Review of Life Cycle Assessment and Environmental Impacts from The Oil & Gas Sector

Received: 28-Jan-2019 / Accepted Date: 19-Feb-2019 / Published Date: 26-Feb-2019 DOI: 10.4172/2472-0518.1000164

Abstract

Introduction: The oil and gas sector is the subject of key interest and concern because of its increasing demand, the dependency of various sectors on it and its high environmental impacts. The life cycle assessment of this sector will give us the idea to enumerate the various emissions, energy use, fuel usage, raw material requirement, resource consumption, material requirement related to each life cycle stages. Based on the literature analysis, we have presented some discussions on recent trends in the oil and gas sector, cleaner technologies and propose future research directions.

Methodology: A detailed literature review was done by identifying the research papers focusing on the LCA in oil and gas sector. The database referred were EBSCOhost, Science Direct, Google Scholar, Web of science. The literature search is limited to academic search from 1990 to 2018.

Findings: In India despite a regulatory lid on polluting fuels, the overall fuel demand showed a healthy trend in 2017-18 on the back of strong growth in transportation fuels. The total consumption of petrol was increased from 10.14 percent to 26.17 MT, while diesel consumption grew by 6.63 percent to 81 MT in 2018. Various studies have confirmed that the main environment polluting hotspot identified in the supply chain was the refining activity, the maximum CO2 emissions is from the exploration and drilling stage i.e., 60%-65% and the local pollutant emission is maximum in the oil usage phase which is approx. SOx emissions is 5.45 MT, NOx is 6.88 MT and black carbon 8.5 MT.

Contributions: The results can be used in the comparative assessment of different crudes, by the government and the industry for decision making, by the various stakeholders and researchers who are conducting LCA and proposing models for systems that are using the petrochemical products in different context.

Keywords: Life cycle assessment; Life cycle models; Emissions; Environmental impacts; Energy balance; Sustainable; Impact categories

Introduction

The oil and gas sector is an important aspect of the world economy. It has the potential to cause severe environmental degradation, not only to the physical environment, but also to the health, culture, and economic and social structure of local and indigenous communities [1]. Since this sector is growing drastically over a period of time, it is their foremost duty to make necessary changes in its supply chain. Oil and gas companies are representing a considerable portion of wealth in the midst of the world’s major industries.

According to the 2015 United Nations Climate Change Conference, India is the third largest GHG (Green House Gas) emitter in the world. India and other developing countries are focusing more on the alternate fuels, but the transportation sector is still dependent on conventional fuels. This is due to the reason that alternate fuels which are assumed to be cleaner are emitting more carbon dioxide as compared to conventional fuels per unit production of energy and the extraction of energy from these renewable sources require high initial costs, lack of social acceptance and severe competition from current fossil fuels [2]. Therefore the existing oil and gas industry requires a lot of attention for the implementation of sustainable and green practices [3].

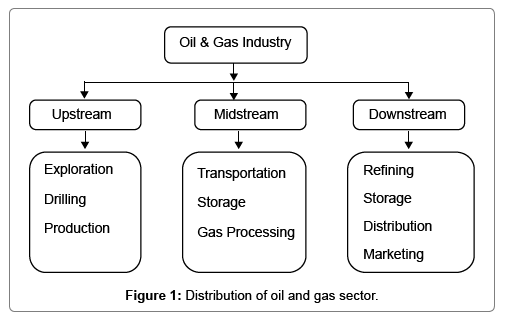

Life Cycle Analysis (LCA) is a technique to assess environmental impacts associated with all the stages of a product’s life from cradle to grave, that is, from raw material extraction through materials processing, manufacture, distribution, use, repair and maintenance, and disposal or recycling (US Environmental Protection Agency, 2010). But according to the recent literature LCA can be used as a tool for assessment of processes and can be used to study the supply chain and make it more sustainable [4] (Figure 1).

The oil and gas sector is divided into three major components i.e., upstream, midstream and downstream. The upstream is also known as Exploration and Production (E&P) and is responsible for the searching of natural oil fields and drilling underground wells. The midstream sector is the storage and transportation of crude oil; it links the upstream and downstream sector. The downstream sector is of refining the crude oil, storage distribution, and marketing. Emissions through direct combustion of fossil fuels are easily recognized as part of the fuel process chain, but the emissions associated with other links in the supply chain is less understood.

Literature Review

The LCA approach was not recognized by many industries but the methodology was gradually getting accepted. Few sectors such as soft drinks, plastics, personal care products, detergents, and automobiles were known to be pioneers investing in LCA. This was followed by other sectors like manufacturing industries, agriculture, mining, oil and gas extraction, construction/building material sector, and retailing, and more recently by infrastructure industries (electricity, gas and water supply, transport, storage, and communication) [4].

