Research Article Open Access

Sustainable Building Materials for Low-cost Housing and the Challenges Facing their Technological Developments: Examples and Lessons Regarding Bamboo, Earth-Block Technologies, Building Blocks of Recycled Materials, and Improved Concrete Panels

Jan Bredenoord*

International Urban Planner/Housing Researcher, Amerikaring 26, 3823 HT Amersfoort, The Netherlands

- *Corresponding Author:

- Jan Bredenoord

Researcher, Housing Research Group

Utrecht University, Amerikaring 26

3823 HT Amersfoort, The Netherlands

Tel: +31 6 22446251

E-mail: janbredenoord@planet.nl

Received Date: March 21, 2017; Accepted Date: March 23, 2017; Published Date: March 30, 2017

Citation: Bredenoord J (2017) Sustainable Building Materials for Low-cost Housing and the Challenges Facing their Technological Developments: Examples and Lessons Regarding Bamboo, Earth-Block Technologies, Building Blocks of Recycled Materials, and Improved Concrete Panels. J Archit Eng Tech 6: 187. doi: 10.4172/2168-9717.1000187

Copyright: © 2017 Bredenoord J. This is an open-access article distributed under the terms of the Creative Commons Attribution License, which permits unrestricted use, distribution, and reproduction in any medium, provided the original author and source are credited.

Visit for more related articles at Journal of Architectural Engineering Technology

Abstract

There is a huge demand for affordable urban housing in the countries of the Global South. Using locally available and/or produced building materials for housing can reduce the buildings impact on the environment. Climate conditions and natural disaster risks, which differ by region, determine the applicability of the sustainable building materials and building structures. This article focuses on five groups of building materials: bamboo, compressed earth blocks and stabilized soil blocks, interlocking blocks of recycled materials, and improved concrete panels. In all cases, technological development and exchange of knowledge with local communities are desired. In order to produce more sustainable building materials, local communities can be trained and educated with regard to house building. Making use of a local workforce and involving local resident’s in house building is beneficial for the communities. This article summarizes the main benefits and limitations of the materials and focuses on their applications in urban areas.

Keywords

Sustainable building materials; Green building materials; Low-cost housing; Self-managed housing; Technical assistance for housing; Bamboo housing; Compressed earth blocks; Stabilized soil blocks; Earth technologies; Interlocking building blocks; Panel blocks

Introduction

This article provides information on the use of building materials for low-cost housing in developing countries, specifically materials that can be seen as ‘sustainable’. The applicability of building materials is always determined by the following local circumstances: the availability of raw materials; the culture of making building materials; the construction methods; the power of individuals, households, and residents’ groups; and the willingness of entrepreneurs to participate in house construction. In theory, all the housing that is needed in the Global South could be built by corporations or building companies. However, in the low-cost housing market, housing is usually built by the households themselves, by local communities, and by small businesses and craftsmen. In this article, I discuss three types of sustainability: technical sustainability (durability), climate friendly sustainability, and social sustainability. The use of sustainable building materials is important for the incremental processes of self-managed house construction and home improvement. Low-incomes households should always be able to buy good-quality and affordable building materials. When households and communities participate in house construction, they can significantly lower the building costs. UNHabitat Executive Director, Dr. Joan Clos, said at the presentation of the World Cities Report 2016 [1]: “To position (affordable) housing at the center of sustainable development, UN-Habitat advocates a twintrack approach; a curative approach which involves improving existing houses, and a preventive approach which involves construction of new housing units”. The following options to support households and communities to implement affordable and sustainable housing are of importance:

1) Sustainable housing and urban planning and housing,

2) Land for housing programs,

3) Tenure security,

4) Basic services,

5) Community participation and contracting,

6) Safe construction,

7) Sustainable (local) building materials, and

8) Access to housing finance [2,3].

The following issues are addressed in this article: sustainable housing, safe construction, and sustainable local building materials. By focusing on these aspects of sustainability and the involvement of the residents in the design and the production of their homes, this article follows UN-Habitat’s theoretical framework on sustainable building materials, as presented in ‘Going Green’ [4] and in other UN publications mentioned in this article. In 2015-2016 the author worked for the World Bank on the development of policy for affordable and incremental housing. In the same period, in cooperation with some NGOs, he visited several promising projects in El Salvador, Uganda and Vietnam.

In order to further develop the skills of local participants in individual and mutual house building, governments and aid organizations provide or should provide assistance for individuals, households, self-help groups, and housing cooperatives to improve their knowledge and skills on house building and home renovations. Therefore, attention is given to five groups of sustainable building materials and building technologies related to aspects of self-help and self-reliance with regard to housing. In general, the following questions are addressed:

• How can technical assistance for low-cost housing be organized?

• How can residents be involved in building and improving homes, in order to lower the costs?

• Why is building control at the building site necessary?

• How can technological innovations with respect to sustainable building materials be supported?

• What is the role of governments, institutes, and private actors in product development?

• What is the role of aid organizations, NGOs and other actors concerning technical assistance?

The article is organized into five sections. In the following section, the background of sustainable building materials and housing is briefly reviewed. In section three, a description is given of five promising building materials and the way they are applied in practice. In section four, the future of technical assistance and product development is described. In the conclusion (section five), the advantages of the described building materials are summarized, as well as ways to overcome their restrictions.

Background of Sustainable Building Materials and Housing

High-quality building materials must always be used in housing, also in low-cost housing. High-quality means among other things that the materials are long-lasting, have nice features, and require only a little maintenance. This can be called ‘basic durability’. A home must provide protection against the effects of the regional climate condition, such as coldness and heat, wind, rain, etc. In addition, the house must offer the residents safety and privacy, and it should never collapse. Natural disasters, such as earthquakes, tropical storms, and floods, place unique technical demands on the dwellings’ structures and materials. In areas that are seriously threatened, the construction of houses must be prohibited, through adequate planning regulations, especially in areas that can’t be protected by technical measures such as dikes in flood areas. Due to climate change, natural phenomena are becoming more violent, and thus the requirements for the durability of a building’s structure and its materials need more attention.

