Research Article Open Access

Risk Assessment: Re-appraisals for Potential Hazards in the Operational Environment and Facilities of Petroleum Refining and Distribution Industry in Nigeria - Research and Review

Tobias I Ndubuisi Ezejiofor*Department of Biotechnology, Environmental Toxicology Unit, School of Science, Federal University of Technology, P.M.B 1526 Owerri, Nigeria

- *Corresponding Author:

- Tobias I Ndubuisi Ezejiofor

Department of Biotechnology

Environmental Toxicology Unit, School of Science

Federal University of Technology

P.M.B 1526 Owerri, Nigeria

Tel: +2348083080375

E-mail: tinezejiofor@gmail.com

Received date: July 04, 2014; Accepted date: November 19, 2014; Published date: November 24, 2014

Citation: Ndubuisi Ezejiofor TI (2014) Risk Assessment: Re-appraisals for Potential Hazards in the Operational Environment and Facilities of Petroleum Refining and Distribution Industry in Nigeria - Research and Review. Occup Med Health Aff 2:187. doi: 10.4172/2329-6879.1000187

Copyright: ©2014 Ndubuisi Ezejiofor TI. This is an open-access article distributed under the terms of the Creative Commons Attribution License, which permits unrestricted use, distribution, and reproduction in any medium, provided the original author and source are credited.

Visit for more related articles at Occupational Medicine & Health Affairs

Abstract

Background: The burden of workplace hazards remains a major concern to all. Viewed from all occupational health indices, including human sufferings and related economic costs, the magnitudes of global impact of occupational accidents, diseases, and industrial disasters are alarming, and therefore deserve serious attention.

Objective: To appraise operational environments and facilities of petroleum refining and distribution industry in Nigeria with a view to establishing the potential hazards/health risks.

Design: A qualitative study involving participatory approach and structured interviews. For purposes of this study, Departments of the studied establishments were split into many smaller units to capture specific hazards of facilities and activities. Setting: The Operational sites (including facilities and activities) of PHRC and PPMC, Eleme near Port Harcourt, Nigeria.

Method: Using a standard checklist, the study involves a personal walk-through and participation in the activities of the various units, as well as structured interviews of staff concerning the health hazards/risks of their workplace.

Result: The specific hazards of the work areas, units, facilities and activities of the industries were captured. A cursory look of the establishments revealed that, while some facilities have themselves become obsolete, defective and hazardous, they have also turned into outlets for various other hazards. Physical, chemical, biological, psychosocial and ergonomic hazards were among the major occupational hazard categories so revealed. It is being suspected that the various job exposures to these workplace hazards are responsible for the accidents, injuries, morbidities and mortalities observed in this industry.

Conclusion: Presently, facilities and activities in the operational units of the petroleum refining and distribution industry in Nigeria are laden with several hazards that can be grouped into the five main hazard categories. The sundry health risks to which staff are disposed by this situation and their overall health implications are roundly discussed, and also call for immediate need for facility upgrade and industrial health Services updates, to ensure hazards abatement and mitigation of associated health risks, as well as securing safer facilities and healthier work environment.

Keywords

Toxicology; Environment; Potential hazards; Health risks; Occupational safety; Petroleum refining; Distribution industry; Nigeria

Introduction

For many occupational toxicologists, industrial hygienists, and others with stake in the field of occupational health and safety, the safety of the work place has always been a major concern. Indeed, the safety of many workplaces can hardly be guaranteed. This sometimes, is as a result of the nature of the work in itself, with certain associated unavoidable hazards, or the manner in which such work is conducteda reflection of the extent to which the essential inputs for the proper conduct of the works are provided [1]. Thus, in spite of the immense benefits derived from work, work itself has become a source of several deaths, ill-health and injuries, as are clearly illustrated by data from relevant authorities including the World Health Organization (WHO) and International labour organization (ILO) [2-4]. WHO in the World Health Report for the year 2000 [5] concluded that workplace hazards are responsible globally for 37% of back pain, 16% of hearing loss, 13% of Chronic Obstructive Pulmonary Disease (COPD), 11% of asthma, 10% of injuries, 10% of lung cancer, and 2% of leukaemia. The magnitude of the problem is said to be grave for the developing countries. In spite of the difficulty in obtaining information concerning occupational diseases and injuries in developing countries due to lack of comprehensive and harmonious data collecting systems, ILO still estimates that 2 million workers die each year from work-related injury and illness. In 2002, in sub-Saharan Africa alone, ILO estimated more than 257,000 total work-related fatalities, including about 55,000 injuries.

Thus, in both industrialized and developing countries, the rapid pace of technological changes combined with the persistence of unsafe or environmentally-threatening working conditions have served to focus attention on the need to create a safe, healthy work environment and to promote a safety culture at the workplace [2]. An important starting point for achieving this target is risk assessment, since by this all aspects of work are considered in a systematic evaluation that not only identifies the hazards of the workplace and the specific groups of workers at risk for purposes of instituting the right kind of preventive/ control measures, but also other measures to be taken to comply with the employer’s duties under the regulations, which include among others, the assessment of health and safety risks faced by workers in the normal course of their activities or duties and the prevention of occupational risks [3,6-9].

Petroleum refining and distribution are among the occupational activities perceived to be hazardous. Once extracted, crude oil is transported to an oil refinery where complex hydrocarbon compounds are separated and converted through various refining operations (fractional distillation, cracking, solvent extractions, then other treatments including formulating and blending) to become useable fuel sources [10]. Present day refineries produce a variety of products including many required as feedstock for the petrochemical industry. The process of refining oil manufactures nearly 2,500 useful products [11]. However, the major end product of oil refining is gasoline, followed by diesel fuel, jet fuel, fuel oil, kerosene, lubricating oil and asphalt used for road paving, and all of these are of great toxicological interest. Beyond these, the refining processes involve a wide array of chemicals including heavy metals compounds – either as process chemicals or products, with resultant complex refinery effluents. Gas production and gas flaring are also part of the fallouts of these processes. Refining operation activities also involve heavy equipment that produces vibrations, radiations, heat, noise, etc. thus contributing to other forms of pollution [10].

Petroleum refining and distribution industry in Nigeria, as elsewhere, constitute a giant industry with many complicated systems. The Port Harcourt refinery complex situated at Alessa-Eleme near Port Harcourt, consists of two refineries in one: the old Port Harcourt refinery (Area 5) established in 1965 with current production capacity of 60,000 barrels per stream day (bpsd), and the New Port Harcourt Refinery (Areas 1-4) commissioned in 1989 with installed capacity of 150,000 bpsd. Both refineries have combined installed capacity of 210,000 bpsd [12]. Each of the five process areas of PHRC houses several operational units: crude distillation unit (CDU), saturated gas concentration unit (SGCU), vacuum distillation unit (VDU)-area1; Naphtha hydrotreating unit (NHU), catalytic reforming unit(CRU) with continuous catalyst regeneration (CCR) section, kerosene hydrotreating unit (KHU)-area2; fluid catalytic cracking unit(FCCU), gas concentration unit (GCU), gas treating unit(GTU), merox unitarea3; dimersol units, hydro-fluoric acid (HF) unit, alkylation unit, butamer unit-area4; crude distillation unit (CDU), crude reforming unit(CRU) and liquefied petroleum gas (LPG) plant-area5. Beside these, the refinery also has a power plant and utility (PPU) section (equipped with boilers and other facilities) that generates its power and other utilities, as well as a waste water treatment (WWT) section, which treats refinery waste water before being discharged to the neighbouring creek. The process of production and the actual products are both sophisticated. PHRC processes crude oil (Bonny Light) into liquefied petroleum gas (LPG), Premium Motor Spirit (PMS), Dual purpose Kerosene (DPK) (Aviation and Domestic), Automotive Gas Oil (AGO–Diesel), Low Pour Fuel Oil (LPFO), and High Pour Fuel Oil (HPFO) as well as many other intermediate products that are industrially and domestically very useful. Through complex network of pipelines and storage tanks, these products of the refineries are passed over to the Pipelines and Petroleum Products Marketing Company (PPMC) for subsequent distribution.

