Shear Thickening of BaTiO3 Nanoparticles-Filled Non-Newtonian Polymer Suspensions

Received: 22-Nov-2016 / Accepted Date: 02-Jan-2017 / Published Date: 10-Jan-2017

Abstract

Present paper represents hydrodynamic approach of describing the rheology of polymer suspensions filled with BaTiO3 nanoparticles. It was found the shear thickening phenomenon at low shear rates with the subsequent shear thinning behavior under high shearing. The addition of various amounts of DBP has led to change in shape and size of the polymer molecule influencing the flow type, flocculation processes and strength of initial microstructure. Shear thickening is caused by elastic deformation of structural bonds «polymer-polymer» in the initial microstructure. Thus, pseudoplasticity indicates high strength and incomplete plasticization; exceptional thixotropy shows excessive plasticizing effect of DBP because of too straightened polymer molecules. The destruction of intramolecular bonds under external forces caused formation of additional molecular entanglements and additional flocculation of unbounded nanoparticles. In turn, the instant transition from rheopexy to thixotropy has occurred at constant hydrodynamic radius of structural elements due to full flocculation of BaTiO3 nanoparticles with polymer molecules providing better printability.

Keywords: Rheology; Shear thickening; Rheopexy; Pseudoplasticity; Thixotropy

42262Introduction

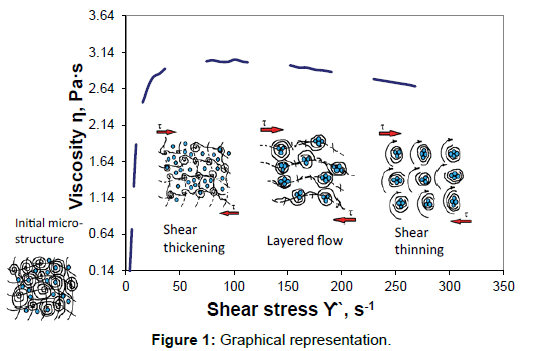

Polymer suspensions based on nanosized oxide particles are the promising objects for obtaining thin smooth films by various methods of colloidal formation. However, further progress of miniaturization depends on understanding of physico-chemical interaction between commensurate polymer molecules and nanoparticles. Furthermore, it permits to design the size and structure of the elements under directed flow for specific object and the formation processes (Figure 1).

It is known that the conventional polymer suspensions based on micron-size powders are shear thinned thixotropic systems. The phenomenon of effective viscosity decreasing is caused by the viscoelasticity of organic medium [1-3]. Typically, organic medium is a solution of polymer in organic solvent wherein the polymer molecules deform continuous and reversibly in viscous solvent. The moving molecules of solvent absorb mechanical energy and delay changes in the elastic phase. Behavior of the system in linear region of viscoelasticity is explained by the Edwards’ tube model, where each polymer is effectively confined to a tube-like region [3]. But at high shear stresses the value of effective viscosity changes and the contribution of hydrodynamic effects increase. The non-linear viscoelastic region corresponds to the high numbers of dimensionless Peclet number, Pe [4-6]. Therefore, Picu and Rakshit [7] and Winter [8] assumed that under intensive shearing the system behaves outside the Edwards’ tube model, forming large structural elements (grains) according to coarse grain model. In turn, the thixotropy of conventional polymer suspensions of solid particles is caused by the reversible changing of initial microstructure [9-12] due to flocculation of solid particles through polymer bridging [13,14].

