Editorial Open Access

Spark Plasma Sintering: A Useful Technique to Develop Large-Sized Bulk Metallic Glasses

Guoqiang Xie*

Institute for Materials Research, Tohoku University, Sendai 980-8577, Japan

- *Corresponding Author:

- Guoqiang Xie

Associate Professor

Institute for Materials Research

Tohoku University, Sendai 980-8577, Japan

Tel: +81-22-215-2492

Fax: +81-22-215-2381

E-mail: xiegq@imr.tohoku.ac.jp

Received Date: May 21, 2013; Accepted Date: May 23, 2013; Published Date: May 24, 2013

Citation: Xie G (2013) Spark Plasma Sintering: A Useful Technique to Develop Large-Sized Bulk Metallic Glasses. J Powder Metall Min 2:e109. doi: 10.4172/2168-9806.1000e109

Copyright: © 2013 Xie G, et al. This is an open-access article distributed under the terms of the Creative Commons Attribution License, which permits unrestricted use, distribution, and reproduction in any medium, provided the original author and source are credited.

Visit for more related articles at Journal of Powder Metallurgy & Mining

Introduction

Metallic glasses exhibit unique combination of physical, chemical and mechanical properties due to their amorphous nature which lacks long range order and defects such as grain boundaries and dislocations [1,2]. In the past two decades, they have been rapidly developed for application in many fields. However, the disadvantages such as poor plasticity and limited dimensions hamper their large-scale industrial applications [3,4]. The most common method to improve plasticity of the monolithic bulk metallic glasses (BMGs) is to produce glassy composites by introducing nano- or micro-scale crystalline phases into the metallic glassy matrix [5-9]. On the other hand, intensive efforts have been made to overcome dimension limitation. Powder metallurgy process is an alternative route to produce large-size metallic glassy alloy parts. It is also favor to fabricate the glassy composites by dispersing crystalline particulates into the glassy matrix. Spark plasma sintering (SPS) as a newly developed rapid sintering technique, has a great potential for producing glassy composites while crystallization of the glassy alloy and coarsening of the dispersed particles are avoided. Furthermore, it is also a type of solid-state compression sintering technique which is similar to hot pressing sintering process, so that the sintered samples with the large-size and complicated shape can be produced [10,11].

In this paper, a short review on history of the technology, features of the spark plasma sintering process, and present status for application to develop large size bulk metallic glasses and their composites is presented.

History and Features of Spark Plasma Sintering Process

The pioneering works related to the SPS process started in 1906 when the first direct current (DC) resistance sintering (RS) apparatus was developed by [12], subsequently carried forward by [13] and [14,15]. In Japan, based on the idea of using the plasma on electric discharge machine for sintering metals and ceramics, a similar process was developed and patented in the early 1960s by [16,17]. However, because of the lack of application technology at that time, limited fields where it could be applied and unsolved problems associated with industrial production, equipment cost and sintering efficiency, it was not put to wide use. There was little literature on investigation of the SPS process until the latter half of the 1970s. In the late 1980s, the patent expired, and various companies utilized these techniques to manufacture equipments. However, these equipments were only smallscale experimental systems, used mainly for new materials development. From the beginning of 1990 to now, the SPS process has been developed to the third generation. The use in the fabrications of large-size gradient and composite materials as a new industrial processing technology has been conducted [11].

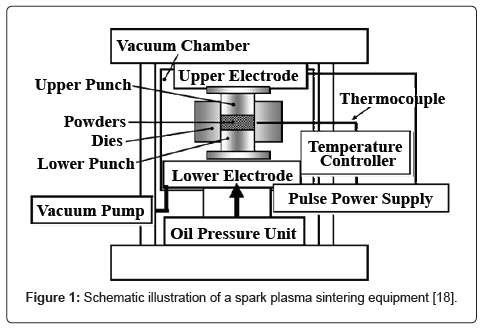

Figure 1 shows a typical schematic illustration of the SPS system. It is mainly consisted of a sintering machine with a vertical uniaxial pressuring system where the sample and the dies are inside, a DCpulse power generator, mechanical driving unit, an applied pressure display and control unit, a position measurement and control unit, a temperature measurement and control unit, punch electrodes with water-cooled system, vacuum system with water-cooled system, a vacuum/air/gas atmosphere control unit and a cooling water control system [18].