About Durability and Sustainability

Besides the durability aspects of housing, sustainable house building also stems from other motivations, namely protecting the environment, the climate and the natural resources. Often, the objective (of the governments, and sometimes the residents) is that housing does not contribute to climate change or emissions of greenhouse gases- CO2 gas in particular. If the import of concrete building materials and the associated high transport costs can be avoided, the (climate) benefits are immediate. If the use of fossil fuels can be avoided, both in the procurement of raw-materials and in the production and the transport of materials, environmental benefits are gained. For example, in the production of bricks and roof tiles, clay is often collected locally and fired with wood in kilns, but then one can’t speak of sustainable building materials even though they may be long-lasting or durable. In general, the use of concrete is not sustainable because a lot of energy is used in the production of cement and the transport of cement, gravel and sand to the construction site. Therefore, one should try to minimize the use of cement and concrete. The conditions in the region determine the construction techniques that are needed regarding strength and resilience. In earthquake zones the houses must be earthquake resistant. This means that frameworks must be created to ensure that the house will remain standing during an earthquake. For house building in flood plains, specially adapted technical requirements may be applied. The safety of the buildings must always have priority. Moreover, fire safety should be taken into consideration. In all cases, adequate building codes and building control must be available and applied, which is not always the case.

Sustainability – General focus

Usually some knowledge about local building materials and construction techniques is available in local communities. Many contemporary building methods – also in rural areas – are influenced by urban building cultures, and natural construction materials are often replaced by cement, concrete and steel. For this reason, one searches for opportunities to introduce technological improvements to traditional building materials and techniques. Pilot projects have been set up and monitored by national and international organizations. Applying new technologies to local building materials can facilitate the improvement of traditional techniques in local communities. Professional assistance for individual households and local communities should be available in order to

1) Avoid disinvestments and apply sustainable materials and techniques,

2) Find financing for the construction of a house or parts of it,

3) Make safety arrangements for those areas threatened by major natural phenomena.

Mostly, these measures are costly, and therefore external aid must be found from governments, aid organizations, private corporations, banks, etc.

Social sustainability through involvement and training

When a national government wants to develop a housing policy, it investigates which building materials, construction techniques, and building cultures are present in a particular district. Research should be performed regarding the presence and quality of local raw materials such as wood, bamboo, sand, gravel, clay, loam, lime, etc. Mostly, these materials are not found in urbanized areas, but in the surrounding rural areas one can find them. Of course, the extraction of the raw materials must be done in a sustainable manner, and physical planning and management are necessary. Local residents, craftsmen, and local companies can be involved in the procurement of raw materials and their processing into ready-to-use building materials. Preferably, the (future) residents are involved in designing their houses by creating the floor plan, choosing the building materials, and participating in the house construction or the home improvement. By doing so, the residents can reduce the costs of their dwellings, which is always the underlying purpose of self-help housing and self-reliance [5]. NGOs should involve the residents in parts of the building processes and simultaneously offer technical assistance, training, and courses in different disciplines of construction. This can be done also by private companies, but NGOs are often the prime actors herewith. However, there are some good examples of corporate involvement in house construction. For example, the program Patrimonio Hoy, of a Mexican cement company, developed a social aid program that offers building materials and technical assistance to self-builders and credit for home renovations. The program benefited more than 250,000 households in 22 Mexican states, [6,7] and it is also working in some other Latin American countries. Another example is in Malawi and other East African countries where a cement company offers the following durable earth and cement building solutions for affordable housing: earth brick production, training on soil analysis and mix design, and project technical assistance. The product is called Stabilized Compressed Earth Bricks [8]. The municipal training program ‘Escuela Taller’ in León, Nicaragua offers training possibilities for young individuals, among others, in basic carpentry, masonry, electricity and welding. Practical training takes place in inner city renovation projects restoring traditional style housing [9]. Comparable education programs are given by vocational training centers. Sofonias Nicaragua – a social companyhas launched a ‘classic apprenticeship program’, where youngsters are taken under contract for two years, at a salary comparable to a mason’s helper [10]. All this should be stimulated strongly. The involvement of local and regional vocational education is of utmost importance to the application of new bamboo and earth technologies. When local residents are involved as much as possible in home construction, and when they acquire knowledge and skills, one can speak of sustainable socio-economic development.

Promising Building Materials for Low-cost Housing Construction

The construction aspect must always be well attended, meaning it requires adequate foundations and structures. Below, attention is given to the following five groups of building materials.

1. Bamboo and timber

2. Compressed earth bricks/blocks

3. Adobe blocks

4. Interlocking blocks of recycled materials

5. Improved concrete panels.

Bamboo and timber

Bamboo has a lot of potential as a building material for low-cost housing. In various countries in Latin America and Asia, bamboo housing is customarily a rural phenomenon, based on local production and processing of the raw material. If bamboo houses were to also become accepted by city dwellers, there would be a need to develop vast bamboo plantations to provide the urban housing markets with bamboo for construction. Bamboo can be used in countries where it has a natural presence. One must choose the right sort of bamboo. For example, the species Guadua angustifolia is native to South America and has the best properties for construction. However, a bamboo housing study conducted in Guayaquil, Ecuador [11], found that gradually after a site has been developed, e.g. by the provision of paved roads – the squatters’ bamboo houses are transformed into concrete houses. This is because the residents eventually prefer a house built with bricks because bricks have a higher status. In a similar example, the NGO IDESAC in Guatemala tried to cooperate with families in rural areas to stimulate house building with bamboo. They found, however, that the concerned families see bamboo as ‘the poor man’s construction material’, and thus they don’t want to use bamboo for their houses (according to Arch. Luis Estrada of IDESAC, interviewed by the author in August 2016). So far, the use of bamboo as a construction material in urban settlements is still limited, but the material is sustainable (in an eco-friendly sense) and a bamboo house is earthquake resistant if constructed well. The construction of complete houses of bamboo, with a strengthening framework, requires technical expertise. If it is done by self-builders, there should be technical assistance by specialized carpenters. Bamboo must be treated with preservers, often chemicals, to prevent termites from destroying it. If bamboo is not treated, the material must be replaced within 5-10 years. If the material is treated well and is under the cover of a roof, it can stand 30-35 years [4]. It is recommended that the outer walls of the bamboo homes are plastered, in order to give protection against the influences of the climate and insects. If the external walls of the house are completely plastered, the houses can look like an ‘ordinary’ house. Currently, there are some promising technological innovations concerning the construction of homes with bamboo. For example, there are strengthening corner joints, and pre-fabricated wall panels that can be used for exterior walls. It is to be expected that there will be more of such innovations on building homes with bamboo. The use of bamboo as a major construction material in dense urban areas is not to be expected, but dividing walls and woven bamboo mats for covering floors can be used in urban housing too.

