Review Article Open Access

Rheological Percolation in Thermoplastic Polymer Nanocomposites

Jiji Abraham1, Sharika T1,2, Soney C George3 and Sabu Thomas1,4*1International and Inter University Centre for Nanoscience and Nanotechnology, Mahatma Gandhi University, Kerala, India

2St.Xaviers College Kothavara, Vaikom, Kerala, India

3Centre for Nanoscience and Nanotechnology, Amal Jyothi College of Engineering, Kerala, India

4School of Chemical Science, Mahatma Gandhi University, Mahatma Gandhi University, Kerala, India

- *Corresponding Author:

- Sabu Thomas

International and Inter University

Centre for Nanoscience and Nanotechnology

Mahatma Gandhi University, P.D. Hills

Kottayam, Kerala, 686560, India

Tel: 91-481-2730003

Fax: 91-481-2590357

E-mail: sabuchathukulam@yahoo.co.uk, sabuthomas@mgu.ac.in

Received date: November 30, 2016; Accepted date: December 26, 2016; Published date: January 02, 2017

Citation: Abraham J, Sharika T, George SC, Thomas S (2017) Rheological Percolation in Thermoplastic Polymer Nanocomposites. Rheol: open access 1:102.

Copyright: © 2017 Abraham J, et al. This is an open-access article distributed under the terms of the Creative Commons Attribution License, which permits unrestricted use, distribution, and reproduction in any medium, provided the original author and source are credited.

Visit for more related articles at Rheology: Open Access

Abstract

The dispersion of nanofillers in in polymer matrix is a critical issue not only because of its scientific importance but also for technical reasons. Quantitative analysis of extent of dispersion of fillers by measuring the rheological characteristics of thermoplastic polymer nanocomposites has great technical importance for improving processing conditions, for understanding the fundamental characteristics of the materials at the nanoscale and structureproperties relationships of nanocomposites materials and in their commercial applications. Viscoelastic properties including the percolation threshold are extremely sensitive to how the nanofillers are dispersed. The percolation threshold, corresponding to the onset of solid-like behaviour can be observed at lower filler concentrations as the dispersion is improved, or the interaction between the nanofiller and the matrix is stronger or the filler aspect ratio is larger. This review highlights the various factors such as nature of filler, dispersion of fillers, fabrication techniques for polymer nanocomposites, interaction between filler and polymer, filler-filler interactions and temperature which affect the rheological percolation of thermoplastic polymer nanocomposites.

Keywords

Rheology; Thermoplastic; Rheological percolation; Microstructure; Dispersion.

Thermoplastic Polymer Nanocomposites

.The development of polymer composites reinforced with nanofillers is a rapidly emerging multidisciplinary research activity that, due to the improved mechanical, physical and thermal properties of these materials can greatly broaden the application of polymer in several industrial fields. Nano fillers of various dimensionality and size can be used for ideal reinforcement material to improve overall performance of polymer matrix. Advantages of nanocomposites over conventional polymer composites are due to the extra ordinary surface area of nanofillers which facilitates better interfacial interaction and effective load transfer between polymer and filler. Due to high aspect ratio of nanofillers property improvements are observed at extremely low concentration [1]. Possible applications of polymer nanocomposites include automobiles, aerospace, injection molded products, coatings, adhesives, fire-retardants, packaging materials, microelectronic packaging, optical integrated circuits, drug delivery, sensors, membranes, medical devices, consumer goods, etc. [2]. Polymers can be classified based on the source, backbone of the polymer chain, structure of polymers, composition of polymers, mode of polymerisation and finally based on molecular forces. Various classes of polymers are shown in Figure 1.

Plastics are the basic ingredients of animal and plant life and form a part of the larger family called polymers. Advantages of plastics include low density, lightness, transparency, resistance to corrosion and colour relatively low processing costs. Long chain molecules are held together by weak van der Waal forces in thermoplastic and the long chain molecules are held together by strong bonds in thermosets. Thermoplastics are well suited for many different types of uses, because it’s relatively easy to manufacture thermoplastic components quickly in high volumes with high precision. Sometimes engineers use thermoplastics instead of metals because of their much lighter weight. Acrylonitrile butadiene styrene (ABS), Acrylic (PMMA), Ethylene vinyl alcohol (EVOH), Polyacrylonitrile (PAN), Polyamide-imide (PAI), Polyamide (PA or Nylon), Polyethersulfone (PES), Polypropylene (PP), Polystyrene (PS), Polytrimethylene terephthalate (PTT) and Polyvinyl chloride (PVC) are some examples for commonly used thermoplastics. Processing of thermoplastic polymer nanocomposites melt blending, solution mixing, coating, in-situ polymerization and nanoinfusion [3]. Advantages of thermoplastics as compared to other polymer composites include.

• The fibre volume fraction can be varied across the section from 0 to ~65%, which is not possible with conventional methods.

• Greater component robustness due to the tougher matrix.

• Improved environmental tolerance properties.

• The ability to post form and weld the material.

• Raw materials are cheaper and have a much longer shelf life than conventional composites.

• Potential for rapid process speeds.

• Eco-friendly composites-use of recycled/reclaim, no use of solvents and are recyclable.

• Greater variety of matrix/fibre combinations and fibre volume fractions available to give your profile the exact.

• Physical and mechanical properties your application requires.

Rheological methods have been widely used to study composites incorporated with fillers, since they can detect the presence of internal structures. So the viscoelastic properties of polymer composites have both practical and basic importance since they are related to composite processing, dynamics and microstructure [4]. Hence, this review offers a comprehensive discussion on rheology of polymer nanocomposites, rheological percolation and factors affecting rheological percolation in polymer nanocomposites.

Rheological Characteristics of Polymer Nanocomposites

Rheology or flow-properties of polymer nanocomposites are lie between those of the pure polymer (melt) rheology and the rheology of colloidal suspensions. The viscoelastic properties of nanofiller/polymer composites have both practical and basic importance since they are related to composite processing, dynamics and microstructure. Since the rheological response of filled polymer systems are closely related to the final structures of the system, melt rheological studies of such systems are valuable both for improving/optimizing the processing conditions and also for understanding the fundamental characteristics of the material at the nanoscale [5]. Nowadays several theoretical and experimental studies have been performed to determine the influence of fillers on the rheological behavior of these polymer nanocomposites [6]. Rheological methods have been widely used to study composites incorporated with fillers, since they can detect the presence of internal structures. The macroscopic connectivity with 3D network produced from physical interactions can be investigated using rheological methods [7]. This 3D network can be produced from the physical interaction between filler-filler, polymer-filler, polymer-polymer, etc. The long-range connectivity can be attributed to various forces, such as van de Waals, hydrogen bonds and electrostatic interactions are responsible for this long range connectivity within the composites. At a critical loading of filler, the viscoelastic response of the composite system changes from liquid like to solid-like behaviour [8]. Structure and final properties of polymer nanocomposites are developed during its processing. Any filled polymer system should be most likely processed in a liquid state and under flow for conversion to a solid composite material. So, it is desired to elucidate not only the basic rheological properties but also structure transformation which a heterophase viscoelastic system undergoes during processing [9]. A monograph on the broad topic of the rheological properties of polymer nanocomposite can be found elsewhere. The general behaviour reported in the literature for oscillatory shear rheological measurements at low frequencies is that the linear rheological properties of filled composites evolve from a liquid-like behaviour to a solid-like behaviour as the nanofiller concentration increases. The application of a power law function to the evolution of properties with filler loading data provides a tool to estimate the percolation threshold, corresponding to the onset of solidlike [10]. The rheological behaviours of polymer composites filled with carbon black, carbon nanotubes and nanoclays have been reported. The rheological data indicated that the addition of fillers like MWNTs in polymer matrix led to the changes of the materials from liquid-like to solid-like behaviour. It was found that for a homogeneous dispersion system, relatively low filler loading may cause the 3D network and the composite system consequently to exhibit solid-like behaviour [11].

Literature studies shows that, the shear viscosity of the neat polymer is characterized by two distinct regions, called the Newtonian region and the shear thinning region. At low shear rate or oscillatory frequency, the Newtonian region shows a shear rate independent behaviour followed by the shear thinning region, where the viscosity linearly decreases with an increase in the shear rate [12]. Remarkable shear thinning behaviours have been reported in some composites embedded with nanofillers such as nanofibers, nanoclays, silica, etc. and is attributed to increasing filler-polymer and filler-filler interactions with increasing the filler loadings. The filler-filler interactions play a dominant role in the rheological behaviour for the composites, resulting in an increase in the shear viscosity without the Newtonian plateau region. Thus rheological data of polymer nanocmposites are interconnected with structural and morphological data, allowing us to explain the main features of structure transformations in heterophase dispersions under strong shear flow.

Rheological Percolation

It is important to determine the percolation threshold because the rheological behaviour of such composites is generally very different before and after the percolation threshold. Rheological percolation represents the long range connectivity of the fractal flocs within the polymer matrix resulting in the formation of a 3D network supramolecular structure. It is well known that the formation of filler network within the polymer matrix have greatest enhancements on the properties of nanocomposites. Furthermore, rheological percolation threshold value for a given composite may depend on the rheological property under consideration (complex viscosity, elastic modulus, loss modulus) [13]. The rheological threshold is usually displayed by sudden rise on the viscosity vs. volume fraction.

Also the percolation threshold of polymer nanocomposites can be shown by a change from a Newtonian behaviour before the percolation threshold to a frequency-dependent behaviour after the percolation threshold. Depending on the accuracy of the measurements performed and their interpretation one finds various results in the literature with respect to the existence of a rheological transition [14]. All those conclusions are misleading insofar as a “rheological percolation” which show the transition from a liquid-like to a solid-like behaviour. As well-known from the literature such a transition is designated by the storage modulus and the loss modulus running in parallel to each other in a double logarithmic plot as a function of angular frequency. At the percolation threshold there exists a formation of ‘gel-like’ structure by the filler resulting in a ‘sol–gel’ transition in the nanocomposites. As the concentration of filler increases in the melt the filler–filler interactions dominate over polymer–particle interactions and eventually lead to percolation. The percolation concentration of filler is often quantified by a plateau in the elastic modulus (G’) at low frequency region. This non-terminal low frequency behaviour can be attributed to the formation of filler network, which restricts the long-range motion of polymer chains. Below percolation concentration, the polymer chains are still fully relaxed and exhibit typical homo polymer-like terminal behaviour [15]. Theoretical approaches including a power law model, a two-phase model, and a scaling model were used to gain insights into the nature of the percolated structure. Electrical percolation threshold, needs direct connection/overlapping of fillers and also the fillers should be close enough to allow hopping and tunnelling of electrons. But for rheological percolation it is not required to have very close contact between filler but should form a network. Therefore, the particleparticle distance required for the rheological percolation threshold is higher than that for electrical percolation threshold [16]. In the case of MWCNT filled composites the alignment of the MWCNT is expected to lower the contact between MWCNT, resulting in an increase in the percolation threshold. McNally et al. found a percolation threshold of 7.5% and explained this high value by the alignment of the MWCNT produced by their passage through an extruder die.