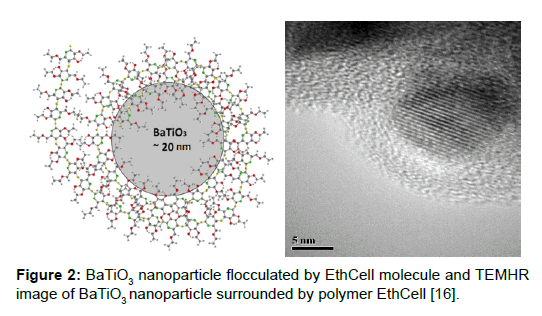

However in our previous works it has been established that unlike traditional systems the suspensions of nanosized BaTiO3 particles in plasticized solution of EthCell in terpineol (pastes) were «thixotropic», «rheopexic-thixotropic» and «rheopexic-pseudoplasticthixotropic » systems [15,16]. Moreover, all systems demonstrated shear thickening phenomenon at the low shear stresses. On the initial stage of deformation, the nonlinear behavior of the effective viscosity indicates the elastic-viscous properties of the system. In this case, the initial microstructure was formed by flocculated BaTiO3 nanopowder and polymer chains with free ends connecting to the network, dangling chains with only one end attached to the network and free chains, not linked to the network. Since it was established that the average probable length of EthCell molecule is 1220 nm, the polymer molecule in its deployed conformation is of 60 times larger than BaTiO3 particle of 20 nm in diameter (Figure 2). The EthCell molecule tends to accept its most energetically favorable form of random coil around the nanoparticles (Figure 2) [16]. Thus, smaller size of BaTiO3 nanoparticle compared with Etchell molecule leads to formation of floccules with fractal structure connected by the friction contacts. Under shearing the floccules deform elastically in viscous continuum polymer medium.

Interaction of plasticized EthCell molecule with BaTiO3 nanoparticles lead to formation of floccules with different sizes and properties resulted in complex character of flow. The plasticization of EthCell reduces the intermolecular interactions between polymer chains and leads to discontinuity of polymer body because of so-called «weak points» - the leisure chains without hemiacetal bond С(1) → С(5) together with closed pyranose cycles [17]. Based on this fact it can be assumed that the shear thickening mechanism of investigated polymer suspensions depends on the state of polymer molecule and its interaction with nanoparticles.

The paper is aimed to establish the shear thickening mechanisms for the plasticized polymer suspensions based on BaTiO3 nanopowder using the hydrodynamic approach.

Materials and Methods

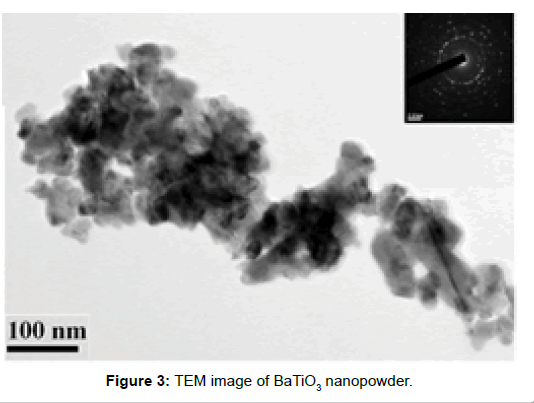

Polymer suspensions based on BaTiO3 nanopowder were prepared as follows. Initial polymer solutions were permanent stirred and heated. Terpineol was used as a solvent (mixture of α- and β-terpineol isomers, Merck GmbH) for polymer EthCell (10 cP, Merck GmbH, 48% of ethoxyl groups) and dibutyl phthalate DBP (Merck GmbH) as a plasticizer. The BaTiO3 nanopowder (NanoTechCenter LLC, mean particle size of 20- 25 nm, Figure 3) was dispersed in ethanol solution of surface-active substance. The particles were disaggregated by trituration for 60 min in a solvent. The appropriate polymer solution was added into the suspension followed by homogenization for 60 min in planetary boll mill Pulverisette 6 (Fritsch) at a rotation speed of 450 rpm.

The rheological tests of suspensions have been carried out using rotary rheometer Rheotest RN 4.1 (Rheotest Messgerate Medingen GmbH) by increasing the shear stresses from 1 to 1000 Pa followed by decreasing them back to 1 Pa. The gap between coaxial cylinders was 1.48 mm. All measurements were carried out at 20 ± 0,5ºС. Herewith, the DBP concentration in solutions was variable (changing from 0 to 40 wt.%). The content of solid phase and EthCell was 10 wt.% and 3 wt.% in all suspensions.

The microscopy studies of printed and dried films were carried out using high resolution transmission electron microscope JEM-2100F (Jeol, Japan) and scanning electron microscope EVO 50 XVP (Zeiss, Germany).