Various technologies used in the oil and gas sector

Oil and gas sector is one the most important sector in the country’s economy. The main challenge faced by this sector is to satisfy the demands for safe, abundant and affordable petroleum products within the evolving regulatory environment (Report on Technology Vision 2020), the technology has the potential to achieve this demands over the coming decades. The changes in prospect are exciting and profound– such as digitization and artificial intelligence, the electrification of transport, and the scaling up of renewable energy. The required technology transition in this sector is discussed below.

From brownfield refinery to greenfield refinery: Most of the Indian refineries are the brownfield refinery; it is already constructed and is upgraded and expanded with time. Recently, three Indian downstream sector – IOCL (Indian Oil Corporation Limited), HPCL (Hindustan Petroleum Corporation Limited), and BPCL (Bharat Petroleum Corporation Limited) have recently signed a Joint Venture (JV) agreement to create the world’s largest refinery-cumpetrochemicals complex Ratnagiri district at the cost of $ 40 billion and a refining capacity of 60 Million Tonnes Per Annum (MMTPA). It will be a Greenfield refinery.

From conventional refinery to bio refinery: The Go Green initiative is now applicable in Refineries too. The conventional petroleum refinery is now changed to a bio refinery by implying the eco fining technology. This pioneering idea will help to encourage the industrial application of the eco fining technology under green refinery project. The eco fining technology undergoes reaction in two stages: firstly the deoxygenating process is completed under hydrogen partial pressure and the product is processed in next stage where isomerization is done, which helps in improving the properties of the obtained products [5]. The eco fining process maximizes the green production which is esteemed as bio components for transportation fuels such as Green Diesel, Green Naphtha, Green LPG and Green Jet.

Moving from desulphurization to bio desulfurization (BDS): Indian refineries have started DHDS (Diesel Hydrodesulphurization) process to bring down the sulfur content which is a threat to public health and corrodes the engine which minimizes its life. This technology has brought down the sulfur content from 10000 PPM to 10 PPM (HPCL Sustainability Report, 2017).

As we are moving towards green processing of fossil fuel, the Bio Desulfurization (BDS) has drawn wide attention for removal of sulfur compounds. Various bacterial species which are able to bio-transform DBT or grow independently as a sole sulfur has been recognized [6].

From wastewater treatment to Zero Liquid Discharge (ZLD) system: ZLD systems help in treating 100 percent wastewater (internal/ process wastewater, fire/storm water, utility wastewater) and effluents [7]. The Zero Liquid Discharge System consistently producing treated effluent (pH 6-8.5, sulphide <0.5 ppm, COD <50 ppm, oil and grease <5 ppm, phenol <0.35 ppm) meeting guarantee parameters for reuse for various effluents.

Other existing clean technologies

Tail gas treating unit: The tail gas treating unit converts the small number of sulfur compounds (<5%), which were not converted in the Sulfur Recovery Unit (SRU), into hydrogen sulfide (H2S) and recycles it back to the SRU for additional processing.

Fluid catalytic cracking (FCC): Fluid Catalytic Cracking (FCC) is an essential component in the petroleum refinery. It converts the long-chain hydrocarbons into the gasoline precursors which can be used in different industries such as fuels, plastics, and lubricants. The FCC minimizes the energy consumption in the processing phase and maximizes the premium gasoline production.

Flare gas recovery unit: Flare Gas Recovery (FGR) is the process of recovering the waste gases that would normally be flared, so they can be used as fuel gas elsewhere in the facility. This results in reduced emissions and cost savings.

Vapour recovery system (VRS): It is the process to recover the vapours of petrochemical fuels and stop them from escaping into the atmosphere. This is generally installed at filling stations which help in reducing pollution.

Inspite of major developments in the oil industry in India, we still depend on developed countries for oil. The main obstacle in technology transfer is firstly the major economic factors. Such as low saving rate, lack of economic growth, lack of investment in R&D, lack of developed manufacturing, management and quality control systems, lack of necessary technical, engineering, and science skill in industry section to improve product technology and process of imported technology [8].

Environmental impacts of oil and gas sector

The demand for oil is growing very rapidly with the economic expansion which is increasing the production. There are 3 main challenges faced by the oil & gas sector which is pollution, global climate change and impact on bio-diversity [9]. The increase in production cause environmental damage in each stage of its life cycle from exploration to refining to its final consumption which is generally referred as Well-to-Wheels (WTW). The effect of pollution is on the regional level as well as global level (Table 1). The majority of pollution is from the oil refineries which are consuming large amounts of energy and water, producing large quantities of wastewaters, releasing hazardous gases into the atmosphere and generating solid waste that is difficult both to treat and to dispose of [10]. Apart from environmental pollution, it also affects human health by causing respiratory diseases [11].