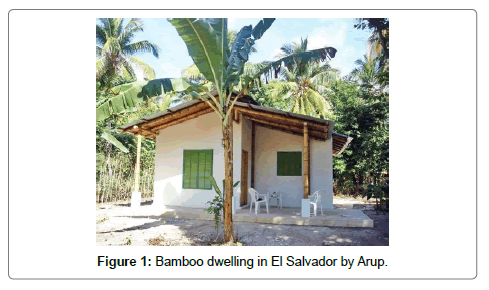

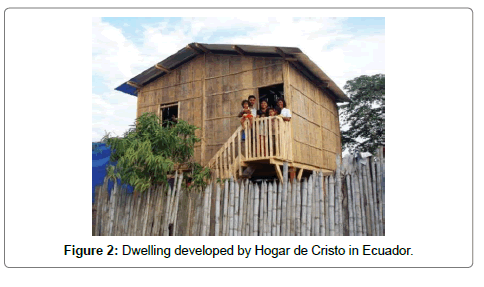

In Costa Rica the National Bamboo Project (1986-1995) started as a new technological approach to preventing deforestation. The idea was to replace the use of wood with an alternative, cost-effective and seismically sound building material. Initially, 700 low-cost houses were built and 200 hectares of bamboo have been cultivated. The project fostered the sustainable use of bamboo as a raw material for an indigenous housing program and for the industrialization and marketing of by-products. Partly due to political reasons, this low-cost housing program did not continue. Another large scale program is to be found in Ecuador, where the NGO Hogar de Cristo has built and delivered (to the year 2012) around 265,000 traditional bamboo homes [4]. This NGO has created new housing models that can be built easily and rapidly. One of the prototypes is the ‘MACAHO’ model, which is a new technology combining high-strength and durability-treated wood, which supports modules consisting of cured reed, designed so the house can grow as the family grows. The basic module of the MACAHO house costs USD 2,045. A completed house with 2 rooms, kitchen, bathroom, etc., will cost USD 4,300 [12]. Another new housing model was developed by Arup (consultancy) in cooperation with technical institutions and aid organizations. It combines traditional technology with modern engineering principles. It's more resilient in the event of an earthquake, using sustainable materials including timber and locally grown cane. Research, community workshops and interviews ensured the new homes met the needs of local people. A building training program enables local families to learn skills in building earthquake-resistant houses. The resulting house is earthquake resistant and community participation was encouraged [13]. All these examples indicate that there is a trend towards the combination of wooden structures and bamboo materials and panels in basic house production. It should be noted, however, that the structures as well as elements of many houses, including expensive ones, are also built completely of bamboo.

Using timber in house construction is comparable to using bamboo, but it is easier to handle. The use of timber in construction is customary worldwide. A structure of timber can be combined with bamboo walls that will be plastered, and of course also with other materials. One must take into account transportation costs and the replanting of trees in the area where the wood was harvested. Building completely wooden houses in dense urban areas is not recommended because of the danger of fires; this aspect must always be considered and controlled also in non-regulated urban areas. Making frameworks is essential in earthquake areas, and in areas that can flood houses can be built on stilts (Figures 1-3).

Compressed earth blocks

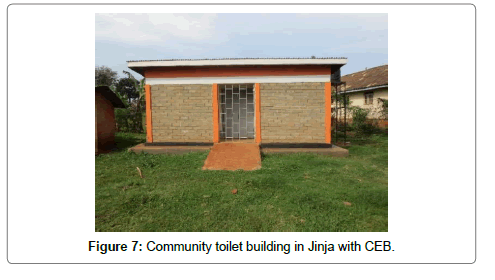

Traditional building materials such as clay, loam, and sand can be used in new ways, such as with uniform, rectangular compressed earth blocks (CEB) and (interlocking) stabilized soil (earth) blocks (SSB or ISSB). In both systems, the use of cement is absent or minimized. In SSB, earth can be mixed with a low percentage of cement or lime. As a professional-grade mix preparation is necessary, a field lab and training of the labor force are required. CEB and SSB blocks are used for the construction of houses, latrines, schools, community facilities, etc. These earth technologies are being used in a series of countries in Africa, Asia and Latin America. Due to their mass, walls made from CEB have good thermal features, reducing heating and cooling costs. If constructed well, buildings made with CEB can be sustainable and durable. This implies that technological improvements can be used small-scale and at the local level, potentially contributing to local economic development. UN-Habitat stimulated in Darfur an early recovery of stabilized soil blocks for sustainable urban growth [14]: “The stabilized soil block production process is a technique consisting of mixing at least 5 per cent cement (less than that of normal bricks) or lime stabilizer with soil and a minimal amount of water (and possibly waterproofing agents). The blocks are compressed using steel hand press machines or mechanical presses machines to produce good quality blocks. Compared with burned bricks, the benefits of this technology include greater energy efficiency and savings on money and on firewood. Other good qualities include the ability for local production; flexible sizing; labor intensiveness that can create jobs; as well as good stability and strength”.

An additional technology that can also be locally produced and applied is the interlocking stabilized soil blocks. This material and method of construction has the advantages of low cost and minimal environmental impact, while providing comparable or better quality to conventional fired brick construction, ‘normal’ SSBs and CEBs [15].