Given the complexities of this work environment and facilities, and given that workers are behind their operations, it is possible that these workers might be liable to certain health hazards on account of sundry job exposures. It has therefore become very imperative to appraise these facilities and their associated operational activities with a view to defining the true nature and extent of real or potential hazards arising from them that might put the workers at certain risks to health or even life ultimately, and this forms the main aim of this study. Most of the studies done with respect to petroleum industry in Nigeria are mostly animal studies centering mainly on the effects of petroleum products on the environment, with emphasis on ecological species other than man (mainly terrestrial and aquatic resources) [13-19]. Apart from our earlier attempts (that were incomplete) to define the hazards of this industry [1,20], there had been no previous study with detailed/ complete report on work environment and facility appraisals for petroleum refining and distribution activities in Nigeria. The present study (a furtherance of our previous ones) therefore seeks to extend the data regarding the comprehensive definition of real and potential hazards of this sector in the Nigerian environment or setting.

Materials and Methods

The study setting was the facilities of and occupational activities of the studied establishments:

(a) Port Harcourt Refining Company Ltd (PHRC) (Petroleum refining industry) and (b) Pipelines and Petroleum Marketing Company (PPMC) (Petroleum distribution industry). Operations of the establishments under study are carried out in departments, which for the purposes of this study were split further into many smaller units in order to capture the specific hazards of the various facilities and the equally many different functions (activities) performed by different sections of a particular department in their particular locations. Ethical clearance and permission to study these industries were obtained from the institutional review committee of the supervisory ministry (Petroleum Resources).

Using a standard checklist (as adapted by the company), the study involved a personal walk-through and participation in the activities of the various units/sections/departments of the establishments. Although the study was not directly on the workers but rather on their working environment and facilities, the implications of sundry exposures from these on their health outcomes warranted the extraction of vital information from them, and this was done through structured interview with randomly selected cross-section of workers (covering all strata/cadre of staff - low, medium and management). By this, the opinion of staff concerning the health hazards/risks of their workplace and facilities was sought, for purposes of comparisons and updating of notes obtained first hand through participatory walkthroughs. Secondary data relating to the study of hazards of the industry by the industrial occupational physician was also used. Data emanating from these sources were collated and analyzed.

Results

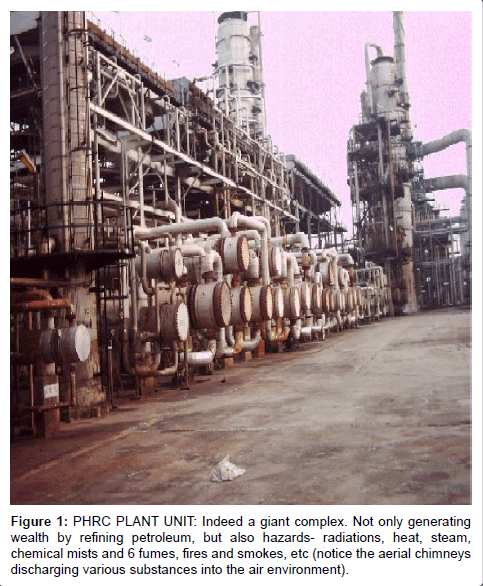

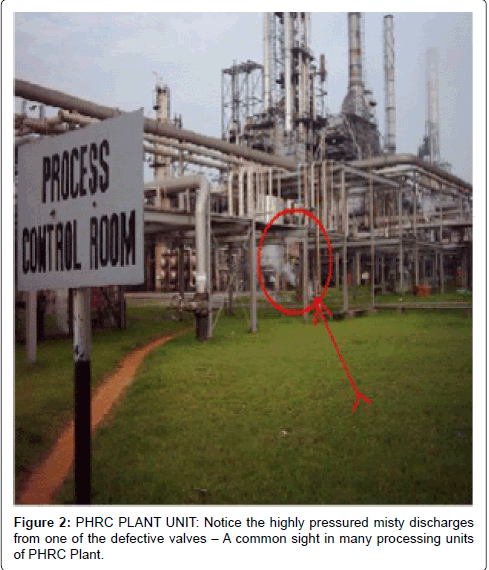

Personal walkthroughs and involvement in the activities of the various work units during the study period, as well as one-on-one interactions with staff through structured interviews gave insight into the hazards of the various operational units of this industry that were collated with the available secondary data and presented in the table below. The personal walk-through also revealed that some operational facilities of the studied establishments have become obsolete and defective, thus allowing the release of hazardous pollutants into the air environment (Figures 1 and 2).

Discussion

Reasonable insight was gained through personal walk-through of the facility areas/units, and participatory involvement in the activities and operations of the various departments of the establishments during the study period. These were corroborated by the information volunteered by the staff during the interactions/oral interviews, revealing that oil refining and distribution activities are indeed fraught with several hazards (Table 1). Observations made here were in tandem with the views of the staff themselves who catalogued a wide range of hazardous experiences encountered over the years in the course of discharging their duties. These findings were also consistent with those reported previously by Ezejiofor et al. [1,20], revealing the identified hazards as belonging to the traditional five major hazard classification categories: physical hazard, chemical hazard, biological hazard, psycho-social hazard and ergonomical hazards. The physical hazards include noise, vibrations, radiations (ionizing or non-ionizing), heat/steam, cold, winds, humidity, pressure extremes, electricity, lightening and thunder strikes, fires and explosions, vehicular movement including forklifts as well as slips, trips and falls to mention this few. This set of hazards applies to almost all sections of the industry particularly as pertains to slips, trips and falls. However, those in the power plant utility (PPU), engineering and technical services department (ETSD), flare stack area, various workshops of maintenance department, etc are more at risk with regards to exposure to vibrations, noise, cold, heat electricity and radiation (e.g. microwave, cathode rays, X-rays and radioactive substances (Table1).

| S/No | Unit Name | Activities/Functions | Hazards |

| 1 | Administration Blocks |

1. Directors/Managers Offices. 2. Meetings 3. Administration |

1. Slips, trips and falls. 2. Prolonged sitting. 3. Prolonged hours of work. 4. High human traffic. 5. Industrial Relations problems 6. Community Relations problems. |

| 2 | Technical Building | 1. Engineering and Technical Staff Offices 2. Technical Meetings |

1. Slips, trips and falls 2 Prolong sitting. 3. Prolonged hours of work. |

| 3. | Equipment and Technical Services Dept. (ETSD).Process Engineering | 1. Routine monitoring of performances of process units and facilities. 2. Identifying the problem solving in the process plants. 3. Trouble shooting of process, equipment and operations aimed at achieving a safer, efficient and economic plant operation. 4. Ensuring laid down procedures are followed in operations and maintenance of process plants and facilities and suggest modifications to procedures and plants where necessary. 5. Carrying out special technical studies and process development work. 6. Evaluating and appraising new products and technologies as they apply to the company. |

1. Noise 2. Heat. 3. Climbing 4. Inhaling of chemicals e.g H2S. 5. Prolonged sitting position. 6. Poor work/office design. |

| 4 | ETSD GeneralEngineering | 1. Identifying and development for implementation, improvement and capital projects.2. Review and advise on third party proposal, Inspection of new technologies, equipment, materials and practice.3. Ensuring equipment reliability and monitoring troubleshooting.4. Liaising with third parties on project imparting on plants operations. | 1. Slips, trips and falls 2. Heat. 3. Climbing 4. Noise 5. Prolonged sitting position 6. Poor work/office design. |

| 5 | ETSD Plant Inspection. |

Inspection of all the process plants, Power plants, and offsite equipments on daily basis | 1. Slips, trips and falls 2. Noise. 3. Climbing. 4. Exposure to biological e.g. Snakes. |

| 6 | ETSD. Computer Services. | 1. Maintenance of computer systemin PHRC these encompasses software and hardware. 2. Playing advisory role to the management on computer operations and other modernization issues. 3. Responsible for control systems such as plants monitoring and control e.g. tank monitoring and tank gauging system. |