| Process in oil | Waste Type | Effect on Environment |

|---|---|---|

| Transportation | Pipeline Explosion | Air and water pollution |

| Oil spillage through pipelines | Ground water underground aquifers contamination, | |

| Oil spillage through ships | Marine pollution | |

| Oil spillage through tank trucks | Pollutes surrounding area | |

| Crude Refinery Source: Steigerwald (1960) Atmospheric emission from petroleum refineries | Oily water | Affected nearby lagoon |

| NOx Sox | Acid Rain | |

| CO2 | Climate Change | |

| Spent Caustic | Nearby lagoon | |

| Process Effluents | Nearby lagoon | |

| Leaked/Spilled oil | Polluted Surrounding rain | |

| Bulk Oil Storage Source: Steigerwald (1960) Atmospheric emission from petroleum refineries | Waste Oil | Marshy Land and Stream |

| Leaked/Spilled oil | Polluted Surrounding air | |

| Final usage for transportation | Unburnt hydrocarbons | Photochemical smog |

| CO | Global warming | |

| NOx | Acid Rain | |

| Lead Oxides | Toxic substance |

Table 1: Effect on the environment of different processes of oil and gas sector.

Review of existing life cycle models for oil and gas sector

The life cycle models have been proposed by various researchers working on LCA which can be easily understood by the readers. The models prepared must be verified by both expert and non-expert LCA users so that the proposed models can be made more perfect and userfriendly [12].These models can be used for future exploration and to establish the relationship between methodologies which can result in more collaborative, in-depth assessments [12].

Some of the models are described below:-

FUNNEL-GHG-CCO (Fundamental Engineering Principle based model for estimation of GHG in Conventional Crude Oil): This LCA model is based on the fundamental scientific principle to compute the GHG emission of all the life cycle stages of differently selected crudes. It is a bottom-up data-intensive model.

OPGEE (Oil Production Green House Gas Emission Estimator): It is an open source engineering based life cycle assessment model which is used to test the reproducibility from well to refinery inlet gate (WTR) GHG emissions. OPGEE (Oil Production Greenhouse Gas Emissions Estimator) is built with separate modules, including drilling, production, processing, and transport of crude. All sources of direct emissions are included in the model, including both combustion emissions and fugitive emissions [13].

Sengupta: This model was proposed for US petroleum refinery operations, which helps in estimating the impacts of refinery operations. The model describes the allocation factors, air emissions, and products and supports the emission modeling research carried by Sengupta and others at the Environmental Protection Agency (EPA) [12].

GHGenius: GHGenius model can estimate the air emissions for past, present, and future (through to 2050). It analyzes the Greenhouse Gas (GHG) emissions and other air emissions related to the production and usage of conventional and alternative transportation fuels [14]. This is done using the historical data and correlations that are stored in the model and changes with time. This model is much suitable for Canadian application [14].

LCA methods

Eco-indicator 99: It is one of the most widely used impact assessment methods in LCA. It is the successor of Eco-indicator 95, the first endpoint impact assessment method, which allowed an environmental load of a product to be expressed in a single score (Pre consultant). Garg uses eco-indicator 99 method to compare the life cycle impacts on ecosystem quality, human, and resources [15]. Nanaki also used this method to compare the LCA of Diesel, Biodiesel, and gasoline and the various impact categories [16].

Impact 2002: The IMPACT 2002+ LCIA (London Court of International Arbitration) methodology implements the combined midpoint/damage a pproach, relating all types of life cycle inventory results (elementary flows and other interventions) via 14 midpoint categories to four damage categories [17].

CML 2002: CML 2001 is an impact assessment method which restricts quantitative modeling to early stages in the cause-effect chain to limit uncertainties. Results are grouped in midpoint categories according to common mechanisms (e.g. climate change) or commonly accepted groupings (e.g. ecotoxicity).

Shi has used CML2000 where 5 environmental impact categories are assessed which are the global warming potential, acidification potential, nutrient enrichment potential, ozone formation potential, and ozone depletion potential [18]. Furuholt also used CML to compare the impact categories of gasoline and diesel which are Global Warming Potential, Photo-oxidant formation, Eutrophication, acidification, consumption of fossil energy and waste generation.

ReCiPe 2008: The ReCiPe method is used to transform the long list of life cycle inventory results, into a limited number of indicator scores. These indicator scores express the relative severity on an environmental impact category (Pre sustainability).

Morales et al. used the ReCiPe 2008 method where the hierarchic perspective was considered for the environmental impact assessment [19,20]. The impact categories considered were climate change, ozone depletion, human toxicity, photochemical oxidation formation, terrestrial acidification, freshwater eutrophication, marine eutrophication, terrestrial eco toxicity, freshwater eco-toxicity, marine eco toxicity, water depletion, mineral depletion, and fossil depletion.

