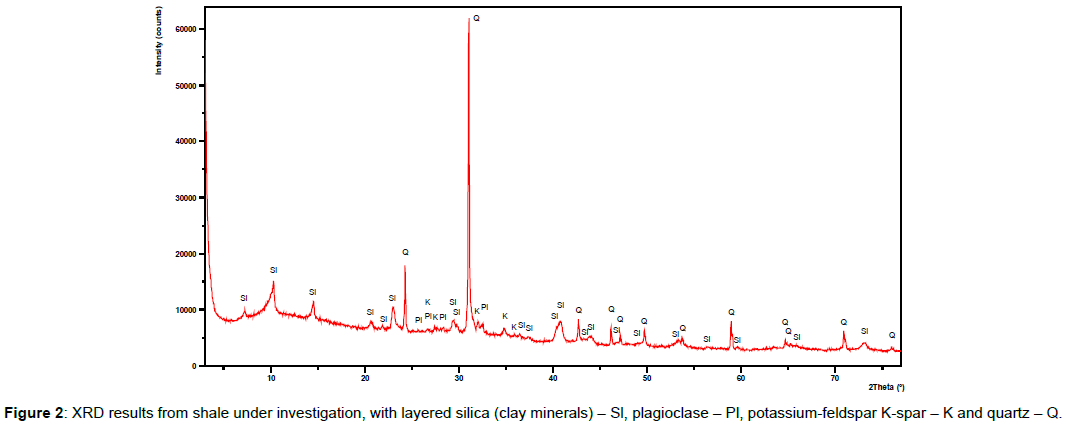

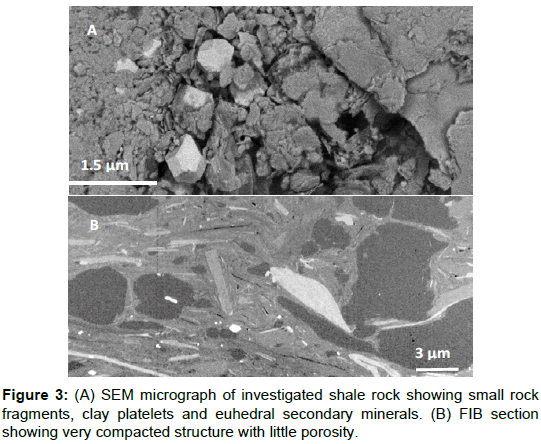

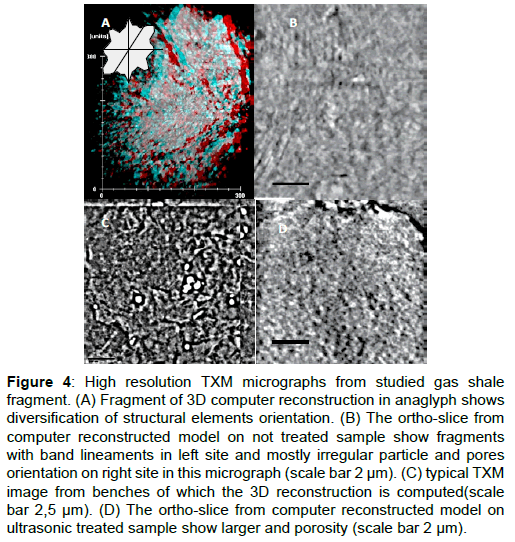

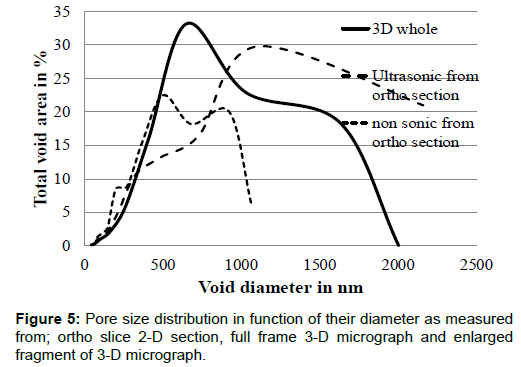

The XRD analysis of the shale rock under investigation is shown in diffractogram (Figure 2) is composed with phyllosilicates (clay minerals) -Si, plagioclase -Pl, potassium-feldspar K- and quartz -Q. Among clay minerals Kaolinite and Illite was identified. The SEM micrograph of shale rock fragment has been shown in Figure 3A, and displays small rocks fragments, platy clay minerals with parallel particle orientation and crystals of euhedral secondary minerals. In this SEM micrograph enlarged void fragment is seen filled by loose clay flakes. In Figure 3B the cross section of shale studied in the dual beam FIB, reveals small porosity which is about 1,5% as calculated from this image. In SEM/FIB micrographs fissility is well visible. This lineament particles arrangement was apparent from macroscopic observation in the hand specimen. Fissility is property of a mudrock that causes it to break along thinly spaced planes parallel to the bedding and to the orientation of the sheet like clay flakes. This property macroscopically manifests in shale rocks and makes their property highly anisotropic. The high resolution 3-D TXM computer tomography reconstruction micrographs like displayed in Figure 4A, show particles of 0,2-2 μm in dimensions and vary in size voids in-betweens them. In TXM images fine layered structure was revealed with thicknesses of layers from 13 to 15 units (24,5 um/unit) which is 0.4-0.45 μm. Most observed voids were elongated and follow distinctive particle orientation. In observed sample in TXM 3-D reconstruction (Figure 4A) particle and voids orientation is confused to few direction with mean anisotropy coefficient Kα- 42% which indicate highly anisotropic structure orientation Sokolov [20]. This observation give evidence that macroscopically observed rock fissility extends into the microscopically level. Confusion of structural elements orientation seen in 3-D image can be observed also in the orientation diagram inserted into this micrograph. Three different orientation directions were observed. Two major direction (42° and 140°) was highlighted by distinctive fissility lines and smaller one (16°) can be attributed to clay flakes distortion. Cause of such structural orientation confusion, seen in the high resolution TXM images, can be obvious when observing much larger sample surface seen in SEM/FIB picture in Figure 2. In this micrograph clay platelet orientation is changing in front of larger mudstone rock fragment. Probably, the compaction pressure which moved stream of highly oriented clay platelets and squeezing them against hard mud rock surface divided this stream into two major directions. In the 3-D reconstruction model seen in Figure 4, all well displayed major lineaments can be much obvious when rotating this 3-D image (not seen here). In this 3-D image, platelet-like clay particles are not always laying parallel to mine structure lineation but are inclined from fissiles mine direction of about 20º. This sort of structure may suggest that after primordial particle sedimentation through the water column sediment were subjected not only compaction but also shire side forces. These forces, probably orogenic in origin, produce banded fissiles which has different orientation from the clay platelets primary orientation inhered during