Studies on Utilizations of Floral Waste by Conversion to Value Added Products

Received: 10-Sep-2021 / Accepted Date: 30-Nov-2021 / Published Date: 07-Dec-2021

Abstract

Ethiopia now has over 130 active flower-growing farms and is the fourth largest non-EU exporter of cut-flower to the European Union and the second largest flower exporter from Africa. Waste disposal is a major concern in the world. Diversity in the content of waste create problem in its reduction. The floral waste is directly disposed into the rivers, lakes and open space which has bad impact on the water quality as well the living organisms present in the waters. The impact on land is eminent spatially when it is in large size. Conventional methods of floral waste disposal include disposal in nearby water sources or in the landfill, incinerations, biogas and composting. The methods create environmental pollution and emission of greenhouse gases into the atmosphere due to aerobic decomposition of the waste material. However, now there are modern approach to convert the floral green wastes into value-added products such as cardboard, carton (packaging materials) and some other useful but still biodegradable products. In this study the natural paper from floral green waste with bleaching agents of (Calcium carbonate, Sodium carbonate, Glue and Magnesium sulphate) used meet the standard of ISO 6519:2016 about Basic Paper for Laminated Wrapping Paper within the parameter of pH and water content and ISO 8218:2015. All of the various papers from floral green waste meet the standard of water content stated by SNI. The result showed that the type of bleaching agent affects the pH value of the paper produced. The pH value for CaCO3 as Bleaching is 7.21 which is the highest value. But for Glue as Bleaching the value stands at 6.70 which is the lowest value. As for commercial paper the value was 7.55. Papers from floral green waste with all bleaching agent used meet the standard of ISO 6519:2016 about Basic Paper for Wrapping Paper on the parameter of pH and water content. The results show that natural wrapping paper from floral green waste with Na2CO3 as Bleaching has the closest characteristics of commercial wrapping paper. It has pH of 6.95, the water content of 7.12%, gram mage of 356.67 gram/m2 and the brightness level of 20.45%.

Keywords

Floral green waste; paper; waste disposal; bleaching agent; environmental pollutions

Introduction

Background and Justifications

Waste disposal is a major concern in the world. Diversity in the content of waste create problem in its reduction. The floral waste is directly disposed into the rivers, lakes and open space which has bad impact on the water quality as well the living organisms present in the waters. The impact on land is eminent spatially when it is in large size [1]. Conventional methods of floral waste disposal include disposal in nearby water sources or in the landfill, incinerations, biogas and composting. The methods create environmental pollution and emission of greenhouse gases into the atmosphere due to aerobic decomposition of the waste material [2].

Another alarming situation concerning flower waste is that degradation of floral waste is an extremely slow process as compared to degradation of kitchen waste [3]. Hence proper and eco-friendly process for floral waste treatment is required. Studies reveal the management and utilization of flower waste can have been carried out.

Ethiopia now has over 130 active flower-growing farms and is the fourth largest non-EU exporter of cut-flower to the European Union and the second largest flower exporter from Africa [1]. Floriculture has contributed to 225 million dollars, or 80 percent of the total foreign revenue earning of the sector. The majority of the production is made of roses (about 80 percent of the production), and the country is noted for the high quality, long stems, large buds and vibrant color of its roses [1]. In addition to the rose farms, five farms are engaged in the production of cuttings and eight farms produce a variety of other types of flower crops, including gypsophilia, Hypercom, iminium, chrysanthemum, carnations, static, pot plants and a range of summer flowers. Also, there are very few reports on the management of floral wastes by conversion to value-added products [1].

The industry uses too much pesticides and chemical fertilizers which damage the environment. Too much pesticide is getting into water bodies damaging the biodiversity and excessive chemicals are killing useful organisms in the soil. Environmentalists are also concerned, that waste materials will damage the environment – will get into the soil, into water bodies or be used by people and cause serious damage. From the many number of horticulture industry in Ethiopia in which we conducted assessments to figure-out to what exact problems which they are facing which can also is our research area is green waste generating in extremely huge amount without any valid benefits posing environmental and socioeconomic problems [1].

These flower wastes are thrown into water or dumped into landside causing water pollution as well as environmental pollution [4]. Many of floral industries throw floral wastes directly in the water bodies. Such disposal of waste creates problems like eel and worm development, water and land pollution and foul odor. Solid waste and littering can degrade the physical appearance of water bodies and cause deterioration of water quality. The floral waste generated gives a filthy look to the streets and roads and also distorts the image of Ghats along the rivers.

There are some standard disposal and treatment options, landfilling; incineration which is controlled combustion of waste materials to a non-combustible residue or ash and exhaust gases. In USA and Europe, incineration is preferred for many organic hazardous and toxic waste streams. In land treatment final state of the waste is disposed by making intimate contact with the soil [4].

Degradation of floral waste is very slow process but it causes cell and worm development at the sites. Floral waste degradation also increases the demand for agro-based products. Solid wastes comprise of various organic and inorganic materials, covering or peels of various vegetables, fruits and cooked materials. It facilitates the proliferation of various group of microbial flora, which may be pathogens [5].

However, now there is a modern approach to convert the floral green wastes into value-added products such as cardboard, carton (packaging materials) and some other useful but still biodegradable products. Only certain parts of the flower products, usually be used as flower products and the remaining parts approximately billions of tons of flower green part remain and often end up as waste and are burned or used for energy generation.

Currently, one of the most widely discussed topics in the green industry, which is promulgated by consumers exhibiting greater degrees of environmental awareness, is the issue of environmental sustainability. This has led to a desire for products that not only solve the needs of consumers, but are also produced and marketed using sustainable production and business practices. Consumers increasingly place a greater emphasis on product packaging and this has carried over to the grower sector in the form of biodegradable packaging and cardboards [4].

Packaging and cardboards as a consumer product offers a undisputed benefits to human society, and it has been proven to be critical in driving most sensitive needs of mankind—principally in areas of security, education, sanitation, and communication—and thus has been produced and consumed worldwide. Its sustainable production and usage is one topic that has featured prominently in many discussion fronts and more often than not ends with recommendations for an alternative source of raw material, improvement in production procedures, and ecological concerns [6].

Sourcing of virgin pulp for paper production begins with felling of trees. Existing data shows that, approximately 4 billion trees worldwide are lost annually for paper production, representing 35% in fraction of all harvested trees [7]. This figure is critical to deforestation and other severe environmental outcomes like drought and desertification. Deforestation alone contributes 25% of the annual carbon emissions caused by human activities as reported by and has many determinants. The most common is incessant cutting of trees that has immediate repercussions such as wind and soil erosion and cumulative remote consequences such as desertification. Unmitigated deforestation also has a cascade effect that eventually spins-off to global warming, melting of polar ice, sea level rise, climate change, extinction of plant and animal species, disruption of forests’ natural duty of carbon bio sequestration. However, with growing effort towards replacing forest material with eco-friendlier and sustainable raw materials such as recyclable packaging and cardboard, non-wood fiber materials, and agro residues are positive initiatives continuously being adopted to counter ecological damage that comes with sourcing of forests for packaging and cardboard production. On the other hand, floral green waste is also an environmental burden which needs to be addressed wisely [8]. In this study the process of addressing this floral green waste is planned to convert it into useful eco-friendly and economically visible products that is biodegradable packaging and cardboard, paper and packaging materials (Figures 1-5).

