Reducing Heat Gain in Building through Walls with Energy Efficient Materials â A Case Study of Frank & Debbie Management Complex, A.M.U

Received: 03-Jul-2023 / Manuscript No. jaet-23-103994 / Editor assigned: 05-Jul-2023 / PreQC No. jaet-23-103994 / Reviewed: 19-Jul-2023 / QC No. jaet-23-103994 / Revised: 22-Jul-2023 / Manuscript No. jaet-23-103994 / Published Date: 29-Jul-2023 DOI: 10.4172/2168-9717.1000347 QI No. / jaet-23-103994

Abstract

Buildings are responsible for significant portion of the world's energy consumption and greenhouse gas emissions. One of the key factors that contribute to high energy consumption of buildings is the heat gain through walls. Heat gain through walls can result in increased cooling load and can cause discomfort to the occupants. Here application of Energy efficient materials (viz. Vacuum Insulated Panels, Aerogel Panels, Polyurethane Foam and Polystyrene Foam) on walls are analyzed on basis of their thermal efficiency and availability.This research focuses on the development of a simulation model of a live Institutional building to investigate the potential of energy efficient materials. The objective is to identify materials that effectively reduce heat transfer through walls and improve the energy efficiency of buildings. The research employs computer simulation by using Ecotect Analysis 2011, to analyze thermal behavior of different wall materials, and evaluate the performance of selected energy efficient materials.

Keywords: Heat gain; Energy efficient materials; Insulation materials; Energy efficiency; Building materials; Simulation model ; Thermal behaviour; Wall materials

Keywords

Heat gain; Energy efficient materials; Insulation materials; Energy efficiency; Building materials; Simulation model ; Thermal behaviour; Wall materials

Introduction

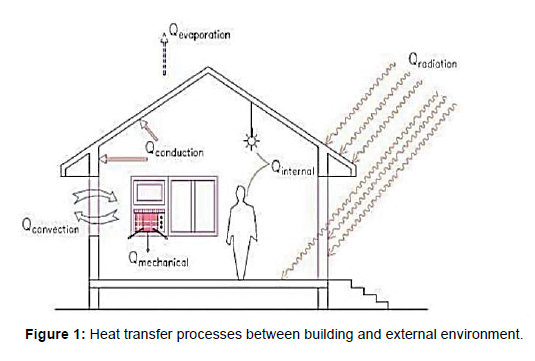

The term "Heat gain" refers to a rise in temperature within a space brought on by heat from the sun (solar radiation), heat from surfaces (long wave infrared radiation), and heat from other sources present in the space (such as heating devices, ovens, people, mechanical systems, lights, and computers), among others. The heat produced by these sources is what alters the ambient temperature in the area. [1]

Heat gain may be beneficial, such as when it offers "free" heating to areas on bright but chilly days, or it can be detrimental, such as when it overheats spaces in the summer and makes them uncomfortable to be in.

Heat gain, generally referred as thermal or solar gain, can happen in a number of ways:

Conduction, the transfer of heat through surfaces like walls and ceilings

When sunlight enters through windows and skylights, radiation results

Convection and infiltration are processes in which warm air and moisture seep through gaps and fissures in walls (Figure 1).

The heat that is produced inside by people and equipment

When the outside air temperature is lower than the inside air temperature, heat loss, which is the reverse of heat gain, occurs through the building's fabric. External walls, floors, and roofs as well as ineffective doors, windows, and other openings all contribute to the heat loss.

Methodology

Sources of heat gain in building, including:

Design variables

Building size, shape, and orientation

Fenestrations

Landscaping

Facade treatments

The size of shade equipment, etc

Materials specifications

Density

Specific heat

Thermal conductivity

Transmissivity, etc. (Figure 2).

Variables affecting the weather/climate include

Solar radiation

Ambient temperature

Wind speed

Humidity, etc

Data on building usage

Internal heat gain caused by people, lights, and equipment.

Exchanges of air, etc

Role of energy efficient materials towards heat gain in building

The thermal characteristics of materials used as building envelopes, such as specific heats (kJ/(kg K), thermal conductivity (W/(m K)), and density (kg/m3), have an influence on the formation of the thermal comfort within the buildings.

The substance serves as a building's exterior, internal framework, pavement, decorative features, and more. Following the purpose of the interior area, the building envelope serves as a barrier between the exterior and inside environments. Heat transfer occurs via the building's structural elements, such as the walls, roof, and floor, whenever there is a temperature differential between the conditioned interior area of a building and the surrounding outside air. Depending on whether heat is being transferred to or from the structure, this is referred to as fabric heat gain or loss. Radiation heat transmission by fenestration is not included in the fabric heat transfer, which only covers sensible heat transfer through all structural components of a structure. [2]

Modelling the energy transfer between a building and its surroundings is what is referred to as a building's thermal performance. Materials that are thought to have strong thermal performance also frequently have good insulating properties, meaning that heat is not easily transferred through them. Contrarily, materials with poor thermal performance tend to be greater heat conductors, allowing heat to transfer from, instance, a heated building to a cooler exterior environment more quickly.

Due to the use of materials with high thermal conductivity on building facades, heat is transferred from the outside to the inside of the structure by radiation and conduction, creating a significant cooling load that raises energy costs for thermal comfort. Therefore, using energy-efficient materials is crucial from an energy-saving perspective as well as for reducing heat gain in buildings to achieve thermal comfort inside the building spaces.

Thermal storage/ thermal capacity

Thermal capacity, also known as heat capacity, the amount of heat necessary to increase a substance's temperature by one degree Celsius or one Kelvin. (It gauges a substance's capacity to store thermal energy. The thermal capacity of a substance depends on its mass, specific heat capacity, and temperature. The unit of thermal capacity is joules per degree Celsius (J/°C) or joules per Kelvin (J/K).

The formula to determine a substance's thermal capacity is

Q = m c T.

Where Q is the needed quantity of heat energy, m is the substance's mass, c is its specific heat capacity, and T is the temperature change.

The following methods can be used to enhance the thermal performance of walls:

Adding an air space between walls and hollow masonry blocks

Increasing wall thickness.