Results and Discussion

Model suspension

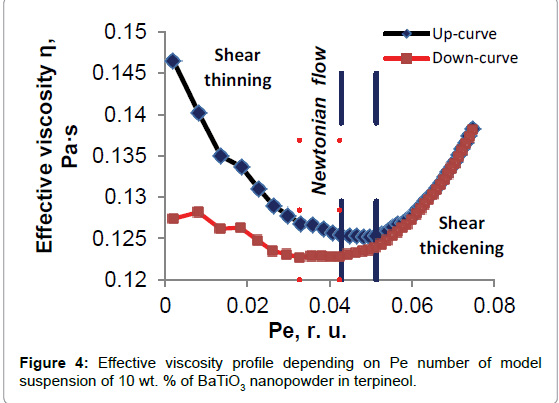

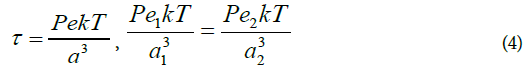

It is known that shear thickening is a type of non-Newtonian flow behavior, in which the energy dissipation increases with shear rate [18]. Firstly, the understanding of shear thickening mechanism of plasticized polymer suspensions was based on analyzing of BaTiO3 nanoparticles interaction under increased shear stresses without the polymer. For this purpose the model suspension of 10 wt.% of BaTiO3 nanoparticles in terpineol (namely «hard spheres», suspended in a Newtonian liquid) was prepared and analyzed using dimensionless Peclet number, Pe [4- 6]. According to [4], Pe relates the shear rate of flow to the particles diffusion rate and can be defined in terms of applied shear stress: was prepared and analyzed using dimensionless Peclet number, Pe [4- 6]. According to [4], Pe relates the shear rate of flow to the particles diffusion rate and can be defined in terms of applied shear stress:

where  - shear rate;τ - shear stress; a - particles hydrodynamic radius; D0 - diffusivity; kT - thermal energy.

- shear rate;τ - shear stress; a - particles hydrodynamic radius; D0 - diffusivity; kT - thermal energy.

Rheological tests showed that the model suspension containing 10 wt.% of BaTiO3 nanoparticles in terpenol has demonstrated typical behavior for suspensions of «hard spheres» [4-6,19,20]. At low Pe from 0.002 up to 0.043 r.u the suspension was shear thinned due to intensive restoring of the initial equilibrium chaotic structure and the high rates of Brownian motion Figure 4. Pe numbers from 0.043 up to 0.051 r.u. indicate the formation of metastable structural elements ordered into the layers at permanent values of effective viscosity. 10 wt.% of BaTiO3 nanopowder in suspension was insufficient to shear thickening because of jamming [21,22] and the increased shearing led to formation of hydroclusters because of decreased contribution of Brownian stresses. Thus, the hydrodynamic interaction caused rising of viscous friction energy dissipation leading to shear thickening and abrupt increasing of Pe number up to 0.08.

Nonplasticizedrheopexic-pseudoplastic-thixotropic» suspension P1

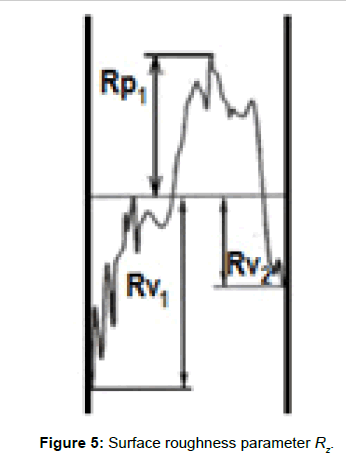

Comparative analysis of nonplasticized «rheopexic-pseudoplasticthixotropic » suspension P1 and model suspension allowed finding the influence of polymer EthCell on structuring under increased shear stresses. The interaction between polymer molecule and solid particles leads to flocculation [23-25] and the hydrodynamic radius of formed structural elements a was calculated by using of surface roughness parameter RZ characterizing the size of powder agglomerates on the surface Figure 5.

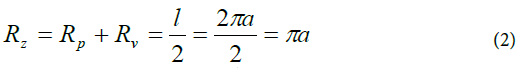

Assuming a rounded shape of the agglomerates:

Where l- circumference, the floccules hydrodynamic radius a was founded as:

To calculate the real floccules size along up- and down-flow curves the values of Pe number of model suspension and the appropriate polymer suspension were equated at the same shear stresses following the similarity principle. According to the formula (1):

where  number value and hydrodynamic radius of structural element of model suspension;

number value and hydrodynamic radius of structural element of model suspension;  number value and hydrodynamic radius of structural element of appropriate polymer suspension. Hence the real floccules size is:

number value and hydrodynamic radius of structural element of appropriate polymer suspension. Hence the real floccules size is:

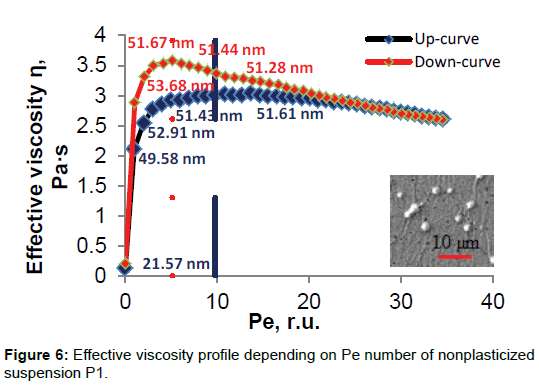

Unlike model suspension, the P1 were shear thickened at the initial stage of deformation up to the shear rate 100 s-1 [16]. Figure 6 shows that during shear thickening region of P1 the Pe numbers increase from 0.02 up to 9.81 r.u. and the floccule hydrodynamic radius rises from 21.57 nm (two BaTiO3 nanoparticles) up to 51.61 nm (four BaTiO3 nanoparticles). And at the Pe numbers from 9.81 up to 16.5 r. u. the P1 demonstrate the shear thinning due to its viscous properties.

It is known that weak physical interactions (Van-der-Waals and -OH bonds) of EthCell cause its intermolecular interactions [26]. According to this fact, the enlargement of floccules almost twice may be explained with calculating of the mechanical energy E consumed for disrupting of initial microstructure:

Where κ- shape factor; τ- shear stress; ΔV- structural element volume change at appropriate shear stress.

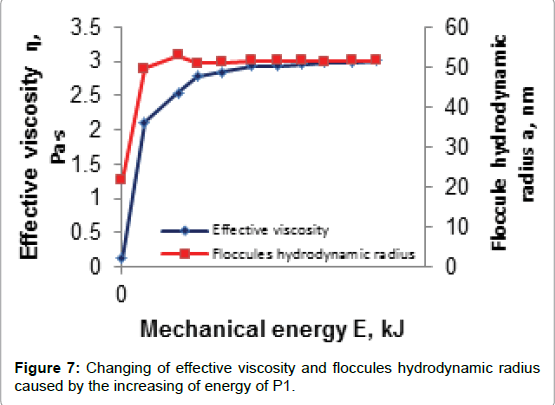

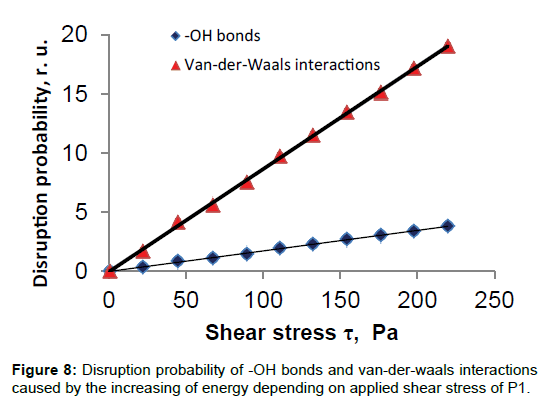

According to the Table 1 and Figure 7, during shear thickening of P1 the floccule was enlarged almost twice and the mechanical energy E was considerably increased. Taking an average values of the -OH bond and Van-der-Waals interaction energy about 20 and 4 kJ/mol, respectively, it was found, that during shear thickening region the 20 Van-der-Waals interactions and 4 -OH bonds have been broken (Figure 8). Thus it follows that shear thickening of P1 was caused by the deployment of EthCell coil and the additional flocculation of free nanoparticles with [16] formed -OH, resulting in enlargement of floccules.

Plasticized suspensions

Generally plasticization leads to predominant destruction of structural bonds «polymer-polymer» of plasticized polymer suspensions due to a high degree of interaction between nanoparticles and molecules [16]. Moreover, plasticized suspensions have much lower Pe numbers reflecting predominant entropic contribution towards hydrodynamic forces. Table 1 shows, that unlike P1, the structural elements of plasticized suspensions were smaller and had a lesser enlargement degree.