1. Exposure to emissions e.g.Cathode rays. 2. Prolonged Sitting. 3. Cold. |

| 7 | The Live Camp | 1. Provide transit accommodation for contractor and expatriate staff. Contractor Offices. |

|

| 8 | Staff Canteen/ Kitchen |

1. Receipt/Storage of raw food items. 2. Preparation (cooking) of staff meal 3. Serving of meal to staff. |

Slip, trip and falls. Manual handling Awkward work positions. Mechanical accidents Fire and explosion Food contamination. High human traffic. Industrial Relations problems. Shift work. |

| 9 | Staff Bus Parking Area | 1.Staff bus boarding point at close of work. | 1. Slips, trips and falls. 2. Interpersonal relationship. 3. Vehicular movement |

| 10 | The Power Plant Unit, PPU. | 1. Electric power generation for therefinery 2. Operating the start-up and shutdown of boilers, turbine generators and their auxiliaries. 3.Preparation of chemical to control the boiler water and steam parameters. |

1.Slips, Trips and Falls 2. Noise. 3.Heat 4.Cold 5.Manual handling. 6.Chemicals: Phosphate, hydrazine,Amine 7.Shift work |

| 11 | The Topping Unit (Area One) | 1. Processing the raw crude from Bonny terminals into different fractions: gasoline, naphtha, kerosene, light diesel oil and butane (cooking) 2. Production of LDO, HDO, SRG, SRN and LPG. The area also houses the Vacuum distillation unit that produces VGO for FCC feed. 4. Operating and monitoring of the compressor, column and the heater to examine the burning of the flame. 4. Operation of the centrifugal pump. |

1.Oil spillage 2. Leakage of gases e.g. LPG, NH3. 3. Noise 4. Heat 5. Cold 6. Chemicals e.g. caustic 7. Climbing of towers 8. Exposure to radiation e.g. ultraviolet light 9. Shift work. |

| 12 | The Reforming Unit (Area Two) | 1. Processing of intermediate product from Area 1. 2. Catalytically upgrading of naphtha into a high octane blending stock. 3. Processing the Reformate. |

1.Slips, Trips2. Noise.3. Heat4. Cold5. Chemicals: Hydrogen sulphide, fuel gas and naphtha.6. Climbing.7. Vehicular Movement (forklift)8. Shift work. |

| 13 | The Fluid Catalytic Cracking Unit, FCCU (AreaThree) | 1Conversion of Vacuum Gas Oil(VGO) and Heavy Diesel Oil (HDO) into FCC Gasoline, LPG, Light Cycle Oil (LCO) and Main Column Bottom Product(MCB). 2.Cracking of heavier hydrocarbon. |

1.Slips, Trips and Falls2.Noise3.Heat4.Cold5.Chemical hazards: AluminiumSilica, H2S, NH3, CO, phenol, Sulphur compounds andcausticNaOH.6.Steam exposure.7.Shift work. |

| 14 | The Hydro-fluoric Acid Unit, HF Unit (Area Four) | 1. Produces unleaded Gasoline by HF alkylations; utilizing HF as catalyst.2. Preparation of butane/butane by isomerization to make it suitable for alkylation’sprocess. | 1. Noise2. Climbing3. Manual Handling4. HF5. Shift work. |

| 15 | The Old Refinery (Area Five) | 1.Production of kerosene, naphtha, diesel, fuel oil and reformate- a blending stock for PMS. This is made up of the Crude Distillation unit; the Platformer unit, and the LPG |

1. Slips, Trips and Falls2. Noise3. Exposure to chemical: e.g. Magnetic 4. Climbing5. Prolonged standing/sitting position.6. Manual handling7. Shift work. |

| 16 | The PPQC Laboratory. -Quality Control Unit |

1. Quality certification of products for public consumption e.g. kerosene, AGO, PMS, Fuel Oil, Cooking gas. 2. Distillation of Petroleum products. 3. Determining the flashpoint of kerosene and diesel |

1. Noise2. Chemicals e.g. Hydrogen sulphide, methane gas, Ammonia Gas, Puritine, Sulphuric Acid, hydrogen chloride.3. Prolonged standing Work positions.4. Prolonged sitting work positions.5. Reptiles e.g. Snakes, and Insect bites6. Shift Work. |

| 17 | The PPQC Laboratory -Utility Unit |

1. Handling the analysis of water that is generated in the system by making use of chemicals with the aid of radioactive equipments that discharge x-rays and gamma rays. | 1.Slips, trips and falls 2. Manual handling 3. Chemicals: Hydrogen Fluoride caustic, pyridine 4. Heat 5. Cold 6. Prolonged standing and sitting position 7Shift work |

| 18 | Crude tank Farm | 1. Receiving crude oil from shell bonny through pipeline into the storage tanks. 2. Preparation of crude tank. E.g. draining of water from the tank before sending the crude oil to process units |

1. Inhalation of hydrocarbon gases e.g. Methane gas and ammonia gas. 2.Climbing |

| 19 | Product Tank Farm | 1. Housing the gasoline-blending unit for the preparation of petrol, fuel oil, HHK, DPK and LPG. | 1. Inhalation of hydrocarbon gases e.g. Methane gas and ammonia gas.2. Climbing.3.Work pressure4.Shift work |

| 20 | The fuel Dump (Petrol Station) | 1. Filling of both official and private vehicles with PMS and AGO | 1.Work Pressure 2.Interpersonal relation 3. Shift work |

| 21 | Gas Filling Area | 1. Filling of Bottles with LPG(Cooking gas). | 1.Slips, trips and falls 2. Manual Handling3. Chemicals e.g. Di-methyl disulphide, LPG gas. 4. Vehicular Movements 5. Noise 6. Work pressure 7. Shift work |

| 22 | The Gas Depot | 1. Collection and accreditation of bottles (cylinders) from the staffs. | 1. Slips, trip and fall2. Manual Handling3.Inhalation of gases e.g.Di-methyl disulphide, LPG gas4. Vehicular movements5. Interpersonal relation6.Work pressure |

| 23 | Oil Movement; pumps and pipelines. (PPMC)` | 1. Receipt of crude oil from the flow stations. 2. Loading of refined petroleum products (e.g. LPG, PMS, AGO. Kerosene and fuel Oil) to the filling stations and for other internal use. 3. Loading the vessels at the jetty with petroleum products to foreign customers. |

1. Inhalation of hydrocarbon vapours e.g. LPG, PMS and kerosene. 2. inhaling chemicals e.g. mercaptansstadis 450 3. Frequent climbing. 4. Prolonged standing/sitting position 5. Noise 6. Cold 7. Shift work |

| 24 | Firs, Safety and Environment – Fire Section |

1. Fire fighting with the aid of extinguisher for rescue purposes 2. Execution of rescue mission with the use of hydraulic platform 3. Product of mechanical foam for the fighting.4. Undergoing fire training |

1. Noise 2. Heat 3. Inhalation of chemicals e.g. caustic 4. Climbing 5. Explosion of fire and the vessels. |

| 25 | Fire, Safety and Environment – Safety Section |

1. Playing advisory role to all operators in all locations on safety issues. 2. Ascertaining the safety aspect of the work carried out by making sure that they are safety insured e.g. toxic and corrosive substances. |

1. Noise 2. Heat 3. Exposure to radioactive materials e.g. microwaves 4. Climbing and vehicular movement. 5. Exposure to biological hazard e.g. snakes. |

| 26 | Fire, Safety and Environment -Environment Section |

1.Pollution Control. 2.Conducts regular inspection of work areas e.g. process workshop, canteen, storage tanks, etc. 3.Ensure proper handling and disposal of Industrial Wastes. 4.Supervises directly the use of weed killer chemicals along product pipe ways 5. Inspection of purchased material/equipment for acceptance. |

1. Noise 2. Heat 3. Vehicular Movement 4. Exposure to chemicals e.g. H2S. 5. Exposure to biological hazards e.g. snakes. |

| 27 | The Security Gates/Posts | 1. Protection of the Plants facilities, workforce and operation from sabotage, arson and pilfering 2. Manning of Security Posts/Gates 3.Crime surveillance and prevention Access control Investigation of relevant cases. |