LCA in the oil and gas sector

GHGs and other toxic gases are emitted in all the stages of fuel production from extraction of raw materials to the combustion of fuels in an engine in the usage phase. Every fuel and production process exhibits different properties, different extraction methods, and GHG emissions, therefore, the source of crude oil should also be considered while performing LCA [10]. Eriksson discusses that fuel used in the refinery; its efficiency and heat usage have an effect on the LCA results. For instance, high-quality insulation of pipes and equipment reduces the need for heating [21]. The fuel used for the heating purpose also plays an important role in the emissions and primary energy use from the refinery. It is also important to perform a complete life cycle assessment of conventional crude oils from a variety of sources to help in policy-making towards sustainability and fulfilling environmental regulations [22].

The main challenges in performing LCA of transportation fuels are (i) Appropriate cost accounting and benefits of alternative fuels (ii) Lack of consistency in including economics-based marginal effects in fuel LCAs. (iii) Inconsistent application of time trends i.e., the energy intensity of crude oil production tends to increase with depletion as a result of increased work of lifting of fluids as an oil field depletes [23]. Hawkins compared the environmental life cycle assessment of conventional vehicles and electric vehicles and discussed the various problems in shifting from conventional vehicles to electric vehicles [24]. Author suggests that electric vehicles would aggregate emissions at a few point sources (power plants, mines, etc.) instead of millions of mobile sources, making it conceptually easier to control and optimize societies’ transportation systems [25] (Table 2).

| Authors (Year) | Assessment Boundaries | LCA Software/Model | Variables Identified | Impact Categories | Findings | Scope | |

|---|---|---|---|---|---|---|---|

| Garg et al. (2013) | Well-to-Storage | Sima Pro | Emissions from different transportat ion fuel, energy efficiency | Human health, acidification, eutrophication | 1. The crude oil source should be considered 2. Total transportation emissions are higher, but not high enough as compared to other stages in the complete LCA of transportation fuels. |

To implement the differential environmental taxes, the research should first focus on impact assessment. | |

| Bicer and Dincer (2018) | Cradle- to-grave | Sima Pro | human toxicity values, | ozone layer depletion, Global warming, Abiotic depletion, acidification, eutrophication, human toxicity, and terrestrial ecotoxicity | To achieve sustainable and clean transportation, the attention should be on the eco-friendly and cost-effective production of vehicles, batteries and alternative fuels. | This study is limited only to the environmental impacts, for the further research life cycle costing of these alternative-fueled vehicles can be performed. | |

| Rahman & Kumar (2015) | Well-to- Wheel | FUNNEL -GHG- CCO | Energy use, emission factors | Global Warming Potential | GHG emissions are calculated using FUNNEL-GHG-CCO model. This model considers all the life cycle stages of production of crude oil from extraction to the combustion in the engines. Amongst all the crudes considered in the paper, gasoline has higher GHG emissions than both diesel and jet fuel. This is due to high energy consumption in gasoline production. | As a future scope of this study, The results can be used in the comparative assessment of different crudes and by the government and the industry for decision making. | |

| Iribarren, Peters & Dufour (2012) | Case study | Not Specified | electricity generation, natural gas production, and direct emissions | Global warming, photochemical oxidant formation, cumulative energy demand, acidification, land competition, ozone layer depletion, and eutrophication | The research paper focuses on the LCA study of the production of biofuels from the fast pyrolysis of biomass system. This shows that the pretreatment of the lignocellulosic biomass feedstock (drying and grinding), the pyrolysis process and the steam reforming of natural gas to provide the hydrogen used in the hydroprocessing stages were the sources with the highest environmental impact. | Not specified | |

| Vineyard & Ingwers en (2017) | Well-to- pump | Review and comparison of various LCA models | Not specified | well-to-pump emissions | This paper has demonstrated the differences and evaluated the data quality of five LCA models. | This comparison can be used by the various stakeholders and researchers who are conducting LCA and making models for systems that make use of petroleum products. | |

| Matos & Hall (2007) | Cradle- to-grave | Not specified | Risk Manageme nt, Stakehol der theory | Global warming potential, ozone depletion, eco- toxicity, energy consumption, nitrification and acidification | The author argues that shift towards the sustainable development has increased the complexities and given indefinite challenges that many environmental management techniques cannot address. It has also provided a framework that addresses these issues and discusses implications for practitioners and management theory. | The proposed framework will help managers to determine if LCA is appropriate or not. | |

| Hsu (2012) | Producti on to end use | Simapro | Emissions | Not specified | In this work, LCA of the production of gasoline and diesel from forest residues via fast pyrolysis and hydroprocessing is performed. Grid electricity and natural gas used account for 81% of the net GHG emissions in the base case. | Pyrolysis of biomass for fuels has been less well studied than gasification, and the greater uncertainty range around fuel yield contributes to the more skewed uncertainty distribution than for gasification in the previous work | |