Statements of the problems

The impact of agricultural waste on the environment depends not only on the amounts generated but also on the disposal methods used. Some of the disposal practices pollute the environment. For example, agricultural waste burning is a common practice in the undeveloped countries, but it is a source of atmospheric pollution. According to agricultural waste burning releases pollutants such as carbon monoxide, nitrous oxide, nitrogen dioxide and particles (smoke carbon). These pollutants are accompanied by the formation of ozone and nitric acid [8], hence contributing to acid deposition thereby posing risk to human and ecological health. Agricultural wastes if not treated, kept or disposed of properly, are likely to cause pollution to the environment or even harm to human health. This calls for increased public awareness on the benefits and potential hazards of agricultural wastes, especially in developing countries [7].

Production of packaging like carton and cardboard begins with felling of trees. Existing data shows that, approximately 4 billion trees worldwide are lost annually for their production, representing 35% in fraction of all harvested trees [7]. This figure is critical to deforestation and other severe environmental outcomes like drought and desertification. Deforestation alone contributes 25% of the annual carbon emissions caused by human activities as reported by and has many determinants. As a result, cost effective well studied solution should be brought forth for this devastating problems. For addressing of this issues this project proposal is developed so that to convert floral green waste in to economically valuable and environmentally sound products such as packaging materials and cardboards [9]. Moreover, the research project will be further developed to more products and services depending on budget availability and time.

Objective of the Study

General Objective

The general objectives of the study are Conversion of Floral Waste to Value Added Products

Specific Objectives

Characterizations of floral waste (green waste) based on their chemical compositions.

To study appropriate methods for the conversion of floral wastes to biodegradable packaging materials(carton)

To study appropriate methods for the conversion of floral wastes to biodegradable cardboards.

To Characterize the biodegradability of the produced products.

To Characterize the strength of the produced products.

To study the socio-economic feasibility of the products.

To study safety of the produced products.

Economic Importance of Plants

According to the United Nations Food and Agriculture Organization, the estimated export value of major plant commodities traded in world markets for 1998 was: rice ($9.9 billion dollars), maize ($9.1 billion), wheat ($15.1 billion), soybeans ($9 billion), coffee greens and roast ($13.7 billion), sugar ($5.9 billion), tobacco ($24.1 billion), cigarettes ($15.4 billion), lint cotton ($8.2 billion), forest products ($123 billion), and forest pulp for paper ($13 billion) [11].

Wastes: How are we affected and how should we treat them?

Waste is any unwanted solid, liquid, or gaseous substance [10]. Poorly managed wastes have adverse effects on humans, animals, plants, and the environment [11]. About 50% of wastes generated are organic thus, the proper management of organic wastes will drastically reduce the volume of pollution arising from improper waste management [12].

Effects of Wastes

Wastes affect the environment leading to severe hazardous impact on lives. Humans and animals alike are affected by these adverse effects, which can cause disease outbreak, reduction in life expectancy, and unsafe environment. Some wastes may rot, but those that do not will smell and generate methane gas, which significantly contributes to the greenhouse effect. The environmental and health impacts of wastes will be described subsequently. Wastes pollute the air, water, and soil. Air pollution includes odor, smoke, and dust. When solid wastes are burnt, greenhouse gases such as carbon dioxide and nitrous oxide are released, these lead to ozone layer depletion and greenhouse effect [13]. Hydrogen sulfide and methane are also released into the air. These substances are toxic to human lives.

Another environmental effect of waste is water pollution. It is reported that approximately 1400 people die daily due to water and water-related problems/disease [14]. Wastes that find their way into water bodies such as rivers, streams, and oceans can have a disruptive influence on the water bodies by lowering the pH and causing toxicity to the aquatic inhabitants and humans that use the water. Some of these pollutants are less soluble in water and are highly lipophilic. Reports have shown the presence of toxic metals in water bodies.

Water polluted with wastes from a location could serve as receiving water in another place. Soil pollution, too can result from improper waste management. Wastes dumped indiscriminately are unfriendly to the sight, breeding disease vectors. Metals from iron, radioactive wastes, etc. are toxic to soil organisms and plants, thereby reducing crop productivity [11] (Figures 6-8).

Human diseases result from improperly treated wastes that harbor disease vectors. Mosquitoes breed in stagnant water bodies, in blocked drainages, in tires that collect rainwater, in empty food cans, plastics, etc. The refuse workers as well face some hazards which include tissue damage, respiratory infection; injuries from glass, razor blades and syringes, as well as parasite infections caused by skin contact with refuse. Though workers use protective measures such as gloves and nose masks, advanced automated means should be encouraged to prevent refuse workers from casualties associated with waste treatment.

In Australia, studied the risk assessment for organic contaminants in composted solid municipal waste. In their study, they were able to categorize the risk levels into low, medium, and high priority, based on the health implications [15]. From this, measures can be put in place on how the individual toxicants from these wastes can be properly and efficiently disposed of. In another study by Gangway, et al. they studied the impact of electronic waste on human health and reported the release of various toxic metals into the air, as a result, causing air pollution [16]. Other studies have also reported the impact of these wastes on human health and the environment [17].

Floral Wastes Disposal and Problems Associated due to their Improper Disposal

There are some standard disposal and treatment options, landfilling; incineration which is controlled combustion of waste materials to a non-combustible residue or ash and exhaust gases. In USA and Europe, incineration is preferred for many organic hazardous and toxic waste streams. In land treatment final state of the waste is disposed by making intimate contact with the soil. The land treatment exploits the natural capacity of the soil to return substances to a condition forthcoming the unique state from which they were won by a process of extraction and purification. Volatilization method is also used for the treatment and disposal of wastes. It is effective for the removal of volatile compounds from soil by using commercial units that heat up the soil to between 100 and 500 AC. Dried and decayed flowers are considered waste material and thus, dumped in landfills, various water bodies, etc.

The example is of a country like Srilanka and India, where about 40% of the total production of flowers are unsold and wasted daily [8]. These flowers are thrown into water or dumped into landside causing water pollution as well as environmental pollution [4]. Many of us avoid throwing flowers and other items which are used for prayers in the garbage and instead put them in the plastic bags and throw them directly in the water bodies. Such disposal of waste creates problems like eel and worm development, water and land pollution and foul odor. Solid waste and littering can degrade the physical appearance of water bodies and cause deterioration of water quality. The floral waste generated gives a filthy look to the streets and roads and also distorts the image of Ghats along the rivers. However, now there is a modern approach to convert the floral wastes into value- added products viz., compost; biofuels; bioethanol; organic acids; pigments; dyes; polyhydroxybutyrateco- hydroxyvalerate production; food products; bio surfactants production; sugar syrup; incense sticks; handmade paper production; etc.