Rheological Percolation threshold of filled polymeric systems directly relates to the material’s microstructure, the state of nanotube dispersion, aspect ratio, orientation of nanotubes and the interactions between nanotubes [17]. Lowering percolation in polymer nanocomposites further increases the potential for applications of nanocomposites. Reducing percolation helps in designing conductive nanocomposites at lower cost using low amount of the conductive fillers. Rheology has applications in various fields such as pharmaceutics, physiology, materials science engineering, geophysics and human biology. Materials science is utilized in the production of many industrially important substances, such as cement, paint and chocolate, which have complex flow characteristics. In addition, plasticity theory has been similarly important for the design of metal forming processes. The science of rheology and the characterization of viscoelastic properties in the production and use of polymeric materials have been critical for the production of many products for use in both the industrial and military sectors. Study of flow properties of liquids is important for pharmacists working in the manufacture of several dosage forms, such as simple liquids, ointments, creams, pastes, etc. The flow behaviour of liquids under applied stress is of great relevance in the field of pharmacy. Flow properties are used as important quality control tools to maintain the superiority of the product and reduce batch to batch variations.

Factors Affecting Rheological Percolation

Nature of filler

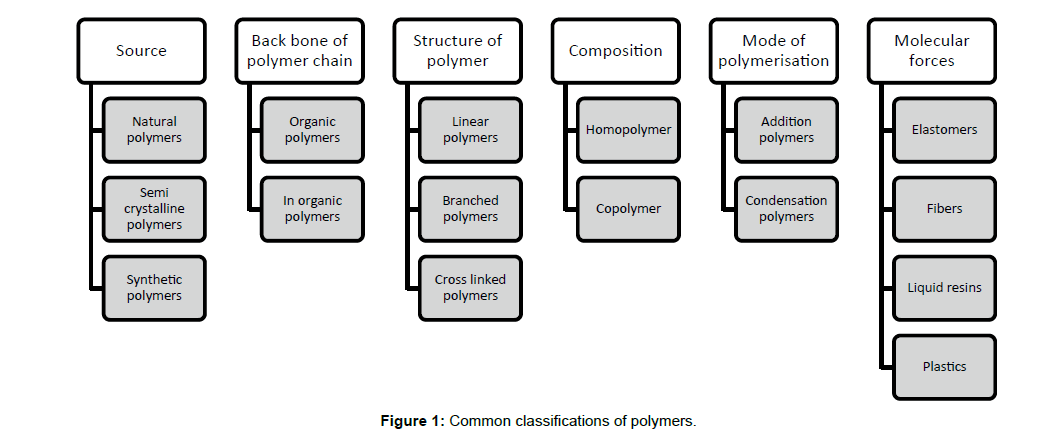

Shape of nanofiller: Zhao et al. compared the rheological behaviour of poly (2-vinylpyridine/fumed silica and poly (2-vinylpyridine/ colloidal spherical silica nanocomposites [18] to understand the role of particle shape on the percolation threshold of their polymer nanocomposites. From rheology they showed that fumed silica NPs readily form a percolated network at low NP volume fractions. They revealed that the NPs act as network junctions with the effectively irreversibly bound polymer chains serving as the connecting bridges. Here lowest percolation was obtained for fumed silica filled poly (2-vinylpyridine) composite is due to the fractal shape and large specific surface area of the fumed silica particles. The Figure 2 shows the storage modulus and loss modulus values of the two composites with angular frequency.

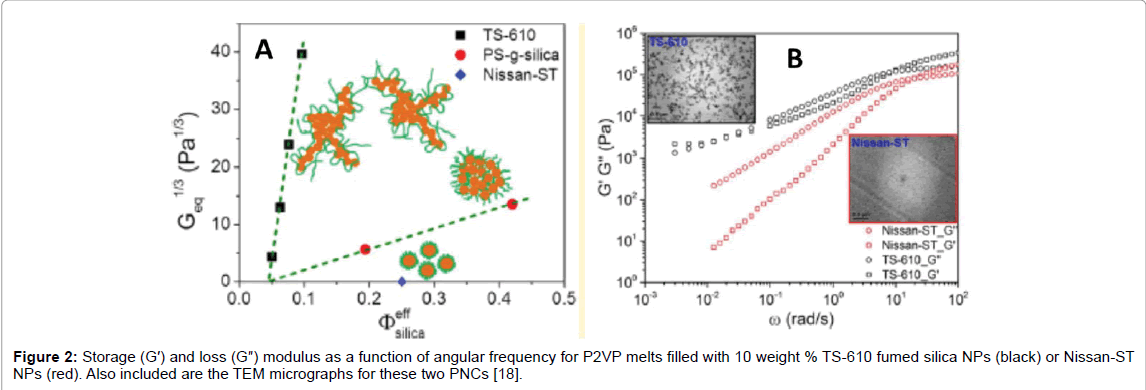

Gallege et al. carried out the rheological analysis for evaluating the filler percolation network of multi-walled carbon nanotubes (MWCNTs) and thermally reduced functionalized graphene sheets (FGSs) in an epoxy resin [19]. They found that FGS did not raise the viscosity of the system as much as MWCNT, maintaining the Newtonian behaviour even at 1.5 weight% FGS. In their study a lower rheological and electrical percolation threshold for MWCNTs is observed. Figure 3 shows the variation of the complex viscosity versus frequency for studied systems. Epoxy resin clearly has Newtonian flow behaviour with the viscosity independent of the frequency. The addition of MWCNTs significantly alters the flow behaviour of the epoxy dispersions. The viscosity gradually increases as the MWCNT content increases. This effect is more pronounced at the low frequency region.

This behaviour can be explained on the basis of the effect of shape of fillers in the rheological percolation of composites. MWCNTs with a rod-like geometry and a very high aspect ratio readily form the filler network. As high enough shear rates are applied, this network breaks down and CNTs can then align in the direction of the flow and/or disaggregate causing the decrease in the viscosity. On the other hand, while the planar structure and functional groups on the FGS does not change the Newtonian regime of the pristine epoxy resin, therefore, the effect of FGS concentration on the viscosity is much smaller compared with the viscosity enhancement produced by MWCNTs. In their case the evolution of the frequency dependence of the viscosity is also fitted by applying the Herschel-Bulkley model.

Figure 2: Storage (G′) and loss (G″) modulus as a function of angular frequency for P2VP melts filled with 10 weight % TS-610 fumed silica NPs (black) or Nissan-ST NPs (red). Also included are the TEM micrographs for these two PNCs [18].

Figure 3: Evolution of the complex viscosity of the epoxy/nanofiller dispersions vs. frequency where the symbols correspond with the experimental result and the solid line with the Herschel–Bulkley model [19].

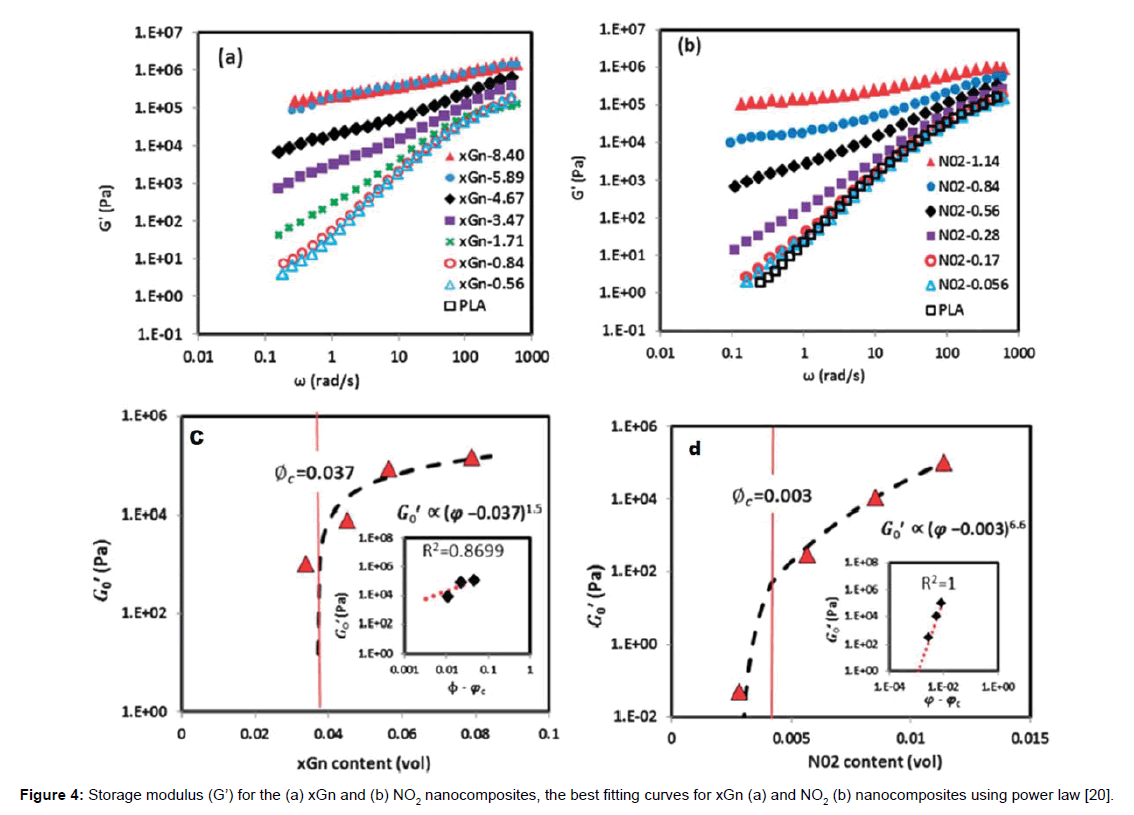

Aspect ratio filler: Sabzi et al. prepared two PLA/graphene nanocomposites containing different types of graphene nano platelets (xGn and NO2) using a solvent casting method [20]. Rheological analysis of this obtained composites are conducted to understand the dispersion and network structure of graphene nano platelets within the polymeric matrix. Also they have used Different theoretical approaches such as a power law model, a two phase model and a scaling model for colloidal gels to know about mechanism of the graphene nanoplatelet network and the nature of the percolated structure. All these studies reveal thatNO2 showed much a lower percolation threshold than xGn because of the former’s larger aspect ratio better dispersion favourable surface structure and chemistry. Hence this study shows the effect of aspect ratio of fillers on the rheological percolation threshold of polymer nanocomposites.

The appearance of a G’ plateau indicated the formation of a threedimensional nanoplatelet percolation network within sample. The slopes of the G’ curves (below 0.51 rad s-1) were calculated and plotted as a function of grapheme concentration, shown in Figures 4c and 4d. The slope decreased at a much faster rate for the NO2 composites the slope decreased at much faster rate than for the xGn ones. This shows that earlier formation of the percolation network in the former composites (Figure 4). Also, G’ of the NO2 composites comprising 1.14 vol% (2 weight%) graphene was comparable to that of the xGn composites comprising 8.40 volume% (14 weight%) graphene, indicating a much stronger NO2 network structure at the same graphene content. Compared to xGN composites, lower percolation threshold for NO2 sample was attributed toNO2’s larger aspect ratio, better dispersion and higher specific surface area.