1.Slip, Trips and Fall2.Noise3.Vehicular Movement 4.Exposure to Chemical e.g. H2S, SO2etc 5.Boredom 6. Prolonged Standing/Sitting Position. 7. Industrial Relations Problems. 8. Community Relation Problems. 9. Hoodlums Attack 10. Shift work |

| 28 | The Flare Stack Areas | 1. Flaring of Gas from the plant | 1.Noise 2.Heat |

| 29 | Chemical Warehouse (MMD) | 1. Recanting, stacking, issuing transferring and delivering of chemicals.2. Transferring of empty drums.3.Office documentation. | Exposure to Chemicals e.g. H2S, NH3 and Sulphuric acid. Heat Noise Vehicular Movement e.g Forklift. |

| 30 | General Warehouse | Distribution of materials, safety equipments, plant spares and industrial chemicals to the user’s department to keep the plants alive. Stacking and scaffolding of heavy-dutyequipments to prevent corrosion. |

Noise Heat Manual Handling Inhalation of chemicals e.g. Hydrogen sulphide, Carbon monoxide and Benzene Psychosocial hazards e.g. Shift work, Overloaded work |

| 31 | Water Treatment Plant (UTILITIES). | Treatment of water for servicing of all Refinery units Production of plant air, instrument air, gaseous and liquid nitrogen. Checking the specification of the tanks level for consumers’ consumption Operating the compressors. |

Noise Manual handling of chemicals e.g. Caustic NAOH. Radiation hazards from electrical switch gear Heat Oil spillage and Pollution. |

| 32 | Waste Water Treatment Unit. | Receipt and treatment of all forms of Waste water from all the Refinery Units including the Jetty base (e.g. laboratory, process plant, power plant, kitchen, sanitary waste, rain water, drainage from tank farm, oily water from tanks, ballast water from ships). | Manual Handling Heat Vehicular Movement Prolonged Standing/Standing Shift Work Exposure to Chemical:Phenol Ammonia gas,H2S, Sulphuric acid Caustic Soda andPhosphoric acid 7.Exposure to Water(Sewage) bornepathogens. 8.Insect bites 9.Reptiles/Rodents |

| 33 | Maintenance Workshop (Planning) | 1.Planning for Routine Preventive, Corrective and Turn Around Maintenancejobs in the Refinery. | Manual handling Noise Heat 4. Inhalation of gases e.g. H2S and Sulphuricacid.5. Exposure to radioactive element e.g. microwaves.6. Shift work |

| 34 | Maintenance Workshop (Process Instrument) | Instant problem solving in process plant. Starting, removing servicing and calibrating of instruments in the process plants. |

1. Noise2, Exposure to Chemicals e.g. H2S, NH3, CO, phenol, Caustic soda etc.3.Exposure to Radioactivesources e.g. Lasers.4. Steam/boiling exposure5. Falling inside ocean at jetty base.6. Communities Relation Problem.7.Shift work |

| 35 | Maintenance Workshop (Electrical Maintenance) | 1. Maintenance and Repairing of Electrical equipments in all the Refinery units’ e.g. electrical motors, high voltage, switchgears and Industrial batteries. | 1.Slips, Trips and Falls2.Noise3.Electricity4.Exposure to Radioactive Sources e.g. X-rays, gamma rays, lasers and microwaves.5.Exposure to Chemical e.g. Phenols.6.Climbing7.Shift work |

| 36 | Maintenance Workshop (Mechanical Maintenance) | Maintenance, Installation and Removal of structures and insulation in all the Refinery units Maintenance of air-conditioning, refrigeration, emergency generators and all appliances. |

Slips, Trips and Falls Noise Heat Welding fumes Climbing Electricity Exposure to Chemicals: Amine, Ammonia, Caustic Soda, etc. Shift work |

| 37 | Maintenance Workshop (Civil Maintenance) | 1. Repairing of sewage lines, road networks and drainages in all the Refinery units.2. Arresting of underground leakages.3. Refractory works execution.4. Insulation works on boiler (1-4).5. Pump foundation.6. Carrying out painting works7. Cleaning of blocked tundishes in the tank farm8. Subsidence in related areas from the plants. | 1. Slips, Trips and Falls2.Vehicular Movement3.Noise4.Heat5.Awkward work positions6.Exposure to Solvents7.Exposure to Chemicals8.Shift work |

| 38 | Fleet Workshop | 1.Company Vehicle Fleet Maintenance | 1.Slips, Trips and Falls2.Manual Handling3.Electricity4.Chemical: Acids5.Use of Fuel, PMS6.Vehicular Movements7.Insect bites8.Reptile/Rodents |

| 39 | The Plant Clinic | Promotion and maintenance of a healthy workforce in the Refinery Ensuring a low (health) risk work environment. Investigating and managing industrial diseases such as occupational Asthma, Noise-Induced Hearing Loss (NIHL), etc. Routine and Emergency health care delivery; In and Out Patient care. Personnel health monitoring. Medical laboratory Services |

Slips, Trips and Falls Manual handling Vehicular Movement Attending to Psychiatric Patients Biological hazards: Infectious Diseases, TB, HIV, Hepatitis A, B, C etc. X-Ray Radiations Industrial Relations Problems Interpersonal Relations Shift work Call duties. |

Table 1: Phrc and ppmc: operational units, activities and identified hazards.

Exposures to physical hazards and health outcomes

Although the exact quantification of these physical hazards and impacts on these oil work environments and their work cohorts was not done in the present study, it is however noteworthy that they abound in almost every unit of the industrial establishments. World Health Organization [21] noted that physical and chemical agents generated by man’s activities may have various effects on human being. Though some substances may not produce adverse effects, others may be liable, if exposures are sufficient to affect such basic phenomena as growth and development. Sometimes, environmental exposures may affect host susceptibility or resistance, or produce functional or prepathological changes. Behaviour may be modified by exposures, especially, to physical agents such as noise, light and radiation – all generated during industrial processes. It is in this connection that the occurrence of these hazards in various units of the PHRC and PPMC must be viewed very seriously, particularly with regard to their potential health risks posed to the workers of these establishments.

Sundry health risks associated with exposures to vibration and noise hazards

Literature abounds linking these physical hazards to various health outcomes. Hand-Arm Vibration Syndrome (HAVS), Noise-Induced Hearing Loss (NIHL), Tinnitus, etc. are some of the health effects associated with occupational exposures to vibration and noise. vibration and noise militate against health generally, since exposure to both are linked to sundry physiological and psychological health effects including annoyance, sleep disturbances, electroencephalographic changes and cardiovascular disorders [22]. Vibration is oscillatory motion about a point. Occupational/Chronic exposure to hand transmitted vibration results in various disorders sometimes collectively known as the “handarm vibration disease or “vibration syndrome”. The syndrome includes vascular, neurological and musculoskeletal disorders that may become manifest individually or collectively. This syndrome, otherwise known as Raynaud’s phenomenon, encompasses a wide range of disorders, as it is responsible for digital blanching and paraesthesias [23]. Workers may be exposed to Segmental vibration responsible for such neurological effects as numbness, tingling, and an elevated sensory threshold to touch, temperature and pain. Different vascular problems such as a pure vasospastic phenomenon, a digital organic microangiopathy, or an occlusive arterial thrombosis can be found. Diffuse vibration neuropathies with involvement of mechanical skin receptors (or carpal tunnel syndrome) are also often associated [24]. The relation between these neurovascular disorders is not clear but automatic dysfunction in carpal tunnel syndrome can induce a Raynaud’s phenomenon, which is curable with surgery [25]. Workers who use hand held vibrating tools are also exposed to diverse environmental and occupational factors, accounting for the wide clinical spectra of the disease [23]. Epidemiological studies have pointed out that the prevalence of Vibration-induced White Finger is very wide, ranging from 0-5% in warm climates to 80-100% in cold climates [26]. In the pure vasospastic Raynaud’s phenomenon, exposure to cold is probably the most triggering factor, and cold protection the most effective preventive measure. In the case of digital blanching associated with carpal tunnel syndrome, other ergonomic factors such as repetitive forceful use of the hands are likely to play a dominant part and a workplace ergonomic modification is indicated [27,28]. Hypothenar hammer syndrome is often associated with digital blanching as often found in mechanics and carpenters who need to stop repetitive hand trauma [29,30].

