Research Article Open Access

Sensitizing Steel Industrial Workers on Dangers and Prevention of Noise Pollution: For Industrial Health, Theory and Practice

Sunday Oni O*

Faculty of Education, University of Jos, Nigeria

- *Corresponding Author:

- Dr. Owojaiye Sunday Oni, PhD

Faculty of Education

University of Jos, PMB 2084

Jos Plateau State, Nigeria

Tel: 08145551257

E-mail: isojaiyeomoobaowojaiyeowojaiye@ hotmail.com

Received date: October 29, 2015 Accepted date: December 15, 2015 Published date: December 29, 2015

Citation: Sunday Oni O (2015) Sensitizing Steel Industrial Workers on Dangers and Prevention of Noise Pollution: For Industrial Health, Theory and Practice. J Community Med Health Educ 5:385. doi: 10.4172/2161-0711.1000385

Copyright: © 2015 Sunday Oni O. This is an open-access article distributed under the terms of the Creative Commons Attribution License, which permits unrestricted use, distribution, and reproduction in any medium, provided the original author and source are credited.

Visit for more related articles at Journal of Community Medicine & Health Education

Abstract

This present “sensitizing steel industrial workers on dangers and prevention of noise pollution: for industrial health, theory and practice.” Hearing inefficiency variables analyzed are: (i) Hearing health and noisy (ii) Danger of noise to hearing apparatus. (iii) Types and characteristic of hearing protective devices. (iv) Hazard of hearing protective devices. (v) Signals on utility of hearing protective devices. (vi) Technicalities inherent in hearing protectors. It was concluded that: (A) Healing protective devices are not worn by workers in noisy industries. (B) Stakeholders in noisy industries do not have the knowledge of hearing problems. It was recommended among others as follows: (I) There should be close surveillance on workers’ compliance to wearing hearing protective devices in noisy environment. (II) Industrial workers in noisy environment must be educated on the hazards of nude to their ears and hearing efficiency.

Keywords

Sensitizing dangers; Noise pollution; Steel industrial workers

Introduction

The pun-din-dun-din sound emitted into the ears by the blacksmith, can cause deafness to an unprotected ears, Also, the noise perceived by the ears from musical gadgets, pepper grinding machines, vehicles horns, and cricket noise and electricity generators emitted sound >85 dBA into the air. This noise is too much for the ear. All these noise sources can inflict hearing impairment of different levels from mild hearing loss to anacuses hearing loss. And added to these noise sources, industrial workers` hearing capability had been impaired at their residences due to excessive noise from radio, GSM phones, grinding machines and generators before they resume for duty each morning at their duty post. Deafness on its devastating part cause communication problems; causing misunderstand and chaos within the community. If these workers must preserve properly and preserve their hearing efficiency, hearing technology knowledge concerning their ear, sound, noise, environment acoustics and attenuation capacity of hearing protective devices become imperative. Furthermore, technique of avoidance of excessive noise emission within the environment must be checked properly than what we have in Nigeria contemporarily.

The purpose of this paper is to present a medium of technological instruction and awareness for the steel industries workers, pepper grinders, groundnut, and food grinders, generators users plus noisy vehicle owners on the need to constantly wear hearing devices while using engines with high sound emission. And to be sensitize on the need to adhere to noise avoidance and noisy music reduction at the work place. Further still, this paper intends to teach all stake holders in the steel industrial development, of the need to import engines attached with silencers with high attenuation induced noise capacity, thus reducing engines’ noise and also wearing hearing protectors as condition of service for workers. This study is approached from the stand point of audiologist from the following perspectives:

1. The need for hearing health.

2. Types and characteristics of hearing protective devices.

3. Hazard of hearing protectors.

4. Signers on usage of ear-plugs and earmuffs.

5. Efficiencies and effectiveness of hearing protectors.

Literature Review

Hearing health and noise

Steel industrial establishment process cannot be effectively accomplished without the importation of noisy machines. And the hearing health of workers that should operate these machines are to be preserved. It therefore becomes inevitable that hearing protective devices ought to be provided and enforced upon the steel workers. Alberti (2008) observed that the introduction of welding; the method of joining steel, generate excessive sound. And these sounds that are emitted intermittently result in steel workers hearing ineffectiveness. Contemporarily pepper, groundnut, maize, cassava and millet grinders and generator users within our immediate environment are exposed to excessive noise; and therefore this may be the genesis of steel industrial noise pollution. Coincidentally, noise is injurious to the hearing physiology like cochlear, eardrum, incus, anvil, and stapes in the ear [1].