Adding insulation to the exterior surface.

Painting the exposed side of the wall with light-colored distemper.

Thermal conductance

According to Cengel and Ghajar, Thermal Conductivity is the rate of heat transfer through a material's unit area and unit thickness caused by a unit temperature differential on the two sides. W/mK, or Watt per metre degree Kelvin, is the unit. For insulators, the conductivity value ranges from 0.03 W/mK to 400 W/mK for metals. As they are better insulators and would lessen the external heat gains from the envelope, materials with lower conductivity are preferred.

Specific heat of material

The specific heat capacity is defined as the quantity of heat (J) absorbed per unit mass (kg) of the material when its temperature increases 1 K (or 1 °C), and its units are J/(kg K) or J/(kg °C). The higher the specific heat, the more resistant the substance is to changes in temperature. Materials like wet mud, clay, granite have more specific heat.

Heat gain through the envelope walls

Walls are a major part of the building envelope which receives large amount of solar radiations. The heat storage capacity and heat conduction property of walls are key to meeting desired thermal comfort conditions. The wall thickness, materials and finishes can be chosen based on the heating and cooling needs of the building. Appropriate thermal insulation and air cavities in walls reduce heat transmission into building which is the primary aim in a hot region.

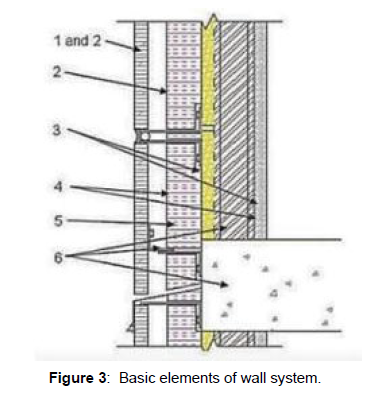

The Wall system's fundamental components are:

Natural or artificial exterior cladding

Drainage plane

Air separating device(s)

Vapour Retarder

Structural components

Insulating Material

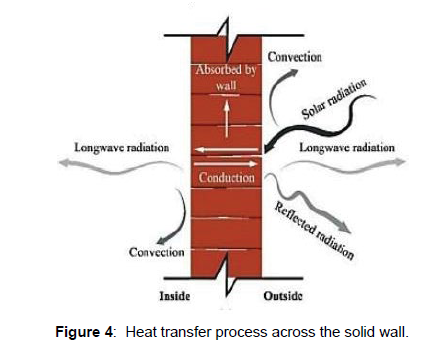

Both conduction heating from outside air and solar radiation are included in the total heat gain via the building wall. Based on the temperature differential across the wall, the wall heat transmission coefficient is used to determine the amount of heat gained via the wall. The suitable heat transmission coefficient for each wall and roof surface must be evaluated in order to determine the overall building heat gain.

The sol-air temperature idea is a useful way to take solar heat input into consideration. According to ASHRAE (2013), the sol-air temperature is the equivalent air temperature that results in the same heat gain through a wall as the heat gains via conduction and solar radiation. As a result, it is a measurement of the impact of both the influence of ambient air temperature and the sun heating effect. The direction of the wall, the outside solar heating for the location and time of year, cloudiness, wind, and the reflectiveness of the surface all have an impact on how much solar heat is gained via a given roof or wall surface. Obviously, facing the sun will result in greater solar heating collection than facing away [3].

Complex and dynamic, conduction, convection, and radiation together make up the heat transfer process through a building wall. For instance, when sunlight strikes an external wall surface throughout the day, some of it is released into the environment while the rest is absorbed and channeled through the material. The room air and other surfaces are then heated by convection and radiation from the internal surface of the wall. These heat transmission techniques control the temperature of the interior air, which affects the level of thermal comfort .

Energy-efficient materials serves as thermally efficient for buildingsThere are several energy-efficient materials available for walls that can help increase the thermal efficiency of buildings. Here are some examples:

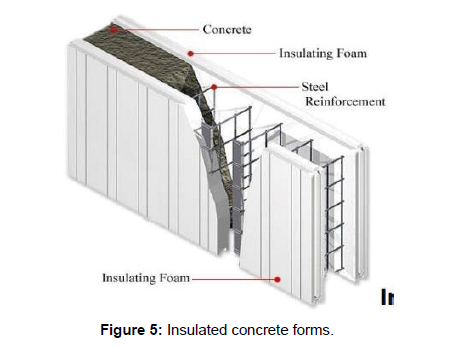

Insulated concrete forms (ICFs): These are hollow polystyrene foam or other insulating material blocks or panels that are filled with concrete to produce a strong and effective wall system. This comprises of a permanent internal and external substrate for walls, floors, and roofs made of hard-thermal insulation. When compared to conventional construction methods, these insulated concrete form buildings require up to 20% less energy to heat or cool .

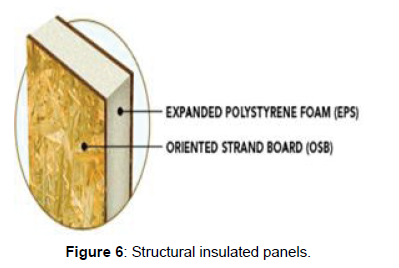

Structural insulated panels: A layer of foam insulation is adhered between denser layers of cement, wood, or other protective material to create structural insulated panels (SIPs). It may save as much as 50% more on heating and cooling than conventional materials and is extremely fire resistant .

Polyurethane insulation (PUR): A solid, cellular polymer with a high heat resistance is polyurethane insulation. It is created by injecting polyurethane foam between two layers of a face material, such metal or plasterboard and are typically put in as insulation on the floors, ceilings, walls, and roofs of new and renovated buildings. The thermal insulation offered by polyurethane is 700% greater than the one supplied by bricks and 50% better than the one provided by glass wool when compared to other materials since these provide a low thermal conductivity with minimum thickness .