It has been observed that workers exposed to occupational sources of Hand Transmitted Vibration (HTV) often suffer from hearing difficulties and tinnitus as well as Vibration-induced White Finger (VWF) and other features of hand-arm vibration syndrome. An association has previously been reported between finger blanching and hearing difficulties, perhaps as a result of sympathetic vasoconstriction. Several surveys involving forestry workers clearly demonstrated this [31- 34]. Such findings have prompted the hypothesis that the sympathetic vasoconstriction observed in VWF affects cochlea blood flow, rendering the workers more vulnerable to noise induced sensorineural hearing loss [31]. However, since earlier research involved workers who were exposed to HTV, the findings may have been confounded by noise from the tools. But, the findings of Palmer et al. [35] supported an association between finger blanching and hearing loss that is not explained by confounding occupational exposure to noise, but suggested that it may extend to causes of blanching other than VWF, since this association occurs even in subjects who have never worked in noisy jobs or with vibratory tools. If according to Palmer et al. [36], a vascular mechanism underlies this association, then, hearing problem ought to be linked with finger blanching even when noise and vibration are absent.

Noise, on the other hand, is an intolerable sound (usually ≥ 90 decibel). Impacts of noise on health could be better illustrated with reports of community surveys around some airports, since these clearly suggested an association between exposure to noise and attendance at general practitioners, self-reported health problems and use of cardiovascular drugs including antihypertensive agents [37-39]. Increased prevalence of hypertension has been found in the areas or among populations exposed to aircraft noise [40,41]. Stronger association have also been found between annoyance and measures of maximum aircraft noise levels compared with energy averaged levels [42] and between increased blood pressure in cross sectional studies of children and after exposure to high levels of military low altitude flight noise in field studies and from recorded aircraft noise in laboratory settings [43-45]. This risk, according to Rosendlund [41], is particularly more important for the older subjects and those not reporting impaired hearing or other hearing disabilities as these had particularly higher risk estimates, i.e., higher prevalence of hypertension related to exposure to aircraft noise. Given these reports, it is quite clear that for different occupational groups servicing the operations at the different airports across the world and members of their families who, for reasons of occupational activities, may have residential abodes near the airports or air routes, the health implications of noise for them are quite phenomenal.

In both developed and developing nations, occupational exposure to noise is an important cause of hearing impairment and disability. Longterm exposure to noise at work causes hearing loss. Although counter measures have successfully reduced noise levels in many industries, noise is still a common occupational hazard, and noise-induced hearing loss is one of the major occupational diseases worldwide [46-48]. Reports indicate that both here in Nigeria and elsewhere, industrial activities are associated with some noise and vibration. It is therefore not surprising that just as found in the studied establishments(PHRC and PPMC), noise and vibration have been listed among the occupational health hazards in the Nigerian textile industries [49] and milling industries [50]; South African construction industry [51] and mining industry [52], mining industries of Ghana [53] and Namibia [54] where they are said to be caused by vibrating objects, flow of air, liquid or gas, and their effects said to include temporary hearing loss, hearing impairment, permanent hearing loss, vibration disease, psychological harm and disability. It is noteworthy that vibrating instruments(some of which are hand-held), vehicles (including forklifts) and other heavy duty machines form part of the operational equipments used in PHRC and PPMC, and some of these generate a great deal of noise, just as some are being operated by manual handling needing lifting, pulling and pushing actions that may also be repetitive, as may be demanded by work situations - all of which are occupational operations producing all the causal conditions predisposing to the aforementioned and other serious health challenges/health risks, and may be responsible for some of the accidents (including vehicular accidents, slips, trips, falls, etc.), morbidities (including NIHL, Tinnitus, Musculoskeletal health conditions, etc.) and mortalities reported previously for these establishments by Ezejiofor [55,56]. In different nations, estimates of the national burdens of hearing impairment attributable to noise at work vary widely according to the source of information. In Europe, around 50 million subjects are exposed to hazardous levels of environmental noise with a risk of Noise-Induced Hearing Loss (NIHL) and Tinnitus [57]. In the early 1980s, it was estimated that some 600,000 workers in the British manufacturing industry were exposed to substantial levels of noise (90 dB(A) [58]; and latter 11% of employed men and 6% of employed women from a large community survey reported nearly always needing to raise their voices to be heard in the workplace, while 3% of men and 2% of women said that as a result, they left work each day with ringing in their ears or temporary deafness [59]. In 1995, 142,000 people were in receipt of state industrial injuries benefit for occupational deafness [60] but in a survey of self-reported work related illness, it was estimated that some 140,000 people in Britain have deafness or tinnitus caused or made worse by their work [61]. Still in Britain, a survey by Palmer et al. [35] found that 2% of working aged adults reported severe hearing difficulties, the problem being greatest in middle-aged men; tinnitus was even more common. Risks of severe hearing difficulty and persistent tinnitus rose with years spent in a noisy job. In Britain, an estimated 153,000 men and 26,000 women aged 35-64 years have severe hearing difficulties attributable to noise at work; and for persistent tinnitus, the corresponding numbers were 266, 000 men and 84,000 women. In Ghana, a survey conducted on the impact of hazardous noise on the workers of a surface Gold mining company [48] revealed that noise levels above 85 dBA occurred in all sections of the company– the pit, processing, analytical laboratory and the borehole except the mess; and of the 252 workers seen, 59 (23%) had the classical Noise Induced Hearing Loss (NIHL), and that NIHL increased as a function of age at 4 Khz, and as the duration of the exposure increased, and also varies with regard to job location. Details regarding the actual quantification of each of the identified hazards in PHRC and PPMC (not done in the present study) are areas needing further studies.

Sundry health risks associated with exposures to electricity and radiations hazards

The risks of occupational exposures to physical hazards in the studied establishment are also likely to extend to those caused by electricity and radiations (cathode rays, cosmic rays, x-rays, etc) because these were also recorded in some units of the establishments (Table 1). Leukaemia, Brain Tumour, Cutaneous Malignant Melanoma and Other Malignancies, are among occupational hazards associated with exposure to electricity and Electromagnetic Fields as noted among various Generation and Transmission Workers. Electricity generation and transmission as an occupational activity, is associated with extremely low electromagnetic fields, exposures to which are recently being considered as potential cause of leukaemia and brain tumour, or other malignancies. Many studies have now been reported which have investigated risk of brain tumours and leukaemia in electrical and electronic workers [62-65]. The study of French and Canadian utility workers provided sporadic positive findings for astrocytoma and benign tumours [61], with a suggestion of electric field conferring increased risk among the French workers [66]. The cohort of several United States electricity utility company employees yielded a clear positive association between magnetic field exposure and brain cancer including a doseresponse gradient, particularly for recent exposures [67]. Also, the nested case-controlled study of Tynes et al. [68] testing the hypothesis that exposure to electromagnetic fields from high voltage power lines increases the incidence of cutaneous malignant melanoma in adults aged 16 and above yielded positive association. By contrast however, studies conducted among Southern Californian Edison workers in the United States [69] and Danish electricity utility workers [70], and the British electricity workers [71,72] showed no indication whatsoever of an association between measures of exposure to magnetic fields and mortality from brain cancer. Similarly increased cancer risks have been associated with exposures to cosmic ionizing radiations. Reports of epidemiological studies on mortality and cancer incidents suggest that pilots are at increased risk of malignant melanoma, non-melanoma skin cancer, and possibly acute myeloid leukaemia, and that female cabin crew are at increased risk for breast cancer and malignant melanoma; again, the association between length of employment and these cancers are compatible with a long induction period [73-77]. Other possible hazards that may play a role in cancer risk for flight crew are irregular working hours and disturbances of circadian rhythm [78]. Exposures to harmful levels of low energy ionizing radiation (such as cosmic radiation) has been shown to cause double stranded DNA deletions and induced genomic instability in human chromosomes [79]. It has been suggested that commercial aircraft personnel may be receiving yearly doses in the order of 3-6 millisieverts (msv) through occupational exposure. This is comparable to the exposure received by workers at nuclear plants but only slightly higher than the commonly occurring background level of radiation [80]. Health effects including cancers of various sites have also been reported in workers occupationally and residentially exposed to various forms and doses of ionizing radiations in the nuclear power plants of Trillo and Zorita (Spain). However, to date there is no conclusive epidemiological evidence to support the hypothesis of greater cancer risk around the nuclear facilities. Some studies found an increased risk for leukaemia [81-83] and certain specific tumours [84-88]. As for x-rays, this type of radiation hazard was noted in the various maintenance workshops and other units where radioactive substances were used including the plant clinic used jointly by both PHRC and PPMC (especially the radiography unit that need and use contrast medium and x-ray films for their work). Concerning the possible effects of these, it is noteworthy that leukaemia and cancers of various body sites were also among the cause of morbidities reported in these establishments [1,55]; however, there is still a need for correlation studies to establish a causal link between these health effects and occupational activities in the establishments.