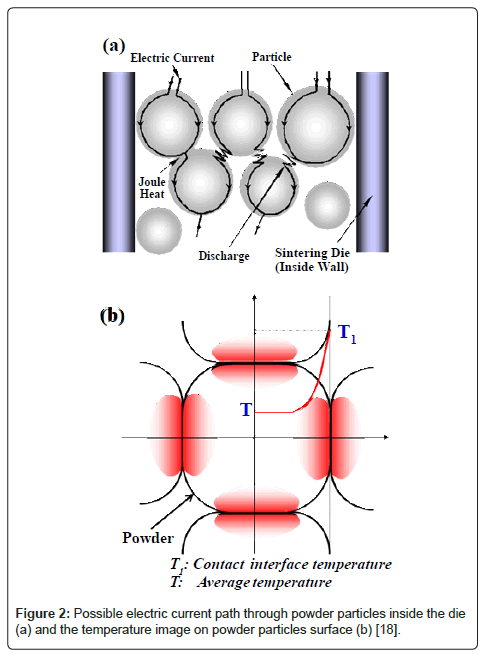

In the SPS process, the pulse electric current (typically, a few thousands of amperes of average electric current) directly flows through the sintered powder materials, a volumic heating rate resulting from the Joule effect, which is in contrast to the conductive heat transport applied in conventional sintering systems, permits a rapid increase in temperature that is able to enhance the mass transport mechanisms responsible for sintering phenomena, thus improving the consolidation rate. Furthermore, the surface effects that is induced by the SPS process also plays a significant role in the densification process. Figure 2 shows possible electric current path through powder particles inside the die and the temperature image on powder particles surface during the SPS process.

Numbers of papers have described the various physicochemical phenomena during spark plasma sintering process [10,11,18-29]. The detail was summarized in the literature [5]. Because of an absence of the direct evidence about spark discharge in the spark plasma sintering process, some publications also called it as pulse electric current sintering (PECS) or plasma-activated sintering (PAS) process [20,21,23-30].

In summary, high heating rate (up to 1000 K min-1), the effect of the current or electric field, and the application of pressure are mainly features of the spark plasma sintering technique.

Present Status

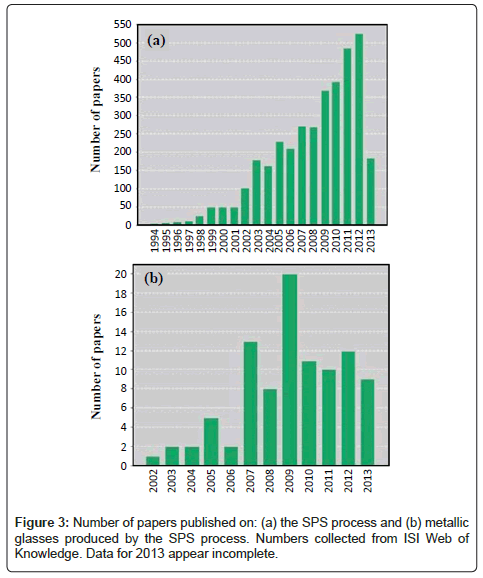

Since an economical SPS system has been developed, this process has become more attractive for the development of advanced materials and the sintering/synthesis of those materials that are very difficult to be sintered by the conventional sintering processes such as hot pressing and hot isostatic pressing processes. Using the spark plasma sintering process, pure metals, alloys, ceramics, polymers, composites, superconductors, thermoelectric materials, functionally graded materials (FGMs), and so on, have been produced. During the last 20 years, the number of papers related to sintering/synthesis of the materials by the SPS technique, as shown in figure 3(a), exhibits a exponential increase. At present, about 500 papers per year are published. The data was collected from ISI Web of Knowledge.