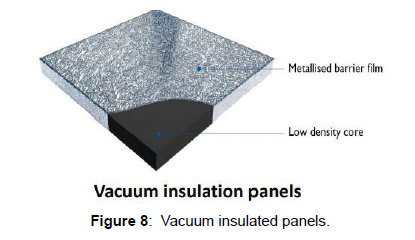

Vacuum insulated panels: It is a form of thermal insulation consisting of a gastight enclosure surrounding a rigid core, such as silica or fiberglass, from which the air has been evacuated. It is used in building construction, refrigeration units, and insulated shipping containers to provide high insulation with very low thickness is required; thermal conductivities up to 10 times lower than traditional thermal insulation materials .

Autoclaved Aerated concrete blocks: AAC is a precast, lightweight foam concrete building material that may be used to create blocks-like concrete masonry units. Cement, lime, sand, and water are combined to make it, and aluminium paste or powder is used to aerate the mixture. The thermal efficiency is two to three times better than clay brick and ten times better than aggregate concrete .

Expanded Polystyrene (EPS): It made from expanded polystyrene beads that are fused together to create blocks. These are rigid, cellular foam insulation. These foams are typically installed as preformed sheets in building for ceiling tiles, wall insulation and floor thermal insulation. They provide good insulation and are lightweight; It results in lowering the thermal conductivity by giving a 20% improvement in thermal resistance.

Aerogel insulation: It made from silica aerogel, which is a highly porous and lightweight material. It has a very high insulation value and is ideal for areas where space is limited (Chen, 2018). Aerogel is made out of silicon-based solid agents in whom air has been substituted for the gel's liquid component. Aero gels have a sponge-like surface made up of millions of tiny holes: Its goods have two to three times less heat conductivity than standard thermal insulation materials, and 99.8% of it is made up of air .

Phenolic foam: It is a type of plastic foam insulation that is made from phenolic resin and a foaming agent. It has a very high R-value (thermal resistance), making it one of the most effective insulating materials available. Also, it is lightweight, fire-resistant, and moistureresistant, making it an ideal choice for building insulation. It has low thermal conductivity. Phenolic foam insulation can reduce heat loss through walls by up to 30% compared to un insulated walls .

Mineral wool: It is a type of fiber insulation made from spun rock or slag fibers. It is a non-combustible and moisture-resistant material that has excellent sound-deadening properties and is an effective thermal insulator. It is commonly used in commercial and residential construction and is often installed in wall cavities, attics, and floors to reduce energy loss. Various other names for it include stone wool insulation, rock wool insulation, and slag wool insulation. This type of insulation is usually used in industrial furnaces and foundries. It results up to 20% lower heating energy consumption compared to uninsulated buildings .

Fly ash-lime-gypsum (Fal-G) blocks: A cementitious compound called Fal-G is made up of fly ash (Fa), lime (L), and gypsum (G). FaL-G bricks absorb less heat than red bricks, which results in reduced heating of constructions. They provide 20%–25% more thermal insulation than red bricks. Red bricks have a thermal conductivity between 0.6 and 1.0 W/mK, while fly ash bricks have a thermal conductivity between 0.3 and 0.4 W/mK .

Cellulose insulation: It is manufactured from recycled paper materials like newspaper and has received fire retardant treatment. It is well recognized to have a high level of insulation and be simple to install .

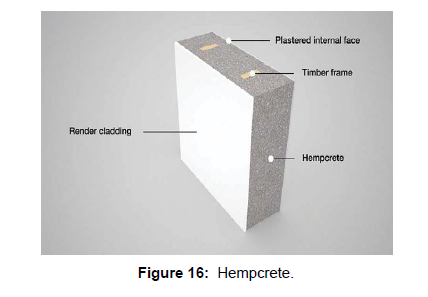

Hempcrete: It made from hemp fibers and a lime-based binder.It is a lightweight material that provides excellent insulation, is mold- resistant, and has a negative carbon footprint .

Criteria for selecting the energy efficient materials for simulation

Several factors are considered for selecting the wall materials which serves thermally efficient for buildings are:

Thermal performance of material

Energy efficiency

Locally available

Natural

Embodied energy consumption Life cycle or durability

Aesthetics

Ease in installment

Maintenance

Waste reduction

Recycle & Reusability etc. (Shahzad et al., 2021)

The table displays the sustainable selection criteria for the energyefficient materials included in this study.

The four materials are selected from above table which shows more positive properties in terms of their thermal efficiency as well as local availability for the purpose of simulation are as follows:

Vacuum insulated panels

Aerogel panels

Polyurethane foam

Polystyrene foam

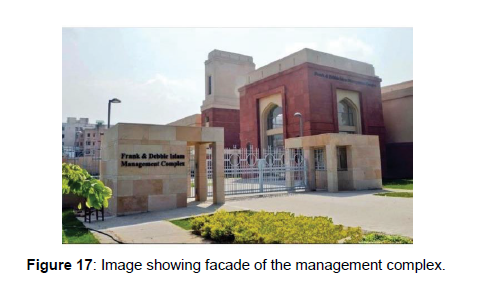

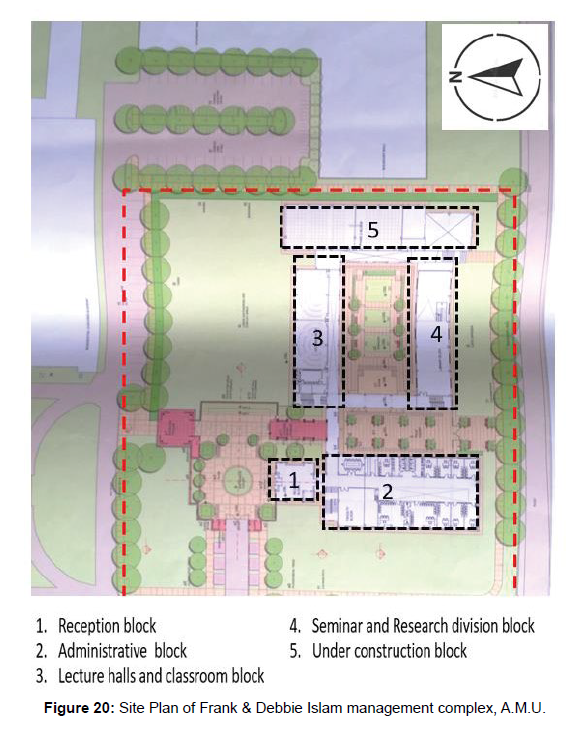

Case study: Frank & Debbie Islam management complex, A.M.U.