Danger of Noise to Hearing Channels

This noise has the propensity to cause injuries on the ear [2] while elucidating [3] discovery on devastation of the hearing capability of blacksmiths elicited that the lesion in the ear produced by noise was noticed in a man aged 75 years, who had worked as a blacksmith for 20 years and whose occupation had exposed him to high intensity noise during his working life at leq 40 khz:140 dBA. Haberman [3] affirmed that the man developed atrophy of the auditory nerve with complete degeneration of the spiral lamina. Thomas and Haberman [3] also asserted that blacksmith and boilermaker developed deafness due to their long exposure to ding-dang-din- from steel hitting and boiler making. The deaf man’s health had been impaired. Money would have to be paid to restore the hearing; social activities would have to be cut short or even abandoned. And non-socializing person suffers a lot of physiological, psychological and moral degradation; steel workers must protect their ear and hearing. But (1) works must be careful because even, while trying to protect excessive noise from injuring the ear. Some hearing aids are developed i.e., ear plugs and ear muffs. The best must be chosen. (2) Some hearing aids have enormous power output above- 140 dBA and maximum acoustic gains of up to 80 dBA. One may become so used to the aids to dependency level. (3) And some hearing aids may cause hearing loss to amplification and high absolute sound pressure levels provided to alleviate hearing impairment. These hearing protective devices can further deteriorate the hearing. Steel workers require implications of sound to hearing in ontological technology.

In the same vein, Ref. [4] professed, that personal protective device of preventing hearing loss form noise is step that individual and industry must intensify. Also, otologist must be prepared to talk to student that grind food items and put on generators, industrial managers and labour force on Hearing conservation program and find time in explaining the problems, hazards and values of hearing loss as well as techniques of prevention as orientation course for new employees and refresher course for older worker. Further still, employers are obliged to provide adequate hearing health for workers if noise levels are considered to be hazardous; this has become imperative in Nigeria since a lot of people listen to excessive sounds even before they step out from their homes. What about noise from machines, pepper grinders, corn crushing and grinding mills, the vehicle repairers, trains, and motor vehicle horns and electricity generators in homes and offices.

Types and Characteristics of Hearing Protective Devices

Alberti [4] postulated that in United State of America, no worker would accept to work with noise with unprotected ears: commercially available hearing protectors in hearing health laboratories are: plugs or muffs. These protectors have different types: (1) Prefabricated earplug, (2) soft plastic earplug (fir cone), (3) “comfit”, “EAR” (4) deci-damp (cylindrical plugs). However, Alberti [4] warned that, these ear plugs and ear muffs can be injurious to the skin of ear, by hardening the skin around the ear, though with time the hardening later wards off, and the pain would disappear, care must be taken that these hearing protective devices are inserted far enough so that jaw movement do not worn them out. These devices should be held in place while expansion occurs. Although effective, they may be difficult to remove, these devices be washed with wax cotton to clean the dust and dirt.

Hazard of Hearing Protective Devices

Rose [2] and Alberti [4] proceeded further; that there may be many people who find the fiberglass protective device irritating to the skin of the ear canal, so, such workers should be given polyurethane plugs (in which the glass is covered with a thin plastic film) to protect their hearing. Reilly et al. [5] found out that in Machigan, earplugs, earmuffs were provided for the industry workers; these hearing protective devices were given to workers in hazardous noise level department and usage of these devices were enforced; non-compliance attracted penalties ranging from query and cut in monthly pay. Monechi et al. [6] discovered that protection of hearing loss covers good lowering of noise level in octave band in- between 1 KHz through 8 KHz. Rayster and Pearson (1990) profess that adequate audiometric testing is necessary for hearing conservation program. Reynolds et al. is in line with Albert [7]. Pawlas et al. [8] advancement that constant hearing test to check the level of hearing loss under medical laboratory is imminent every week. Also, Rose [2] postulated that hearing tests should be conducted to determine hearing acuity, speech reception threshold and speech discrimination to know whether amplification is required.