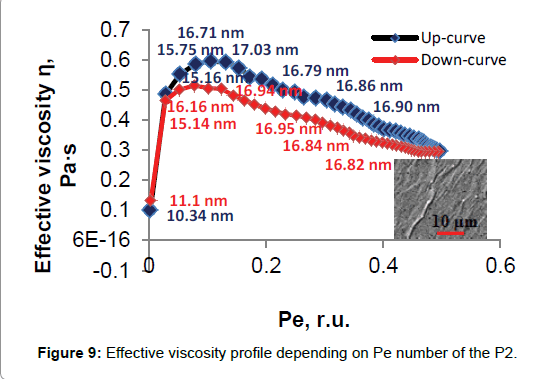

«Thixotropic» suspension Р2 was characterized by the highest degree of structural elements enlargement (about 1.47; Table 1) among plasticized suspensions. However at 5 Pa the P2 demonstrated lowest Pe numbers but further shearing led to abrupt rising of Pe and hydrodynamic radius of structural elements due to increasing of hydrodynamic forces (Figure 9).

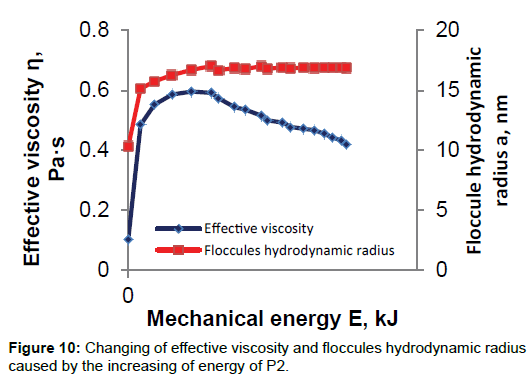

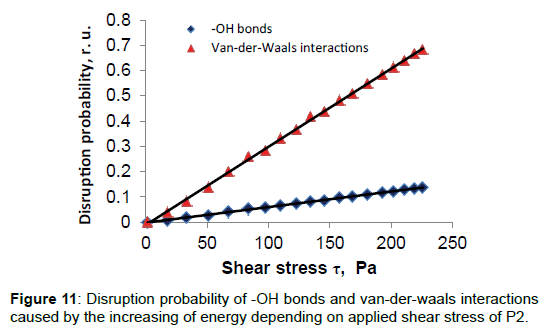

According to Figures 10 and 11, the shear thickening of the P2 was accompanied also with the growing of mechanical energy E, sufficient for disrupting only one Van-der-Waals bond because of low strength of initial microstructure. Thus, shear thickening of the P2 was caused by the disrupting of structural bonds of initial polymer transient network. Herewith the polymer chains were released and subsequently interacted with free BaTiO3 nanoparticles, initiating additional flocculation.

| Paste | DBP content, wt. % | η0,1, Pa·s | Ре at 5 Pа, r.u. | Ре at 20 Pа, r.u. | Ре at τ of maximal shear thickening, r.u. | τ of maximal shear thickening, Pа | а at 5 Pа, nm |

а at 20 Pа, nm | а at τ of maximal shear thickening, nm | Enlargement degree а(20 Pа)/а(5 Pа), r.u. |

|---|---|---|---|---|---|---|---|---|---|---|

| «Rheopexic – Pseudoplastic - Thixotropic» | ||||||||||

| Р1 | 0 | 2.11 | 0.02001 | 0.99098 | 9.80709 | 219.6 | 21.57 | 49.58 | 51.61 | 2.30 |

| Р4 | 5 | 1.70 | 0.04658 | 0.09388 | 0.14056 | 84.64 | 17.89 | 19.08 | 18.34 | 1.07 |

| «Thixotropic» | ||||||||||

| Р2 | 2.5 | 0.49 | 0.00221 | 0.02830 | 0.10649 | 83.4 | 10.34 | 15.16 | 16.72 | 1.47 |

| «Rheopexic – Thixotropic» | ||||||||||

| Р16 | 22.5 | 0.34 | 0.00383 | 0.01565 | 0.05873 | 65.4 | 12.43 | 12.44 | 13.71 | 1.00 |

Table 1: Values of Pe numbers and hydrodynamic radii of floccules.