sediments compaction within sedimentation basin. So structure of shale rock fragments diversify strongly from largely isotropic structured mudstone grains and highly oriented clay rich lineaments. These lineaments directions changes in micro-scale as clay layers encapsulate mudstone grains. So, very different structural elements can be seen in these TXM micrographs seen in Figures 4A and 4B. In 3-D micrograph in Figure 4A, stream of lineaments oriented by clay platelets have changing direction which split streams of particles against mudstone fragment. In the 2-D ortho-slice micrograph (Figure 4B) fragment from this rock displays disturbed layered and highly oriented clay rich structure in the left side of micrographs and relatively isotropically structured right side of picture which possibly represents the mudstone fragment structure. Detailed structure of these different structural environments were not been studied as observed structural diversity was found during result analysing. Further investigation of these structurally diverse rocks fragment is planned. Because of the high focus distance (~50 μm) many particles can be seen simultaneously in the same place through entire photographed area. This makes most 2-D images from TXM technique difficult for interpretation. To help in micrographs interpretation, ortho-slices (Figure 4B) were produced from computer space model reconstruction. The entire space model was cut into consequent sections enable to observe particle and void in sections without obscuring them by other particles which may be in focus behind and in front of studied section. The cross section of the rock sample makes voids and particles much easier to be measure. Obtained ortho-slices show complex microstructures where mine linear lamellas are distorted and platelet shaped particles were deviated from the mine lamellas direction. The large and regular in shape voids observed in ortho-slice image (Figure 4B) were in majority between 150 to 400 nm in diameter when these more elongated, fissure like pores, were of few micrometer long and fraction of micrometer thick. Layered structure seen in 2-D slice-section (Figure 4B) displays signs of plastic deformation from straight line in many void highlighted lineaments. Porosity of studied sample, estimated from the ortho-slice sections gave average values vary between 12 and 21% with average voids diameter 125-200 nm. Void total area distribution accordingly to their diameter calculated using STIMAN technique from TXM micrographs is presented in Figure 5. From calculation taken of the ortho-slice shale sample cross section, the three modal curve was obtained. Maximum void density as shown in diagram is concentrated within diameter range between 0.25-0.45 μm with the pick maximum about 350 nm in diameter and represents the inter particle voids within major lamellas of fissile microstructure. Smaller voids, with maximum about 180 nm in the pore diameters represent voids within clay aggregates and larger, mostly elongated voids, are these between major lamella fissiles. The permeability index was extremely small 0,001 mD with the voids of diameters between 0.3 to 0.7 μm significantly contributing into filtration. Less clear for image analysing program calculation, but better for structure visualisation were original TXM micrographs and space 3-D stereoscopic images like shown in Figure 4C. These images display continuously structural features on larger