| Hsu (2012) | Producti on to end use Gate-to- grave | Simapro CMLCA | Emissions Impact assessment | Not specified Abiotic depletion, GHG emissions, Ozone layer depletion, Photochemical oxidation, Human and eco-toxicity, Acidification, Eutrophication | In this work, LCA of the production of gasoline and diesel from forest residues via fast pyrolysis and hydro-processing is performed. Grid electricity and natural gas used account for 81% of the net GHG emissions in the base case. The research has focused on the LCA of gasoline and ethanol as fuels and results showed that ethanol fuels are better than gasoline, while gasoline is a better fuel where human toxicity, eco-toxicity, acidification, and eutrophication are concerned. | In the future case scenario ethanol industry can be made more economically attractive by studying its cost model and technological development can be studied which helps in lowering the environmental impacts. | |

| Luo, Voet & Huppes (2009) | Gate-to- grave | (Chain Manage -ment by LCA) | fuel usage | Abiotic depletion, GHG emissions, Ozone layer depletion, Photochemical oxidation, Human and eco-toxicity, Acidification, Eutrophication | The research has focused on the LCA of gasoline and ethanol as fuels and results showed that ethanol fuels are better than gasoline, while gasoline is a better fuel where human toxicity, ecotoxicity, acidification, and eutrophication are concerned. | In the future case scenario ethanol industry can be made more economically attractive by studying its cost model and technological development can be studied which helps in lowering the environmental impacts. | |

| Garraín et al. (2014) | Well-to- tank | Not specified | Temperat- ure | fossil energy | The research shows that HBD (Hydrobiodiesel) systems have good environmental & technical performance when its compared to FAME (Fatty Acid Methyl Ester) and diesel. Regarding the impact categories analyzed, the reductions in terms of fossil energy use and GHG emissions | Future research must focus on the matter of indirect Land Use Change (iLUC), which is leading to higher GHG emissions related to biofuel or renewable diesel production | |

| Nanaki & Koroneos (2012) | well-to- wheel | Simapro 5.0 | Ecotoxicity, Acidification, inorganic respiratory effects, fossil fuels, eutrophication, Organic respiratory effects, greenhouse effect and carcinogenic effects. | The author has compared the environmental impacts of the use of gasoline, diesel, and biodiesel in Greece. From the environmental point of view, biodiesel seems to be eco- friendly because the GHG emissions are very low as compared to gasoline and diesel. Methane emission is also low. But, the use of biodiesel as the transportation fuel increases emissions of PM10, nitrous oxide, nitrogen oxides (NOx) as well as nutrients such as nitrogen and phosphorous; which is the main reason for eutrophication. | This study can be considered as an opportunity for further research and evaluate the available options for a sustainable | ||

| Morales et al. (2015) | well-to- wheel | Simapro v8 | Acidification,human toxicity, Climate change, Ozone depletion, terrestrial eco-toxicit y, water depletion, marine eutrophication, mineral depletion photochemical oxidation formation, marine ecotoxicity, terrestrial freshwater eutrophication, freshwater eco-toxicity, and fossil depletion | The outcomes of refining activities and use of gasoline in cars are extremely sensitive to the allocation approach considered. The maximum impacts were found in the economic allocation, then by the volume allocation and lastly energetic allocation. The high impacts resulting from the economic allocation were due to the high price assigned to the gasoline in the Chilean market | Future improvements of technologies in gasoline production and transport sector can be done. It can be identified as the key subsystems within the life cycle of gasoline. | ||

Table 2: Various LCA study focusing on the oil and gas sector.

Discussion and Findings Based on The Review

The dependency of humans on the oil and gas sector is increasing very rapidly. The LCA of this sector has helped us to study the supply chain which will identify the various emissions, energy usage, fuel usage, raw material requirement, resource consumption, material and energy balances related to each life cycle stages and the environmental impacts from these stages. It has also identified the major impact categories like according to the study done by [19,22]. Transportation phase and combustion phase are responsible for nearly half of the impact which is followed by the refinery. SOx and NOx are the major pollutants (Table 3).

| Author( Year) | Country Studied | Functio nal Unit | Boundary selected | Software/LCIA methods | Impact category Analyzed | Findings |

|---|---|---|---|---|---|---|

| Cavalett et al. (2012) | Brazil | 1 MJ of fuel | Cradle to grave | Comparison of the seven midpoint LCIA methods CML 2001, Eco- indicator 99, TRACI 2, ReCiPe, EDIP 2003, Impact 2002+ and Ecological Scarcity 2006 | Global Warming Potential (GWP), fossil depletion and Ozone layer Depletion Potential (ODP). | Authors have compared different LCIA methods of ethanol and gasoline and found that ethanol has less impact than gasoline in main impact categories such as global warming, fossil depletion, and ozone layer depletion. But ethanol has much higher impacts in acidification, eutrophication, photochemical oxidation, and agricultural land use categories. |