Figure 4: Storage modulus (G’) for the (a) xGn and (b) NO2 nanocomposites, the best fitting curves for xGn (a) and NO2 (b) nanocomposites using power law [20].

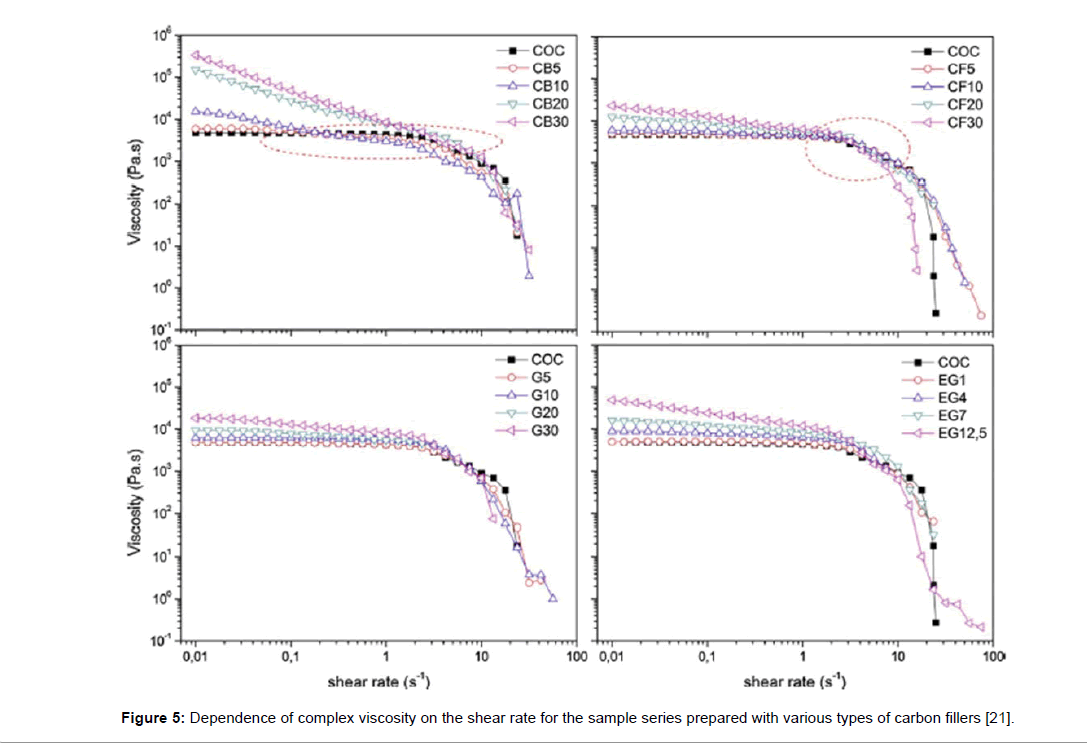

Kasgoz et al. investigated the rheological properties of cycloolefin copolymer composites filled with different types of carbon fillers such as carbon black, carbon fiber, graphite and expanded graphite [21]. Figure 5 shows the dependence of complex viscosity on the shear rate for the sample series prepared with various types of carbon fillers. It is seen that the dynamic viscosity values of composites are higher than that of CO2 at low shear rates depending on the type and amount of filler. This enhancement in viscosity is more pronounced for the composites prepared with the CB and EG. They have determined the intrinsic viscosity and maximum packing fraction values with the Krieger-Dougherty model. It was found that the intrinsic viscosity values of samples prepared with the various types of fillers decreased in the order of expanded graphite>carbon black>graphite>carbon fiber. The greater viscosity enhancement in composites by CB and EG are due to their high surface area and agglomerated structure. Consequently, this study reveals that the geometric feature of filler is an important structural parameter in the rheological properties of carbon filled thermoplastic composites.

Dispersion of fillers

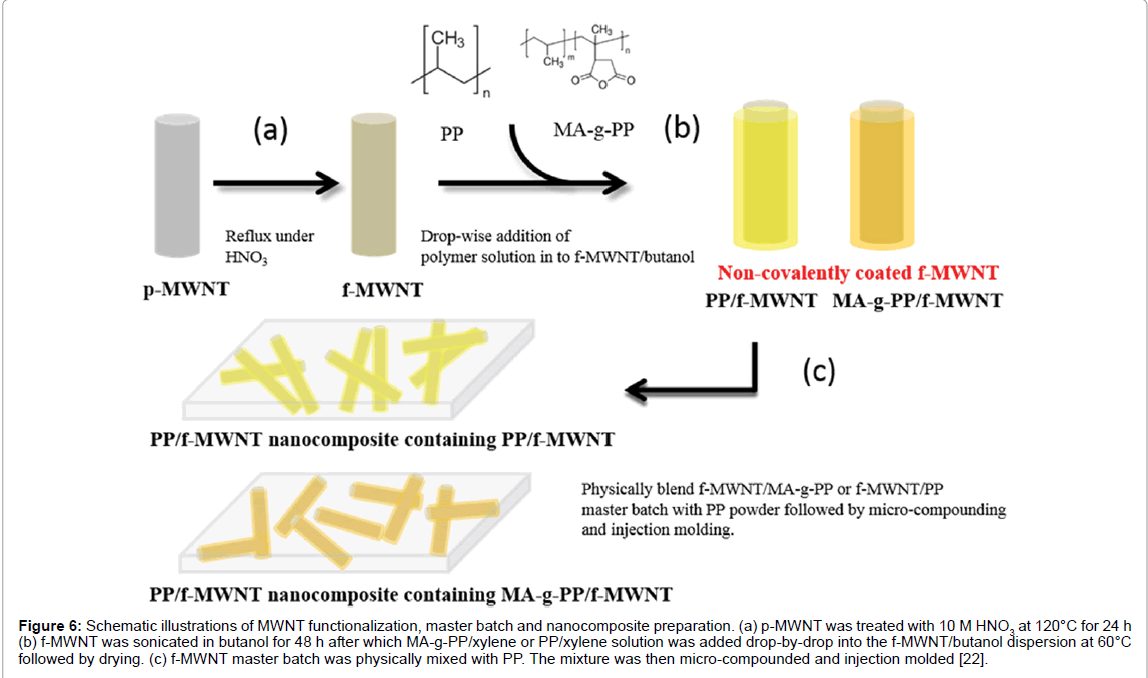

Effect of functionalization: It is difficult to fully disperse pristine MWCNTs into the polymer matrices. This problem can be avoided by the proper surface functionalization of CNT. It is possible to fully exploit the properties of CNT based polymer nanocomposites by the proper dispersion of CNT in polymer matrix and making good interfacial interaction between MWCNT and the polymer matrix. Wang et al. prepared maleic anhydride grafted polypropylene composites containing polymer coated MWCNT with enhanced dispersion and filler polymer interaction and the schematic diagram representing the nanocomposite preparation is shown in figure 6 [22]. Rheological studies of prepared composites revealed that due to the superior dispersion of f-MWNTs in grafted polypropylene an enhancement in overall performance of composites was observed. Here good dispersion and better interfacial interaction between non-covalent functionalised MWCNT and maleic anhydride grafted polypropylene can reduce the rheological percolation values to lower concentration of MWCNT.

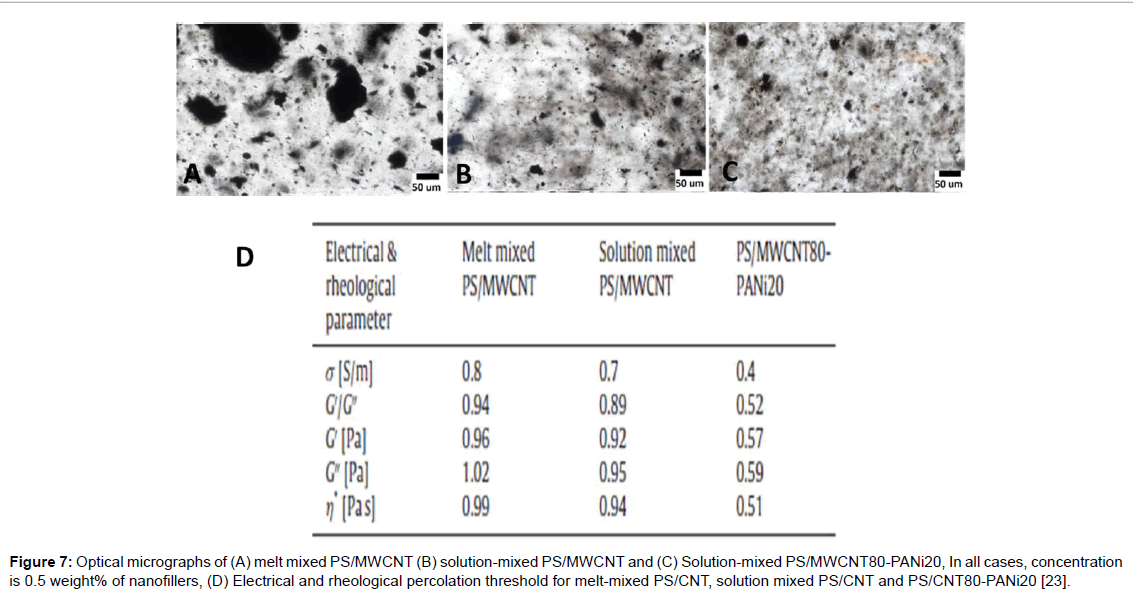

Rheological percolation in polystyrene composites filled with polyaniline-coated multiwall carbon nanotubes investigated by Sarvi et al. [23]. The proposed study revealed the effect of polymer coating on MWCNT in the formation of filler networks in polymer matrix which may further reflected in the rheological characteristics of prepared composites. They also compared the rheological characteristics and optical microscopy images of composites prepared by two different methods via melt mixing and solution casting method (Figure 7). Here lowest percolation was obtained for PANI coated MWCNT prepared via solution casting due to the efficient interfacial interaction between filler and polymer and also due to the homogeneous and uniform dispersion of modified MWCNT. Network formation of nanofillers was evidenced from rheological measurements and in this study rheological percolation defined by indirect rheological parameters such as the ratio (G’/G”), matches electrical percolation behaviour.

Figure 5: Dependence of complex viscosity on the shear rate for the sample series prepared with various types of carbon fillers [21].

Figure 6: Schematic illustrations of MWNT functionalization, master batch and nanocomposite preparation. (a) p-MWNT was treated with 10 M HNO3 at 120°C for 24 h (b) f-MWNT was sonicated in butanol for 48 h after which MA-g-PP/xylene or PP/xylene solution was added drop-by-drop into the f-MWNT/butanol dispersion at 60°C followed by drying. (c) f-MWNT master batch was physically mixed with PP. The mixture was then micro-compounded and injection molded [22].

Figure 7: Optical micrographs of (A) melt mixed PS/MWCNT (B) solution-mixed PS/MWCNT and (C) Solution-mixed PS/MWCNT80-PANi20, In all cases, concentration is 0.5 weight% of nanofillers, (D) Electrical and rheological percolation threshold for melt-mixed PS/CNT, solution mixed PS/CNT and PS/CNT80-PANi20 [23].