Critical reviews have shown that physical and psychological factors within the workplace are determinants of musculoskeletal disorders of the neck and upper limbs [89-92]. Physical risk factors at work have included the application of force, high repetition, vibration, and awkward working postures while the psychosocial risk factors at work have included intensified workload, time pressure, low job control, monotonous work, and low support from coworkers and management. These risk factors were also among those noted in PHRC and PPMC, and similarly, various musculoskeletal and cardiovascular symptoms were among the commonest conditions reported by the workers [55,93]. Despite the development of modern technology, extensive automation, mechanization and work-related interventions, many occupations still require Manual Material Handling activities (MMH) such as pushing, pulling and lifting which pose physical stresses on to the individual. These are manifested as strains on the musculoskeletal and cardiovascular systems. If the strain causes physical overload, it may result in the development of discomfort, fatigue or musculoskeletal injuries or disorders.

Sundry health risks associated with exposures to hazards of temperature extremes (cold and heat)

Cold and heat were among the physical health hazards noted in different sections of PHRC and PPMC. While cold was noted for some sections of the establishments including the Topping Unit (Area One), the Reforming Unit (Area Two), the Fluid Catalytic Cracking Unit (FCCU), Utility unit of the Petroleum product quality control (PPQC) Laboratory; Oil movement, pump and pipelines(PPMC), etc. heat was also recorded for most facilities in areas 1-3 including the various units of the Equipment and Technical Services Department (ETSD) where most engineering and technical repair works are carried out, the various maintenance workshops, the Power plant utility(PPU) where power that drives the industrial operations are generated and the associated waste water treatment plants, the FSE (Fire, safety and environment), particularly the fire section, the warehouse, the Fire stack area, etc. For health hazards of both cold and heat, staffs of the security department are vulnerable since for the two temperature extremes, a particular staff must be on either night or day duty shift when the whether condition might be either cold or hot as the case may be (see various units in Table 1).

The physical factor of temperature creates the thermal work environment- one of the most prevailing environments facing human beings, and this may be either natural or artificial. Natural cold environments occur in some African countries during winter, while artificial cold environments occur primarily at the workplace, one example being cold-storage warehouses. Similarly, natural hot environments occur in every African country during summer, and all year round in countries located in the tropics. There are several types of artificial hot environments. Two widespread categories of artificial hot environments are heat combined with high humidity, such as in paper mills, textile mills and laundries; and high temperature associated with low humidity, an environment which is common in most metal working industries e.g. steel mills, foundries and forging mills [94]. Heat stress is the aggregate of environmental and physical work factors that constitute the total heat load imposed on the body. The environmental factors of heat stress are air temperature, water vapour pressure, radiant heat, and air velocity. Physical work contributes to the total heat stress of the job by producing metabolic heat in the body, heat being in proportion to the work intensity. Not only the environment and physical factors, but also age, sex, physical fitness, health status, clothing and acclimatization may be major factors contributing to the changes which occur in human physiological response to heat stress i.e. heat strain [94]. Human beings must maintain thermal and other bio-physiological factors in the body within relatively narrow limits. The balance between man and the environment is especially important when one is working in extreme thermal condition [95,96]. The metabolic heat produced by metabolic activities is lost to the environment by peripheral vasodilatation and sweating to maintain the body temperature at 37°C. The heat, which affects workers particularly in the tropics, can be due to exogenous and endogenous factors. The exogenous factors are air temperature and speed, relative humidity, mean radiant temperature, duration of exposure and clothing, while the endogenous thermal load depends on basal metabolism and physical activity [97]. The heat load generated by endogenous or exogenous sources can lead to heat stress, which is characterized by problems including diminished vigilance, heat stroke, heat-related cramps, rashes and collapse, and exhaustion caused by water and salt depletion [97]. The effects of occupational exposure to hot environments are well documented. These effects are known to be reflected not only in the workers physiological reactions and health e.g. increased body heat content, increases in cardiovascular and respiratory functions, sweating, heat cramps, heat exhaustion and heat stroke, but also as deterioration of the worker’s performance of either physical tasks or sedentary and mental tasks, such as vigilance and tracking, etc. The relationship between the worker’s safety behaviour and ambient temperature was found to form a U-shaped curve, with the minimum unsafe behaviour occurring within the zone of preferred temperature (approximately 20°C to 25°C).

Owing to the location of most African countries in or near the tropics, the effects of the hot environment on the workers’ health, safety and performance are aggravated throughout the continent [94]. Using the Jua kali industries in Kenya as a model, Atambo [98] described a common observations that characterize the largely small scale industries that populate most developing nations particularly in the tropical Africa. These industries are known as Jua kali or ‘Hot Sun’ industries because of the places in which they operate (usually not fixed premises) the sites commonly consist of roadsides, open spaces and pavements in front of buildings. The workers operate in outdoor areas, except for a few organized workers who have made temporary sheds. Some of the industries grouped as ‘Jua kali’ according to Atambo [98], include Motor vehicle repairers, Furniture makers, Fruit and vegetable sellers, Metal artisans, and Second-hand cloth sellers, to mention this few. The workers are exposed to hot sun, rain, and changes in the weather, all of which affect their health. Although people who work regularly in a hot environment gradually become acclimatized, most of these workers are malnourished and in poor physical condition. Heat cramps are common along with headache and dizziness. Exposure to certain dangerous weather conditions e.g. rain, may predispose the workers to common cold and pneumonia [98], while exposure to the sun (as is often the case among most people around the tropics who engage in these ‘Hot sun’ industries) may bring various dangerous health outcomes. Apart from fluid and electrolyte losses and subsequent dehydration [99], occupational exposure to sunlight have been reported to be associated with certain cancers including non-melanoma skin cancer [100-102] because of the damage it can cause to the skin’s DNA. This association is also reported to bring about mortality from ovarian and prostate cancers, following occupational exposure to sunlight [101]. With regard to the effects of hot conditions on individuals, Khogali and Awad El-karim [103] also pointed out that working under thermal heat stress not only taxes an individual’s physiological function but also poses a serious threat to his health status. They also showed that casualties due to direct exposure to solar energy in outdoor agricultural activities are significant and require special handling, precautions and control. Regarding this hazard, Changnon et al. [104] also stated, “the loss of human life in hot spells of summer exceeds that caused by all other weather events in the united states combined, including lightning, rainstorms, floods, hurricanes and tornadoes. Weather hazards such as tornadoes, floods, lightning and winter storms- each results in about 100 deaths per year on average, while heat waves result in about 1000 deaths per year on average”. In addition, heat stress can cause multivariate problems to workers’ efficiency and productivity, especially when the workers are engaged in heavy or very physical activity. Industries (such as construction and mining industries) have been noted as some of the major occupational sectors prone to physical hazards of extreme heat or cold, windy, rainy, snoozing or foggy weather, and non-ionizing ultraviolet radiation that usually occur from exposure to the sun and electric arc welding [51,95,96,105,106]. The workers of numerous other (informal) small-scale enterprises are equally at risk of exposure to these hazardous extreme weather conditions. These include farmers and others in farm-related activities [107,108], those of textiles, metal work, auto repairs and panel beating, radio and television repairs, brick making, etc. [109]. The list of those at risk of working particularly outdoors in cold environments was extended by Makambaya [106] to include workers engaged in building and construction and in civil engineering works, farm employees, and workers in services including power supply, post and telecommunications, forestry etc. Of special interest are security guards who have to protect premises day and night and who sometimes have a low level of activity while working on average of 12-hours shifts. Indoor conditions causing cold stress may include chilling, freezing and general cold storage. Those deserving mention are workers involved with processing of meat i.e. from slaughtering to packaging and dispatch. A small survey of these operations revealed that depending on the area, temperature ranging from -40°C to +12°C has to be maintained.