The Department of Business Administration and Faculty of Management Studies and Research are housed at the Complex. This structure was built on a 3 Acre block of land in the Sir Syed House Complex.

General information

Owner : Aligarh Muslim university

Location : AMU Campus Aligarh

Climate : Composite climate

No. of floors : G+1

Typology : Institutional

Aligarh Muslim University's management complex is an innovative project funded by alumni. This construction project seeks to give the Faculty of management studies and research, a flagship institution of AMU, state-of-the-art physical infrastructure.

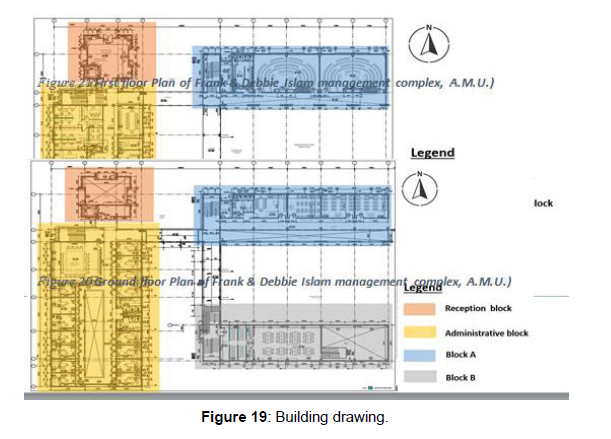

Building drawing

Building modelling

Geometrical description

The complex consists of five rectangular, two-story buildings, four of which have been built and one of which is still under construction. There are connecting tunnels between each of the construction pieces. As seen in fig. 22, the blocks are organised along an Amphitheatre court [4].