Rheological characteristics of covalently functionalised MWCNT reinforced polymer nanocomposites were investigated by Arrigo et al. [24]. Effect of covalent functionalised and un-functionalised nanoparticles on nanocomposites internal structure and processing properties was examined by melt rheology. Presence of hydroxyl groups on the surface of modified MWCNT improves the interfacial interaction between filler and polymer and it led to the better load transfer from polymer to MWCNT. Therefore, the compatibility and strong interactions between CNTs-OH and the matrix greatly enhance the dispersion as well as the interfacial adhesion, strengthening the overall mechanical performance of the nanocomposite. Both viscosity and storage modulus for functionalised MWCNT reinforced polymer matrix shows higher values than one with unmodified MWCNT due to the better compatibility and uniform dispersion of modified MWCNT. Disappearance of Newtonian plateau in nanocomposites suggest the arrangement of both bare and functionalized CNTs in interconnected structures, resulting in the formation of a semi-3D network of nanoparticles into SBS matrix. Rotational rheological behaviours of PLA/quaternary fulvic acid (QFA) functionalised saponite nanocomposites demonstrated that incorporation of QFA-saponite increased rigidity of the network structure in PLA matrix which was confirmed by an increase in the G’ in the frequency range [25]. The higher value of storage modulus for nanocomposite as compared to neat polymer indicates the better reinforcing ability of functionalised saponite. The nucleating effects of functionalise saponite improved the crystalline domains of poly lactic acid which further supports the increased storage modulus value.

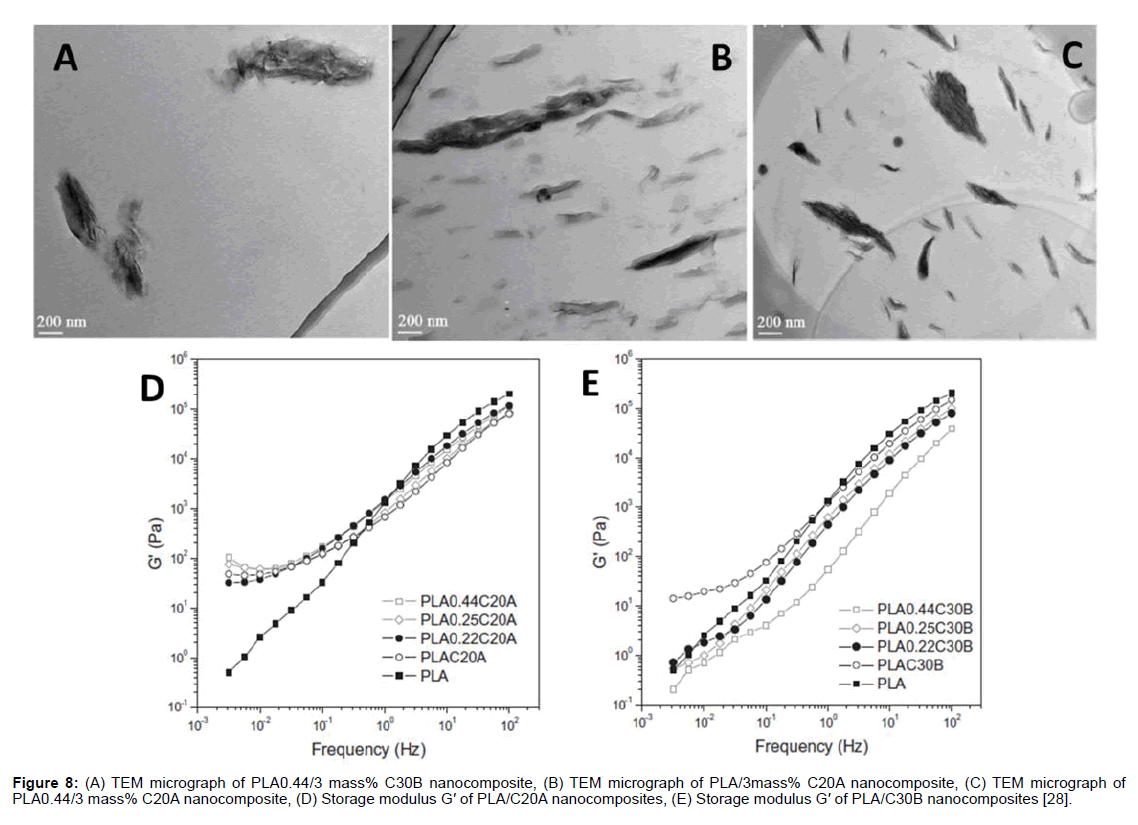

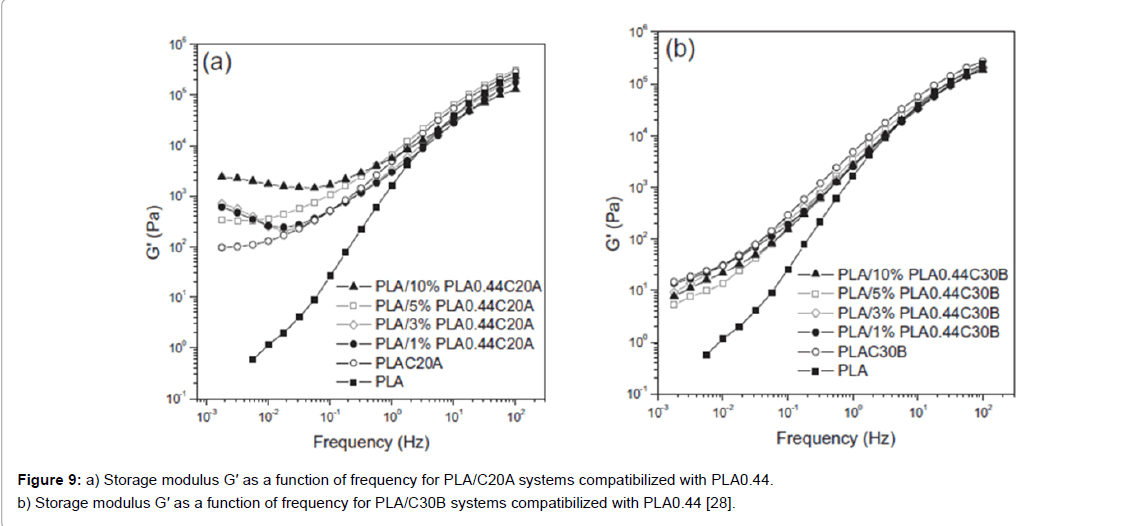

Effect of compatibilizer: Rheological analysis of polystyrenegrafted graphene as compatibilized nanofillers was done by Beckert et al. [26]. High degree of compatibility between graphene and polymer matrix was achieved through Hydrophobic modified graphite oxide grafted with polystyrene chains (PS-g-FG). Evolution of the solid-like network structure during temperature and shear exposure was well monitored by melt rheological characterization and simultaneously conducted dielectric spectroscopy. This study has addressed a nice correlation between rheology, electrical conductivity, and statistical morphology analysis, taking into account the effect of graphene/ polymer compatibilization by grafting polymers onto graphene. The effects of different or compatibilizers on the morphology of organoclay based PLA nanocomposites and their rheological properties under oscillatory shear were investigated by Acik et al. [27]. Composites containing to different types of compatibilizer such as ethylene-glycidyl methacrylate (E-GMA) and ethylene-butyl acrylate-maleic anhydride (E-BA-MAH), were prepared using a twin screw extruder. Nature of compatibilizer has a significant effect on the rheological properties and microstructure. Better compatibility is obtained by using E-GMA due to the matching polarity and the high reactivity of the epoxide group in E-GMA with the end groups of PLA, possibly resulting in a network structure in the final product. The degree of intercalation is governed by the compatibility between filler and polymer and here high degree of intercalation was obtained for samples containing E-GMA. These changes in the microstructure were reflected in the final rheological characteristics (Figure 8). The addition of E-GMA to PLA introduced a distinct solid-like behaviour to PLA at low frequencies. The solidlike behaviour of PLA/E-GMA blend was reduced by the addition of organoclay, possibly due to positioning of the organoclay layers in the ternary nanocomposites. Effect of the nature of montmorillonite intercalant and anhydride maleic grafting on polylactic acid structure and properties was examined by Issaadi et al [28]. Maleic anhydride grafted poly(lactic acid) (PLAgMA) can either be used as a matrix or as compatiblizer and two different types of clay Cloisite® 20A and Cloisite® 30B as fillers. The rheological behaviour of nanocomposites with PLA as matrix showed strong shear-thinning behaviour and nonterminal viscoelastic behaviour at low frequencies. PLA containing C20A and C30B shows a gradual deviation of the G′ slope at low frequencies indicating a “pseudo solid-like behaviour.” This behaviour was characteristic of the formation of clay mineral network-like structures that reduced the mobility of polymer chains and can be attributed to the percolation of the fillers. On comparing viscoelastic properties of neat PLA and grafted PLA with 3weight% clay mineral (Cloisite® 20A), it is observed that the use of grafted PLA matrix has a very small effect on the pseudo solid-like behaviour. Higher plateau obtained for most of the grafted PLA matrix was due to the better exfoliation of silicate minerals in polymer matrix due to peeling effect, i.e., after intercalation of the polymer chains between the clay mineral layers of C20A, the carbonyl groups of maleic anhydride will repel them and cause them to peel. But the nanocomposites with grafted PLA and Cloisite® 30B exhibited pseudo-Newtonian liquid behaviour in the low frequency region. However, we observed that the solid-like behaviour changed to liquid-like behaviour with increasing percentage of maleation. With the introduction of 1 to 10 mass% of grafted PLA to PLA containing 3 mass% of Cloisite® 20A, the terminal behaviour is disappeared with increasing the amount of compatibilizer and a perfect solid like behaviour at low frequency region is observed when the comaptibilzer content reaches 10%. But for the systems with Cloisite® 30B, C30BPLA nanocomposite exhibited a pseudo solid-like behaviour at low frequency but the introduction of PLAgMA induced a light increase in the slope G′ vs. ω (Figure 9)

Figure 8: (A) TEM micrograph of PLA0.44/3 mass% C30B nanocomposite, (B) TEM micrograph of PLA/3mass% C20A nanocomposite, (C) TEM micrograph of PLA0.44/3 mass% C20A nanocomposite, (D) Storage modulus G′ of PLA/C20A nanocomposites, (E) Storage modulus G′ of PLA/C30B nanocomposites [28].