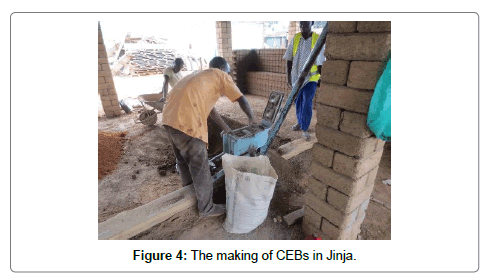

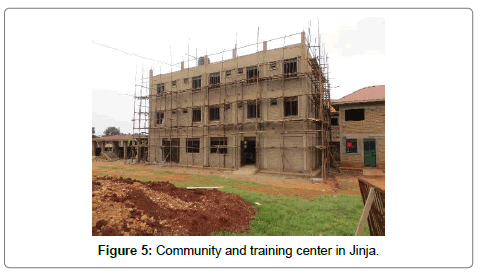

Building materials facility for CEBs and community training center in Jinja, Uganda

The National Slum Dwellers Federation of Uganda (NSDFU) and the NGO ACTogether, both working for and with the urban poor in Uganda, support a key project in the city of Jinja, concerning sustainable housing and the production of building materials. Both organizations jointly facilitate local initiatives to improve the daily living conditions of the poor in Jinja, in particular through the establishment of community savings groups [16]. These initiatives include the establishment of a community center in Walukuba East Settlement, which aims to accommodate of the following activities for the low-income groups living in the informal neighborhoods of Jinja:

• The provision of space where local slum dwellers can meet, or live temporarily;

• Teaching and training facility for people who want to improve their house-building skills;

• Vocational training for income-generating activities.

Various workshops are also given to federation members who come from outside the city of Jinja. For the accommodation of these members, guest rooms have been built on the two upper floors of the community and training center. The facility in Jinja produces sustainable building materials with which homes can be built or improved by means of selfhelp. The facility sells the building materials directly to the households, which may obtain technical assistance for the proper and professional use of the materials in self-help construction. The project provides training in construction skills to aspirant construction workers and self-building residents. Students of local technical schools can also do internships in this project and thus acquire practical skills. This center is also called a ‘self-reliance center’ (SRC) according to the model that was developed in South Korea [17]. The aim of this SRC is to support self-reliant communities which are able to create incremental housing elsewhere in the city. For the operation of the SRC, community members from informal settlements need to actively participate in the programs and mobilize their collective labor toward such efforts as producing bricks or concrete blocks or elements, and participating in construction or improvement (Figures 4 and 5).

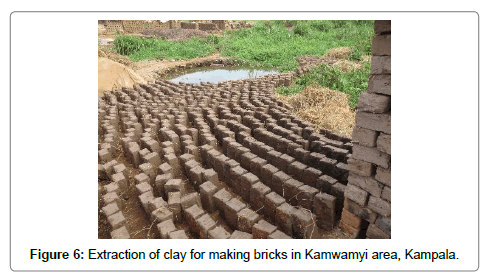

Sustainability aspects of compressed earth blocks: In Uganda, the walls of houses are usually built with fired bricks. This means that clay is extracted from the soil, and that the bricks are fired in kilns. Wood is used to fuel the kilns, which leads to deforestation and the emission of CO2 among other things. This is far from sustainable, certainly because this happens on a large scale and also in urban areas, such as in the district of Kamwanyi, near Kampala’s city center. Moreover, the process results in uneven bricks and 20 percent waste as the bricks closest to the heat source are over-fired while those farther away are under-fired. Building walls with uneven bricks leads to excessive use of mortar. An alternative environmentally friendly and cheaper way of building walls is through the use of compressed earth blocks (CEB), put together from locally mined sand and loam, which is mixed with a (low) percentage of cement or lime. Although the work is mostly done by local people, it requires a certain amount of knowledge and training. There is an urgent need for funds to serve a large amount of households who need a core house or home renovation in the area. One might use NSDFU funds, which is called ‘Suubi and Loaning’. Besides using their own savings, households in Jinja might obtain small loans and build quicker with the help of the building materials and training facility (SRC) as described above. This means that a fund for the scaling up of house construction and home renovation in Jinja is necessary. The NGO ACTogether is also working with NSDFU to find new financial opportunities. All actions mentioned might lead to a new phase of their Jinja project, namely, a more intensive use of the existing building materials facility and community training center. In this respect, the production of climate friendly compressed earth blocks and the needed housing finance are central [14] (Figures 6-8).