micrometre scale without quantification. From this space reconstruction images it is clear that voids are much more abundant than seen in SEM/ FIB images. Micrographs show complex network of clay aggregates and small particles joined into lamellar structure. The void total area distribution accordingly to their diameter calculated from these 3-D micrographs show that most pores are within range of 650 nm to 1 μm in diameter and as in studied slide sections represent inter-particle and inter aggregate voids within lamellas. Smaller pores of maximum diameter about 150 nm may represent clay intra-aggregate voids, and larger up to 2 μm in diameter can be recognised as between fissure voids or fissures. Structure is not uniform in microscale and some places like from magnified area in Figure 4C, where mostly clay size particles were observed, porosity was larger 19,8% and represents mostly inter and intra-aggregate voids of diameters not exciding 0,5 μm. The permeability index calculated from 3-D images was about 1, 5E-5 Darcy, and voids/channels of diameters between 0.9 to 1.2 μm significantly contributing into filtration. In 3-D anaglyph images (not shown here) network of clay aggregates divided by elongated fissures can be observed. Aggregates consists of platelets 260 nm long and about 60 nm thick, or more compact aggregates 300-400 nm in diameter. Within network of aggregates voids of diameters up to 600 nm were frequently seen. Larger fissures were fragmenting all observed sample on few μm in size fragments. Fissures, within observed frame area can be ~300 nm wide. From sample which was process by ultrasonic action the ortho-cross section were plotted like shown in Figure 4D. Significant porosity increase was observed after from these micrographs statistical processing. Porosity in average was about 30% and pores were much broadly distributed towards larger diameters in comparison with data collected from non-treated sample with the peak maximum between 1-1.5 μm. Larger pores and channels causing increase rock permeability index after ultrasonic treatment ~9E-5 Darcy. Direct observations on TXM and 3-D micrographs analyses gave interesting look into microstructure of shale rocks with continuous not quantified space and without artefacts which may be produced during sample pre-treatment. Much larger volume of voids was observed and larger porosity value was calculated from TXM micrographs than been observed and calculated from SEM micrographs and reported from other sources where different method were used in shale rock studies. 3-D observations show that studied shale rock is composed on the basic levels of compact clay aggregates arranged with chained network. Chains, build of 200- 400 nm in diameter compact aggregates, looks in small volume disoriented and quaint porous with average porosity up to 20%. Ultra-pores within aggregates were not included in this calculation as were below resolution of TXM method. However porosity in average 28.2% was reported from Fayetteville shale gas rock studied using dual beam method . So, shale rocks may be surprisingly more porous than it has been believed but small dimension of majority of pores make it more difficult to be observed. Also porosity system characterize by very small permeability making filtration impossible without artificial cracking. With more volume of voids seen in the 3-D TXM micrographs in these rocks the possible gas reservoir may be larger than predicted.