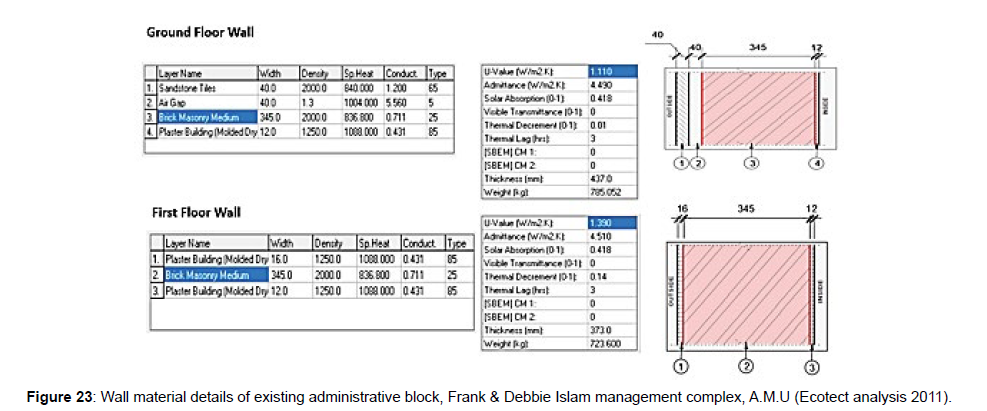

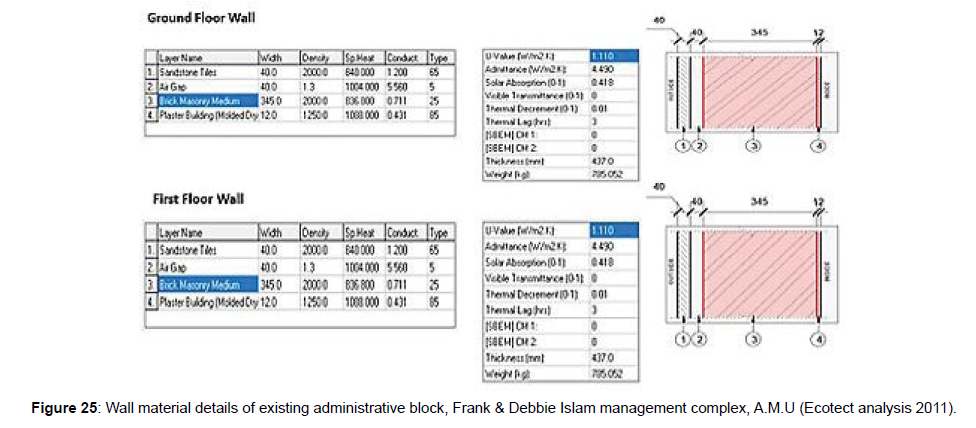

Material description

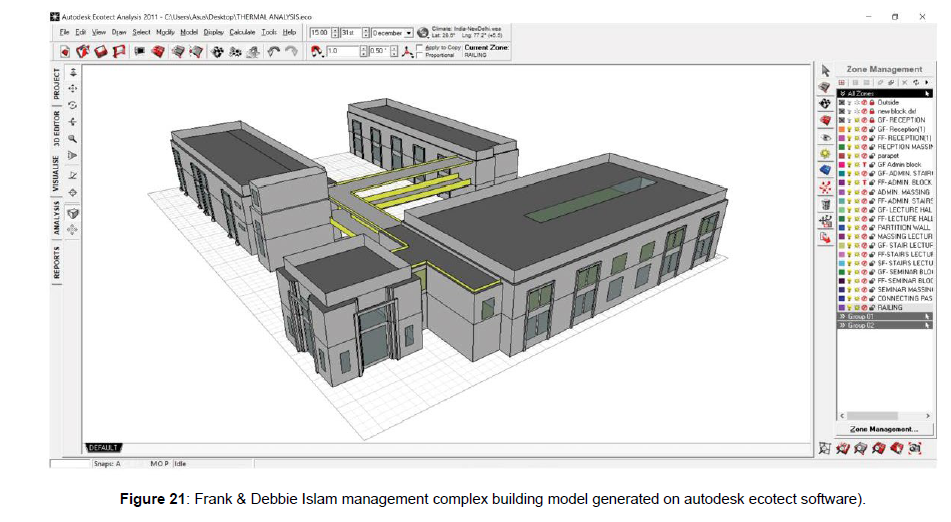

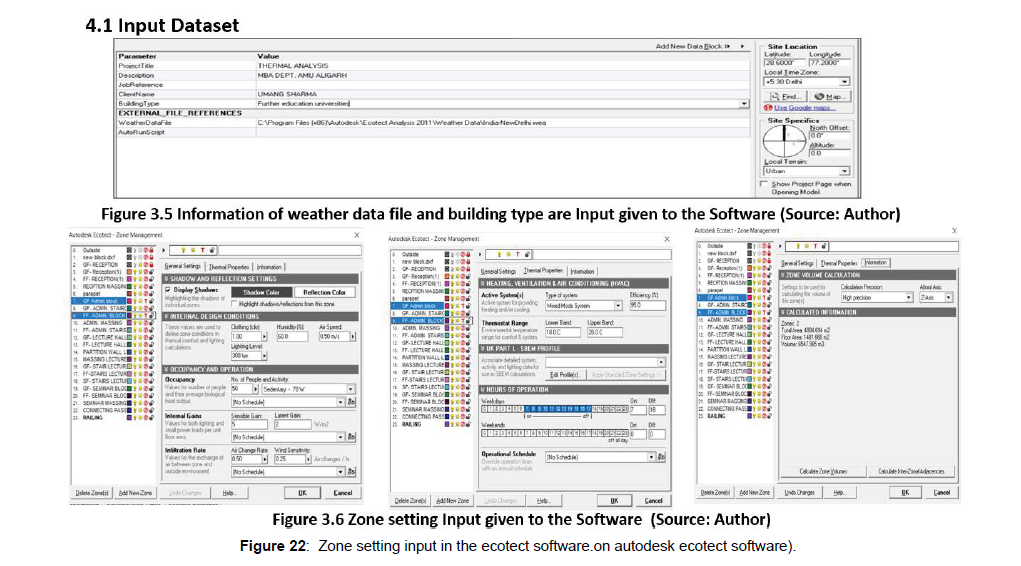

Model generated on the Autodesk Ecotect analysis 2011 software

The Autodesk Ecotect software is a powerful simulation tool for buildings and their surroundings. Its main purpose is to improve energy efficiency in various climatic conditions, including sunlight exposure, daylight availability, and thermal comfort .

To achieve this, the software relies on the thermal properties of different materials used in construction. By assigning these properties to each component of a building, such as walls, floors, and roofs, the software can conduct accurate simulations for each zone.

Model generated on the Autodesk Ecotect analysis 2011 software

The Autodesk Ecotect software is a powerful simulation tool for buildings and their surroundings. Its main purpose is to improve energy efficiency in various climatic conditions, including sunlight exposure, daylight availability, and thermal comfort.

To achieve this, the software relies on the thermal properties of different materials used in construction. By assigning these properties to each component of a building, such as walls, floors, and roofs, the software can conduct accurate simulations for each zone.

Over Ecotect, a basic model of the Management Complex's existing building is created. Then, each zone or model object was given the same materials, specifications, and properties. Following that, simulrerunwith the correct inputs to learn the model's current pattern of operation.

Site weather information is included in this data, which is essential for building energy, thermal comfort, and day lighting simulations since it provides the necessary climatic conditions for the calculations to run. Software needs the position and size of window apertures in addition to the geometry of the building to accurately display the solar incidence inside the structure. Additional datasets are required to calculate the building's thermal heat gains, including information about the building's construction and usage. The figures 24 and 25 show the input data that was given to the Ecotect programme .

Simulation result

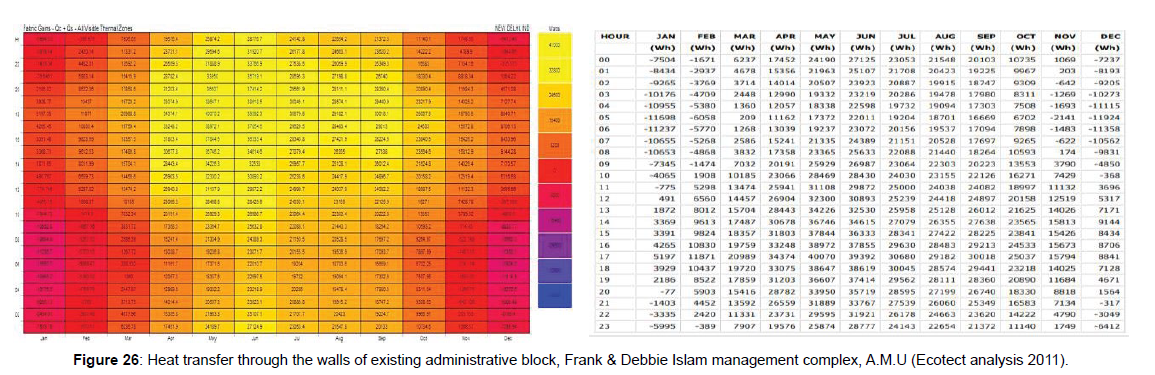

Internal heat gain

These figures show the graphical results of fabric heat transfer in the existing administrative block of Frank & Debbie Islam management complex. In the given graph, the various colour codes depicts heat transfer values through building fabric to interior spaces

Result of fabric heat gain of existing building model

The graphs depict the heat gain distribution of the building's fabric. Figure 27 shows the average monthly heat gain of the existing administrative block of management complex. The maximum overall heat gain through building fabric in existing building is comes out to be 41922.7 watts (i.e. 42 KW) during the month of May and can be reduced substantially by using alternate energy efficient materials which have better thermal performance than existing.

Simulation result of base model (with exterior stone cladding on both floors)

Internal heat gain

These figures show the graphical results of fabric heat transfer in the existing administrative block of Frank & Debbie Islam management complex. In the given graph, the various colour codes depict heat transfer values through building fabric to interior spaces [5].