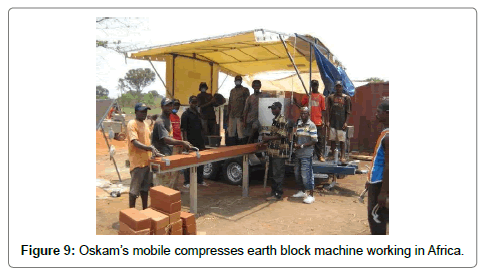

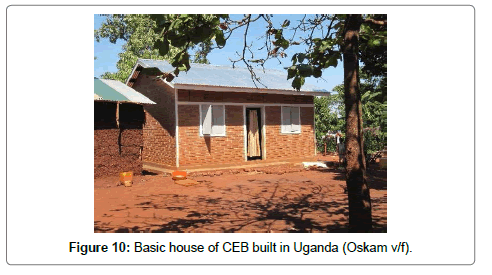

Technological development of CEBs: Technological development of compressed earth blocks (CEBs) can be achieved by using CEB machines to make the bricks or blocks. This ensures the bricks are consistently sized and highly pressure resistant. Another advantage is that bricks can be produced in larger volumes. A CEB machine is costly and demands the use of fossil fuel, but only a very limited amount compared to fired bricks. Homes made with CEBs have better moisture regulation and are more comfortable than homes made with hollow concrete blocks. Most producers of CEB machinery also offer training for the construction workers. Oskam v/f sells a mobile set of machines for the production of compressed earth blocks consisting of a press, mixer, and pulveriser, spraying system, screens and dosage equipment. The machine can be transported by any 4-wheel drive vehicle. Production capacity is 360 blocks per hour, for a block size of 295 × 140 × 90 mm. Operation of the CEB machine requires the labour of 8-10 people. The machine can be operated anywhere, with a separate mobile generator. With this machinery, several low-cost housing projects – consisting of houses of 35 m2 – were built in Jinja, Uganda. In a project of around 300 homes, the costs were USD 3500 per unit. Housing was executed with the help of NGOs, and local workers and residents were trained to be brick producers and brick layers. Load-bearing walls can be made from these compressed earth bricks, and eventually more urban housing complexes can be made with them. A thin bed of earth mortar is needed to make a strong load-bearing wall. Concrete pillars and plastering are not necessary for this type of housing [18]. The houses that can be built with ‘Oskam’ CEBs are more expensive than the houses built with handmade bricks in Jinja, Uganda, but are probably of a higher quality. In addition, there are other producers of CEB machines, which offer machines that produce compressed earth blocks of various shapes, sizes and features (Figures 9 and 10).

Adobe blocks

Adobe blocks are made from a mixture of clay-based soil, water, and sometimes straw. Wet adobe is formed into bricks and then laid out to dry in the sun for several days. The greatest disadvantage of adobe is its vulnerability to water and rain. Sometimes adobe is locally regarded as ‘the material of the poor’, which may restrict its application [19]. Adobe blocks are used for the construction of walls, with wet adobe serving as the mortar. Methods of construction vary considerably by climate. Most homes have a coating of adobe on the outside to create a smooth surface, which can be painted. Adobe is applicable in rural areas but in urbanizing areas, with higher densities, the use of this sustainable material is not very common.

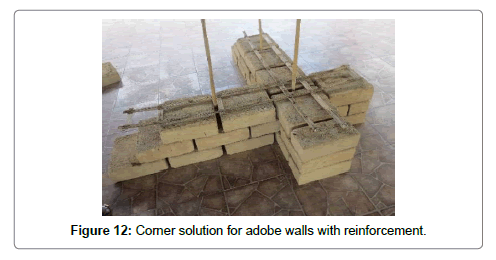

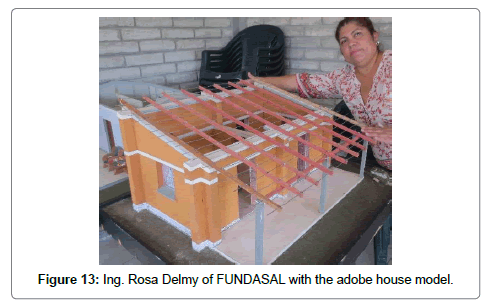

Building blocks of adobe for housing in El Salvador: El Salvador is one of the countries in Central America where the indigenous population traditionally has extensive experience in building houses of adobe. It is a material that is found and shaped in the rural villages. Governments, aid organizations, and the mutual aid cooperative movement FESCOVAM (Salvadorian Federation of Housing Cooperatives with Mutual Aid) promote the use of adobe because it is considered to be a sustainable and durable building material, in comparison with the use of concrete, concrete blocks, and fired bricks. If adobe block houses are built correctly, they offer sufficient insulation and can be earthquake resistant. Other benefits of adobe bricks are that no cement is used and less CO2 is emitted. The local and traditional construction methods in rural and isolated areas can be well-preserved and re-developed. For some years, the NGO FUNDASAL (Salvadorian Foundation of Development and Minimal Housing) has invested heavily in the development of adobe building blocks and corresponding construction techniques, to renew the local knowledge and promote contemporary applications of adobe for house construction. It is crucial that the quality of the homes improves, and the cost of the building materials lowers. When one builds houses with adobe as the building material, the raw materials should be available in the vicinity of the building site. The quality of the adobe blocks should be checked and monitored, for example with regard to the dimensions of the blocks (30/30/10 cm), the making of good mixtures, the application of suitable construction techniques, earthquake-resistant building techniques, and proper plaster or stucco work on the walls. The latter can be done in different earth colors. FUNSDASAL already has this knowledge available in El Salvador and can offer instructors and trainers for building teams, as well as small mobile laboratories for experiments with soil types and mixtures (sand, clay, mud, granular, glue, lime) in remote areas. The plasticity and strength of the blocks and mortars are crucial. To reinforce houses with adobe bricks (to make them earthquake-resistant), the walls should be built with internal reinforcement with steel bars and/or organic vertical and horizontal bracing. The finishing of the walls with stucco or plaster is important to fill in the cracks, crevices, and cavities. This will help to protect the population against insects, such as the chinche picuda, which is a transmitter of the ‘Mal de Chagas’ disease in some rural areas. The plaster is also necessary to protect the walls from the rain (outside) and humidity (inside). One should be able to make good mixtures from different ingredients, if possible from local raw materials. Professional assistance can help ensure good execution of the entire process, including the manufacturing of the blocks, the construction of the houses and the finishing of the walls. This can be provided in a way that empowers the local workers and the population. Engineer Rosa Delmy is the head of the Construction Department of FUNDASAL and is leading the development of various new earth technologies and concrete products [19] (Figures 11-14).

Interlocking blocks of recycled materials

Interlocking bricks or building blocks can be used for building walls. These bricks are available or are being developed in different shapes and sizes, for example by using the principle of the well-known Lego blocks, or using comparable interlocking building systems. If accurate dimensions of these bricks can be reached, they can be clicked onto each other, and thus need little to no cement or mortar. If this is possible, the blocks can even be reused in another building. Another advantage of these building blocks is that the homes can be built from them quickly and by a committed team of unskilled workers, volunteers and/or future residents. Moreover, it can be used as building material for temporary houses, or emergency housing. The building blocks have a good insulation value comparable to the common hollow concrete blocks. Interlocking bricks can be used as an alternative to fired bricks, and they are far more sustainable. The building material can be made of concrete in the form of hollow concrete building blocks, solid soilcement blocks, concrete made of recycled materials such as bricks, and recycled plastics, or recycled plastics mixed with organic materials like rice husks.