Talking about the effect of cold on the body, one notes that the human body can only function efficiently within a narrow internal temperature range at an average of about 37°C. It can only tolerate minor deviations of +2.5°C from this mean. Upon exposure to adverse cold conditions the body will automatically respond by trying to conserve heat by vasoconstriction of peripheral blood vessels followed by shivering to generate more heat. Further temperature drops can result in reduction in body temperature, and cooling of the brain may result in confusion, incoordination and in extreme cases collapse and death. Aside low temperatures, other factors such as clothing, wind velocity, activity level, etc. also affect the body’s heat balance. The following, according to Makambaya [106], are some of the effect of exposure to cold temperatures.

*Frost bite: - freezing of tissue, which may result in cell damage. Depending on conditions, some of the effects are reversible if proper action is taken, but in some instances, gangrene ensues and the affected body part may have to be removed by surgery.

*Hypothermia: - excessive heat loss which may lead to death.

*Vibration white finger: - this result mainly from the use of vibrating hand tools e.g. chain saws and pneumatic drills in combination with low temperature.

*Immersion foot: - caused by a combination of wet and cold conditions and restrictive shoes

*Feeling of discomfort depending on task and other environmental factors.

Sundry health risks associated with exposures to chemical hazards

The study also revealed a wide range of chemical hazards of diverse nature, although this is not quite surprising given that a great deal of chemical substances are associated with activities of this industrial sector, either as production and/or process chemicals (as compiled in the material safety data sheet (MSDS), products, or part of the discharged effluents in the form of solids, liquids, solvents, gases, mists, vapours and fumes (including fuels and welding fumes), oil spills, flammable and/or explosive substances. With regards to the vapour and fumes, all staff in the operational areas is at risk. However, regarding the risks of the hydrocarbons and other chemical fumes and vapours, those deployed at crude tank farm, product tank farm, the fuel dump (Petrol Station), Gas Filling Area, the Gas Depot, the oil movement, pumps and pipelines (PPMC); FSE (Fire, Safety and Environment), particularly the Fire Section; ETSD, PPU, the topping unit (Area One), the reforming unit (Area Two), the fluid catalytic cracking unit (FCCU) (Area Three), and the hydro-fluoric acid unit(HF Unit) (Area Four) are some of the work groups that were more at risk of the chemical hazards (Table 1). Man’s activities, particularly industrial activities, have resulted in an increasing circulation of naturally occurring substances, and the massive introduction of synthetic chemicals (Xenobiotics) in the environment. As the number and varieties of industrial types are legion, so also are the chemicals. The number of chemicals is so staggering that well over 750,000 of them now exist [110]. A wide range of pathological states in different organs may be induced by exposure to environmental agents and even death may be caused or hastened by such exposures. However, the reaction to exposure to a chemical depends on inherited and acquired characteristics and the life-style of the human subject (or other biological system), the properties and form of the chemical and the circumstances of the contact. The outcome may be no effect, some adverse effect with recovery, or toxicity with morbidity [110]. No matter the circumstance of contact (which may be recreational, residential, or occupational), human health is affected by all the activities of an individual who is subject to a continuum of chemical exposures in the external environment including air, water, soil and food [110]. In spite of all these, chemical exposure at work is almost without exception higher than the exposures of the general population [111], therefore, the adverse effect of chemicals are most likely to appear at work. This is true for both acute poisoning and for the more insidious long-term effects [112]. Exposure to chemicals may cause human disease in several ways. First, a certain disease may result directly from exposure to a specific chemical compound [113]. Second, exposure to a chemical may be only one of several factors contributing to the development of a disease, and, thus, be part of a multi-causal relationship Tsuchiya et al. [114]. Chemical exposure may also aggravate a pre-existing disease. For example, air pollution with nitrogen oxides will provoke airway symptoms in patients with respiratory diseases [115]. Thus, exposure to chemicals may constitute a leading factor in the development of a range of human diseases. An important determinant of health however, is the balance between the status of the milieu interieur and that of the milieu exterieur. Excess or deficiency of naturally occurring chemicals may alter this balance by making the body tissues more vulnerable [116]. Health effects of chemical toxicity include organ system damages, including those of the liver, kidneys, bones/joints, gastrointestinal tract, respiratory system, brain and nervous system, blood-forming system etc. Some of these effects are immediate and acute; others are delayed and result in chronic situations, while others are long term effects including sterility, mutations and birth defects [21,117]. Chemicals have caused, and continue to cause immense sufferings in the form of acute poisonings, reproductive failures and terata, cancers and allergic reactions. They are also the cause of deterioration of the environment [112].

Some of the chemical substances recorded as hazards in parts of PHRC and PPMC work environment include petroleum fumes, Benzene ,Toluene, Xylene, gases such as hydrogen sulphide (H2S), Hydrogen Fluoride(HF), ammonia (NH3), and methane, Polycyclic aromatic hydrocarbons(PAH), asbestos, several salts and acids, to mention this few (Table 1). This is not surprising at all because crude oil and refined petroleum contain four major groups of hydrocarbons- alkanes, olefins, alicyclics and aromatics; and gasoline, the major refined petroleum product normally contains more than 20 different chemicals [118,119]. Also, while gasoline is largely generally constituted of alkanes and aromatic compounds, it typically contains a variety of additives (e.g. Methyl tertiary-butyl ether (MTBE) for improving engine performance [118]. Evidence from previous studies revealed that those exposed to some of these chemical substances under various occupational settings have accumulated larger doses of these compounds compared to the unexposed, and that some of them have been associated with some negative health outcomes. For instance, an evaluation of the contribution of traffic fumes to exposure to benzene in urban workers was carried out on personal exposures to benzene and alkyl benzene during the work shift in 139 policemen who controlled medium to high traffic areas and in 63 office police (who served as control group). Results show that on a Time Weighted Average (TWA), exposure to benzene was consistently higher among traffic police than among indoor workers [120]. Although the BTEX complex chemical family (benzene, toluene, ethyl benzene and xylene) produced in an environment of petroleum refining, present related health effects, that of benzene is more prominent because it is an integral component of petroleum produced at high levels. Thus, benzene is a ubiquitous environmental pollutant that has significant health-damaging effects [121-124]. Several studies have shown that benzene exposure is associated with deleterious health effects in humans [125,126]. Human exposure to benzene has been shown to increase the risk of developing carcinogenesis, specifically, leukemia, lymphoma, aplastic anemia, pancytopenia and chromosomal aberrations [124,127-130]. In addition, several adverse respiratory effects including pulmonary oedema, acute granular tracheitis, laryngitis, bronchitis, and massive haemorrhaging are associated with benzene exposure. Moreover, exposure to benzene can cause a wide range of adverse effects on central nervous system, haematological, hepatic and renal functions [131-135]. Thus, communities living near petroleum refineries have significant health risks due to the increased probability of being exposed to benzene and other toxic chemicals [136]. Occupational exposure to benzene and its polymers such as ethyl benzene or styrene (a catalytic hydrogenation product of ethyl benzene) is associated with colour vision loss, even if the exposure concentration was lower than 10 ppm [137,138]. Styrene has been reported to be a neurotoxic substance [139,140]. Exposure to styrene was found to have neurobehavioral effects and was also associated with persistence of complaints in workers exposed to styrene in a polyester boat building plant [141]. Similarly, Occupational exposures in a sulphate manufacturing plant have been reported to increase the risk of death from certain malignancies including brain tumours, liver or biliary tract cancer, and leukaemia, as well as lung cancer and pleural mesotheliomas (probably due to co-exposure to asbestos) [142]. Studies on occupational risk factors for male bladder cancer revealed that males in the highest tertiles of occupational exposure to polycyclic aromatic hydrocarbons (PAHs), aromatic amines and diesel exhaust had non-significantly higher age and smoking adjusted incident rate ratios of bladder cancer than men with no exposure [143]. Similarly, Occupational exposures in a sulphate manufacturing plant have been reported to increase the risk of death from certain malignancies including brain tumours, liver or biliary tract cancer, and leukaemia, as well as lung cancer and pleural mesotheliomas (probably due to coexposure to asbestos) [142]. Brief toxicological information obtained for some of these hazardous materials shows that:

Ammonia: It acts as an alkali, and anhydrous ammonia reacts with moisture in mucosal surfaces (eyes, skin and respiratory tract) to produce ammonium hydroxide, which may cause injury. Ammonia is a severe respiratory tract irritant with acute inhalation effects including dry mouth with sore throat, and eyes, tight chest, headache, ataxia and confusion. After massive exposures, chronic airway hyperactivity and asthma associated with obstructive changes in pulmonary function may occur [144].