| Morales et al. (2014) | Chile | distance of 1 km driven by a middle size passeng er car | Well to Wheel | Simapro software v8 CML 2000 method | Climate Change (CC), Ozone Depletion (OD), Human Toxicity (HT), Photochemical Oxidation Formation (POF), Terrestrial Acidification (TA), Freshwater Eutrophication (FE), Marine Eutrophication (ME), Terrestrial Ecotoxicity (TET), freshwater ecotoxicity (FET), marine ecotoxicity (MET), Water Depletion (WD), Mineral Depletion (MRD) and Fossil Depletion (FD). | The majority of emission is from refining process and combustion phase. Climate change is the main impact category identified which is due to these emissions from the refinery and combustion phase. The climate change impact category is 3.9. 10-1 kg CO2 eq which is highest among all impact categories studied. |

| Restianti and Gheewal a (2012) | Indonesia | 1 kL of gasoline | Cradle to gate | CML 2000 method | Global Warming Potential (GWP), Acidification Potential (AP), Eutrophication Potential (EP), Abiotic Resource Depletion Potential (ADP), Human Toxicity Potential (HTP), and Eco toxicity Potential (ETP). | The results showed that the combustion phase contribute 93%, 84%, 95% for the Global Warming potential, Acidification potential and eutrophication potential respectively followed by oil refining and then by crude extraction phase. GWP for the combustion phase is 3.35W+04 g CO2 eq. and for full process chain is 3.61E+04 |

| Rahman et al. (2014) | North America | 1 MJ of fuel | Well to Wheel | LCA Model FUNNEL-GHG-CCO | GHG emissions | The result showed that gasoline has high GHG emissions than both diesel and jet fuel which is due to higher energy consumption The well-to-wheel GHG emissions for the three transportation fuels range from 97.55 g-CO2eq/MJ-gasoline to 127.74g-CO2eq/MJ-gasoline, 95.0 g- CO2eq/MJ-diesel to 126.02 g-CO2eq/MJ diesel, and 88.17 g-CO2eq/MJ-jet fuel to 118.17g-CO2eq/MJ-jet fuel (HTP), and Eco toxicity potential (ETP). |

| Nguyen and Gheewal a (2008) | Thailand | 1 1gasoline equivale nt consum ed by a new passeng er car to travel a specific distance | Cradle to grave | Not specified | net energy use, fossil energy use, GWP, AP, and NP | The results show that using MoE in the form of E10 as a gasoline substitute leads to fossil energy and petroleum savings |

Table 3: Comparison of LCA study of various countries.

In the review of various papers, it is found that while selecting a boundary for doing LCA it is important to consider the source and all the stages where the emissions and environmental impacts are higher. According to one report on Global Climate Disclosure Framework in the year 2012 for oil and gas companies, the bulk of GHG emissions generated through the oil and gas lifecycle are in the consumption and combustion of the final product, So while doing the LCA study this stage has to be considered. Literature also argues that the shift towards sustainable development have increased complexities and presented indefinite challenges that many current environmental management techniques cannot adequately address the issue [26].

The main impact categories studied are the Global Warming Potential (GWP), Climate Change (CC), Ozone Depletion Potential (ODP), Acidification Potential (AP), Eutrophication Potential (EP) and Human Toxicity Potential (HTP). Authors have identified these as impact categories [15,19,27-35].

We have compared five LCA studies done in different countries and found that there is difference in LCA result due to factors such as geographical locations, refining technology, fuel price supply, and demand, source of crude oil and other methodological factors such as data quality, system boundary and databases [31-36].

Inspite of so many technological innovations, we are still in the phase of conventional refineries which needs to be upgraded. Various clean technologies are identified and used such as flare gas recovery system, vapor recovery system, tail gas treatment which has helped in minimizing the emissions but, Since the world has moved towards the concept of bio refinery and using the green methods such as Bio Desulphurization (BDS), We also need to be more advanced in making oil and gas supply chain a sustainable Green supply chain [37-44].

Conclusion

This paper gives a brief idea of the present various LCA models used in different context by authors and various LCA methods and their impact categories. Different technologies used in this sector are also [45-51]. The Life cycle assessment of the oil and gas sector performed by various authors in different countries has been reviewed but there is very limited study in the Indian context. The LCA studies have given the complete insight of supply chain of oil and gas sector and helped to identify the Life cycle stages which are more environmentally intensive [52-55]. It is concluded that the LCA studies help us in estimating the available options for more sustainable transportation.

References

- Wawryk AS (1997) International Environmental Standards In The Oil Industry: Improving the Operations of Transnational Oil Companies in Emerging Economies.

- Grubb M (2001) Who’s afraid of atmospheric stabilization? Making the link between energy resources and climate change. Energy Policy 29: 837-845.

- Raut R, Narkhede B, Bhaskar BG, Luong H (2018) An ISM approach for the barrier analysis in implementing sustainable practices: The Indian oil and gas sector. Benchmarking: An International Journal 25: 1245-1271.