Figure 4: High resolution TXM micrographs from studied gas shale fragment. (A) Fragment of 3D computer reconstruction in anaglyph shows diversification of structural elements orientation. (B) The ortho-slice from computer reconstructed model on not treated sample show fragments with band lineaments in left site and mostly irregular particle and pores orientation on right site in this micrograph (scale bar 2 μm). (C) typical TXM image from benches of which the 3D reconstruction is computed(scale bar 2,5 μm). (D) The ortho-slice from computer reconstructed model on ultrasonic treated sample show larger and porosity (scale bar 2 μm).

Conclusions

From larger view investigation using SEM and mosaic TEM it was found that shale gas rock is highly anisotropic system. It contains largely isotropic structured mudstone grains and highly oriented clay rich lineaments. These lineaments directions changes in micro-scale as clay layers encapsulate mudstone grains.

The mudstone shale rock structure was investigated using computer tomography system based on synchrotron powered Transmission X-Ray Microscopy. Computer 3D reconstruction images were proof of giving new possibilities to measure porosity system of the studied sample and angles of major lineation. Ortho-slice images from aligned 3D reconstructions were suitable for structure statistical analysis using popular 2-D widely available image analysing programs. Initial structure displays anisotropic aggregate network with highly elongated voids 0.2 to 1.5 μm in diameter and the bulk porosity about 12-20%. Microstructure of studied shale rock was laminar which resemble it fissility observed in the macroscale. Three distinctive lamellas direction can be observed like measured angle between two major directions in space image with almost right angle between them. Minor direction observed with angle 16º was generated by platelets distortion probably of orogenic origin. The average distances measured between mine stream lamellas was around 450 nm which is less than half of the aggregate-grain dimension. The X-Ray microscopy method with high resolution structure reconstruction looks very useful in the gas shale sample characterisation and especially when anisotropic rocks are to be studied. Such a complex texture of shale rocks may influence it anisotropic physical behavior like preference to produce complex cracks and fissures under pressure during hydraulic fracturing within gas reservoirs. Shale rock under investigation show surprisingly more porous structure than it has been believed from other method of measurements. However, small dimension of majority pores make it more difficult to be investigated and yields very small permeability values making filtration impossible without artificial cracking. With more volume of voids seen in the 3-D TXM micrographs in these rocks the possible gas reservoir may be larger than predicted. It was noticed that ultrasonic action on the shale rock has significant influence altering it microstructure. Voids becoming larger after sonication and porosity system increased in value above 30%, pushing up the rock permeability. This observation needs more detailed study and it may have implication in gas extraction fracking technology improvement. The mudstone fragments and clay rich layers are very different structural elements in studied shale gas rock and further detailed investigation is necessary involving both these elements using sectioning them by FIB technique with subsequent study in TEM and TXM. Space oriented samples studied in TXM may be useful in range of engineering fields helping predict rock physical behaviour under stress like during hydraulic cracking, under foundations, also about best condition of cracking processes and water usage with possible drilling well production.

Acknowledgements

This work was supported by the Australian Synchrotron Research Program (ASRP).

References

- Josh M, Esteban L, Delle C, Sarout J, Dewhurst DN, et al. (2012) Laboratory characterization of shale properties. Journal of Petroleum Science and Engineering pp: 88-124.

- Karastathis A (2007) Petrophysical measurements on Tight Gas Shales. PhD thesis.