Treatment Methods for Floral Green waste

Composting

Composting needs to be a managed process, in order to produce good quality compost. It is vital to plan the type and location of the composting unit based on the volume, weight and variety of waste to be composted, staff resources and the intended end use. It is also important that staff should be given sufficient training to ensure the most up to date composting techniques are being used. Staff should also be given Health and Safety training in order to help reduce risks [10]. Green waste management and composting is regulated by the Environment Agency under the Environmental Permitting Regulations, which allows various activities to be carried out under restrictions imposed through permits and registered exemptions to minimize damage to the environment and human health. While some operations might be covered under Environmental Permitting Regulations basic rules, registered exemptions or environmental permits are needed for a wide range of green waste management and composting activities, including mulching, composting, and burning [14].

As beneficial as composting is, it takes a longer time to be ready, produces offensive odor, has long mineralization time, and may contain some pathogens that can withstand high temperature to some extent, i.e., thermo-tolerant pathogens and insufficient nutrient content. All these have discouraged farmers from incorporating them as a means of sustainable agriculture. This made the synthetic counterpart (chemical fertilizers), which is readily available, preferred to the organic source, i.e., composting. Compost should be appreciated after the comparison of the advantages and disadvantages of the two sources of nutrients [10].

More information on how to trap odor, a rapid method of pathogen and heavy metal detection will make composting more utilized. Several works have focused majorly on the agronomic evaluation, microbial contamination, and nutrient composition of compost leaving out the causes of long duration in composting and prospects to alleviate odor, pathogen and heavy metals [18-20]. This review evaluates the challenges associated with composting and the prospects which can make composting to ensure sustainable agriculture. Therefore, this review recommends that mono-nutrients could be extracted from compost, rapid methods should be developed to detect pathogens and heavy metals, odor- trapping techniques should be sorted. In addition, the concept of slowly composting organic materials should be well explored to ascertain if they contain specific nutrients and if they could be sustainable in biennial and perennial farming, composts should also be enriched with nutrient-rich activators, antibacterial, antifungal, antiviral and anti-nematode agents.

Composting Shortcomings

Although composting has many reported benefits that have been mentioned above, various challenges are posed by this method of waste management, from its effects on climate change to its release of carbon dioxide into the atmosphere and the depletion of oxygen, as well as the production of offensive smells from the release of hydrogen sulfide produced from anaerobic activity. As a result of these health impacts, various regulations have been put in place by different bodies in different countries concerning the use of the method. These limitations show that this method should still be improved to address various concerns mentioned. Two major areas of improvement are the temperature regulation and the control of oxygen flow [10].

These are key to the function of the microbes carrying out the composting process. The various microbes at each stage have the temperature at which they function, so these must be well-monitored, and they need oxygen so that the anaerobes will function less. Increased activity of the anaerobes increases the production of more carbon dioxide and the release of hydrogen sulfide, which can cause various health issues. If these can be sorted, then opportunities abound for this process to be effective in proper waste management.

Composting can eradicate degradable organic wastes. Degradable organic wastes are otherwise known as biodegradable wastes. Composting is a workable means of transforming various organic wastes into products that can be safely used and beneficially employed as bio fertilizers. Recalcitrant substances, polythene bags, and plastics, among others, cannot be composted. Composting is a safe way of managing organic wastes, but it is associated with odor production and release of greenhouse gases (CO2, SO2, and NO2) [18].

Although the composting of green waste is good conservation practice and helps reduce the amount of green waste sent to landfill sites, it also has the potential to cause environmental pollution, harm to human health and be a nuisance. The process can give rise to dust, fire, litter, leachate and liquor, noise, odors, pathogens, pests including rats, potentially harmful bio-aerosols, and it can be unsightly. To avoid these problems composting needs to be a carefully planned and well managed activity [21].

Smell Can Be an Issue: Compost can smell, and attracts flies

Can Attract Flies, Insects & Rodents: That want to feed on the organic matter

Takes Up Extra Waste Room At Home, & Can Increase Cost Of Public Waste Collection: Three bins (for general waste, recycling, and compost) can take up room in some homes, and the extra service of composting can actually increase the price residents pay in some areas i.e. they are penalized for doing the right thing.

Potential Contamination Issues: Compost can be contaminated if the wrong waste is put in there – which spoils the whole compost mix.

There Can Be Health & Safety Concerns with Composting: For example, some types of meats, fatty foods, and also human, dog and cat waste and feces should be avoided for their potential to carry bacteria like E coli.

Can Take Work & Time to Develop Good Humus/Fertilizer:

Developing a good compost soil nutrient mix can take work and time (right balance of nitrogen and other nutrients, and manual turning and stirring of the mix) – and if you aren’t putting the right balances of organic matter into the compost, the end compost ‘humus’ can actually be damaging or have a neutral effect on the soil you spread it on [17].

In a nutshell – it’s not a perfect fertilizer by any means.

Pathogens, some of which have killed or seriously harmed unsuspecting gardeners. Inspectors should familiarize themselves with these illnesses, some of which can be contracted in other parts of the house. Listed below are some of the more common physical ailments that can result from unprotected contact with compost [16].

Refuse Dump by Incineration

This is the process of burning combustible wastes at high temperatures. This method reduces the volume of such wastes by 90%. The leftover from the burning of materials like ashes, glass, and metals are then disposed of in a sanitary landfill [20]. This method only reduces the size of wastes, it is not a total means of waste disposal, and it is also associated with fire disaster and the release of greenhouse gases. Energy can be produced from incineration. This energy is preferable to energy produced from coal. This method could save about 2–2.6 Mt of CO2 eq per year [22].

Biofuels, Bioethanol and Biogas Production

Microorganisms are used as a tool by fermentation biotechnologists for the conversion of sugar into ethyl alcohol. Due to severe energy crisis in today’s world, ethanol is considered most suitable energy source amongst different fossil fuels. In India, various parts of Andhra Pradesh, Maharashtra, Chhattisgarh, some tribal communities are involved in cultivating and harvesting mahua flowers for alcoholic beverages using traditional methods. Mahua flowers are used for the production of vinegar and alcohol production. Preparation of sugars and analysis of flowers from various districts have been studied. The utilization of mahua flower as a substrate for the production of ethanol through submerged fermentation is of great economic advantage [20].

Flowers which are available in abundance in India including the immediate environment is a very good feedstock for biogas production [20]. Flowers give high yields of biogas and at faster rate which is important advantage. Study has been done on biogasproduction using floral wastes as raw material [20]. There is a report on biogas production from rose by anaerobic digestion in a batch reactor. The biogas from floral waste can be used for electricity generation and as a fuel (Figures 9,10).

Disadvantages of Biofuels

High Cost of Production

Even with all the benefits associated with biofuels, they are quite expensive to produce in the current market. As of now, the interest and capital investment being put into biofuel production is fairly low, but it can match demand. If the demand increases, then increasing the supply will be a long term operation, which will be quite expensive. Such a disadvantage is still preventing the use of biofuels from becoming more popular [2].

Use of Fertilizers

Biofuels are produced from crops, and these crops need fertilizers to grow better. The downside of using fertilizers is that they can have harmful effects on the surrounding environment and may cause water pollution. Fertilizers contain nitrogen and phosphorus. They can be washed away from soil to nearby lakes, rivers or ponds.