- Jacquemin L, Pontalier PY, Sablayrolles C (2012). Life cycle assessment ( LCA ) applied to the process industry: a review. The International Journal of Life Cycle Assessment 17:1028–1041.

- Srivastava VC (2012) ChemInform Abstract: An Evaluation of Desulfurization Technologies for Sulfur Removal from Liquid Fuels. ChemInform 43:18. Â (link not available online)

- Popat A (2015) Zero liquid discharge from concept to commissioning in refineries and downstream petrochemicals. International Conference on Petroleum, Refining and Environmental Technologies, Rotterdam.

- Asghari M, Rakhshanikia MA (2013) Technology transfer in oil industry, significance and challenges. Procedia- Soc Behv 75: 264-271.

- Arscott L (2004) Sustainable development in the oil and gas industry. J Energ Resour 126: 1-5.

- Mariano JB, Lèbre E, Rovere L (2000) Environmental impacts of the oil industry.

- Morsali S (2018) A novel perspective to bitumen refineries life cycle assessment and processes emissions. Acta Ecologica Sinica 38: 242-247.

- Vineyard DL, Ingwersen WW (2017) A comparison of major petroleum life cycle models. Clean Technologies and Environmental Policy 19: 735–747.

- Vafi K, Brandt AR (2014) Reproducibility of LCA models of crude oil production. Environmental Science and Technology 48: 12978–12985.

- Stanciulescu V, Fleming JS (2006) Life cycle assessment of transportation fuels and GHGenius. IEEE EIC Climate Change Conference.

- Garg A, Vishwanathan S, Avashia V (2013) Life cycle greenhouse gas emission assessment of major petroleum oil products for transport and household sectors in India. Energy Policy 58: 38–48.

- Nanaki EA, Koroneos CJ (2012) Comparative LCA of the use of biodiesel, diesel and gasoline for transportation. Journal of Cleaner Production 20: 14–19.

- Jolliet O, Margni M, Charles R, Humbert S, Payet J, et al. (2003) Impact 2002+: a new life cycle impact assessment methodology. Int J Life Cycle Ass 8: 324.

- Shi J, Li T, Peng S, Liu Z, Zhang H, et al. (2015) Comparative Life Cycle Assessment of remanufactured liquefied natural gas and diesel engines in China. Journal of Cleaner Production 101: 129 136.

- Morales M, Gonzalez-GarcÃa S, Aroca G, Moreira MT (2015) Life cycle assessment of gasoline production and use in Chile. Sci Total Environ 505: 833-843.

- Goedkoop M, Heijungs R, Huijbregts M, De SA, Struijs J, et al. (2009). ReCiPe 2008 A life cycle impact assessment method which comprises harmonised category indicators at the midpoint and the endpoint level.

- Eriksson M, Ahlgren S (2013) LCAs of petrol and diesel- a literature review. SLU, Swedish University of Agricultural Science Department of Energy and Technology.

- Rahman MM, Canter C, Kumar A (2015) Well-to-wheel life cycle assessment of transportation fuels derived from different North American conventional crudes. Applied Energy 156: 159–173.

- Wallington TJ, Anderson JE, De KRD, Kim HC Maas H, et al. (2017) When Comparing Alternative Fuel-Vehicle Systems, Life Cycle Assessment Studies Should Consider Trends in Oil Production. Journal of Industrial Ecology 21: 244–248.

- Hawkins TR, Gausen OM, Stromman AH (2012) Environmental impacts of hybrid and electric vehicles- a review. Int J Life Cycle 8: 997-1014.

- Mckinsey, Company (2009) Paths to low carbon economy-version 2 of the global green house gas abatement cost curve. Chicago IL, USA

- Matos S, Hall J (2007) Integrating sustainable development in the supply chain: The case of life cycle assessment in oil and gas and agricultural biotechnology. Journal of Operations Management 25: 1083–1102.

- Bicer Y, Dincer I (2018) Resources,Conservation & Recycling Life cycle environmental impact assessments and comparisons of alternative fuels for clean vehicles. Resources, Conservation & Recycling 132: 141–157.

- Iribarren D, Peters JF, Dufour J (2012) Life cycle assessment of transportation fuels from biomass pyrolysis. Fuel 97: 812-821.

- Luo L, Van DVE, Huppes G (2009) Life cycle assessment and life cycle costing of bioethanol from sugarcane in Brazil. Renewable and Sustainable Energy Reviews 13: 1613-1619.

- Aung TS (2017) Evaluation of the environmental impact assessment system and implementation in Myanmar: Its significance in oil and gas industry. Environ Impact Asses 66: 24–32.

- Burnham A, Han J, Clark CE, Wang M, Dunn JB, et al. (2011) Life-Cycle Greenhouse Gas Emissions of Shale Gas, Natural Gas, Coal, and Petroleum. Environmental Science & Technology 619–627.