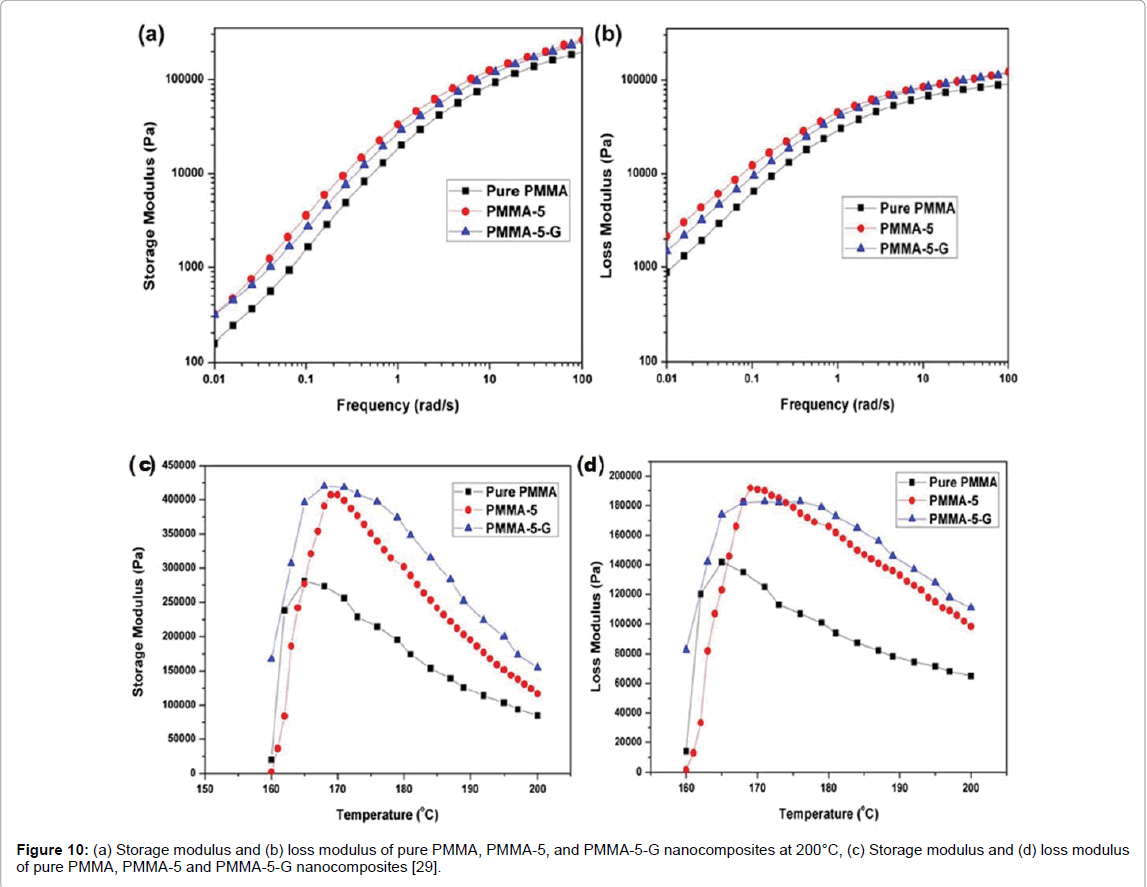

The influence of nanoclay and compatibilizer on the rheological behaviour of PMMA nanocomposites as a function of temperature and frequency is investigated by Kumar et al. [29]. From figure 10 it was evident that storage and loss modulus increased as the frequency increases and it was less dependent at higher frequency for a fixed temperature. The complex viscosity of different PMMA nanocomposites (with and without compatibilizer) decreased under varied frequency at 200 °C. However for different temperature range analysis (160-200°C), the polymer chains started separating from each other with an increase in the temperature and polymer-nanoclay network no more exists; therefore, both the moduli and complex viscosity reduced. It was also observed that the rheological properties of PMMA-5-G nanocomposite are better with respect to other samples at different temperatures. In the case of PMMA-5-G sample, formation of interfacial bond between the anhydride groups of PMMA-g-MA and amino groups in nanoclay can entangle with polymer chains of matrix to form a continuous polymernanofiller network (Figure 9).

Chemically functionalized MWCNTs containing polypropylene composites with two different kinds of compatibilizers were prepared by melt compounding using a twin-screw extruder and effects of interfacial interaction and dispersion on electrical and rheological properties of the composites were investigated. There was a strong improvement in the rheological properties of heat treated MWCNT/PP composites as compared to pure PP and untreated MWCNT/PP composites. The MA-g-SEBS compatibilizer yielded enhanced elongational viscosity due to increased interaction between treated MWCNTs and PP matrix. Significant change in the rheological and electrical behaviour was observed at 2.0 weight% of MWCNT loading and the percolation thresholds were observed at the MWCNT concentration between 1.0 weight% and 2.0 weight%, due to the three dimensional network structure formation [30].

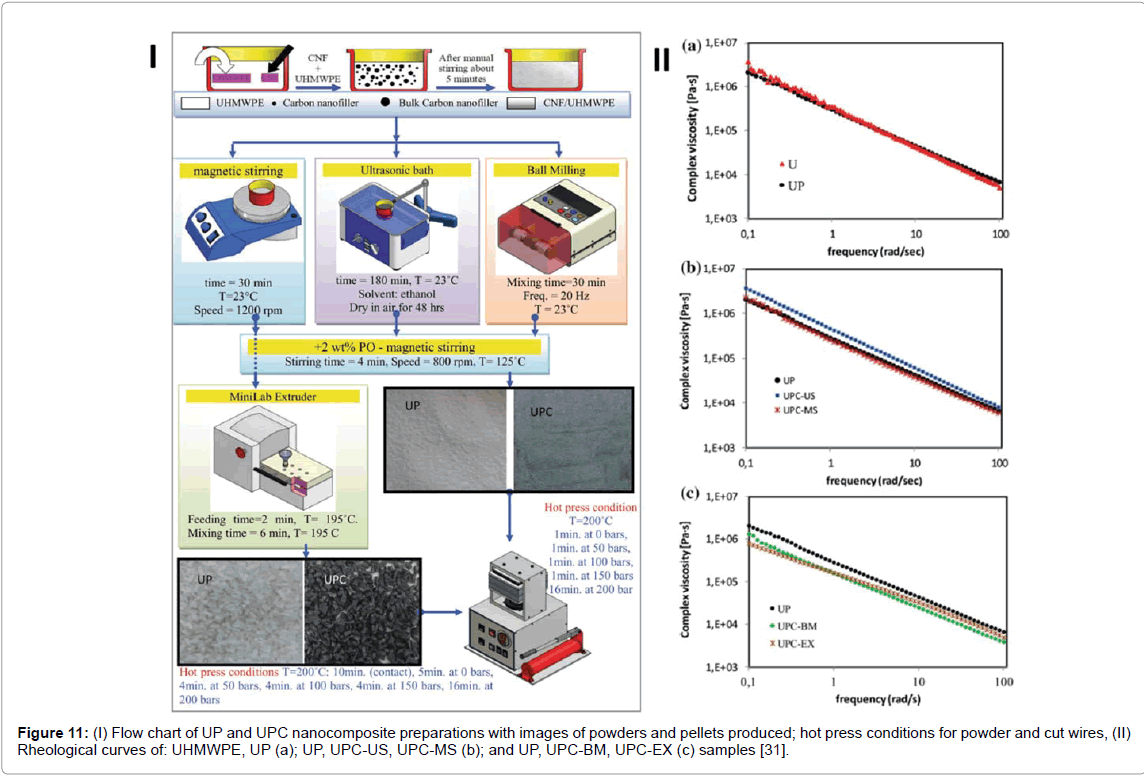

Processing conditions: Visco et al. compared the rheological behaviours of nanocomposites based on UHMWPE/Paraffin Oil/ Carbon nanofiller obtained by using different dispersion techniques such as magnetic stirring(MS), ball milling (BM) and ultrasonic and Mini-Lab extruder (EX). Experimental results highlighted that the nanocomposites produced by EX and BM exhibits the best dispersion, good filler matrix interaction and had significantly improved mechanical properties compared to pure UHMWPE. Due to the better efficiency of EX and BM mixing methods as compared to MS, highly exfoliated morphology was obtained in former mixing methods as compared to latter which is reflected in the rheological characteristics of final composites (Figure 11). So the use of the ball milling and the extrusion processes as the best techniques for the preparation of UHMWPE/PO/carbon nanofiller- based nanocomposites and tailored possible applications of these materials due to the different features of the nanocomposites [31].

Figure 9: a) Storage modulus G′ as a function of frequency for PLA/C20A systems compatibilized with PLA0.44.

b) Storage modulus G′ as a function of frequency for PLA/C30B systems compatibilized with PLA0.44 [28].

Figure 10: (a) Storage modulus and (b) loss modulus of pure PMMA, PMMA-5, and PMMA-5-G nanocomposites at 200°C, (c) Storage modulus and (d) loss modulus of pure PMMA, PMMA-5 and PMMA-5-G nanocomposites [29].

Nanocomposites based on biodegradable thermoplastic polymer with three different nanosized fillers (natural montmorillonite (Nanofil 116), Cloisite 15A, Cloisite 30B) were prepared by a twinscrew counter-rotating extruder and the effect of elongational flow on dispersion and rheological characteristics of nanocomposites were investigated by Mantia et al [32]. The rheological characterization pointed out that the Cox-Merz rule does not apply to the investigated nanocomposites systems and the use of Cloisite 15A and Nanofil leads to an increase of viscosity and non-Newtonian behaviour, while Cloisite 30B leads to decreased viscosity and greater deviations from Newtonian behaviour. This was attributed to Cloisite 15A and Nanofil being the less polar and thus being just intercalated, while Cloisite 30B showed no traces of agglomerates suggesting that a better dispersion and a certain degree of exfoliation was achieved. It is found the increase of the draw ratio leads to an orientation of the nanoparticles in the draw direction which leads to the improvement in the overall mechanical performance of nanocomposites. Injection molding parameters influence the dispersion of clay in PP matrix as attested by the modification of dynamic rheological properties of master batch based melt-mixed PP/clay nanocomposites. Nanocomposites injectionmolded at higher back pressure, screw rotational speed, injection flow rate and holding pressure display higher storage modulus and complex viscosity compared to those manufactured with process parameters set-up at lower level. Such improvement achieved with more severe injection molding conditions was attributed to optimized dispersion during injection molding [33]. It is observed that continuous ultrasonic extrusion method led to rapid intercalation and a partial exfoliation of HDPE/clay nanocomposite with dramatical changes in rheological characteristics [34]. The complex viscosity increased further with ultrasonic treatment and attained its maximum level at amplitude of 5 mm. At amplitude of 7.5 mm the complex viscosity is still higher than that of the untreated nanocomposite. The complex viscosity decreased at amplitude of 10 mm. The great enhancement of complex viscosities of ultrasonically treated nanocomposites was attributed to the nanoscale dispersion of clay within HDPE, which improved the compatibility between the polymer matrix and layered silicate.