Industrial Pollution

The carbon footprint of biofuels is less than the traditional forms of fuel when burnt. However, the process with which they are produced makes up for that. Production is largely dependent on lots of water and oil. Large scale industries meant for churning out biofuel are known to emit large amounts of emissions and cause small scale water pollution as well. Unless more efficient means of production are put into place, the overall carbon emission does not get a very big dent in it. It also causes an increase in NOx [10].

Global Warming

The biofuels, which are mostly hydrogen and carbon, burning them produce carbon dioxide, which contributes to global warming. It is true that biofuels produce less GHG emissions than fossil fuels, but that can only serve to slow global warming and not stopping or reversing it. Therefore, biofuels may be able to help ease our energy needs, but they won’t solve all of our problems. It can only serve as substitutes for the short term as we invest in other technologies [10].

Weather Problem

Biofuel is less suitable for use in low temperatures. It is more likely to attract moisture than fossil diesel, which creates problems in cold weather. It also increases microbial growth in the engine that clogs the engine filters [2].

Organic Acids, Dyes and Pigments

In India, major raw material for oxalic acid is sugarcane. In view of the occurrence of more sugar in mahua flowers, it constitutes an alternate potential to oxalic acid production [20]. Oxalic acid is largely used as a preservative and chelating agent. There is a report where marigold and rose flowers from temples of Aurangabad have been used for the preparation of dyes [10]. Biodegradable dyes have emerged as important alternative to synthetic dyes. There is a report on use of petal part of the saffron flower to extract dye for application on the Pashmina shawl [23]. The potential use of Hibiscus as a natural dye in textile coloration has been reported [11].

The main advantage of floral dyes is that they are very eco-friendly and have no allergic action on skin. Also, flowers are cultivated widely; easily available and inexpensive, which facilitates their use for dyeing paper at the level of small and medium enterprises as well as larger commercial scale. There is a report where patuletin dye extracted from marigold (Tagetes erecta L) and French marigold floral wastes (Tagetes patula L) is used in textile industries and also in antioxidant treatment [12]. Flowers have colours due to carotenoids, betalains and anthocyanins [22]. Antioxidant and radical scavenging activity of betalains shows its future use in medicine [23,21]

Safflower pigments viz. red (carthamin) and yellow (carthamidin) are used as material for dye(broilers, in particular) is affected by the composition especially the carotenoid content of their diet. Extract of marigold flowers is used commercially as an additive to poultry feed to improve the bird and egg yolk pigmentation [24]. Carotenoids, in particular the xanthophylls, lutein and zeaxanthin are the compounds of interest in the marigold flower extract for poultry pigmentation [25].

There is a report on utilization of waste flower Tagetus erecta for dyeing of cotton, wool and silk on industrial scale [12]. There is also a report on xanthophylls extracted from fermented African marigold flowers, where xanthophylls yield of 17.8 g kg-1 dry weight and 65% efficiency were obtained [13].

Application of Floral Wastes in Biosorption Studies

Heavy metals are extensively used in industries like electroplating, paint pigments, steel works, electrical accumulators, batteries, etc. These metals cannot be degraded biologically into harmless products and are mostly disposed in water [26]. Biosorption is a attractive technology for removal of heavy metal ions which utilizes low-cost biosorbents [27].

Floral Waste as Source of Raw Material for Handmade Paper Production

Flower waste management from temples can serve as a sustainable source of raw material for handmade paper production [3]. This method not only reduces the generally discarded waste produced by city temples, but also recycles and reuses it as an environment friendly paper. The handmade paper made from flower waste has many advantages viz., 100% free from wood and all chemicals; leaves no harmful by-products during the manufacturing [3]. Hence, the concept of reduce; reuse and recycle which is important can be implemented in handmade paper making. Also, the problem of disposing the floral wastes can be solved.

Materials and Methods

Materials

Chemicals and Reagents

Chemicals used throughout the experiments were: Sulfuric acid for the treatments of floral wastes, Nitric acid for preservation, hydrochloric acid and sodium hydroxide for lignin removal, hydrogen peroxide (H2O2) as bleaching agent, sodium carbonate(Na2CO3) for bleaching agent, floral waste (green waste) for productions of valuable products. Distilled water was used in all experiments. Hydrogen peroxide (H2O2) solution and glacial acetic acid (CH3COOH) were used for macerations. The chemicals that were used for bleaching (whitening) are chlorine dioxide (first bleaching), for second bleaching hydrogen peroxide or sodium hydroxide was used.

Instruments

Magnetic stirrer model GL-3250A: was used to agitate mixture.

• Filter paper (Whatman, 0.45 μm): to filter the sample

• Oven

• Electronic balance model No.: JD210-4: to weigh the samples.

• Mixing pot

• Compressing machine

• Wire screen mash

• Blending machine/blender

Methods

Experimental procedure

The floral waste processing method was according to [3]. Flower were collected from Orange Dumen from different horticulture farms, and Herburg horticulture farm. The collected were washed and soaked for about 5 days.

The soaked sample were washed at least for 6 times by water followed by hydrogen peroxide (H2O2) 30% so as to remove chemicals such as pesticide, herbicide, fungicide, different fertilizers and insecticides. Ligning is among important parts of plants waste since it affects the strength and quality of the products of our experiments. As a result of these ligning contents of the plant were first removed manually so as to enhance its further removal by chemical treatments and dried in a hot air dryer at 50°C. Then it will be preserved and stored in cool dry places for prevention of any chemical actions.

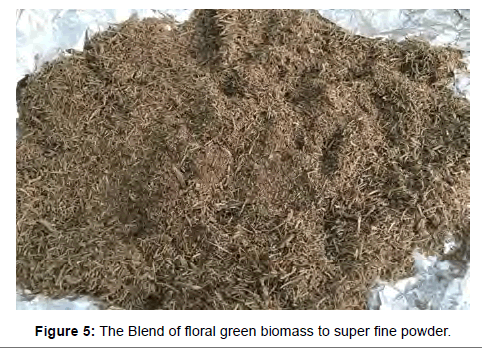

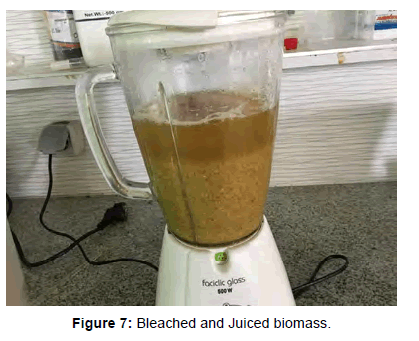

Weighted sample of 100 gm biomass were washed by sodium hydroxide (8%) solutions so as to remove the remaining ligning content. The samples were boiled in water bath of 81°C for about 5hours. The Treated biomass sample were reduced to small size and blended by blender until the samples became very small and super fine powder.