Below two examples of promising building materials and construction techniques are presented. These examples are relevant to the development of sustainable building materials for low-cost housing. In both cases, the technological development requires financial support, in order to use the materials and techniques more widely. Help from technological institutions and NGOs may be possible, especially for small-scale entrepreneurs with a social commitment, who develop sustainable new building materials.

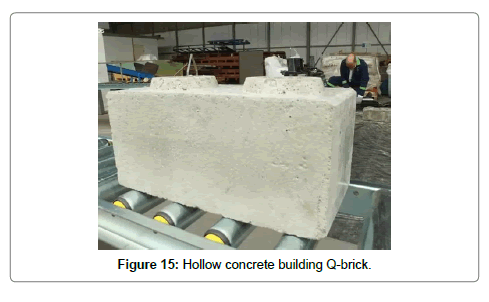

Concrete building blocks of recycled debris, in Haiti: The ‘Mobile Factory’ is a technical concept capable of converting debris into concrete building blocks known as ‘Q-bricks’, which can be clicked together like Lego blocks. Multi-story houses can be built with these blocks as well. Victims of war or natural disasters can quickly build core houses and rebuild their houses and communities, with external technical, organizational and financial assistance. The realized cottages (2016) of 18 m2 and 24 m2 respectively, are prototypes of emergency housing that can be built with the Q-bricks. The bricks are produced locally in a mobile production unit or ‘mobile factory’, consisting of two converted shipping containers. The Mobile Factory’s strategy will facilitate ongoing housing production in Haiti, where six years after the big earthquake of 2010 the land is still covered with 25 million tons of construction debris. This debris can become the raw material for the equivalent of thousands of affordable homes [20].

The first location is on the edge of Port-au-Price on 6,000 m2 of land. Unskilled and partly unemployed family members create this housing project themselves with technical assistance delivered by specialists and craftsmen. A number of knowledge institutes and private corporations are involved in this initiative. The local group of 30 families has a commitment with a newly established housing corporation called ‘Petit Paradis’, which is owned by the (Dutch) Haiti Housing Community S.A. and two Haitian partners. The Mobile Factory transforms construction debris into certified building materials or Q-bricks for the houses that are earthquake and hurricane resistant. Petit Paradis establishes regulations and provides financing for housing, local builders and other building materials. Heads of households pay one third of their monthly salary to the housing corporation that provides housing finance for the houses. Furthermore, during the construction phase, every household provides a worker, who is trained to become a construction worker. He or she obtains a salary, of which one third is used to pay for the houses’ pay-off arrangement. The homes are obtained by the families on rentalpurchase basis with a term of 10 years (Figure 15).

Blocks of recycled plastic and rice husks in Vietnam: As basic raw materials for building blocks, two materials are used:

1) Recycled plastic in the form of polypropylene and

2) Rice husks (or hulls) which are a by-product of rice cultivation [21].

The building materials (RHPP) can be manufactured sustainably. Rice husks are the hard protective coverings of grains of rice. After they have protected the rice during the growing season, rice husks can be put to use as a building material, insulation material, or biofuel. In Vietnam, the rice husks are usually burned in the open air or are just thrown away in rivers. The new building material RHPP is used to construct houses supported by a solid foundation and a steel framework. The materials are produced in Ho Chi Minh City by Trong Danh Co. The components of these ‘TD building materials’ are rice husks, polypropylene plastic, baking powder, catalyst, and other additives. The resulting material is resistant to fire and provides heat insulation and sound insulation. Moreover, it is waterproof and lightweight, which reduces transport costs and makes it easy to handle the materials during the construction. RHPP is produced in specially designed machines that perform all of the necessary operations, namely mixing the raw materials, heating them, mixing them again and finally pressing the end products. The results are sustainable building materials for housing (blocks and roof tiles). These building materials and the light building construction techniques together enable people to quickly build basic houses in areas affected by natural disasters, and in areas designated for social and low-cost housing in rural and peri-urban districts. These building materials can also be used to construct floating homes in delta regions. All of this demands development funding and collaborations with technological institutes and other parties. For example, scientists could investigate whether polypropylene could be replaced by bio plastics, to create an entirely organic material that is suitable for housing. The ‘TD Housing concept’ is suitable for using in earthquake-prone areas, and floating homes can be made of it.

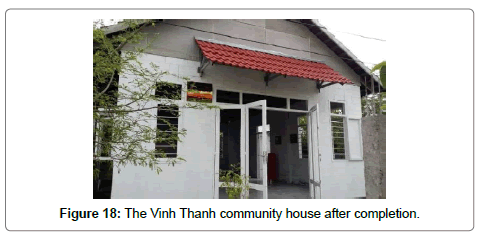

In 2014, Trong Danh and the Australian foundation for the peoples of Asia and the Pacific (AFAP) built several family homes and a community center in the village of Vinh Thanh, Soc Trang Province, Vietnam. The community participated intensively in the construction (Figures 16-19).