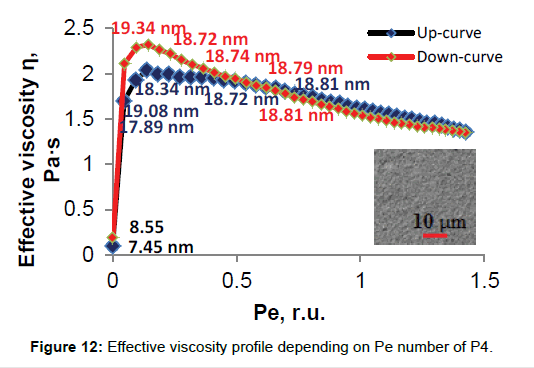

«Rheopexic–pseudoplastic-thixotropic» suspension P4 has the similar to unplasticized suspension P1 flow type (Figure 12) from 0.1 s-1 up to 32 s-1 the shear thickening and the enlargement of structural elements of 1.07 times were observed (Table 1).

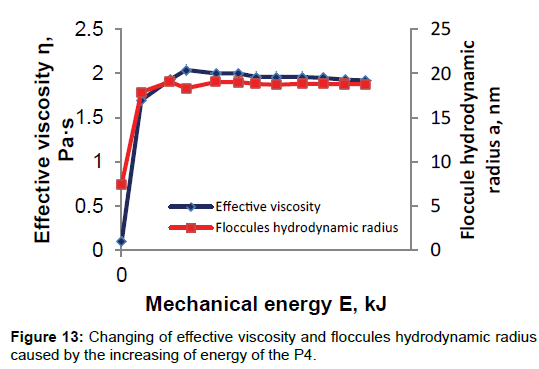

The presence of plasticizer led to decreasing of initial hydrodynamic radius of structural elements almost twice. Also, the much lower value of Pe numbers compared to the P1 was observed due to prevalent contribution of entropic stresses against the hydrodynamic. However, the P4 was characterized by the abrupt increasing of mechanical energy with the values of several orders of magnitude less (Figure 13).

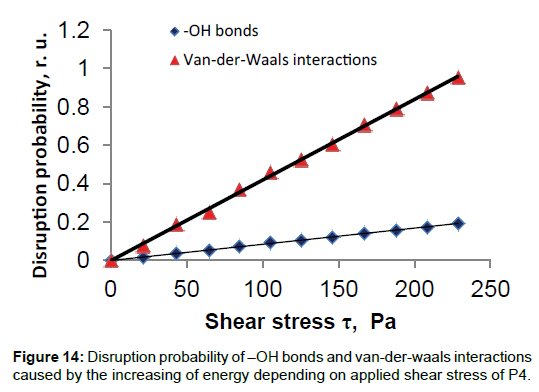

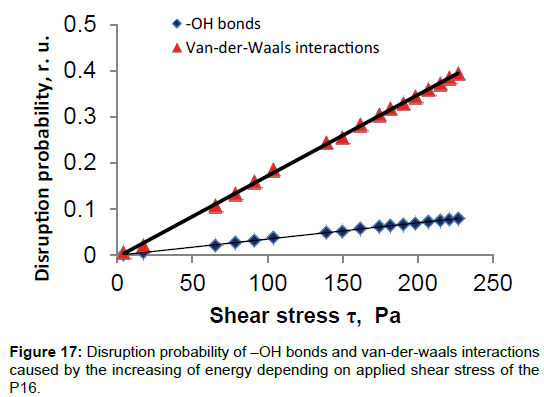

Thus, addition of 5 wt.% of DBP led to discontinuity of polymer body and to almost complete interaction of EthCell molecules with BaTiO3 nanoparticles. As a result, the structural elements with smaller hydrodynamic radius were formed. Moreover, the lesser values of mechanical energy E caused disrupting only one Van-der-Waals interaction. Figure 14 shows, that increasing of E was completely inadequate for breaking of -OH bonds making impossible the unfolding of initial polymer coil and structuring through additional flocculation.

According to those facts, the shear thickening of the P4 was accompanied with elastic deformation of initial polymer microstructure and subsequent elongation and orientation along the flow direction causing the pseudoplastic region.