Result of fabric heat gain of base model (with exterior stone cladding on both floors)

The graphs depict the heat gain distribution of the building's fabric. Figure 29 shows the average monthly heat gain of the existing administrative block of management complex. The maximum overall heat gain through building fabric in existing building is comes out to be 40070.2 watts (i.e. 40 KW) during the month of May and can be reduced substantially by using alternate energy efficient materials which have better thermal performance than existing.

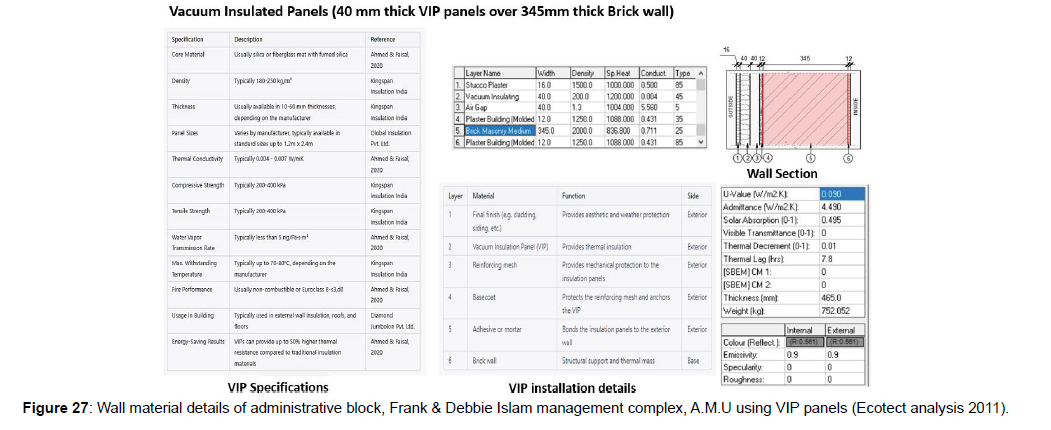

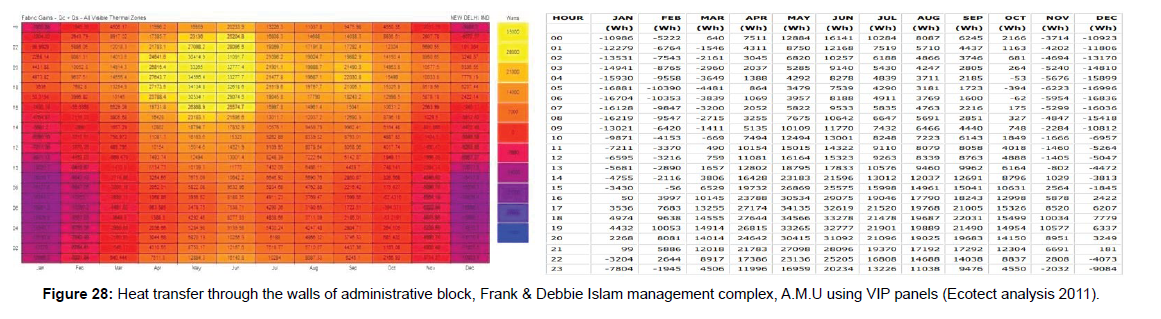

Simulation result of building model using VIP panels (Model A)

Internal heat gain

These figures show the graphical results of fabric heat transfer in the administrative block using VIP panels over brick wall of Frank & Debbie Islam management complex. In the given graph, the various colour codes depict heat transfer values through building fabric to interior spaces.

Result of fabric heat gain of building model using VIP panels over brick wall

The graphs depict the heat gain distribution of the building's fabric. Figure 31 shows the average monthly heat gain of the administrative block of management complex by modelling 40mm thick VIP panels over 345 mm thick brick wall. Then the maximum overall heat gain through building fabric building is reduced to be 34566.4 watts (i.e. 34.5 KW) [6, 7].