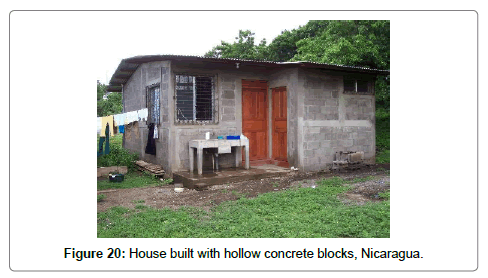

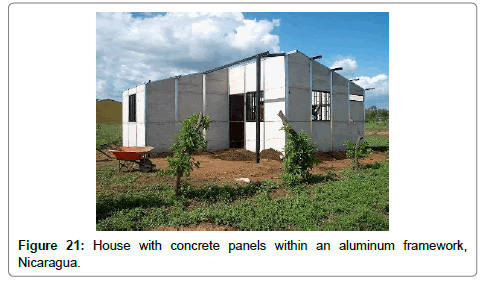

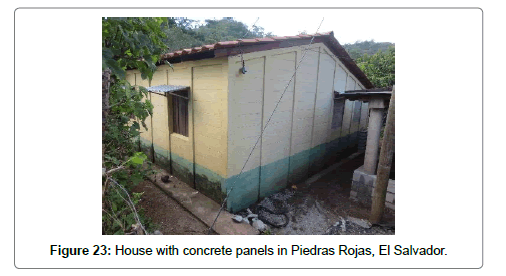

Improved concrete panels

Good-quality, basic homes can be built of hollow concrete blocks with a framework. Traditionally built homes can be made with hollow concrete blocks so that they are earthquake resistant and have good insulation values. This is a durable building material that is used on a very large scale. If these blocks are locally produced using local raw materials such as sand and pebbles, the material can be seen as rather sustainable. Basic homes can be built faster with concrete panels that are sandwiched between concrete piles and columns. The piles must be well anchored in the foundation and covered with horizontal bars (called the ‘crown’) that complete the framework of the building. The frameworks can be made of wood (timber-framed homes), bamboo, concrete, aluminum, steel, etc. If constructed correctly, these homes are earthquake resistant. Within the frameworks, the space between the posts, columns and beams can be filled with different kinds of building materials, which don't have a bearing function in the house’s structure. The materials to build the walls between the posts and beams can be masonry, compressed earth bricks, wood, or bamboo; the walls can be finished with plasterwork but that is not necessary for the construction. In tropical regions, a high insulation value for the walls for temperature as well as sound is desired by the residents. The NGO FUNDASAL in El Salvador is a partner in the TAISHIN research project [22] which is promoting earthquake-resistant technologies with prefabricated columns, panel blocks and elements. These are necessary for the building of safer homes in El Salvador, and thus they could improve the quality of life of the most vulnerable people who are constantly affected by disasters. The goal of the national government is improving the technology of construction and the system of dissemination of the seismic-resistant social housing, which started in 2009 [23].

The technical quality of the built houses is high and they can survive earthquakes up to a certain magnitude. The construction system has a short construction period, and the residents can provide the labor for the house construction, under professional supervision. Technological improvements might take place with the use of ferrocement or ferro-concrete (a system of reinforced mortar applied over a layer of metal mesh, woven expanded-metal or metal-fibres), and lightweight concrete, which have good strength and resistance features. Panels of ferro-cement for example are well known in Cuba and have been used there for housing for some decades. There was another application directly after the 2011 earthquake in Haiti, when an EcoSur team of Nicaraguan technicians and their local trainees started with the erection of solid core units made of ferro-cement panels [24]. When used in house construction in developing countries, it can provide good resistance to fire and earthquakes. Lightweight concrete can also be applied, probably more in the urban areas than in rural areas (Figures 20-23).

Technical Assistance and Technological Development

The building materials described in this article show some new and sometimes experimental features, but in all cases professional attention is needed for the further development of the (sometimes) traditional building materials and techniques. Herewith, technological development demands institutional support and new pilot projects. In the near future the institutional support should be directed also to sustainable building materials that can be applied in urban areas. The actual questions stated in the introduction are addressed below:

How can technical assistance for low-cost housing be organized?

The participation of residents is of great importance concerning low-cost housing. Because the concerned households construct parts of their houses by themselves, technical assistance in respect of housing, design, choice of building materials, construction techniques, etc., is of the utmost importance. This should be carefully organized by governments, aid agencies, or by both in a good cooperation. In this article some examples are presented in which technical assistance and training for self-builders and home-building groups is carried out by NGOs and relief organizations. Examples of these are FUNDASAL, IDESAC in Central America and NGOs related to Slum Dwellers International (SDI) in Africa and Asia. Many aid organizations are present locally, and can be involved so that the proper building materials can be chosen and used in low-cost housing in cooperation with local stakeholders.

How can residents be involved in improving their homes, in order to lower the costs?

Most of the building materials described in this article can be used by households that want to build their own homes individually or in small groups, which is mostly done to lower the building costs. These groups might be involved in the production of local building materials as well. If properly organized, groups of residents can take advantage of housing projects that are initiated by local authorities and charity organizations. Some materials are more durable than others. For example, elements and building blocks made of concrete are durable but not always ecologically sustainable. From the perspective of social sustainability, most of the projects described are beneficial, especially the ones that used mutual-aid and obtained technical assistance. The lack of financial aid, in the form of subsidies and loans, is often a constraint for development amongst others in the case of Jinja, Uganda.

Why is building control at the building site necessary?

Technical building control must always be provided in order to create good quality (i.e. long lasting and environment friendly) housing. Disinvestments must be prevented. Herewith, the technical NGOs and the local authorities have their own tasks. Municipal construction supervision is the capstone of building control. The provision of technical assistance in advance is the most effective way to prevent failures in the construction and disinvestments. This is the ideal situation, but local government building control is sometimes lacking.

How can technological innovation related to sustainable building materials be supported?

Technological innovation is often related to the needs of local actors such as residents, local producers of building materials, local craftsmen, and small construction businesses. These needs include the following: information, research, and education and training for (local groups of) households, students, entrepreneurs, distributors, traders, lenders, and local government's officers. Technological innovation should continue in all countries and be applied and developed locally as much as possible. Local experiences must be shared, so that in other regions and cities one can easily benefit from the obtained experiences. This means that the results of experiments and pilot projects must be examined, documented, and published as ‘open accesses.

What is the role of governments and institutes and private actors in product development?

National and regional institutes play a very importance role in the development of sustainable building materials, by facilitating knowledge transfer to (groups of) homebuilders, small business owners, etc. Government institutions as well as educational and research institutes can do this by sharing their experiences in other regions and with other institutions. This article shows that private initiators, including entrepreneurs, can take the initiative and provide technical assistance. In such cases, cooperation with other stakeholders and sharing new technologies and visions is necessary. Urban planning and building control always remains a task of the local government.

What is the role of aid organizations, NGOs and other actors concerning technical assistance?