- Passey Q, Bohacs K, Esch W, Klimentidis R, Sinha S (2010) From oil-prone source rock to gas-producing shale reservoir-geologic and petro physical characterization of unconventional shale gas reservoirs. In: International oil and gas conference and exhibition in China.

- Luffel DL, Guidry FK, Curtis JB (1992) Evaluation of Devonian shale with new core and log analysis methods. J Pet Technol 44: 1192-7.

- Sigal RF (2014) Mercury capillary pressure measurements on Barnett core, submitted in petro physics.

- Curtis ME, Ambrose RJ, Sondergeld CH, Rai CS (2010) Structural characterization of gas shales on the micro- and nano-scales. Society of Petroleum Engineers Canadian Unconventional Resources and International Petroleum Conference 3.

- Loucks RG, Reed RM, Ruppel SC, Jarvie DM (2009) Morphology, genesis, and distribution of nanometer scale pores in siliceous mudstones of the Mississipian Barnet shale. J Sediment Res 79: 848-861.

- Schieber J (2010) Common themes in the formation of intrinsic porosity in shale and mudstones- illustrated with examples across the Phanerozoic. SPE Unconventional Gas Conference p: 428

- Ambrose RJ, Hartman RC, Diaz M, Akkutlu IY, Sondergeld CH (2010) New Pore-scale considerations for Shale Gas in Place Calculations. Society of Petroleum Engineers, SPE Unconventional Gas Conference held in Pennsylvania USA pp: 1-17.

- Kuila U, Dewhurst DN, Siggins AF, Raven MD (2011) Stress anisotropy and velocity anisotropy in low porosity shale. Tectonophysics 503: 34-44.

- Colletta B, Letouzey J, Pinedo R, Ballard JF, Bale P (1991) Computerized X-ray tomography analysis of sandbox models examples of thin-skinned thrust systems. Geology 19: 1063-1067.

- Wellington SL, Vinegar HJ (1987) X-ray computerized tomography. J Pet. Technol.39: 885-898.

- Yin GC, Tang M,Song YF, Chen F,Liang KS, et al. (2006) Energy-tunable transmission x-ray microscope for differential contrast imaging with near60nmresolution tomography. Appl Phys Lett 88: 241115-2411153.

- Attwood D (2006)Nano tomography comes of age 442: 642-643.

- Zbik MS, Frost RL, Song YF (2008)Advantages and limitations of the synchrotron based transmission X-ray microscopy in the study of the clay aggregate structure in aqueous suspensions. J Coll Int Sci 319: 169-174.

- Osipov VI, Sokolov VN, Eremeev VV (2004) Clay Seals of Oil and Gas Deposits. Balkema Publishers, Lisse Tokyo p:288.

- Osipov VI, Sokolov VN (2013) Clays and Their Properties. Composition, structure, and formation of properties, Moscow GEOS p: 576.

- Sergeev YM, Spivak GV, Sasov AY, Osipov VI, Sokolov VN, et al. (1983) Quantitative morphological analysis in a SEM microcomputer system I Quantitative shape analysis of single objects. Morphological analysis of complex SEM images J Microsc135: 1-12.

- Smart R, Zbik M, Morris GE (2004) Stiman observation of aggregate structure in clay flocculation. 43rd Annual Conference of Metallurgists of CIM pp: 215-228.

- Sokolov VN (1988) Engineering-geological classification of clay microstructures. Proc. 6th, Inter. IAEG Congress pp:753-760.

Relevant Topics

Recommended Journals

- Oil & Gas Research Journal

- Renewable Energy and Applications Journal

- Oceanography Journal

- Industrial Pollution Control Journal

- Coastal Zone Management Journal

- Climatology & Weather Forecasting Journal

- Geoinformatics & Geostatistics Journal

- Engineering and Technology Journal

- Petroleum & Environmental Biotechnology Journal

- Polymer Sciences Journal

Article Tools

Article Usage

- Total views: 11778

- [From(publication date):

April-2016 - Apr 03, 2025] - Breakdown by view type

- HTML page views : 10832

- PDF downloads : 946