Research Article Open Access

Strength and Behavior of Concrete Contains Waste Plastic

Manhal A Jibrael1 and Farah Peter2*1Department of Civil Engineering, Koya University, Koya, Kurdistan region, Iraq

2Deaprtment of Chemical Engineering, Koya University, Koya, Kurdistan region, Iraq

- *Corresponding Author:

- Peter F

Department of Civil Engineering

Koya University, Koya

Kurdistan region, Iraq

Tel: +964 748 012 7520

E-mail: farah.ayad@koyauniversity.org

Received April 22, 2016; Accepted May 24, 2016; Published May 31, 2016

Citation: Jibrael MA, Peter F (2016) Strength and Behavior of Concrete Contains Waste Plastic. J Ecosys Ecograph 6:186. doi:10.4172/2157-7625.1000186

Copyright: ©2016 Jibrael MA, et al. This is an open-access article distributed under the terms of the Creative Commons Attribution License, which permits unrestricted use, distribution, and reproduction in any medium, provided the original author and source are credited.

Visit for more related articles at Journal of Ecosystem & Ecography

Abstract

This paper presents a method of strengthen concrete by the addition of percentages recycled waste plastic (polyethylene). Almost 126 samples of concrete are prepared, the concrete Strength (compressive, splitting tensile and flexural strength) are investigated along a time interval of 7 to 28 days using 1%, 3% and 5% from fine aggregate recycled waste plastic (polyethylene). It is found that when waste plastic bottles increased from zero to 5% of the sand in the mix, the compressive, tensile and flexural strength of concrete decreased by the ratios of 12.81, 10.71, and increase by 4.1% respectively at 7 days age and also these concrete strength decrease by the ratios 7.93, 28.6, and 23.6% at 28 days age.

Keywords

Recycled plastic waste; Polyethylene; Concrete; Environment; Strengthen concrete

Introduction

The rapid urbanization and industrialization all over the world has resulted in large deposition of waste polymer materials. The world’s annual consumption of plastic materials has increased from around 5 million tons in the 1950s to nearly 100 million tons in 2001 [1]. Plastic waste materials consist of surplus, obsolete, broken, old plastic furniture, different household plastic materials, equipment, anti-static packaging materials and devices made of plastic. These polymer wastes are almost non-degradable in the natural environment even after a long period of exposure.

Inclusion of polymer waste in concrete can be a proper utilization of this valuable property. Thus, utilization of waste polymer material in making concrete/mortar can be good solution to this environmental hazard. Very few information is available regarding recycling of polyurethane formaldehyde (PUF) -based polymer wastes and its use as construction materials. In the Dhaka city corporation area, about 3,315 tons of solid waste had been generated per day during 2005, of which 4.15% was composed of plastic materials [2]. In view of this, a unique, novel experimental work has been conducted. The safe use of plastic waste (plastic bags or plastic containers such as water bottle) is very important because plastics are normally stable and not biodegradable. In Iraq approximately 11.3 million tons of solid waste is produced annually. The aim of this research is to investigate the effect of two types of waste plastic on strength of concrete.

Details of Specimens

The experimental program consists of casting and testing of 42 (100 mm × 100 mm × 100 mm) cubs for determining compressive strength (fcu), 42 cylinders (100 mm × 200 mm) for determining indirect tensile strength (fct) and 42 prisms (100 mm × 100 mm × 500 mm) for determining flexural strength or modulus of rupture (fr) of concrete.

The specimens classify into seven groups, each group contains 6 cubs, 6 cylinders and 6 prisms. The first group is planned to study the compressive, indirect tensile and flexural strength. Group two is used to study the same parameters as group one, but with 1% recycled waste plastic bottle as partial replacement, in concrete mix instead of natural aggregate. Groups three and four, in contrast, are used to study the same parameters, but with 3% and 5% recycled waste plastic bottle as partial replacement, in concrete mix instead of natural aggregate respectively. Groups five, six and seven are used to study the same parameter but with 1%, 3% and 5% non-recycled plastic bags as partial replacement, in concrete mix instead of natural aggregate respectively.