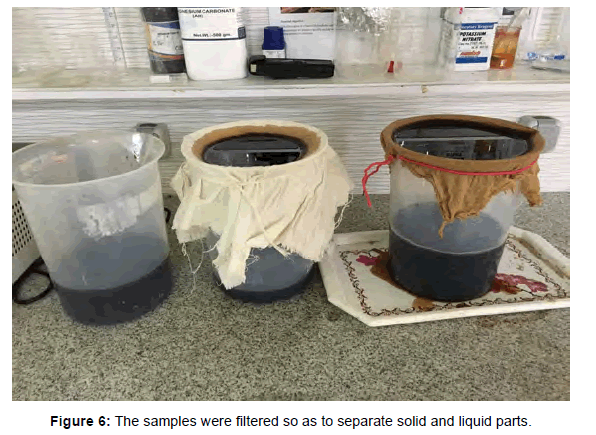

The blended biomass was made juiced and treated with sodium hydroxide (8%) solutions boiled in water bath of 81°C for about 5hours. The sample then thoroughly washed for about 5 times so as to remove any alkaline solutions present during treatments. The samples were filtered so as to separate solid and liquid parts.

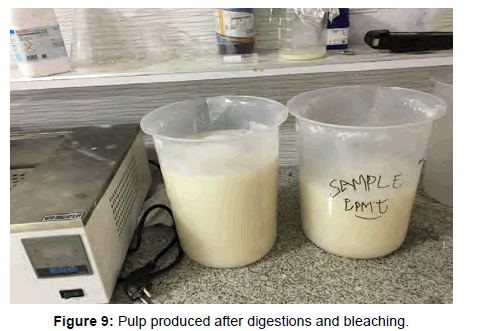

After wards the filtered solid parts of the sample were bleached by hydrogen peroxide (30%) of 50 ml for 1000 ml of overall solution or mixtures. The solutions were boiled at water bath of 72% for about 4 hrs. The samples were washed repeatedly by water so as to remove the impurities. The sample was bleached by hydrogen peroxide (30%) of 50 ml for 2000 ml of overall solution so as to make sure that the samples were bleached the acceptable degrees. According to Ibrahim, digestion is achieved when the pulp is formed, that is when the flower stalk has softened. At the end, the pulps will be washed and screened into accept and reject (the one with knots and uncooked sample, due to incomplete reaction of the sample with the macerating chemicals). Finally, the accepted pulp will be oven dried so as to determine the yield [9].

For writing purposes whiteness of paper is important, therefore, pulp is bleached using mostly oxygen bleaching techniques rather than chlorine bleaching due to its high environmental pollution problem. Dark color lignin is removed during the bleaching process. Most of the strength of paper comes from hydrogen bond between fibers. Beating and refining of the pulp increase surface area of fibers so that better contact between fibers will result in higher mechanical properties of the paper.

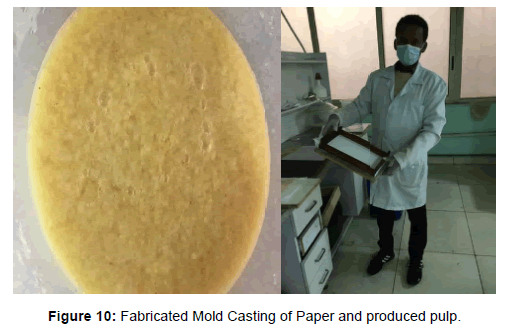

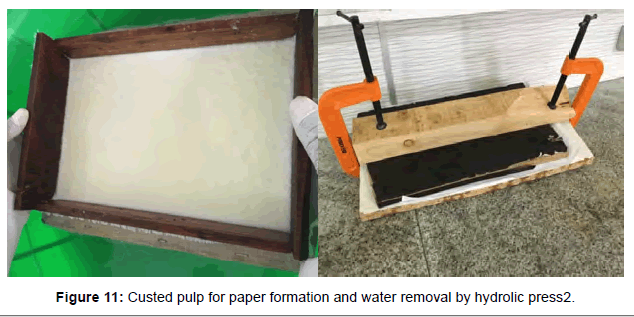

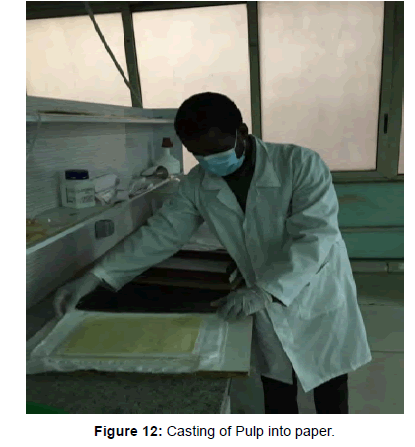

As a result of these the bleached pulp was reputedly washed by water so as to remove any bleaching agent left. This is also seen from above picture and the process the black solution indicates the presence of lignin and should be removed by alkaline solution and appropriate bleaching agent. After bleaching and formation of good quality pulp, the pulp then transferred to pots contain 5L of water and pulp solutions. The solution then casted with prepared mold which is also supported by porous metal mesh and cotton sheets so that the water removed thoroughly. Pulp flows on the screen of the four drainer, and water is drained away with the help of a series of vacuum boxes and other equipment before a thin sheet of fiber mat is formed.

Once the paper web is formed in a sheet, its moisture content is reduced first using suction units, called the wet press area, and later by drum type dryers. Paper sheet continuously runs through a series of draying stages and heated up to (93°C) oven to ensure the sheet has approximate 4-5% moisture contents.

Evaluation of Some of the Properties of Paper

Physical and mechanical properties are very important in determining overall quality of the final sheet. Tensile strength, compression strength, bending stiffness, tears and burst resistance are some of the mechanical properties of paper. Measure of the force perpendicular to the plane of the paper required to tear several pieces is used to evaluate tearing resistance. Burst strength is determined by applying pressurized air to the surface of the sheet. Stiffness is determined by bending a small sample in both directions in specially designed equipment, such as a Taber Instrument.

Opacity, the measurement of light passing through a sheet of paper and brightness and the percentage of light reflected from the surface of paper are two physical characteristics influencing overall printing quality. Also, texture of paper, including smoothness and finish quality, is important for many applications.

A sufficiently smooth surface is a basic requirement for most printing papers for proper transfer of ink. Surface smoothness of paper is well known to correlate with printability. Efforts to measure the surface smoothness can be classified into two groups: simulating the printing process by pressure on the surface and determining an original surface profile.

The Sheffield smoothness tester, which measures the air leak in contact with paper under the condition of a fixed weight of measuring head, is a typical example of the first group. The stylus profilometer that falls in the second group presents an original surface profile of the paper as accurately as possible.

Moisture Content Analysis

The moisture of materials influences the textile strength which alters its many properties including tearing or fracture. As result low moisture contents of the cardboard and packaging material are preferable. One gram of the prepared sample placed in an oven of 105 for 24 hours. The difference between initial mass (mi) and the final mass will be calculated and percentage moisture co-ntent will be determined.

The experiment will be carried out in triplicate and the average will be reported.

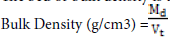

Bulk Densities

The bed or bulk density is the mass of sample in a specific volume.

= Mass of oven dry sample) &

= Mass of oven dry sample) & = Total volume (cm3)

= Total volume (cm3)

Chemical Characterizations

The water content test was conducted by the dry-oven method based on SNI ISO 287: 2010. The pH test was done based on SNI ISO 6588-1: 2010 on how to test pH in the water extract-part 1: Cold extract.

Physical Characterization

Physical characterization was conducted at The Institute of Pulp and Paper. Grammage test was performed based on SNI ISO 536: 2010; meanwhile, the brightness test was done based on SNI ISO 2470: 2010.