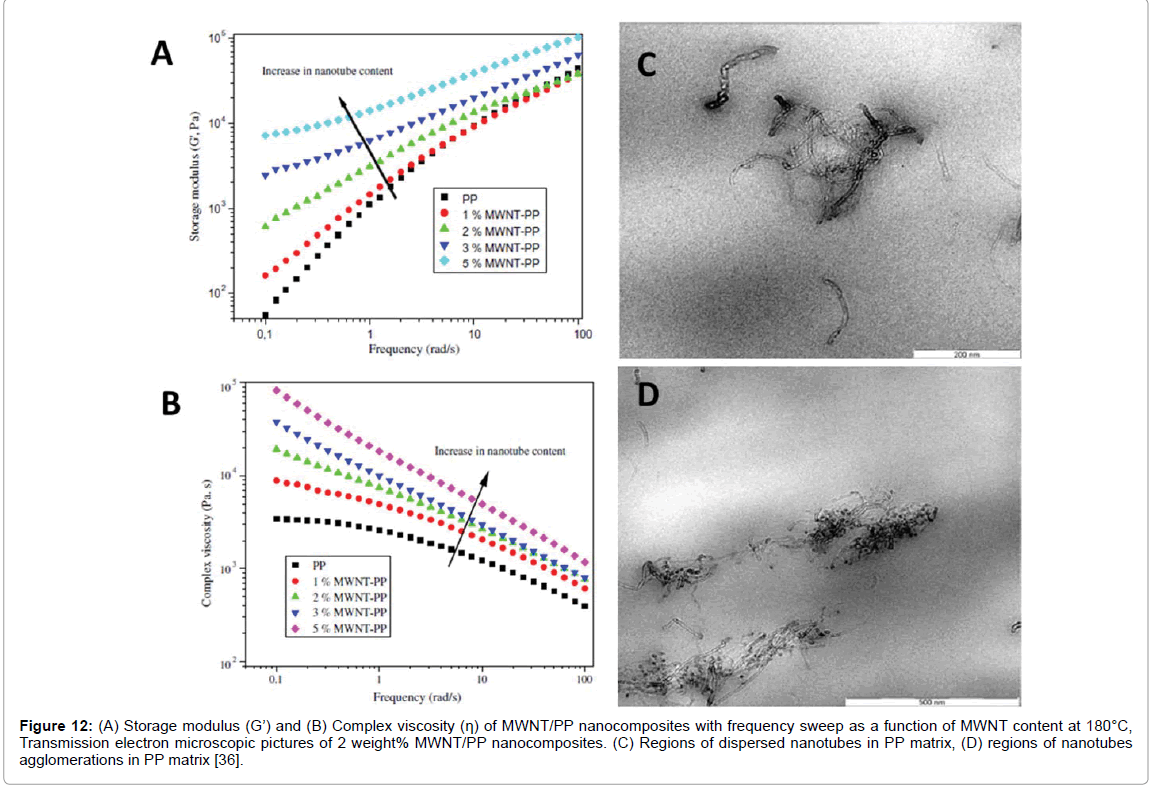

Fabrication techniques for polymer nanocomposites

The comparison between the effects of solvent casting and melt intercalation mixing processes on different characteristics of polylactide-nanographite platelets composites was evaluated by Narimissa et al. [35]. Three processing techniques: (i) dry mixing and melt intercalation; (ii) solvent casting using dichloromethane organic solvent; and (iii) combination of solvent casting and melt intercalation techniques were performed to compare the effictiveness of fabrication method rheological characteristics of nanocomposites. Morphological analysis of the samples revealed that solvent casting technique can independently improve the dispersion of NGP nanofillers within PLA matrix, as expected. However, when this mixing technique was followed by melt intercalation, the optimum level of nanofiller dispersion (i.e., exfoliation) was achieved. The shear rheological analysis of the samples revealed that although both mixing techniques could individually damage the rheological properties of neat PLA and PLA/ NGP composites, the detrimental effects of solvent casting on samples is extended when it is combined with extrusion [35]. Preparation of nanocomposites from master batch dilution is an excellent method to obtain well-dispersed CNTs, while limiting the handling difficulties in plastics processing industrial workshops. Polypropylene (PP)/ multi-wall carbon nanotubes (MWNTs) nanocomposites prepared by diluting a PP/MWNT master batch by melt compounding with a twin screw extruder showed improved dispersion of MWCNT and enhanced interfacial interaction between MWCNT and PP. The rheological results showed that the materials experience a fluid–solid transition at the composition of 2 weight%, beyond which a continuous MWNT network forms throughout the matrix and in turn promotes the reinforcement (Figure 12). Microscopic pictures indicate an effective dispersion of nanotubes via extrusion process by master batch dilution technique. Chafidz et al. [36] studied the rheological and mechanical properties of polypropylene/calcium carbonate nanocomposites prepared from master batch. In the melt rheological study, a frequency sweep test showed that the complex viscosity |η|, the storage modulus (G’), and the loss modulus (G”) of the nanocomposites increased with nano-CaCO3 loading. The increase in |η| was approximately 1.4-1.9 times greater than that of the PP matrix. Shear thinning behaviour was also observed for the nanocomposite samples. Additionally, the relaxation time spectrum and the relaxation modulus, G (t), were determined by fitting experimental data (G’ and G”) using the Maxwell element method via numerical analysis.[37].

Figure 11: (I) Flow chart of UP and UPC nanocomposite preparations with images of powders and pellets produced; hot press conditions for powder and cut wires, (II) Rheological curves of: UHMWPE, UP (a); UP, UPC-US, UPC-MS (b); and UP, UPC-BM, UPC-EX (c) samples [31].

Interaction between filler and polymer

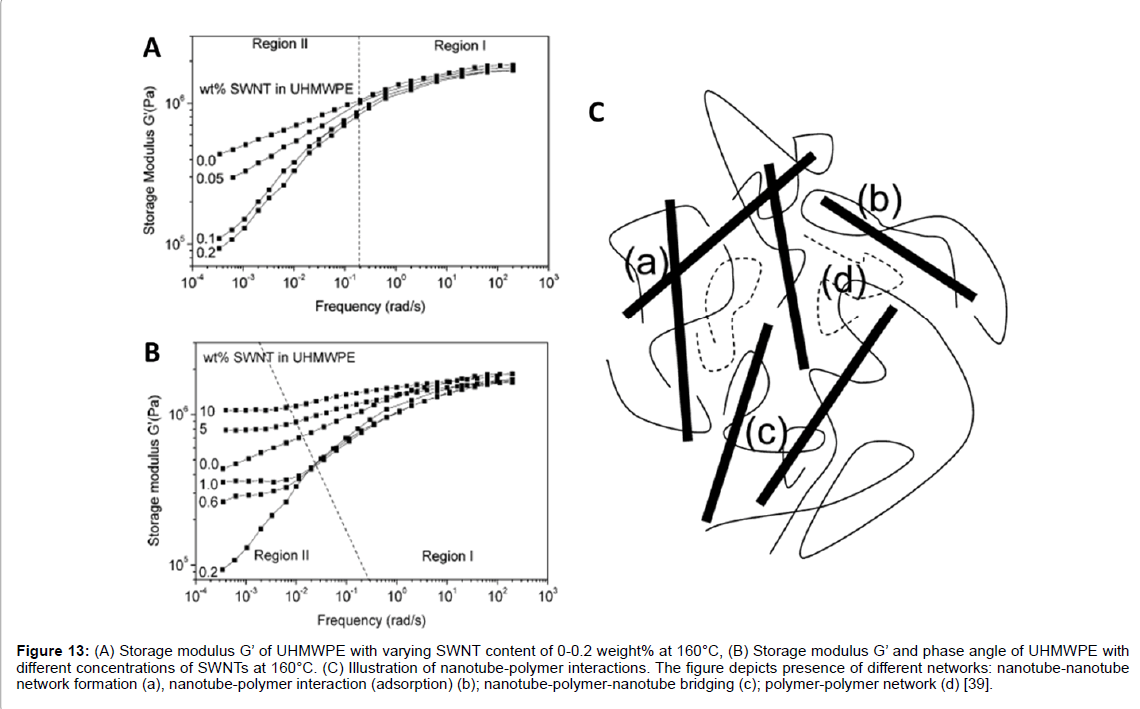

Effect of hydrogen bonding on the rheology of polycarbonate/ organoclay nanocomposites was investigated by Min Lee et al. [38]. Rheology of polycarbonate (PC) composites with two types of organoclay Cloisite 30B and natural montmorillonite (Cloisite Na+) were investigated. Hydrogen bonds are formed between hydroxyl groups at the end of the aliphatic tail (bis-2-hydroxyethyl) of Cloisite 30B and carbonyl groups PC and thereby enhancing compatibility between PC and Cloisite 30B platelets and also dispersion of nanoclay in polymer matrix. Due to the better dispersion of Cloisite 30B in PC than that of Cloisite Na+ better rheological properties were observed for composites containing modified nanoclay. As per the investigation of Zhang et al. homogeneously disperse single-walled carbon nanotubes bundles (SWNTs) in an intractable polymer were obtained by special method, by spraying an aqueous solution of SWNTs by using a surfactant SDS onto a fine UHMWPE powder directly obtained from synthesis [39]. The complicated rheological characteristics of prepared nanocomposites were due to following interactions, (a) depicts SWNTFigure SWNT network due to overlap of two nanotubes, (b) a PE-SWNT network where the polymer may be entangled or adsorbed on the nanotube, (c) depicts SWNT bridging by polymer, and (d) refers to polymer network formation in the polymer matrix through temporary entanglements. This study reports the storage modulus values of extreme low concentration of MWCNT i.e. 0.05weight%. At low frequencies the storage modulus decreases considerably with an addition of low amount of SWNTs in the UHMWPE ranging from 0.05 to 0.2 weight%. No other studies were reported on this unusual behaviour, i.e., decrease in storage modulus for such a low loadings of nanotubes. As the MWCNT loading increases beyond 0.2 weight% the storage modulus value at low frequencies becomes independent of frequency due to the formation of interconnected networks (Figure 13). The polydispersity of UHMWPE in nanocomposites has a distinct impact on the viscoelastic behaviour of the nanocomposites. The observations are that in a polydisperse UHMWPE sample with increasing concentration of SWNTs a clear minimum exists in dynamic viscosity (modulus). However, such a minimum is not realized in a sample having a relatively sharp molar mass distribution. Selective adsorption of the high molar mass fraction on the dispersed SWNTs seems to be a possible explanation for the observed minimum. Because of the selective adsorption of the high molar mass, the apparent molar mass of the polymer matrix decreases; consequently, the phase angle shows a more viscous-like response as anticipated for the lower molar mass.

Figure 12: (A) Storage modulus (G’) and (B) Complex viscosity (η) of MWNT/PP nanocomposites with frequency sweep as a function of MWNT content at 180°C, Transmission electron microscopic pictures of 2 weight% MWNT/PP nanocomposites. (C) Regions of dispersed nanotubes in PP matrix, (D) regions of nanotubes agglomerations in PP matrix [36].

Filler-filler interactions

Zhang et al. presented the effects of nanostructured reagglomerations that occur in SWNT and PMMA-decorated SWNT modified RTM6 epoxy nanocomposites in both uncured suspension and cured bulk materials [40]. The pristine SWNT modified suspensions with a more pronounced re-agglomeration show a significant increment in both modulus and viscosity, which suggests a more effective and lower cost nanocomposites system. On the other hand, the strong bonding inhibited the stick-slip mechanism for energy dissipation, resulting in a lower loss modulus and loss factor for the PMMA-SWNT modified composites. The effect of re-agglomeration on improving composites damping performance is less pronounced because of the strong bonding.