Aid agencies play a vital role as well, for without their involvement community development seems to be almost impossible. These agencies can be (inter)national charity organizations that act as donors, but locally operating technical and social aid organizations, mostly NGOs, do most of the work with the residents and the residents organizations. Land local authorities can stimulate and facilitate that. The cooperation between the different aid organizations is of the utmost importance. The private construction companies are able to play a certain role in the development of low-cost housing in developing countries, but then, local working NGOs are also involved because the residents trust them.

Conclusion

All of the building materials described above is sustainable in a certain way. The possible applications of these materials depend on local and regional circumstances. In each country or region, the specific conditions of the soil and the plants and trees, etc., can be examined, to find suitable soil for bricks and plants (bamboo, etc.) for the making of building materials. It is beneficial if the use of wood for housing is reduced, either by using an alternative material with similar properties (bamboo instead of timber) or by producing bricks made of soil so wood is not burnt to fire the bricks. Taking these steps against deforestation helps to achieve climate objectives. The creation of bamboo plantations can also help herewith.

The earth-block technologies are emerging in many countries and in general this is well supported. This development creates opportunities for the local extraction of raw materials for useful and cheap building materials that can be processed locally in the housing construction industry. By providing vital technical assistance, technical aid teams enable residents to produce and apply sustainable building materials for the construction of their homes. Technical assistance can be provided by aid organizations such as housing NGOs, local authorities, and building materials producers and traders. Local government building control is always a capstone in the building process. The available power of local communities is to be used by the local authorities in their housing policy to stimulate the construction of adequate (low-cost) housing for their citizens.

There are several limitations regarding the application of the presented building materials. For example, there may be organizational, political, and financial constraints. Aid agencies can often play an important role, in several respects. However, the authorities should create the right conditions. In each country, a technological institute can follow the technical developments and investigate the possibilities and limitations of certain building materials and aid-giving models. Due to the growth of cities and urban regions worldwide, in the future the focus of the promotion of sustainable building materials will increasingly be on semi-urban applications, in projects with higher housing densities. This presents a challenge for the improvement of sustainable building materials. Herewith, technological development and increasing the scale of the production of these sustainable materials are important.

References

- UN-Habitat (2016) World Cities Report 2016. Urbanization and development Emerging Cities. Nairobi UN-Habitat.

- Choguill C (2006) The search for policies to support sustainable housing. Habitat International,pp: 143-149.

- Bredenoord J (2016) Sustainable Housing and Building Materials for Low-income Households. J ArchitEng Tech 5: 158.

- UN-Habitat (2012) Going Green A handbook of Sustainable Housing Practices in developing countries. Nairobi: UN-Habitat.

- Bredenoord J, Lindert VP (2014) Backing the self-builders assisted self-help housing as a sustainable housing provision strategy. In: Bredenoord J, van Lindert P and Smets P (eds.) Affordable Housing in the Urban Global South, seeking sustainable solutions. Routledge, London, New York, USA.

- Bredenoord J, Montiel CL (2014) Affordable housing for low-income groups and urban housing challenges of today. In Bredenoord J, van Lindert P and Smets PAffordable Housing in the Urban Global South, seeking sustainable solutions. Routledge, London, New York.

- CEMEX Programa Patrimonio Hoy.

- LafargeHolcom ‘Durabric’.

- Municipality of León, Nicaragua. ‘Escuela Taller’.

- EcoSouth. Dual education. Switzerland Grupo Sofinias.

- Livingston M (2009) Bamboo housing and the Mangrove of Guayaquil. Tennessee Institute of tropical architecture, University of Tennessee.

- Cristo HD, Ecuador Catálogo, Viviendas Hogar de Cristo.

- House of bamboo in El Salvador.

- UN-Habitat (2012) Economic Benefits of Stabilized Soil Block Technology in Sudan. Nairobi: UN-Habitat.

- UN-Habitat (2012) Human Settlements in Crisis. Interlocking Stabilized Soil Blocks. Appropriate earth technologies in Uganda. Nairobi: UN-Habitat.

- Bredenoord J, LindertVP (2015) Building Materials Facility and Community Training Center in Jinja, Uganda. Utrecht NLD Housing Research Group.

- KRIHS (2014) Case Studies on the Incremental and Affordable Housing. With practical lessons from Jinja, Uganda and Malabon City, Philippines; implications from Korea. Seoul: Korea Research Institute for Human S ettlements.

- OSKAM v/f ND.

- Hashemi A, Cruickshank H, Cheshmehzangi A (2015) Environmental Impacts and Embodied Energy of Construction Methods and Materials in Low-Income Tropical Housing. In Sustainability 7: 7866-7883.

- The Mobile Factory (2016) Petit Paradis Haiti. PowerPoint Presentation. AmsterdamThe Mobile Factory.

- TrongDanh Co (2015) Low-cost housing with sustainable building materials for Vietnam; using recycled plastic and rice husks. TrongDanh, with PUM: Ho Chi Minh City, Vietnam.

- TAISHIN and Viceministerio de Vivienda y Desarrollo Urbano-VMVDU (2011) Manual Popular de Construcción de una vivienda con Mampostería de Ladrillo de suelo cemento confinado. San Salvador: VMVDU, and its partner organizations.

- Viceministerio de Vivienda y Desarrollo urbano-VMVDU (2011) Manual Técnico Sistema Constructivo Bloque Panel. San Salvador: VMVDU, and its partner organizations.

- Eco South A creative solution for fast, durable and affordable reconstruction after the Haiti earthquake 2010. Light weight ferro-cement elements. Switzerland: GrupoSofinias.

Relevant Topics

- Architect

- Architectural Drawing

- Architectural Engineering

- Building design

- Building Information Modeling (BIM)

- Concrete

- Construction

- Construction Engineering

- Construction Estimating Software

- Engineering Drawing

- Fabric Formwork

- Interior Design

- Interior Designing

- Landscape Architecture

- Smart Buildings

- Sociology of Architecture

- Structural Analysis

- Sustainable Design

- Urban Design

- Urban Planner

Recommended Journals

Article Tools

Article Usage

- Total views: 79224

- [From(publication date):

April-2017 - Jul 15, 2025] - Breakdown by view type

- HTML page views : 74363

- PDF downloads : 4861