Based on the features of the spark plasma sintering process, sintering/synthesis of the materials can be carried out at a lower temperature and in a shorter time than that by conventional sintering processes. Therefore, the SPS process is favored to sinter materials that need suppress crystallization and grain growth, such as metallic glasses and their composites. During the last 10 years, a large number of studies about consolidating metallic glasses and their composites by using the SPS process have been carried out. Figure 3(b) shows the number of papers associated to metallic glasses produced by using the SPS technique, exhibiting a continuously increase.

Using the SPS process, large-size and high-strength Zr-based [31-34], Cu-based [35-37], Ni-based [5,6,38-40], Fe-based [40-43], Tibased [44-47], Mg-based [48,49] and Al-based [50] BMGs and their composites have been developed. It has been demonstrated that the BMGs produced by the SPS process exhibited high strength which was similar to that of as-casting glassy alloys. By spark plasma sintered the mixed powders of the glassy alloy powder blended with metal or ceramic particulates, bulk metallic glassy composites simultaneously with ultra-high strength, enhanced ductility, and satisfying large-size requirements have been produced

References

- Inoue A (2000) Stabilization of metallic supercooled liquid and bulk amorphous alloys. Acta Mater 48: 279-306.

- Johnson WL (1999) Bulk glass-forming metallic alloys: science and technology. MRS Bull 10: 42-56.

- Greer AL (1995) Metallic glasses. Science 267: 1947-1953.

- Bruck HA, Rosakis AJ, Johnson WL (1996) The dynamic compressive behavior of beryllium bearing bulk metallic glasses. J Mater Res 11: 503-511.

- Xie GQ, Louzguine-Luzgin DV, Kimura H, Inoue A (2010) Microstructure and mechanical properties of crystalline particulates dispersed Ni-based metallic glassy composites fabricated by spark plasma sintering. Intermetallics 18: 851-858.

- Xie GQ, Louzguine-Luzgin DV, Kimura H, Inoue A, Wakai F (2008) Large-size ultrahigh strength Ni-based bulk metallic glassy matrix composites with enhanced ductility fabricated by spark plasma sintering. Appl Phys Lett 92: 121907.

- Kato H, Yubuta K, Louzguine DV, Inoue A, Kim HS (2004) Influence of nanoprecipitation on strength of Cu60Zr30Ti10 glass containing µm-ZrC particle reinforcements. Scripta Mater 51: 577-581.

- Hays CC, Kim CP, Johnson WL (2000) Microstructure controlled shear band pattern formation and enhanced plasticity of bulk metallic glasses containing in situ formed ductile phase dendrite dispersions. Phys Rev Lett 84: 2901-2904.

- Eckert J, Seidel M, Kübler A, Klement U, Schultz L (1998) Oxide dispersion strengthened mechanically alloyed amorphous Zr-Al-Cu-Ni composites. Scripta Mater 38: 595-602.

- Mamedov V (2002) Spark plasma sintering as advanced PM sintering method. Powder Metall 45: 322-328.

- Tokita M (1999) Development of large-size ceramic/metal bulk FGM fabricated by spark plasma sintering. Mater Sci Forum 308: 83-88.

- Bloxam AG (1906) GB Patent, No. 27,002; and GB Patent, No. 9020.

- Duval D’Adrian AL (1922) US Patent, No. 1,430,724.

- Taylor GF (1932) GB Patent, No. 385,629.

- Taylor GF (1933) US Patent,No. 1,896,854; and US Patent,No. 1,896,853.

- Inoue K (1962) U. S. Patent, No. 3,241,956.

- Inoue K (1966) U. S. Patent, No. 3,250,892.

- Xie GQ (2003) Sintering process and interfaces microstructure of metal powders by pulse electric current sintering. Ph.D. Thesis. Niigata University, Japan.

- . Omori M (2000) Sintering, consolidation, reaction and crystal growth by the spark plasma system (SPS). Mater Sci Eng A 287: 183-188.