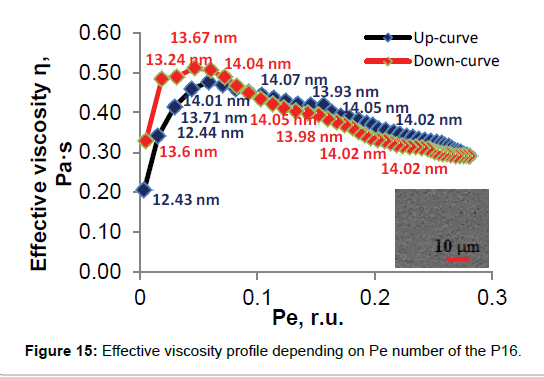

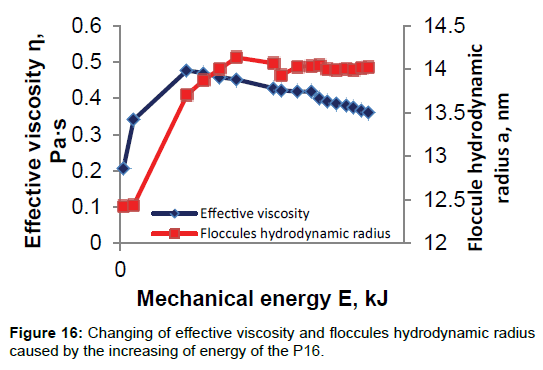

In the case of «Rheopexic-thixotropic» suspension P16 addition of 22.5 wt.% of DBP led to full flocculation of BaTiO3 nanoparticles with EthCell molecules at the stage of suspension preparation. And the structural elements with hydrodynamic radius of 12.5 nm (one flocculated BaTiO3 nanoparticle!) were formed. Figure 15 shows that the P16 was characterized by the lowest Pe numbers and hydrodynamic radii of floccules did not changed throughout the entire range of shear stresses.

Obviously, shear thickening of the P16 was caused by elastic deformation of the initial microstructure with further disruption of both longitudinal and transverse structural bonds «polymerpolymer ». Abrupt increasing of mechanical energy E was insufficient for disrupting of any physical interactions of EthCell (Figures 16 and 17). Thus, exceeding of τ of maximal shear thickening led to releasing of separate floccules and absence of intermediate pseudoplastic flow region. Further, separate structural elements moved with the average velocity of the gradient flow. They rotate in a perpendicular direction, colliding and mutually shielding each other, affecting the rotating rate [16,27].

Based on the obtained results it may be concluded that the addition of plasticizer allows control the hydrodynamic radii of structural elements and the quantity of unbound BaTiO3 nanoparticles in the initial microstructure of polymer suspension. Moreover, plasticized suspensions were characterized by low values of Pe numbers throughout the range of shear stress, demonstrating the high contribution of entropic forces and minor enlargement degree of structural elements.

Conclusion

Large Pe number matches the high probability of EthCell disrupting and the largest sizes of structural elements. Here, the tendency towards enlargement was due to increased size of the molecule as a result of disruption of -OH bonds between macromolecule segments as a result of its unfolding. In the case of nonplasticized suspension P1, deformation of initial microstructure was accompanied by the flocculation of free BaTiO3 nanoparticles [16] with formed -OH bonds due to unfolding of EthCell molecule resulting in enlargement of floccules almost twice. It was established that pseudoplasticity indicates high strength and incomplete plasticization; exceptional thixotropy shows excessive plasticizing effect of DBP because of too straightened polymer molecules. Thus under the influence of external forces there was the destruction of intramolecular bonds that caused formation of additional molecular entanglements and additional flocculation of unbounded nanoparticles. In turn, the instant transition from rheopexy to thixotropy led to the constancy of hydrodynamic radius of structural elements due to full flocculation of BaTiO3 nanoparticles with the polymer molecules.

So, it could be concluded, that plasticized rheopexic suspensions were characterized with almost full flocculation at the stage of preparation. Since the values of mechanical energy E were insufficient for unfolding of initial polymer floccules and coils. The shear thickening was caused by elastic deformation of structural bonds «polymerpolymer » of initial microstructure and depending on their strength a particular flow regime was realized.

Acknowledgement

The authors are grateful the Tatiana Konstantinova and Valentina Glazunova (Dоnetsk Institute for Physics and Engineering named after O.O. Galkin of the National Academy of Sciences of Ukraine) for microscopic investigations.

References

- Schurz J (1991) Rheology of polymer solutions of the network type. Prog Polym Sci 16: 1-53.

- Doi M (1988) The theory of polymer dynamics. Oxford Science Publications.

- Wagner NJ, Brady JF (2009) Shear thickening in colloidal dispersions. Phys Today 62: 27-32.