Material Used

Concrete is used as the main material. The concrete mixed design was chosen from a previous study. The concrete mix proportion was 1:1.67:2.5 (cement: sand: gravel) and water cement ratio was 0.46. The materials used are listed in Table 1:

| Basic materials | Specifications |

|---|---|

| Cement | Ordinary Portland cement from Tasluja factory in Sulaimaniah was used. |

| Sand | The fine aggregate was sand from Bogid Pit having a specific gravity 2.7. |

| Gravel | Maximum size of 12.5 mm, specific gravity of 2.72 was used as coarse aggregate. |

| Waste Plastics | Recycled waste plastic (polyethylene) with a percentage 1%, 3% and 5% from the sand was used. Waste plastic bags with a percentage 1%, 3% and 5% from the sand also used after washing and grinding with specific gravity equal to 1.04. |

| Water | Fresh water was used for mixing process and curing. |

Table 1: Materials used.

The component of concrete for production 1 m3 concrete in kg was; cement 400, sand 688, gravel 1000 and water 184.

Experimental Work: The Applied Processes

Mixing

First gravel and sand are added to an electrical mixer for one minute. The cement is then added into the mixer, followed by gradual addition of water, mixing is continued until a homogenous blend is formed.

Tests for fresh concrete: Slump Test

This test is used to determine the consistency of concrete. The consistency, or stiffness, indicates how much water has been used in the mix. The stiffness of the concrete mix should be matched to the requirements for the finished product quality. The slump test resulted values are within the range of 7 to 9 mm.

Casting

Molds are cleaned and oiled before casting, and then they are put on the level area. The molds are filled with the concrete mix. Concrete surface are leveled by trowel, and then marked. After casting, molds are put on the level ground assuring no vibration or compaction, the molds are kept in the laboratory for 24 hours.

Curing

After a day of casting process, the molds are removed, and concrete specimens are put into the curing tank for periods of 7 and 28 days.

Tests for Harden of Concrete

The fifth and final process is to test the concrete hardness after strengthen, and that is done after drying the samples for 30 minutes. Rebeiz et al. [3] investigated on the structural behaviors of polymer concrete beam using recycled plastic. Al- Manaseer et al. [4] studied the effect of plastic aggregates on the bulk density and compressive strength of concrete. Soroushian et al. [5] also reported the effect of plastic aggregates on compressive strength, furthermore, Elzafraney et al. [6] considered the energy-efficiency of buildings using recycled plastic aggregates in concrete. Kumar et al. [7] characterized waste plastics and optimized modifier content (waste plastic). Batayneh et al. [8] recommended recycled waste plastic materials modified concrete in certain civil engineering applications, Kumar et al. [9] reported the effect of waste plastics on mechanical strength. Siddique et al. [10] investigated on the effect of recycled plastic on the properties of fresh and hardened concrete. Based on the literature, three main tests are carried out, and these are listed below:

Compressive strength test

It is the most common of all tests on hardened concrete; in addition, compressive strength is the most important parameter in structural design. Three standard cubes of 100 mm3 are formed for each mix. The compressive strength test is carried out according to the BS EN 12390-3 (2002) at ages of 7 and 28 days.

Indirect tensile test

An indirect test for tensile strength of concrete, established originally in Brazil, has recently come into rather general use and standardized (ASTM C496- 62T). The specimen is the conventional 100 mm × 200 mm, cylinder. The cylinder is loaded in compression along two axial lines which are diametrically opposite through bearing strips of plywood.

The plywood cushion distributes the compressive load over a small width which is Sufficient to avoid undue concentration of stress, and it compensates for surface irregularities. The compressive force produces a transverse tensile stress which is practically constant along the vertical diameter.