- Munir ZA, Anselmi-Tamburini U, Ohyanagi M (2006) The effect of electric field and pressure on the synthesis and consolidation of materials: a review of the spark plasma sintering method. J Mater Sci 41: 763-777.

- Orrù R, Licheri R, Locci AM, Cincotti A, Cao G (2009) Consolidation/synthesis of materials by electric current activated/assisted sintering. Mater Sci Eng R 63: 127-287.

- . Xie GQ, Ohashi O, Yoshioka T, Song M, Mitsuishi K, et al. (2001) Effect of interface behavior between particles on properties of pure Al powder compacts by spark plasma sintering. Mater Trans 42: 1846-1849.

- Xie GQ, Ohashi O, Yamaguchi N, Wang A (2003) Effect of surface oxide films on the properties of pulse electric-current sintered metal powders. Metall. Mater. Trans. A 34: 2655-2661.

- Xie GQ, Ohashi O, Song M, Furuya K, Noda T (2003) Behavior of oxide film at the interface between particles in sintered Al powders by pulse electric-current sintering. Metall. Mater. Trans. A 34: 699-703.

- Yanagisawa O, Hatayama T, Matsugi K (1994) Recent research on spark sintering process. Materia Japan 33: 1489-1496.

- Yamazaki K, Risbud SH, Aoyama H, Shoda K (1996) PAS (Plasma activated sintering): transient sintering process control for rapid consolidation of powders. J. Mater. Processing Technol. 56: 955-965.

- Xie GQ, Ohashi O, Yamaguchi N, Song M, Mitsuishi K, et al. (2003) Behavior of oxide film at interface between particles of Al-Mg alloy powder compacts prepared by pulse electric-current sintering. Jpn J Appl Phys 42: 4725-4728.

- Xie GQ, Ohashi O, Sato T, Yamaguchi N, Song M, et al. (2004) Effect of Mg on the sintering of Al-Mg alloy powders by pulse electric-current sintering process. Mater Trans. 45: 904-909.

- Xie GQ, Ohashi O, Yamaguchi N, Song M, Mitsuishi K, et al. (2004) Reduction of surface oxide films in Al-Mg alloy powders by pulse electric current sintering. J. Mater. Res. 19: 815-819.

- Grasso S, Sakka Y, Maizza G (2009) Electric current activated/assisted sintering (ECAS): a review of patents 1906-2008. Sci Technol Adv Mater 10: 053001.

- Xie GQ, Zhang W, Louzguine-Luzgin DV, Kimura H, et al. Inoue A (2006) Fabrication of porous Zr-Cu-Al-Ni bulk metallic glass by spark plasma sintering process. Scripta Mater 55: 687-690.

- Xie GQ, Louzguine-Luzgin DV, Kimura H, Inoue A (2007) Fabrication of ZrCuAlNi metallic glassy matrix composite containing ZrO2particles by spark plasma sintering process. Mater. Trans. 48: 158-162.

- Xie GQ, Louzguine-Luzgin DV, Wakai F, Kimura H, Inoue A (2008) Microstructure and properties of ceramic particulate reinforced metallic glassy matrix composites fabricated by spark plasma sintering. Mater. Sci. Eng. B 148: 77-81.

- Chu ZH, Kato H, Xie GQ, Yuan GY, Lu C, et al. (2013) Correlation between the enhanced plasticity of glassy matrix composites and the intrinsic mechanical property of reinforcement. Mater Sci Eng A 560: 40-46.

- Kim CK, Lee S, Shin SY, Kim DH (2007) Microstructure and mechanical properties of Cu-base amorphous alloy matrix composites consolidated by spark plasma sintering. Mater. Sci. Eng. A 449-451: 924-928.

- Xie GQ, Louzguine-Luzgin DV, Fukuhara M, Kimura H, Inoue A (2010) Cu particulate dispersed Cu50Zr45Al5 bulk metallic glassy composite with enhanced electrical conductivity. Intermetallics 18: 1973-1977.

- Chu ZH, Kato H, Xie GQ, Yuan GY, Ding WJ, et al. (2012) Consolidation and mechanical properties of Cu46Zr42Al7Y5 metallic glass by spark plasma sintering. J Non-Cryst Solids 358: 1263-1267.