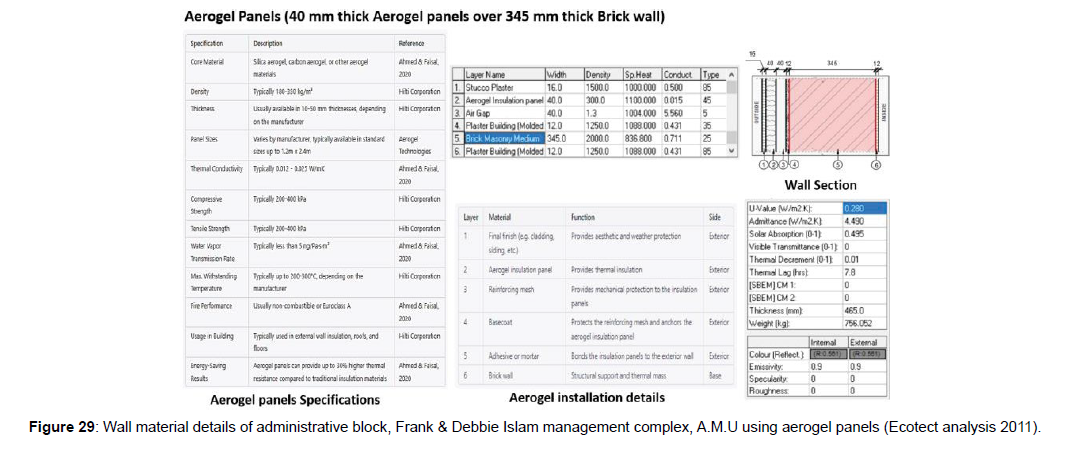

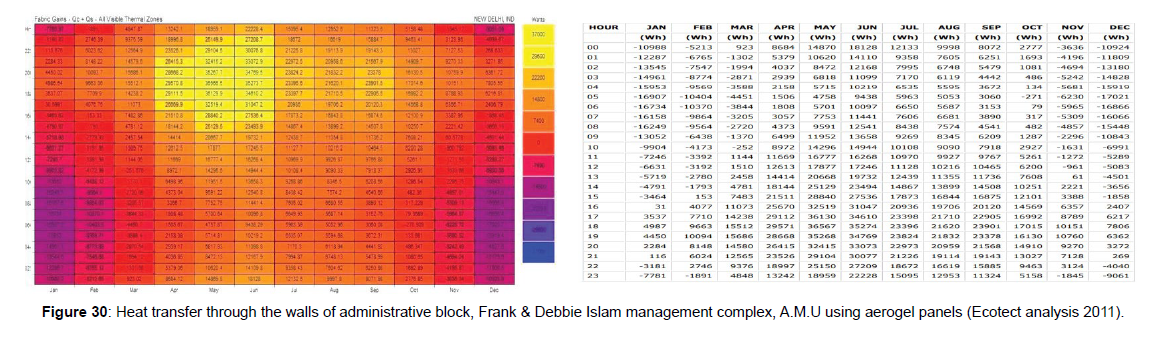

Simulation result of building model using aerogel panels (Model B)

Internal heat gain

These figures show the graphical results of fabric heat transfer in the administrative block using Aerogel panels over brick wall of Frank & Debbie Islam management complex. In the given graph, the various colour codes depict heat transfer values through building fabric to interior spaces.

Result of fabric heat gain of building model using Aerogel panels over brick wall

The graphs depict the heat gain distribution of the building's fabric. Figure 33 shows the average monthly heat gain of the administrative block of management complex by modelling 40mm thick Aerogel panels over 345 mm thick brick wall. Then the maximum overall heat gain through building fabric building is reduced to be 36566.5 watts (i.e. 36.5 KW).

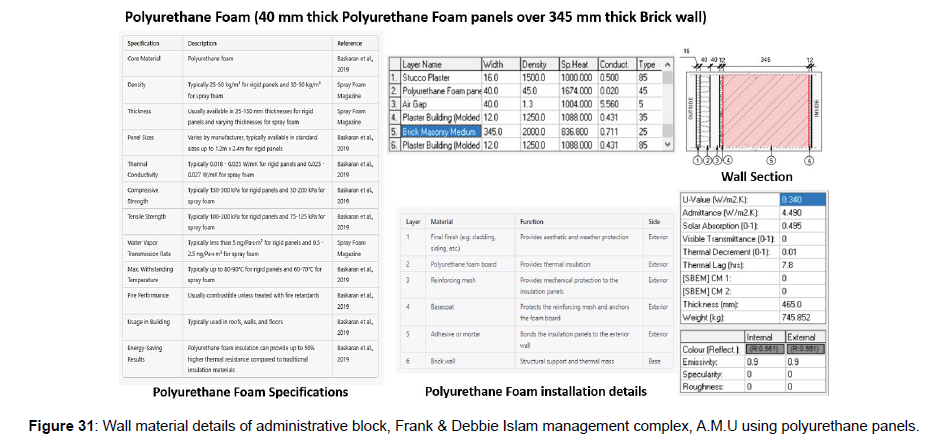

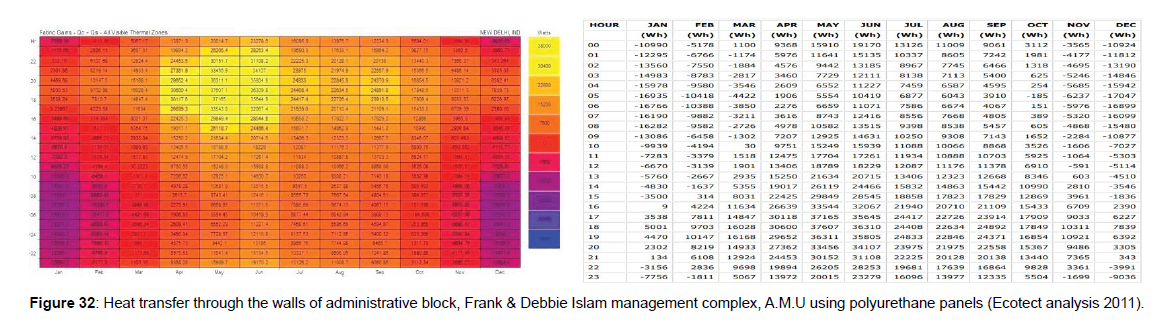

Simulation result of building model using polyurethane foam panels (Model C)

Internal heat gain

These figures show the graphical results of fabric heat transfer in the administrative block using Polyurethane Foam panels over brick wall of Frank & Debbie Islam management complex. In the given graph, the various colour codes depict heat transfer values through building fabric to interior spaces [8].

Result of fabric heat gain of building model using polyurethane foam panels over brick wall

The graphs depict the heat gain distribution of the building's fabric. Figure 35 shows the average monthly heat gain of the administrative block of management complex by modelling 40mm thick Polyurethane foam panels over 345 mm thick brick wall. Then the maximum overall heat gain through building fabric building is reduced to be 37607.1 watts (i.e. 37.6 KW). 9.6 Simulation result of Building model using Polystyrene foam panels (Model D)

Simulation result of building model using polyurethane foam panels (Model C)