Paper Brightness -

The brightness of Paper allows monitoring the quality of paper. In a Brightness Tester (such as Spectrophotometer, Colorimeter or other brightness tester machine) the instrument measures the percentage of blue light reflected from the surface of paper at a specific weavlength of 457 nanometers (Full width at half maxima is 44 nm). The brightness of paper is measured on a scale of 0 to 100% – the higher the number, the brighter the paper. In other words, 91 brightness paper reflects more light than an 85 brightness paper [28].

Using the specific blue light to measure this reflection ignores all other longer and shorter wavelengths, including green and red. Because of this, two types of paper with the same brightness can visually appear very different, even though their “brightness” is the same [29].

There are 3 different type of brightness measurement and testing process using worldwide as per TAPPI standard.

ISO brightness ISO 2470 – 1 or TAPPI T 525:

This standard testing method is following in Europe and many other parts of the world including Bangladesh. Here the paper sample is illuminated with a CIE Illuminant C Light source. The instrument illuminates the sample with light projected by two lamps into an integrating sphere. Photocell or diode receptors are positioned at the 0’ position perpendicular to the plane of the paper sample [29].

D 65 Brightness (ISO 2470 -2)

The D 65 measurement system is essentially same as ISO 2470– 1, only exception is the CIE illuminant is D 65, an outdoor daylight containing more amount of UV energy.

ISO brightness ISO 2470 – 1 or TAPPI T 525:

This standard testing method is following in Europe and many other parts of the world including Bangladesh. Here the paper sample is illuminated with a CIE Illuminant C Light source. The instrument illuminates the sample with light projected by two lamps into an integrating sphere. Photocell or diode receptors are positioned at the 0’ position perpendicular to the plane of the paper sample [28].

D 65 Brightness (ISO 2470 -2)

The D 65 measurement system is essentially same as ISO 2470– 1, only exception is the CIE illuminant is D 65, an outdoor daylight containing more amount of UV energy [28].

Important Fact:

1. D 65 brightness measurement will be higher result for same paper sample compare to other ISO 2470 and T 452 method, when the sample paper contains OBA agent.

2. Each of these brightness measurement methods will produce a different brightness number when used to measure the same paper sample.

3. T 452 or GE brightness will show lowest result for the same paper sample.

Grammage of paper and paperboard

Customary or commercial term for expressing the “weight” per unit area (more properly “mass per unit area”) of paper has been “basis weight,” “ream weight,” or “substance.” These are defined as the mass in pounds of a ream of a given sheet size and number of sheets (usually 500 sheets, occasionally 480 sheets). In most other countries the mass per unit area is expressed in grams per square meter, g/m2. The French term for mass per unit area, “grammage,” is recommended by ISO Committee TC 6 on Paper for use in English as well as in French because of its convenience and clear relationship to g/m2. The mass per unit area of paperboard has been expressed in the customary system as the mass in pounds per thousand square feet, and in the metric system as grams per square meter (g/m2) [30].

Significance

Most paper is bought and sold in accordance with its mass per unit area, and therefore the grammage has great significance both to the consumer and the producer in defining price. The values of many physical properties such as bursting strength, thickness, and bulk are interpreted and specified with regard to grammage. The grammage is also used to calculate the index properties of many strength properties and thus the proper measurement of basis weight is critical for the correct calculation of these indexes [30].

Apparatus

Scale, readable and accurate to within 0.25% of the applied load shielded from air currents. Special sheet-weighing devices designed to weigh test specimens of a given size may be used, provided that the above conditions are fulfilled and that the total area of each test specimen (see 6.3) in a single weighing is not less than 500 cm2 (80 in.2). For a test specimen of smaller total area, an analytical balance is essential to obtain the required accuracy.

Cutting device, such as a “four square” cutter, circular cutter, precise puncher or other device for ensuring parallelism of the opposite edges, normally capable of repeatedly cutting out test specimens whose area, in at least 95 instances out of 100, falls within 0.5% of a known area, as determined by the method specified in 5.2.1. When a template is used for preparing test specimens, the specimen shall be cut accurately as described in 4.2 with a sharp knife on a hard surface, such as a hardwood board. Scale, a steel rule graduated in 0.5 mm (1/50 or 1/64 in.) increments, capable of measuring the dimensions of the test specimen to an accuracy of 0.2% [30].

Results and Discussions

Bulk Density

The bed or bulk density is the mass of adsorbent in a specific volume. The bulk density of the prepared product of paper was (0.645g/ cm3) which is comparable with that of commercial paper (0.487 g/ cm3) [2].

Moisture Content

One of the most important factors that affect the strength of the paper is its moisture (water content). As result low moisture contents of were preferable. The percent moisture contents of this paper were about (6.1%) and that of commercial one was (4.8%).

Paper from Floral Green Waste

Floral Green Waste can be used as raw material in the making of paper because of its high concentration of cellulose. Mashing process of this waste is essential as floral green waste should be brushed, lacerated, and pushed to expand the fibers. While expanding, the outer layer of the fiber will be decomposed, and the fibrils come out. The process which causes the fiber surface to get larger is necessary to tighten the fiber of the paper. In the process of cooking, the temperature should not exceed 100°C since the high temperature in cooking process will decrease the pulp quality. It then causes the pulp not to last for the long period. Moreover, cooking process will shade the color of pulp from yellow to dark brown indicating the process of lignin extraction from the cellulose.

The bleaching process was done to remove the lignin contained both in pulp and fiber. It then results in the high and stable brightness. In this process, the H2O2 solution was used due to the characters of hydrogen peroxide which has strong oxidation properties with the bleaching concept of Totally Chlorine Free [31]. Also, hydrogen peroxide also has a weak acid, is easily decomposed when heated, and releases the oxygen. Due to its ability to release the oxygen, hydrogen peroxide is effective as the bleaching material. The O2 will act as the oxidizer to bleach the material.

In bleaching process, the pulp shaded from dark brown to yellow later on to white; this color shows that lignin has been removed. Moreover, the heating process generated bubbles from the decomposition reaction of the hydrogen peroxide into oxygen and water [32].