- Xie GQ, Louzguine-Luzgin DV, Kimura H, Inoue A (2007) Nearly full density Ni52.5Nb10Zr15Ti15Pt7.5 bulk metallic glass obtained by spark plasma sintering of gas atomized powders. Appl. Phys. Lett. 90: 241902.

- Xie GQ, Louzguine-Luzgin DV, Li S, Kimura H, Inoue A (2009) Densification of gas atomized Ni-based metallic glassy powders by spark plasma sintering. Mater. Trans. 50: 1273-1278.

- Xie GQ, Louzguine-Luzgin DV, Li S, Kimura H, Inoue A (2009) Dual phase metallic glassy composites with large-size and ultra-high strength fabricated by spark plasma sintering. Intermetallics 17: 512-516.

- Shen BL, Inoue A (2003) Fabrication of large-size Fe-based glassy cores with good soft magnetic properties by spark plasma sintering. J. Mater. Res. 18: 2115-2121.

- Ishihara S, Zhang W, Kimura H, Omori M, Inoue A (2003) Consolidation of Fe-Co-Nd-Dy-B glassy powders by spark-plasma sintering and magnetic properties of the consolidated alloys. Mater. Trans. 44: 138-143.

- Xie GQ, Kimura H, Louzguine-Luzgin DV, Men H, Inoue A (2012) SiC dispersed Fe-based glassy composite cores produced by spark plasma sintering and their high frequency magnetic properties. Intermetallics 20: 76-81.

- Zhu SL, Wang XM, Xie GQ, Qin FX, Yoshimura M, et al. (2008) Formation of Ti-based bulk glassy alloy/hydroxyapatite composite. Scripta Mater 58: 287-290.

- Wang DJ, Huang YJ, Shen J, Wu YQ, Huang H, et al. (2010) Temperature influence on sintering with concurrent crystallization behavior in Ti-based metallic glassy powders. Mater Sci Eng A 527: 2662-2668.

- Xie GQ, Qin FX, Zhu SL, Inoue A (2012) Ni-free Ti-based bulk metallic glass with potential for biomedical applications produced by spark plasma sintering. Intermetallics 29: 99-103.

- Xie GQ, Qin FX, Zhu SL (2013) Recent progress in Ti-based metallic glasses for application as biomaterials. Mater. Trans. 54(8): in press. DOI: 10.2320/matertrans.MF201315.

- Méar FO, Xie GQ, Louzguine-Luzgin DV, Inoue A (2009) Recent progress in Ti-based metallic glasses for application as biomaterials Mater. Trans. 50: 588-591.

- Zheng BL, Ashford D, Zhou YZ, Mathaudhu SN, Delplanque JP, et al. (2013) Influence of mechanically milled powder and high pressure on spark plasma sintering of Mg-Cu-Gd metallic glasses. DOI: 10.1016/j.actamat.2013.04.011.

- Li XP, Yan M, Imai H, Kondoh K, Wang JQ, et al. (2013) Fabrication of 10 mm diameter fully dense Al86Ni6Y4.5Co2La1.5 bulk metallic glass with high fracture strength. Mater Sci Eng A 568: 155-159.

Relevant Topics

- Additive Manufacturing

- Coal Mining

- Colloid Chemistry

- Composite Materials Fabrication

- Compressive Strength

- Extractive Metallurgy

- Fracture Toughness

- Geological Materials

- Hydrometallurgy

- Industrial Engineering

- Materials Chemistry

- Materials Processing and Manufacturing

- Metal Casting Technology

- Metallic Materials

- Metallurgical Engineering

- Metallurgy

- Mineral Processing

- Nanomaterial

- Resource Extraction

- Rock Mechanics

- Surface Mining

Recommended Journals

Article Tools

Article Usage

- Total views: 19241

- [From(publication date):

July-2013 - Jul 01, 2025] - Breakdown by view type

- HTML page views : 14327

- PDF downloads : 4914