- Cheng X, McCoy JH, Israelachvili JN, Cohen I (2011) Imaging the microscopic structure of shear thinning and thickening colloidal suspensions. Science 333: 1276-1279.

- Hoffman RL (1998) Explanations for the cause of shear thickening in concentrated colloidal suspensions. J Rheol 42: 111-123.

- Picu RC, Rakshit A (2007) Dynamics of free chains in polymer nanocomposites. J Chem Phys 126: 144909.

- Winter U (2009) Coarse grained simulations of a small peptide: Effects of finite damping and hydrodynamic interactions. J Chem Phys 131: 104102.

- Mewis J, Wagner NJ (2009) Thixotropy. Adv Colloid Interface Sci 147: 214-227.

- Dullaert K, Mewis J (2005) A model system for thixotropy studies. Rheol Acta 45: 23-32.

- Dullaert K (2005) Thixotropy: Build-up and breakdown curves during flow. J Rheol 49: 1213-1230.

- Dullaert K (2006) A structural kinetics model for thixotropy. J Nonnewton Fluid Mech 139: 21-30.

- Otsubo Y (1999) Rheological behavior of suspensions flocculated by weak bridging of polymer coils. J Colloid Interface Sci 215: 99-105.

- Otsubo Y (1992) Effect of particle size on the bridging structure and elastic properties of flocculated suspensions. J Colloid Interface Sci 153: 584-586.

- Dulina I, Umerova S, Ragulya A (2015) Plasticizer effect on rheological behaviour of screen printing pastes based on barium titanate nanopowder. J Phys Conf Ser IOP Publishing 602: 012035.

- Umerova SO, Dulina IO, Ragulya AV, Konstantinova TE, Glazunova VA (2016) Rheology of plasticized screen printing pastes based on BaTiO3 nanopowder. Appl Rheol 3: 1-9.

- Umerova SO, Dulina IO, Ragulya AV (2015) Rheology of plasticized polymer solutions. ÉpÃtöanyag 4: 119.

- Brown E, Jaeger HM (2014) Shear thickening in concentrated suspensions: phenomenology, mechanisms and relations to jamming. Rep Prog Phys 77: 046602.

- Pusey PN, Megen WV (1986) Phase behavior of concentrated suspensions of nearly hard colloidal spheres. Nature 320: 340-342.

- Lu PJ (2013) Colloidal particles: Crystals, glasses and gels. Annu Rev Condens Matter Phys 4: 217-233.

- 21. Cates ME, Wittmer JP, Bouchaud JP, Claudin P (1998) Jamming, force chains and fragile matter. Phys Rev Lett 81: 1841.

- Cates ME, Wittmer JP, Bouchaud JP, Claudin P (1998) Jamming, force chains and fragile matter. Phys Rev Lett 81: 1841.

- Liu AJ, Nagel SR (1998) Nonlinear dynamics: Jamming is not just cool any more. Nature 396: 21-22.

- Phair JW (2008) Rheological analysis of concentrated zirconia pastes with ethyl cellulose for screen printing SOFC electrolyte films. J Am Ceram Soc 91: 2130-2137.

- Fan A, Turro NJ, Somasundaran P (2000) A study of dual polymer flocculation. Colloids Surf A: Physicochemical and Engineering Aspects 162: 141-148.

- Phair JW (2008) Rheological analysis of concentrated zirconia pastes with ethyl cellulose for screen printing SOFC electrolyte films. J Am Ceram Soc 91: 2130-2137.

- Khodakov GS (2003) The rheology of suspensions. Phase flow theory and its experimental validation. Rus Chem J 47: 33-44.

Citation: Umerova S, Ragulya A (2017) Shear Thickening of BaTiO3 Nanoparticles-Filled Non-Newtonian Polymer Suspensions. Rheol: open access 1: 105.

Copyright: © 2017 Umerova S, et al. This is an open-access article distributed under the terms of the Creative Commons Attribution License, which permits unrestricted use, distribution, and reproduction in any medium, provided the original author and source are credited.

Select your language of interest to view the total content in your interested language

Share This Article

Open Access Journals

Article Usage

- Total views: 5236

- [From(publication date): 0-2017 - Jul 08, 2025]

- Breakdown by view type

- HTML page views: 4260

- PDF downloads: 976