Flexural strength test

The prismatic beam 500 × 100 × 100 mm3 specimens are used in this test to computing modulus of rupture of concrete. One central point load is used. Firstly, place each support, then a central point load is marked, the same rod is also used at mid-span for concentrated load.

Experimental Results

Compressive strength

Table 2 indicates the test results of compressive strength of hardened concrete; equation 1 is used to calculate the compressive stress in MPa.

fcu = P/A (1)

| Percentages of added plastic waste | fcu (MPa) at 7 days | fcu (MPa) at 28 days | ||

|---|---|---|---|---|

| with waste plastic bottles | with waste plastic bags | with waste plastic bottles | with waste plastic bags | |

| 0% | 35.04 | 35.04 | 46.6 | 46.6 |

| 1% | 37.673 | 29.9 | 44.7 | 45.89 |

| 3% | 28.41 | 24.81 | 43.8 | 39.1 |

| 5% | 30.55 | 27.04 | 42.93 | 38.95 |

Table 2: Results from the compressive test.

It is obvious from Table 2 that the compressive strength of concrete decreases with increasing the percentages of waste plastic bottles. The compressive strength of concrete also decreases with increasing the percentages of waste plastic bags.

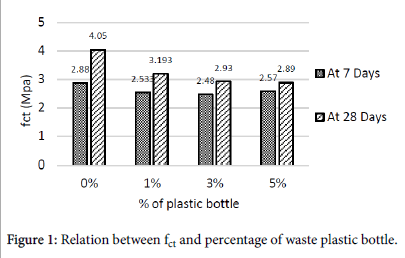

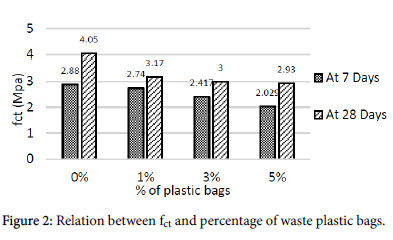

Indirect tensile strength

Table 3 indicates the test results of indirect tensile strength of hardened concrete; equation 2 is used to calculate the indirect tensile stress in MPa.

fct = 2P/π DL (2)

| Percentages of added plastic waste | fct (MPa) at 7 days | fct (MPa) at 28 days | ||

|---|---|---|---|---|

| with waste plastic bottles | with waste plastic bags | with waste plastic bottles | with waste plastic bags | |

| 0% | 2.88 | 2.88 | 4.05 | 4.05 |

| 1% | 2.533 | 2.74 | 3.193 | 3.17 |

| 3% | 2.48 | 2.417 | 2.93 | 3.0 |

| 5% | 2.57 | 2.029 | 2.89 | 2.93 |

Table 3: Results of indirect tensile test.

It is clear from Table 3 that when the percentage of added waste plastic bottle increases the strength on the contrary decreases. Similarly for concrete strengthen with waste plastic bags.

Flexural strength (modulus of rupture)

Table 4 indicates the test results of flexural strength (modulus of rupture); Modulus of rupture is calculated using equation 3:

fr = MC/I (3)

| Percentages of added plastic waste | fr(MPa) at 7 days | fr(MPa) at 28 days | ||

|---|---|---|---|---|

| with waste plastic bottles | with waste plastic bags | with waste plastic bottles | with waste plastic bags | |

| 0% | 3.63 | 3.63 | 3.8 | 3.8 |

| 1% | 3.1 | 3.64 | 3.66 | 3.3 |

| 3% | 2.71 | 2.298 | 3.2 | 2.88 |

| 5% | 3.78 | 3.340 | 2.9 | 2.64 |

Table 4: Results of flexural strength test.

It indicates that the increasing ratios of waste plastic bottle lead to a decrease in the modulus of rupture when using both, the waste bottles and plastic bags.

Figure 1 shows the indirect tensile and modulus of rupture for concrete with waste plastic bottle percentage for ages of 7 and 28 days.