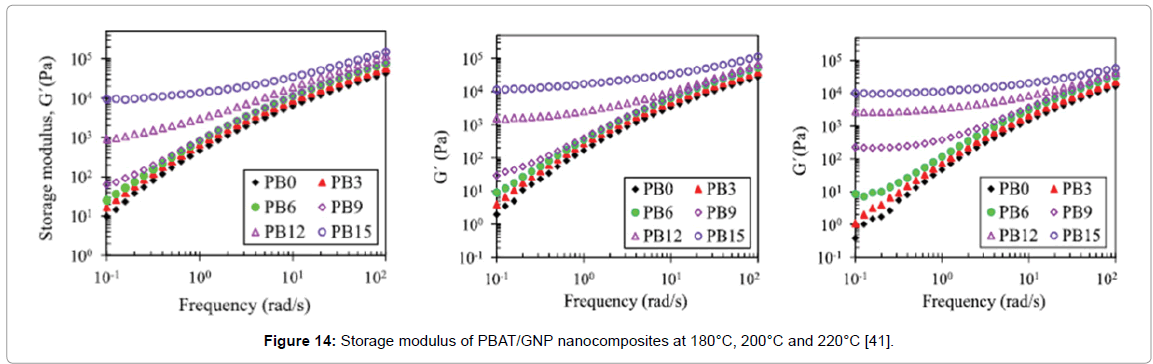

Temperature

Kashi et al. investigated the effect of temperature on the Variations of dynamic and steady shear rheology of Graphene Nano particles (GNP) dispersed poly (butylene adipate-co-terephthalate) (PBAT) composites via oscillatory measurements [41]. They observed that with increasing temperature the liquid-solid transition was found to occur at lower GNP concentrations; dropping from 11.5 weight% at 160°C to 7 weight% at 220°C. At low temperature (180°C) PB15 displayed a distinct plateau over the low frequency region, at 200°C, PB12 also exhibits frequency independency at low frequencies. But as the temperature is raised to 220°C, PB9 and PB6 demonstrate plateau over the low frequency region, as well. Furthermore, the storage modulus, G’ plateau of nanocomposites with 15 and 12 weight% GNPs extend to higher frequencies with increasing temperature. However this observation indicates that the rheological percolation threshold of GNPs in PBAT is temperature sensitive and it decreases as the temperature is raised. Such temperature dependency of percolation threshold suggests that the liquid-solid transition does not necessarily originate from the formation of a percolating network by the nanoparticles alone. They concluded that at CNT concentration of rheological percolation, the density of physical contact between the nanotubes was still low and that the nanotube-nanotube interactions could not be responsible for the rheological percolation at the temperatures they investigated. Reports show that to explain the variation of the rheological percolation with increasing temperature in filled polymeric systems, a combination of polymer-polymer, polymer-filler and filler-filler interactions has been proposed to be responsible for the percolating network within the matrix. With increasing temperature, the rheological property is dominated by the liquid-like behaviour of the melt (terminal zone).

Figure 13: (A) Storage modulus G’ of UHMWPE with varying SWNT content of 0-0.2 weight% at 160°C, (B) Storage modulus G’ and phase angle of UHMWPE with different concentrations of SWNTs at 160°C. (C) Illustration of nanotube-polymer interactions. The figure depicts presence of different networks: nanotube-nanotube network formation (a), nanotube-polymer interaction (adsorption) (b); nanotube-polymer-nanotube bridging (c); polymer-polymer network (d) [39].

Figure 14: Storage modulus of PBAT/GNP nanocomposites at 180°C, 200°C and 220°C [41].

It has also been suggested that the polymer-filler interactions might become stronger at elevated temperatures.

Kelarakis et al. mentioned that at higher temperature the molten polymer chains could be strongly adsorbed on the nanofiller surface (swell the particle) and hence increase their apparent volume fraction [42]. The polymer segments could be in contact, though not tightly bound, with the nanoparticles and form a dense layer in the interface between the adjacent nanofillers and act as bridges between the particles. Based on these ideas the authors concluded that the decreasing trend of GNP percolation threshold in PBAT shows that the rheological percolation of this system is a result of the combination of polymer-polymer, polymer-GNP and GNP-GNP interactions and the contribution of each of these interactions to the overall rheological response of the system is dependent on the temperature as well as the GNP loading. However, the nature of the changes in these interactions with increasing temperature is still to be further investigated. Table 1 shows rheological characteristics of recently reported thermoplastic polymer nanocomposites.

| Sl.No | Polymer | Filler | Preparation | Rheological percolation | References |

|---|---|---|---|---|---|

| 1 | Thermoplastic Polyurethane | Carbon nanotubes | One shot, hand cast bulk polymerization method |

0.43 volume% | [43] |

| 2 | Polypropylene | Carboxyl –COOH |

Melt mixing | 2.5 volume% | [44] |

| 3 | Poly(methyl methacrylate) | Reduced graphene oxide | In situ polymerization | 2.0 weight% | [45] |

| 4 | Poly(methyl methacrylate) | Organoclay | Solvent blending | 5weight% | [46] |

| 5 | Poly(ethylene-butyl acrylate) |

Graphite nanoplatelets | Melt mixing | 2.5 volume% | [47] |

| 6 | Polystyrene | Graphene nanosheets | Solution coagulation method | 0.05 volume% | [48] |

| 7 | Polystyrene | MWCNT | Solution coagulation method | 0.10 volume% | [49] |

| 8 | Polypropylene | carbon black | Melt blending | 6.8 weight% | [50] |

| 9 | Maleated Polyethylene | Nanoclays | Melt-blending technique | 3 weight% | [51] |

| 10 | Polystyrene | MWCNT | Solvent blending | 0.5 weight% | [51] |

| 11 | Polylactic acid | Cellulose nanocrystals | Melt-blending technique | 3 weight% | [52] |

| 12 | Poly(ε-caprolactone) | Poly(sodium 4-styrenesulfonate) wrapped carbon nanotube | Solution coagulation technique | 0.3weight% | [53] |

| 13 | Poly(butylene succinate) | Poly(sodium 4-styrenesulfonate) wrapped carbon nanotube | Solution coagulation technique | Between 0.1 and 0.3 weight% | [54] |

| 14 | Polystyrene | Polyaniline-coated multiwall carbon nanotubes | Melt mixing | 0.4 weight% | [54] |

| 15 | Polystyrene-b-polybutadiene-b-polystyrene | MWCNTs | Melt mixing | 1.1 weight% | [55] |

| 16 | Poly(methyl methacrylate) | Graphene Oxide | Precipitation polymerization process | 0.2 weight% | [56] |

| 17 | Polyamide 6 | Microcrystalline cellulose | Melt mixing | 10 weight% | [57] |

| 18 | Polypropylene | Cellulose nanocrystals | Melt compounding | 2.5 weight% | [58] |

| 19 | Polycarbonate | MWCNT-COOH | Melt compounding | 2.5 weight% | [59] |

| 20 | Acrylonitrile-butadiene-styrene | Graphene | Facile coagulation method | 0.13 volume% | [60] |

Table 1: Rheological characteristics of recently reported thermoplastic polymer nanocomposites.

Conclusion and Future Outlook

Rheological analysis of thermo plastic polymer nanocomposites provides a deep insight into the internal structure of these materials which may further useful in the processing point of view and for understanding the structure property relationship. All the nanocomposites reviewed here show viscous nature at low filler loading and a solid like behaviour at high concentration of filler. Transition from viscous to solid like behaviour is attributed to the formation of three dimensional network structures of filler in the polymer matrix. Fillers with small size and high aspect ratio favours the formation of network structure in the polymer matrix at low concentration of filler. So a transition from viscous to solid behaviour is observed at lower filler loading. It is found that dispersion state of fillers is affected by effect of functionalization, effect of compatibilizer, processing conditions, fabrication techniques for polymer nanocomposites, interaction between filler and polymer, filler-filler interactions and temperature. In conclusion filler dispersion and better compatibility between filler and polymer dramatically change the filler percolation concentration. Polymer nanocomposites offer both great potential and great challenges, marking it as a vibrant area of work for years to come. The improvement and application of these composites will depend on how effectively we can handle the challenges in the better dispersion and efficient interaction between filler and matrix. Nano composites represent one of the new classes of materials, but further research and development in the area of rheological characteristics is needed before they gain significant position in the market.

Acknowledgement

Financial support from Council for Scientific and Industrial Research is greatly acknowledged.

References

- Chee WK, Lim HN, Huang NM, Harrison I (2015) Nanocomposites of graphene/polymers: A review. RSC Adv 5: 68014-68051.

- Hu K, Kulkarni DD, Choi I, Tsukruk VV (2014) Graphene-polymer nanocomposites for structural and functional applications. Prog Polym Sci 39: 1934-1972.

- Olabisi O, Adewale K (2016) Handbook of thermoplastics. CRC press.

- Majesté JC (2016) Rheology and processing of polymer nanocomposites: Theory, practice and new challenges. Rheology and Processing of Polymer Nanocomposites 69: 134.

- Uren╠?a-Benavides EE, Kayatin MJ, Davis VA (2013) Dispersion and rheology of multi-walled carbon nanotubes in unsaturated polyester resin. Macromolecules 46: 1642-1650.

- Nusser K, Schneider GJ, Richter D (2013) Rheology and anomalous flow properties of poly (ethylene-alt-propylene)-silica nanocomposites. Macromolecules 46: 6263-6272.

- Majumdar S, Krishnaswamy R, Sood AK (2011) Discontinuous shear thickening in confined dilute carbon nanotube suspensions. Proc Natl Acad Sci 108: 8996-9001.

- Makarova VV, Tolstykh MY, Picken SJ, Mendes E, Kulichikhin VG (2013) Rheology-structure interrelationships of hydroxypropylcellulose liquid crystal solutions and their nanocomposites under flow. Macromolecules 46: 1144-1157.

- Díez-Pascual AM, Naffakh M, Marco C, Ellis G (2012) Rheological and tribological properties of carbon nanotube/thermoplastic nanocomposites incorporating inorganic fullerene-like WS2 nanoparticles. J Phys Chem B 116: 7959-7969.

- Vega JF, Martinez-Salazar J, Trujillo M, Arnal ML, Muller AJ, et al. (2009) Rheology, processing, tensile properties and crystallization of polyethylene/carbon nanotube nanocomposites. Macromolecules 42: 4719-4727.

- Jiang Z, Zhang H, Han J, Liu Z, Liu Y, et al. (2016) Percolation model of reinforcement efficiency for carbon nanotubes dispersed in thermoplastics. Composites Part A: Applied Science and Manufacturing 86: 49-56.

- Herasati S, Zhang L (2014) A new method for characterizing and modeling the waviness and alignment of carbon nanotubes in composites. Compos Sci Technol 100: 136-142.

- Penu C, Hu GH, Fernandez A, Marchal P, Choplin L (2012) Rheological and electrical percolation thresholds of carbon nanotube/polymer nanocomposites. Polymer Engineering & Science 52: 2173-2181.