Paper Printing/Production

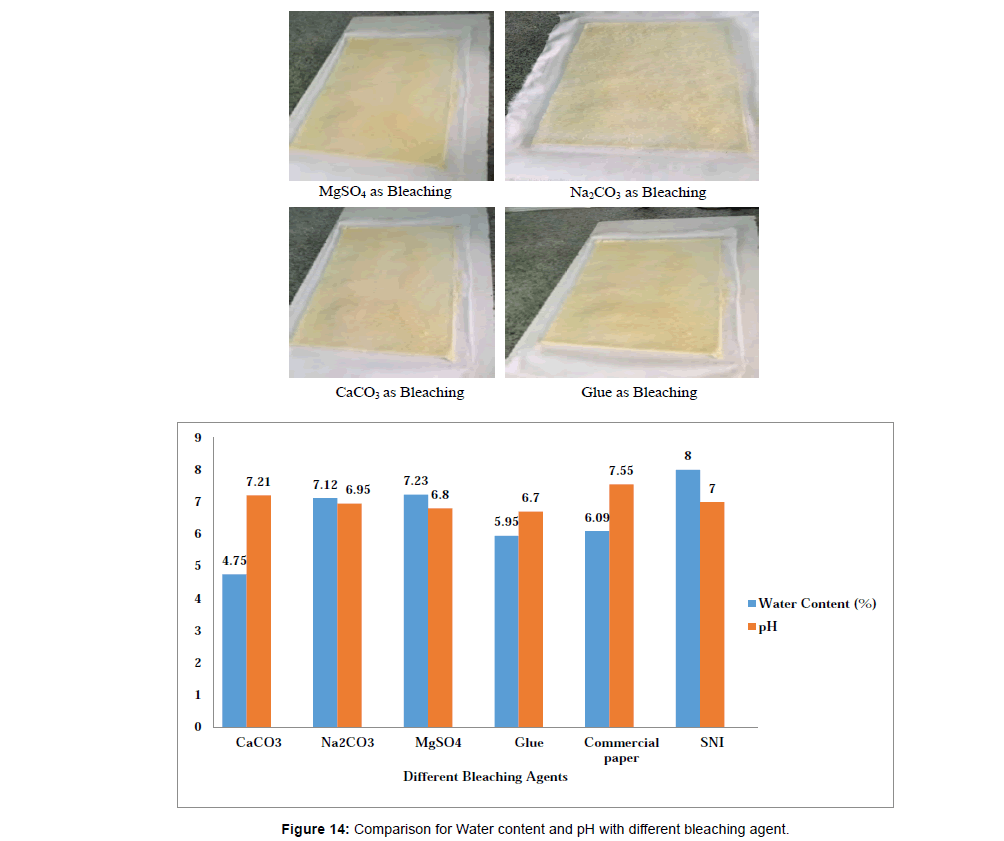

This is the finishing process in which the formed pulp was printed to produce the paper. The form of the paper is shown in Figure 11 and Figure 12. Physically, all of the papers were yellowish white in which they have the different level of color and slightly rough texture.

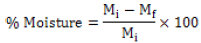

Chemical Characterization

The chemical characteristics of paper, include water content and pH, are shown in Table 1. SNI ISO 6519:2016 states that the water content of the basic paper for Wrapping Paper should not exceed 8%. All of the various papers from floral green waste meet the standard of water content stated by SNI.As we can see from thr graph as we use different bleaching agent the water content is also affected having different value for each bleching agent is used. Moreover, there may be another factor affecting the water content, namely drying process, room humidity, air flow, air pressure, the numbers of sample and the thickness of the sample. As we can see from the graph, as we use different bleaching agent the water content is also affected having different value for each bleaching agent used [33].

/Viewing GeometryIlluminant /

Light Source1*ISO

Brightness (ISO 2470 -1)Diffuse

(d/0°)CIE

illuminant C2D 65

Brightness (ISO 2470 -2)Diffuse

(d/ 0°)CIE

Illuminant D 653TAPPI T 452 /

GE BrightnessDirectional

C45 0 I oo )CIE

Illuminant C

Table 1:Different brightness Testing method by TAPPI [32].

Moreover, there may be Factor affecting the water content, namely drying process, room humidity, air flow, air pressure, the numbers of sample and the thickness of the sample. SNI ISO 6519:2016 states that the water content of the basic paper for Wrapping Paper should not exceed 8%. All of the various papers from floral green waste meet the standard of water content stated by SNI. As we can see from the graph, as we use different bleaching agent the water content is also affected having different value for each bleaching agent used. Moreover, there may be another factor affecting the water content, namely drying process, room humidity, air flow, air pressure, the numbers of sample and the thickness of the sample. The pH value is essential to be noticed since it affects the skin response when contacting the paper. SNI ISO 6519:2016 states that the Basic Paper for Laminated Wrapping paper must have pH value in the range of 6-9. All of the various papers from floral green waste meet the standard quality. The result showed that the type of bleaching agent affects the pH value of the paper produced. The pH value for CaCO3 as Bleaching is 7.21 which is the highest value. But for Glue as Bleaching the value stands at 6.70 which is the lowest value. As for commercial paper the value was 7.55. In general, the obtained values for all bleaching agent used were in the ranges of neutral to slightly basic indicating it were in the ranges of standard value and also the since the acidic solution affects the fiber strengths of the paper by destroying essential cellulose contents. The result of the research on chemical characteristics parameters shows that papers from floral green waste with all bleaching agent used meet the standard of ISO 6519:2016 about Basic Paper for Laminated Plastic Wrapping Paper on the parameter of pH and water content [34].

Grammage is the mass of paper of a particular unit area. According to SNI, paper and cardboard grammage for food packaging range from 255-500 g/m2. Grammage is essential to be measured due to the function of parameter value on the tensile index and tear measurement. All variations of floral green waste paper with the bleaching agent are meet the standard of SNI 8218:2015 about Paper and Cardboard for Food Packaging on the parameter of grammage (Food packaging with high grammage). Grammage related to the strength of the tear. Paper with high grammage shows the high number of the fibers contained. The amount of fiber will play a role in the process of tearing because each fiber will draw up a sheet of pulp on the particular grammage that contribute to the overall energy needed to tear (Table 2).

NumberDifferent Bleaching AgentWater Content (%)pH1CaCO3 as Bleaching4.577.212Na2CO3as Bleaching7.126.953MgSO4 as Bleaching7.236.804Glue as Bleaching5.956.705Commercial paper6.097.556SNI=86-9

Table 2. Chemical Properties of Natural Wrapping Paper.

Table 3 Shows that the brightness level in % of the produced paper from floral green waste. It ranges from the values from 16.87% for MgSO4 as Bleaching to that of Na2CO3 as bleaching which is at 20.45%. As for CaCO3 as Bleaching it is 19.80%, for Glue as Bleaching 17.54% for Commercial paper the value stands at 22.82%.

Table 3. Physical Properties of Natural Wrapping Paper.

In addition to being adapted to ISO standards, the produced paper is also compared to the characteristics of commercial wrapping paper. All of the natural wrapping papers produced have higher water content and lower pH value than commercial wrapping paper. The results show that natural wrapping paper from floral green waste with Na2CO3 as Bleaching has the closest characteristics of commercial wrapping paper. It has pH of 6.95, the water content of 7.12%, grammage of 356.67 gram/m2 and the brightness level of 20.45% (Figures 13,14).

Conclusion

The natural paper from floral green waste with bleaching agents of(Calcium carbonate, Sodium carbonate, Glue and Magnesium sulphate) used meet the standard of ISO 6519:2016 about Basic Paper for Laminated Wrapping Paper within the parameter of pH and water content and ISO 8218:2015. All of the various papers from floral green waste meet the standard of water content stated by SNI. As we can see from the graph, as we use different bleaching agent the water content is also affected having different value for each bleaching agent used. Moreover, there may be another factor affecting the water content, namely drying process, room humidity, air flow, air pressure, the numbers of sample and the thickness of the sample. All of the various papers from floral green waste meet the standard quality. The result showed that the type of bleaching agent affects the pH value of the paper produced. The pH value for CaCO3 as Bleaching is 7.21 which is the highest value. But for Glue as Bleaching the value stands at 6.70 which is the lowest value. As for commercial paper the value was 7.55. In general the obtained values for all bleaching agent used were in the ranges of neutral to slightly basic indicating it were in the ranges of standard value and also the since the acidic solution affects the fiber strengths of the paper by destroying essential cellulose contents. Papers from floral green waste with all bleaching agent used meet the standard of ISO 6519:2016 about Basic Paper for Wrapping Paper on the parameter of pH and water content. All variations of floral green waste.