Signals on Usage of Hearing Protective Devices

Rose [2] recommended that (1) any programme of hearing conservation requires constant education and monitoring of the use of protective devices. 2>the plant nurse must be skilled in fitting training and encouraging workers to use the devices appropriately. On workers phobia, Walkins and Martins advanced that they would not be able to communicate; in noise; that they will not be able to hear warning signals; and they would not hear conversation; ‘when wearing protector devices. Albert et al. [7] and Kryster [9] findings professed very sensitive technological variables to zllay the workers’ fears.

Albert et al. [7] tried to sensitize workers on hearing protection and postulated as follows:

1. Hearing protectors do not remove all Sound, they are to be likened to sunglasses which remove some of the brightness from vision without obliterating what t eye is seeing completely.

2. If signal is loud enough to be heard above background noise, then it will be heard by those wearing protectors.

3. A signal of sound spectrum totally different from the background noise may be discernible to the unprotected ear at a low intensity and be masked by hearing protectors.

4. In speech communication, someone talking above the level of background noise should be heard and understood by a normally hearing subject wearing hearing protector.

5. If two normally hearing persons are conversing, each wearing hearing protectors, then because of the speaker’s use of protectors his voice will be lower because he hears less background noise against which to raise it. He may be inaudible.

Technicalities Inherent in Hearing Protectors

The technicalities involved in the use of hearing protectors become imperative in Nigeria. This is due to the attitude of industrial workers to wearing certain procedural materials; especially materials that are not for cosmetic purposes, And that Nigerians do not regard healthy status as important until they are ill.

In furtherance of the sensitization of workers on the need to constantly utilize hearing protective devices Kryster [9] also submitted the following tips:

1. In workers the problem sighted is that, with pre-existing hearing loss, particularly of a high frequently type, when this is added to the predominantly high frequency attenuation of the protector, the preexisting high frequency loss becomes a precipitous drop. They may suffer deterioration in communication when integrated in hearing conservation programme.

2 To be effective, hearing protectors must be worn at all times because even short periods of non-compliance in high noise effectively reduce the protection by considerable amounts.

These submissions are for Americans, can such prescriptions be accredited for Nigerian workers? For the efficiency of these hearing protectors, Martins also professed that:

1. Hearing protectors with an effective attenuation of 30 dB worn in an environment of 115 dB (A) reduce sound levels at the wearers ear to 85 dB (A). If the user fails to wear it for a total of 10 minutes, he will be exposed to 115 dB (A) for 10 minutes. Which is equal to Leq 10:98d8 (A) for 8 hours and the effective protection has thus been reduced from 30d6(A) to 17(A).

2. Hearing protection devices must not only be worn, it must be worn properly, promptly and continuously.

These experts (Albert et al. [7], Kryster [9] and Martins) submissions, on health of hearing capability could have been dogmatically adhered to, in America, due to the level of literacy; were the health of individual is importantly paid for, by the ;government and individual workers value their healthy living. Can these guidelines be imposed on Nigerian workers where if one cares too much on neighbors; the care may be termed to be offensive? May not be necessary for the Nigerian government to include in the company law; certain punitive or penalties for non-compliance with wearing hearing protective devices? This is because citizen’s health must be achieved totally in the year 2000s!

Recommended Effective Hearing Protection Devices

According to Ref. [4] Earmuffs are very effective because,

(1) This hearing protector consists of a cup worn around the ear filled with a sound absorbing material.

(2) It is sealed to the side of the head by plastic or rubber gasket.

(3) Due to uneven shaping of the head, the gasket is preferably filled with liquid of foam rubber.

(4) The muffs must press to the side of the head, and are worn with spring bands.