Correspondingly, Figure 2 illustrates the indirect tensile strength of plastic bags based-concrete decreased by the ratio of 29.54% at 7 days age and by the ratio 27.4% at 28 days age.

Conclusion

In general, the compressive strength, indirect tensile strength and modules of rupture are found to be decreased with increasing the percentages of waste plastic bottle and waste plastic bags. Furthermore, when percentages of waste plastic bottles are increased from zero to 5% of the sand in the mix, the compressive, tensile and flexural strength of concrete are found to be decreased by the ratios of 12.81, 10.71, and are increased by 4.1% respectively at 7 days age, also these concrete strength decrease by ratios 7.93, 28.6, and 23.6% at 28 days age.

On a similar manner, it is noticed that when percentages of added waste plastic bags are increased from zero to 5% of the sand in the mix, the compressive, tensile and flexural strength of concrete are decreased by ratios of 27.5, 29.54, and 7.98% respectively at 7 days age, also these concrete strength decrease by ratios of 16.41, 27.4, and 30.52% at 28 days age.

It can be also stated that the effect of waste plastic bottles on the decreasing strengths is less than the waste of plastic bags. To add, the usage of waste plastic in concrete leads to a change in the modes of failure from brittle (rapid) failure to more ductile failure. It can be summed that one can use the waste plastic bottles and bags in nonstructural concrete members.

References

- United Nations Environment Program (2009) Converting waste plastics into a resource, Industry and Economics International Environmental Technology Centre. Osaka/Shi pp: 1-69.

- Waste Concern Consultant (2006) Report on composition of plastic waste and market assessment of the plastic recycling sector in Dhaka city, pp: 1-79.

- Rebeiz KS, Serhal SP, Fowler DW (1994) Structural behavior of polymer concrete beams using recycled plastic. J Mater CivEng 6: 150-165.

- Al-Manaseer AA, Dalal TR (1997) Concrete containing plastic aggregates. J ConcrInt 19: 47-52.

- Soroushian P, Plasencia J, Ravanbakhsh S (2003) Assessment of reinforcing effects of recycled plastic and paper in concrete. ACI Mater J 100: 2003-2007.

- Elzafraney M, Soroushian P, Deru M (2005) Development of energy-efficient concrete buildings using recycled plastic aggregates. J ArchitEng 11: 122-130.

- Kumar KBV, Prakash P (2006) Use of waste plastic in cement concrete pavement. Adv Mater Res J 15: 1-21.

- Batayneh M, Marie I, Asi I (2007) Use of selected waste materials in concrete mixes. J Waste Manage 27: 1870-1876.

- Kumar M, Dev SG, Yadav IS (2008) Laboratory investigations of the properties of concrete containing recycled Plastic aggregates. M.Sc. Engg thesis, Civil Engineering Department, Thapar University, Patiala, India.

- Siddique R, Khatib J, Kaur I (2008) Use of recycled plastic in concrete: A review. J Waste Manage 28: 1835-1852.

Relevant Topics

- Aquatic Ecosystems

- Biodiversity

- Conservation Biology

- Coral Reef Ecology

- Distribution Aggregation

- Ecology and Migration of Animal

- Ecosystem Service

- Ecosystem-Level Measuring

- Endangered Species

- Environmental Tourism

- Forest Biome

- Lake Circulation

- Leaf Morphology

- Marine Conservation

- Marine Ecosystems

- Phytoplankton Abundance

- Population Dyanamics

- Semiarid Ecosystem Soil Properties

- Spatial Distribution

- Species Composition

- Species Rarity

- Sustainability Dynamics

- Sustainable Forest Management

- Tropical Aquaculture

- Tropical Ecosystems

Recommended Journals

Article Tools

Article Usage

- Total views: 57822

- [From(publication date):

June-2016 - Apr 04, 2025] - Breakdown by view type

- HTML page views : 52049

- PDF downloads : 5773