Paper with the bleaching agent are meet the standard of SNI 8218:2015 about Paper and Cardboard for Food Packaging on the parameter of grammage (Food packaging with high grammage). It ranges from the values from 16.87% for MgSO4 as Bleaching to that of Na2CO3 as bleaching which is at 20.45%. As for CaCO3 as Bleaching it is 19.80%, for Glue as Bleaching 17.54% for Commercial paper the value stands at 22.82%. The results show that natural wrapping paper from floral green waste with Na2CO3 as Bleaching has the closest characteristics of commercial wrapping paper. It has pH of 6.95, the water content of 7.12%, grammage of 356.67 gram/m2 and the brightness level of 20.45%.

References

- Ethiopian Horticulture Producers & Exporters Association (EHPEA); Ethiopian Investment Commission (EIC) database of licensed projects, 2014.

- Kulkarni MB and Ghanegaonkar PM (2019) Biogas generation from floral waste using different techniques, Global J Environ Sci Manage 5: 17-30.

- Wood IM (1981) Theutilizationoffieldcropsandcropresiduesforpaperpulp production,FieldCropAbstr 34: 557–68.

- Anvitha V (2015) The Importance, Extraction and Usage of Some Floral Wastes. J Biotech Bioinform and Bioeng. 2: 1-6.

- Shakhes J, Zeinaly F, Marandi M, Saghafi T (2018) The effect of processing variables on the soda and soda-AQ pulping of kenafbast fibers. BioResour6: 4626–39.

- Kiaei M, Samariha A, Kasmani JE (2011)Characteristicsofbiometryandthe chemicalandmorphologicalpropertiesoffibersfrombagasse,corn,sun-452 flower,riceandrapeseedresiduesinIran,Agric 16: 3762–7.

- Azizi M, Ainun Z, Rushdan I (2010) Chemical, morphological, and technological properties of cultivated Kenaf (Hibiscus cannabinus) fibers. Bio Resour 5: 2112–22.

- Akgul M, Tozluoglu, A (2009)Somechemicalandmorphologicalpropertiesof juvenilewoodsfrombeech(FagisorientalisL.)andpine(PinusnigraA.) plantation,TrendsAppl.Sci Res 4: 116–25,

- Sallam S, Bueno I, Nasser M, Abdalla A (2010) Effect of (Eucalyptus citriodora) fresh or residue leaves on methane emission in vitro. Ital J Anim Sci9: 299–303.

- Singh A, Jain A, Sharma B, Abhilash P, Singh H, et al. (2013) Solid waste management of temple floral offerings by vermicomposting using Eisenia fetida. Waste Manag 33: 1113–8.

- Gurav M, Pathade G (2011) Production of vermicompost from temple waste (Nirmalya): A case study. Univers J Environ Res Technol 1: 182–92.

- Luo X, Liu G, Xia Y, Chen L, Jiang Z, et al. (2017) Use of biochar-compost to improve properties and productivity of the degraded coastal soil in the Yellow River Delta, China J Soils Sediments 17: 780–9.

- Cai, QY, Mo CH, Wu QT, Zeng, QY, Katsoyiannis A, et al. (2007) Concentration and speciation of heavy metals in six different sewage sludge-composts. J Hazard Mater 147: 1063–72.

- Langdon (2019)A preliminary ecological and human health risk assessment for organic contaminants in composted municipal solid waste generated in New South Wales, Australia. 100:199-207.

- Pane C, Spaccini R, Piccolo A, Celano G, Zaccardelli M, et al. (2019) Disease suppressiveness of agricultural green waste composts as related to chemical and bio-based properties shaped by different on-farm composting methods. Biol Control 137: 104026.

- Agarwal T, Quraishi A,Tiwari K., Jadha S (2013) Ethanol production from mahua (Madhuca indica J.F. Gmel) flowers by soil bacteria. Researcher 5: 102–6.

- Mohanty S, Behera S, Swain M, Ray R (2009) Bio-ethanol production from mahua (Madhuca latifolia L.) flowers by solid state fermentation. Appl Energy 86: 640–4.

- 21.CompostingindustryCodeofPracticeorganicsrecycling.org.uk/dmdocuments/Composting_Industry_Code_of_Practice.pdf .

- Pandey A, Bhati P (2011) Study about the changes in physical parameters during vermicomposting of floral wastes. J Environ Res Dev 6: 63–68.

- Prasad R (1991)Mahula the tree of the poor. J Trop For 7: 171–9.

- Sailaja D, Srilakshmi P, Shehanaaz PriyankaH, Bharathi D, Begum A, et al. (2013) Preparation of vermicompost from temple waste flower. Int J Innov Sci 3: 367–75.

- Bai J, Shen H, Dong S (2010) Study on eco-utilization and treatments of highway greening waste. Pro Environ Sci 2: 25–31.

- Pane C, Palese AM, Celano G, Zaccardelli M (2014) Effects of compost tea treatments on productivity of lettuce and kohlrabi systems under organic cropping management. Ital J Agron 9: 153–6.

- Ventorino V, Pascale A, Fagnano M, Adamo P,Faraco V, et al. (2019) Soil tillage and compost amendment promote bioremediation and biofertility of polluted area. J Clean Prod 239: 118087.

- Understanding of paper brightness – Article SAPPI – North America

- TAPPI T 410 om-08Grammage of paper and paperboard (weight per unit area)

- Widiastuti ES, Agustina, Elfi Susanti VH (2018) J. Phys.: Conf. Ser. 1022 012032.

- Yu H, Xie B, Khan R, Shen G (2019) The changes in carbon, nitrogen components and humic substances during organic-inorganic aerobic composting. Bioresour Technol 271: 228–35.

- Ibrahim H (2008) EvaluationofthreeNigerianfibre sourcesforpulpandpaper production,MSc.Thesis,AhmaduZariaUniversity.

- Ullah S, Pakkanen H, Lehto JA (2018) comparable study on the hot-water treatment of wheat straw andokrastalkpriortodelignificationbiomassconv.Bioref 8: 413.

Citation: Ahmed A, Dadi L, Jida M, Emana M (2021) Studies on Utilizations of Floral Waste by Conversion to Value Added Products. Environ Pollut Climate Change. 5: 251

Copyright: © 2021 Ahmed A, et al. This is an open-access article distributed under the terms of the Creative Commons Attribution License, which permits unrestricted use, distribution, and reproduction in any medium, provided the original author and source are credited

Share This Article

Recommended Journals

Open Access Journals

Article Usage

- Total views: 4061

- [From(publication date): 0-2021 - Apr 02, 2025]

- Breakdown by view type

- HTML page views: 3280

- PDF downloads: 781