- Burnham A, Zhang H, Kumar A (2016) Evaluation of uncertainty in the well-to-tank and combustion greenhouse gas emissions of various transportation fuels. Appl Energ 184: 413-426.

- La Rovere EL, JB Mariano (2015) Environmental Impacts of the Oil Industry. Petroleum Engineering.

- Frischknecht R, Jungbluth N, Althaus HJ, Doka G, Dones R, et al. (2005) The ecoinvent database: Overview and methodological framework. Int J Life Cycle Ass 10: 3–9.

- GarraÃn D, Herrera I, Lechón Y, Lago C (2014) Well-to-Tank environmental analysis of a renewable diesel fuel from vegetable oil through co-processing in a hydro treatment unit. Biomass and Bioenergy 63: 239-249.

- Granovskii M, Dincer I, Rosen MA (2006) Life cycle assessment of hydrogen fuel cell and gasoline vehicles. Int J Hydrogen Energ 31: 337-352.

- Guinée J (2016) Life Cycle Sustainability Assessment: What Is It and What Are Its Challenges?. In: Clift Z, Druckman A (eds) Taking Stock of Industrial Ecology. Springer, Cham Heidelberg New York Dordrecht London.

- Guinée JB, Heijungs R, Huppes G, Zamagni A, Masoni P, et al. (2011) Life cycle assessment: Past, present and future. Envir Sci Tech 45: 90–96.

- Guinée JB, Gorrée M, Heijungs R, Huppes G, Kleijn R, et al. (2002) Handbook on Life Cycle Assessment. Operational Guide to the ISO standards 7: 311.

- Devold H (2013) Oil and gas production handbook An introduction to oil and gas production, transport, refining and petrochemical industry. ABB Oil & Gas.( link not available online)

- Hawkins TR, Singh B, Majeau-Bettez G, Strømman AH (2013) Comparative environmental life cycle assessment of conventional and electric vehicles. J Ind Ecol 17: 53-64.

- Hsu DD, O’Donoughue P, Fthenakis V, Heath GA, Kim HC, et al. (2012) Life cycle greenhouse gas emissions of crystalline silicon photovoltaic electricity generation. J Ind Ecol 16.

- ISO (1998) Environmental Management — Life Cycle Assessment — Principles and Framework.

- International Standard 14041 (2006) International Standards Organization (ISO), Geneva, Switzerland.

- Keesom B, Blieszner J, Unnasch S (2011) EU Pathway Study: Life Cycle Assessment of Crude Oils in a European Context, Exectutive Summary, Jacobs Consultancy, Calgary, Canada.

- Klöpffer W (2008) Life cycle sustainability assessment of products. The International Journal Life Cycle Assessment 13: 89–95.

- Mahony S (2011) Life Cycle Assessment of Biodiesel from Cannabis Sativa L for transportation fuel in UK. University of East Anglia.

- Oborn R (2012) From Ground to Gate: A lifecycle assessment of petroleum processing activities in the United Kingdom. Activities in the United Kingdom.

- Schneider J, Campbell D, Vargo C, Hall R (2011) An analysis of reported sustainability-related efforts in the petroleum refining industry. Journal of Corporate Citizenship 44: 69-84.

- Stanciulescu V, Fleming JS (2006) Life cycle assessment of transportation fuels and GHGenius. IEEE EIC Climate Change Conference.

- Wang M, Lee H, Molburg J (2004) Allocation of energy use in petroleum refineries to petroleum products. The International J Life Cycle Ass 9: 34-44.

- Zhou H, Qian Y, Kraslawski A, Yang Q, Yang S (2017) Life-cycle assessment of alternative liquid fuels production in China. Energy 139.

- Zhou Z, Jiang H, Qin L (2007) Life cycle sustainability assessment of fuels. Fuel 86: 256–263.

- Tiwari S, Tripathi I, Tiwari Hl (2013) Effects of Lead on Environment. 2278-9359.

- Ibem V (2010) Environmental Control in Oil & Gas Exploration & Production. Digital Scientific Archive.

Citation: Shrivastava S, Unnikrishnan S (2019) Review of Life Cycle Assessment and Environmental Impacts from The Oil & Gas Sector. Oil Gas Res 5: 164. DOI: 10.4172/2472-0518.1000164

Copyright: © 2019 Shrivastava S, et al. This is an open-access article distributed under the terms of the Creative Commons Attribution License, which permits unrestricted use, distribution, and reproduction in any medium, provided the original author and source are credited.

Select your language of interest to view the total content in your interested language

Share This Article

Recommended Journals

Open Access Journals

Article Tools

Article Usage

- Total views: 7253

- [From(publication date): 0-2019 - Nov 16, 2025]

- Breakdown by view type

- HTML page views: 6034

- PDF downloads: 1219