Hydrogen cyanide

It is absorbed by inhalation, ingestion and through the eyes and intact skin. Cyanides act extremely quickly once absorbed. Principal signs and symptoms of acute systemic effects are headache, dizziness, vomiting, anxiety, confusion, weakness, ataxia, hyperventilation, dyspnoea, hypotension, bradycardia and collapse. Cyanide may also cause acute effects in the eyes - for example, irritant effects, conjunctivitis and eyelid oedemas have all been reported after exposure to cyanogens chloride [145]. Effects of chronic exposure to cyanide include respiratory tract irritation, chest discomfort, and exertion dyspnoea, and varying degrees of rhinitis, nasal obstruction and bleeding have been seen in workers chronically exposed to cyanide [146].

Polycyclic Aromatic Hydrocarbons (PAHs)

In general have a low order of acute toxicity in humans. Cancer is the most significant endpoint of PAHs toxicity. Increased incidents of cancers of the skin, bladder, lungs, and gastrointestinal tract have been described in workers exposed to PAHs. Chronic exposure can also produce various non-cancer effects. These chronic effects include eye irritation and photosensitivity, respiratory irritation with cough and bronchitis, leukoplakia ‘coaltar warts’ (precancerous lesions enhanced by exposure to ultraviolet light), erythema, dermal burns, dermal photosensitivity, acneiform lesions, dermal irritation, mild hepatoxicity and haematuria. Also several PAH compounds are immunotoxic and some suppress selective components of the immune system [147]. It is noteworthy that most of the symptoms noted above made the list of symptoms reported previously for PHRC and PPMC [55], and organ-system effects such as toxic nephropathy [148], Cardiovascular health risks [93] and hepatoxicity [149] had also been reported among their workers. However, the possibility of chemically-facilitated health effects among the staff of PHRC and PPMC is not a peculiar one. The reports are in tandem with findings in most chemically hostile occupational environments, since evidence from previous studies show that industries and other environments with potentials for chemical exposures are often associated with sundry health hazards/risks [150- 154].

Sundry Health Risks associated with Exposures to biological Hazards

Depending on the peculiarities of different work places vis-à-vis the hygienic standards, many workers of different workplaces had been afflicted with one infection or the other on account of biological hazards. Agents of biological origin cause biological hazards. The biological hazards are mainly from exposure to disease agents of infections and infestations such as bacteria, viruses, rickettsiae, coxiella, chlamydiae, fungi, helminthes, protozoan parasites, other parasites/ Pathogens including the vectors of these, and sundry other conditions that predisposes to diseases and infirmities including bites from rodents, reptiles and insects including malaria-causing mosquitoes, as well as contamination of food/water. Workers at risk of infectious diseases are health care personnel, workers who come into contact with infected animals or with animals’ products, persons engaged in ground breaking activities (miners, farmers), sex workers and workers from non endemic areas e.g. military personnel, travelers [97].

In the case of PHRC and PPMC, While all are equally exposed, those of the plant clinic, Waste Water Treatment (WWT) Unit, kitchen/staff canteen, Security services, tank farm, as well as those of the Fire, safety and Environment (FSE) departments particularly the gardeners/mowers of the Environmental unit of the (FSE) are more at risk of this set of hazards (Table 1). Apart from the plant clinic staff with peculiar exposures, the risks of biohazards from zoonotic pathogens and bioaerosols are most likely for the workers of the other aforementioned units of the establishments under study, because such staff will inevitably come into contact with contaminated soil/ vegetation, infected animals or products of such animals. According to Decosemo and Griffiths [155], Bioaerosols’ release and the consequent pollution of the workplace air are hazardous events associated with certain occupational activities. Bioaerosols occur ubiquitously as inhalable mixtures of air and microorganisms, or organic substances of microbial and plant origin. Besides livestock breading and farming, the increasing number of large-scale compost facilities for sewage sludge, and yard and solid wastes being established within the scope of modern disposal concepts, can release bioaerosols. Health-relevant moulds (Aspergillus fumigatus) and actinomycetes accumulated in compost material become airborne as vegetative cells or spores through movement of the materials [156,157)]. In the outdoor air, exposure to bioaerosols (for example, containing Aspergillus fumigatus) can occur from natural or anthropogenic sources [156,158,159]. Farmers are also at risk of occupational hazards associated with bioaerosols. Short-term exposure to airborne microbial agents during farm work was reported to be responsible for a high occurrence of symptoms of the nose and eyes as well as cough among farmers. Those symptoms were associated in a dose–dependent manner with exposure to fungal spores. Nose symptoms were also said to be associated with exposure to silica [160]. Noninfectious microorganisms and microbial agents such as bacterial endotoxins are known to cause respiratory effects through toxic and immunological mechanisms. In various working populations asthma, chronic obstructive pulmonary disease, extrinsic allergic alveolitis, and organic dust toxic symptoms (febrile episodes with transient lung function changes not associated with occupational asthma or extrinsic allergic alveolitis) are associated with inhalation of airborne microorganisms [161]. Health effects typical for exposure to noninfectious microbial agents are usually not dependent on viability of microorganisms but are caused by such specific agents as allergens and toxins that are present in both viable and nonviable microorganisms.

Farming and certain other occupational engagements always put the workers at risk of insect and snakebites. While insects oftentimes serve as the vectors for many disease pathogens, snakebites may inject venom, which at times, can be fatal. Plant quarantine and pesticide inspectors (of Tanzania) are by the nature of their duties exposed to this biological hazards of Insect and Snake bites, and sometimes, inhalation of pollen and fungal spores that can cause respiratory allergies [108]. According to Chippaux [162], snakebites constitute a serious public health problem in Africa. The annual number of accidents involving snakes is said to reach one million, resulting in 600,000 envenomations and more than 20,000 deaths [163]. The incidence ranges from 300 to 400 bites per 100,000 inhabitants per year in rural areas. Of these bites, half causes envenoming and without treatment the mortality may reach 5 to 30% depending on the region especially in the rainy season. By the very nature of their job, the security services (whose duties involved outdoor patrolling activities), and the gardeners/mowers of the environmental unit of the FSE department (whose jobs could be likened to those of farmers), it is very clear that these occupational groups in both PPMC and PHRC are mostly at risk of the bites of insects (mosquitoes) and snakes, with the associated risks of deaths from vector-borne diseases (e.g. malaria) and from snake venoms as the case may be.

Occupational health concerns exist for janitorial and laundry workers, nurses, emergency medical personnel and waste handlers. Injuries from sharps and exposure to harmful chemical waste and radioactive waste can also pose health hazards to workers. These health hazards do not stop with the hospital occupants. Medical wastes can also adversely affect the general public health. Improper practices such as dumping of medical waste in municipal dustbins, open spaces, water bodies etc. can lead to the spread of disease. Emissions from incinerators and open burning can also lead to workers exposure to harmful gases, which can cause cancer and respiratory diseases. Exposure to radioactive wastes in the waste stream can also pose serious health hazards to workers.