(5) Different types of muffs must be worn for effectiveness, e.g., muffs for left ear is different from muffs for the right ear.

(6) The most expensive muffs [4] observed, is the most sophisticated. Effective muffs is that built directly into the flying helmets of modern jet fighter and which has highest attenuation figure.

The choice of plastic and rubber muffs may however be embedded is the phobia of electrocution if metal temples are used; this gesture however reduces the attenuation of the muff; wearing long hair also added some significant percentage in the reduction of muffs attenuation [4].

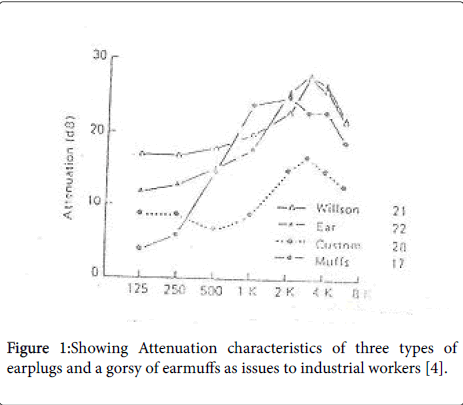

Earplugs i.e., fabricated single flanged plug, soft plastic earplug called fir cone or corn-fit), foam polyurethane ear plug, all are hearing protection devices which can get loosened even when well fitted, with aw movements These earplugs do not reduce effect of noise as do :e muffs. The level of effectiveness of these different types of hearing Presented by Ref. [4] protectors are as follows:

In Figure 1, the muffs are the best hearing protector with the highest attenuation capacity, then willson earplug, custom earplug. The muffs can protect the ear as bringing noise of 28 dB and at 4 khz to low as 4 dBa and at 125 hertz.

Therefore, industrial workers in steel industries are advised to stick to wearing ear muffs to protect their ears and hearing capability. Also, industries related to steel making, should insist that the proprietors purchase hear muffs and not any other ear and hearing protectors. Furthermore, steel industrial workers are advised to desist from wearing musical instruments with loud noise and with earplugs. If music should be listened to, it should be that recommended for the hospital environment pepper grinders and generator users who are steel industrial workers should also wear ear muffs.

References

- Pracy R, Sieglea J, Stell PM (1999) Ear, Nose and Throat. Elbs Prints, USA.

- Rose OE (2001) Noise and hearing loss. Journal ArticlePostaradMed 70: 119-129.

- Haberman J (1890) Uber die schwerhorighkeit de Kesselschmiede. Archiu for ohrenheikUnde 30: 1-25.

- Alberti PW (2002) Personal Hearing Protection in Industry. Raven Press, New York, USA.

- Reilly MJ, Rosenman KD, Kalinowski KJ (1998) Occupational NoiseInduced-Hearing Loss Surveillance in Michigan. JournalArticle QccupEnvironMed 40: 667-674.

- Monechi G, Gianchi A, PrompettiA (1990) Evaluation of risk and acoustic damage in a department of metallic carpentry. Italy JournalArticle G ltalLaw 2: 31-36.

- Albert PM, Riko K, Madson A (2007) Speech intelligibility, noise with ear protectors. 62: 575.

- Pawalas K, Grzeskil J (1990) Efficiency of ear Protectors in laboratory and real life tests. JournalArticleinArchOccupEnrionHealth 62: 323-327.

- Kryster KD (2005) The Effects of Noise on Man. Academic Press, New York, USA.

Relevant Topics

- Addiction

- Adolescence

- Children Care

- Communicable Diseases

- Community Occupational Medicine

- Disorders and Treatments

- Education

- Infections

- Mental Health Education

- Mortality Rate

- Nutrition Education

- Occupational Therapy Education

- Population Health

- Prevalence

- Sexual Violence

- Social & Preventive Medicine

- Women's Healthcare

Recommended Journals

Article Tools

Article Usage

- Total views: 11272

- [From(publication date):

December-2015 - Apr 18, 2025] - Breakdown by view type

- HTML page views : 10377

- PDF downloads : 895