- Münstedt H, Starý Z (2016) Is electrical percolation in carbon-filled polymers reflected by rheological properties. Polymer 98: 51-60

- Nair ST, Vijayan PP, Xavier P, Bose S, George SC, et al. (2015) Selective localisation of multi walled carbon nanotubes in polypropylene/natural rubber blends to reduce the percolation threshold. Compos Sci Technol 116: 9-17.

- Basuli U, Chaki TK, Chattopadhyay S (2012) Rheological signatures of ethylene methyl acrylateÔ?Émulti-walled carbon nanotube nanocomposites. Polym Adv Technol 23: 65-76.

- Mittal V, Chaudhry AU, Luckachan GE (2014) Biopolymer–thermally reduced graphene nanocomposites: Structural characterization and properties. Mater Chem Phys 147: 319-332.

- Zhao D, Ge S, Senses E, Akcora P, Jestin J, et al. (2015) Role of filler shape and connectivity on the viscoelastic behavior in polymer nanocomposites. Macromolecules 48: 5433-5438.

- Martin-Gallego M, Bernal MM, Hernandez M, Verdejo R, López-Manchado MA (2013) Comparison of filler percolation and mechanical properties in graphene and carbon nanotubes filled epoxy nanocomposites. European Polymer Journal 49: 1347-1353.

- Sabzi M, Jiang L, Liu F, Ghasemi I, Atai M (2013) Graphene nanoplatelets as poly (lactic acid) modifier: Linear rheological behavior and electrical conductivity. J Mater Chem A 1: 8253-8261.

- Kasgoz A, Ak─▒n D, Ayten AI, Durmus A (2014) Effect of different types of carbon fillers on mechanical and rheological properties of cyclic olefin copolymer (COC) composites. Composites Part B: Engineering 66: 126-135.

- Wang PH, Ghoshal S, Gulgunje P, Verghese N, Kumar S (2016) Polypropylene nanocomposites with polymer coated multiwall carbon nanotubes. Polymer 100: 244-258.

- Sarvi A, Sundararaj U (2014) Rheological percolation in polystyrene composites filled with polyaniline-coated multiwall carbon nanotubes. Synthetic Metals 194: 109-117.

- Arrigo R, Morici E, Dintcheva NT (2015) High performance thermoplastic elastomers/carbon nanotubes nanocomposites: Mechanical behavior, rheology and durability. Polymer Composites.

- Zhen W, Wang W (2016) Structure, properties and rheological behavior of thermoplastic poly (lactic acid)/quaternary fulvic acid-intercalated saponite nanocomposites. Polym Bull 73: 1015-1035.

- Beckert F, Held A, Meier J, Mu╠?lhaupt R, Friedrich C (2014) Shear-and temperature-induced graphene network evolution in graphene/polystyrene nanocomposites and its influence on rheological, electrical, and morphological properties. Macromolecules 47: 8784-8794.

- Acik E, Orbey N, Yilmazer U (2016) Rheological properties of poly (lactic acid) based nanocomposites: Effects of different organoclay modifiers and compatibilizers. J Appl Polym Sci, p: 133.

- Issaadi K, Habi A, Grohens Y, Pillin I (2015) Effect of the montmorillonite intercalant and anhydride maleic grafting on polylactic acid structure and properties. Appl Clay Sci 107: 62-69.

- Kumar M, Shanmuga Priya N, Kanagaraj S, Pugazhenthi G (2016) Melt rheological behavior of PMMA nanocomposites reinforced with modified nanoclay. Nanocomposites 2: 109-116.

- Lee SH, Cho E, Jeon SH, Youn JR (2007) Rheological and electrical properties of polypropylene composites containing functionalized multi-walled carbon nanotubes and compatibilizers. Carbon 45: 2810-2822.

- Visco A, Yousef S, Galtieri G, Nocita D, Pistone A, et al. (2016) Thermal, mechanical and rheological behaviors of nanocomposites based on UHMWPE/paraffin oil/carbon nanofiller obtained by using different dispersion techniques. JOM 68: 1078-1089.

- La Mantia FP, Arrigo R, Morreale M (2014) Effect of the orientation and rheological behaviour of biodegradable polymer nanocomposites. Eur Polym J 54: 11-17.

- Rajesh JJ, Soulestin J, Lacrampe MF, Krawczak P (2012) Effect of injection molding parameters on nanofillers dispersion in master batch based PP-clay nanocomposites. Express Polym Lett 6: 237-248.

- Swain SK, Isayev AI (2007) Effect of ultrasound on HDPE/clay nanocomposites: Rheology, structure and properties. Polymer 48: 281-289.

- Narimissa E, Gupta RK, Kao N, Choi HJ, Bhattacharya SN (2015) The comparison between the effects of solvent casting and melt intercalation mixing processes on different characteristics of polylactideÔ?Énanographite platelets composites. Polymer Engineering & Science 55: 1560-1570.

- Prashantha K, Soulestin J, Lacrampe MF, Krawczak P, Dupin G et al. (2009) Master batch based multi-walled carbon nanotube filled polypropylene nanocomposites: Assessment of rheological and mechanical properties. Compos Sci Technol 69: 1756-1763.

- Chafidz A, Kaavessina M, Al-Zahrani S, Al-Otaibi MN (2014) Rheological and mechanical properties of polypropylene/calcium carbonate nanocomposites prepared from master batch. Journal of Thermoplastic Composite Materials, pp: 1-30.

- Lee KM, Han CD (2003) Effect of hydrogen bonding on the rheology of polycarbonate/organoclay nanocomposites. Polymer 44: 4573-4588.

- Zhang Q, Lippits DR, Rastogi S (2006) Dispersion and rheological aspects of SWNTs in ultrahigh molecular weight polyethylene. Macromolecules 39: 658-666.

- Zhang XC, Scarpa F, McHale R, Peng HX (2016) Poly (methyl methacrylate)-decorated single wall carbon nanotube/epoxy nanocomposites with re-agglomeration networks: Rheology and viscoelastic damping performance. Polymer 87: 236-245.

- Kashi S, Gupta RK, Kao N, Bhattacharya SN (2016) Viscoelastic properties and physical gelation of poly (butylene adipate-co-terephthalate)/graphene nanoplatelet nanocomposites at elevated temperatures. Polymer 101: 347-357.

- Kelarakis A, Yoon K, Somani RH, Chen X, Hsiao BS, et al. (2005) Rheological study of carbon nanofiber induced physical gelation in polyolefin nanocomposite melt. Polymer 46: 11591-11599.

- Pircheraghi G, Powell T, Bonab VS, Manas-Zloczower I (2016) Effect of carbon nanotube dispersion and network formation on thermal conductivity of thermoplastic polyurethane/carbon nanotube nanocomposites. Polymer Engineering & Science 56: 394-407.

- Patti A, Russo P, Acierno D, Acierno S (2016) The effect of filler functionalization on dispersion and thermal conductivity of polypropylene/multi wall carbon nanotubes composites.

- Tripathia SN, Malika RS, Choudharya V (2015) Melt rheology and thermomechanical behaviour of poly (methyl methacrylate)/reduced graphene oxide nanocomposites. Polym Adv Technol 26: 1558-1566.

- Kumar M, Kumar V, Muthuraja A, Senthilvelan S, Pugazhenthi G (2016) Influence of nanoclay on the rheological properties of PMMA/organoclay nanocomposites prepared by solvent blending technique. Macromol Symp 365: 104-111.

- Oxfall H, Ariu G, Gkourmpis T, Rychwalski RW, Rigdahl M (2015) Effect of carbon black on electrical and rheological properties of graphite nanoplatelets/poly(ethylene-butyl acrylate) composites, Express Polym Lett 9: 66-76.

- Chiu YC, Huang CL, Wang C (2016) Rheological and conductivity percolations of syndiotactic polystyrene composites filled with graphene nanosheets and carbon nanotubes: A comparative study. Compos Sci Technol 134: 153-160.

- Chen Y, Chen Q, Lv Y, Huang Y, Yang Q, et al. (2015) Rheological behaviors and electrical conductivity of long-chain branched polypropylene/carbon black composites with different methods. J Polym Res 22: 119

- Al-Juhani AA (2015) Rheology, mechanical properties and thermal stability of maleated polyethylene filled with nanoclays. J Nanomater, p11.

- Sen P, Suresh K, Kumar RV, Kumar M, Pugazhenthi G (2016) A simple solvent blending coupled sonication technique for synthesis of polystyrene (PS)/multi-walled carbon nanotube (MWCNT) nanocomposites: Effect of modified MWCNT content. Journal of Science: Advanced Materials and Devices, p: 1.

- Kamal MR, Khoshkava V (2015) Effect of cellulose nanocrystals (CNC) on rheological and mechanicalproperties and crystallization behavior of PLA/CNC nanocomposites. Carbohydrate Polymers 123: 105-114.

- Du AK, Yang KL, Zhao TH, Wang M, Zeng JB (2016) Poly (sodium 4-styrenesulfonate) wrapped carbon nanotube with low percolation threshold in poly(ε-caprolactone) nanocomposites. Polym Test 51: 40-48

- Zeng RT, Hu W, Wang M, Zhang SD, Zeng JB (2016) Morphology, rheological and crystallization behavior in noncovalently functionalized carbon nanotube reinforced poly (butylene succinate) nanocomposites with low percolation threshold. Polym Test, p: 50.

- Santos JPF, Bretas RES (2016) Effect of polymer matrix on rheological and electrical percolation threshold of MWCNTs. American Institute of Physics 040013.

- Thomassin JM, Trifkovic M, Alkarmo W, Detrembleur C, Je╠üro╠?me C, et al. (2014) Poly (methyl methacrylate)/graphene oxide nanocomposites by a precipitation polymerization process and their dielectric and rheological characterization. Macromolecules 47: 2149-2155

- Kiziltas A, Nazari B, Gardner DJ, Bousfield DW (2013) Polyamide 6-cellulose composites: effect of cellulose composition on melt rheology and crystallization behavior. Polymer Engineering & Science 54: 739-746.

- Khoshkava V, Kamal MR (2014) Effect of cellulose nanocrystals (CNC) particle morphology on dispersion and rheological and mechanical properties of polypropylene/CNC nanocomposites. ACS Appl Mater Interfaces 6: 8146-8157.

- Tzounis L, G€artner T, Liebscher M, P€otschke P, Stamm M, et al. (2014) Influence of a cyclic butylene terephthalate oligomer on the processability and thermoelectric properties of polycarbonate/MWCNT nanocomposites. Polymer, p: 55.

- Gao C, Zhang S, Wang F, Wen B, Han C, et al. (2014) Graphene networks with low percolation threshold in ABS nanocomposites: Selective localization and electrical and rheological properties. ACS Appl Mater Interfaces 6: 12252-12260.

Relevant Topics

Recommended Journals

Article Tools

Article Usage

- Total views: 9315

- [From(publication date):

March-2017 - Nov 21, 2024] - Breakdown by view type

- HTML page views : 8167

- PDF downloads : 1148