Internal heat gain

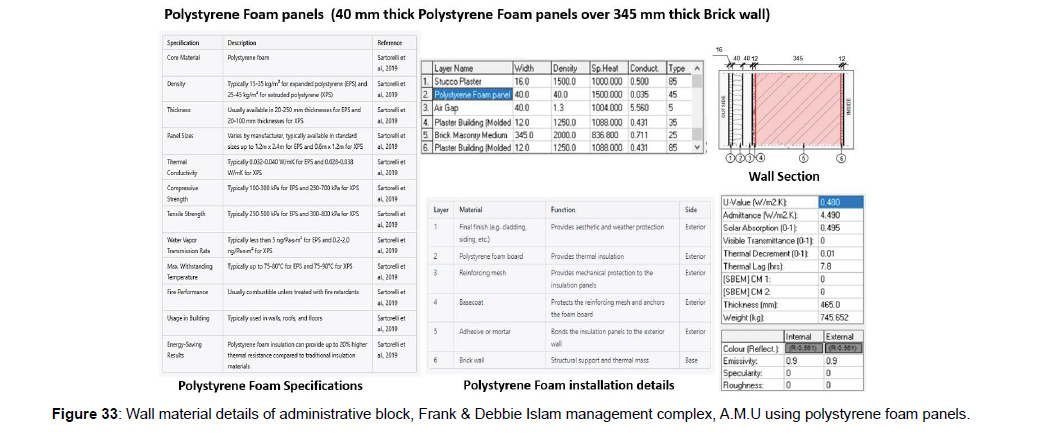

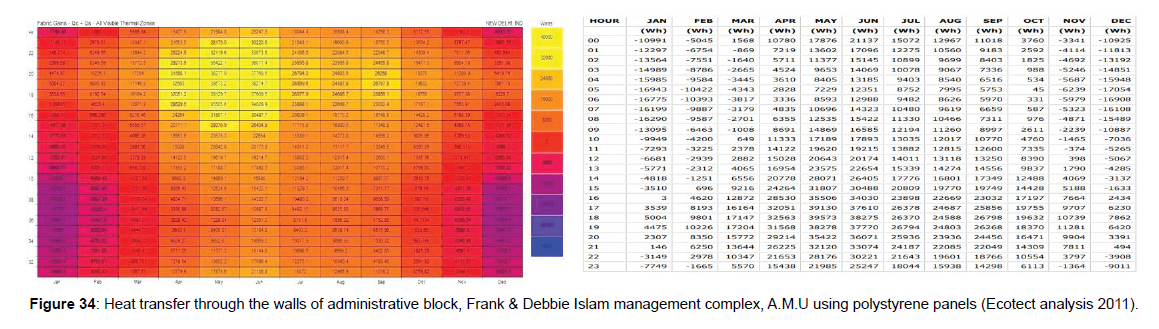

These figures show the graphical results of fabric heat transfer in the administrative block using Polystyrene foam panels over brick wall of Frank & Debbie Islam management complex. In the given graph, the various colour codes depict heat transfer values through building fabric to interior spaces [9, 10].

Result of fabric heat gain of building model using polystyrene foam panels over brick wall

The graphs depict the heat gain distribution of the building's fabric. Figure 37 shows the average monthly heat gain of the administrative block of management complex by modelling 40mm thick Polystyrene foam panels over 345 mm thick brick wall. Then the maximum overall heat gain through building fabric building is reduced to be 39573.2 watts (i.e. 39.6 KW).

Comparative result of fabric heat gain of building of existing model with the selected alternate materials

The graphs depict the heat gain distribution of the building's fabric. Figure 27 shows the average monthly fabric heat load of existing model (i.e. Base Model) with same specifications and materials of the administrative block of management complex. The maximum overall heat gain through building fabric in existing building is comes out to be 41922.7 watts (i.e. 42 KW) during the month of May. And the maximum overall heat gain through building fabric in Base model (with stone cladding on both floors) with same specifications of the administrative block of management complex is comes out to be 40070.2 watts (i.e. 40 KW) during the month of May as shown in figure 29.

Similarly, the Figures 31, 33, 35 & 37 shows the average monthly fabric heat load of Model A, Model B, Model C and Model D respectively are 34566.4 watts (i.e. 34.5 KW), 36566.5 watts (i.e. 36.5 KW), 37607.1 watts (i.e. 37.6 KW) and 39573.2 watts (i.e. 39.6 KW).

Where,

Model A: VIP insulated panels are used on outer side over 345 mm thick external brick wall

Model B: Aerogels insulated panels are used on outer side over 345 mm thick brick wall

Model C: Rigid Polyurethane foam panels are used on outer side over 345 mm thick brick wall

Model D: Polystyrene panels are used on outer side over 345 mm thick brick wall

Inferences (findings from simulation analysis)

From all the above models, Model A with VIP insulation panels over 345 mm thick external brick wall (U value 0.08 W/m2 ⋅K) is tested to prove to be a better insulation material among all models.

The results show of fabric heat transfer values of various models along with base models in ascending order of fabric heat load are as follows:

Model A < Model B < Model C < Model D < Base Model (with exterior stone cladding on both floors) < Base Model (Existing building)

The above result in terms of better thermal efficiency or better heat gain reduction is as follows:

Model A > Model B >Model C > Model D > Base Model (with exterior stone cladding on both floors) > Base Model (Existing building)

Conclusion & Recommendations

In conclusion, the construction industry must prioritize the development and implementation of technological advancements in materials to ensure a better future for humanity. This can be achieved by embracing more innovative materials and continuously improving the industry's technology.

India's economic growth has led to an increase in the use of advanced energy-efficient materials. Buildings consume a substantial portion of the world's energy, with building materials playing a major role in this consumption. Implementing advanced energy-efficient materials or insulation on building facades has proven to greatly reduce heat gain and promote the development of high-efficiency buildings.

The findings of this research demonstrate that the use of different energy-efficient materials can effectively decrease heat gain through a building's structure, particularly when the building's longer side faces north-south in a composite climate. These conclusions were drawn based on thermal analysis simulations. Base model with existing materials, as it results the maximum fabric heat gain or load inside the building is 41922.7 watts (i.e. 42 KW) and the maximum heat gain through building fabric in Base model (with stone cladding on both floors) with same specifications is comes out to be 40070.2 watts (i.e. 40 KW).

While the model A with VIP insulation panels over external wall has resulted in the minimum heat transfer i.e. 34566.4 watts (i.e. 34.5 KW). In the models B, C & D the fabric heat gain load is minimum in model B is 36566.5 watts (i.e. 36.5 KW) than in model C is 37607.1 watts (i.e. 37.6 KW) and maximum in D is 39573.2 watts (i.e. 39.6 KW).

The final result in terms of better thermal efficiency or better heat gain reduction is as follows:

Model A > Model B >Model C > Model D > Base Model (with exterior stone cladding on both floors) > Base Model Existing

Where,

Model A: VIP insulated panels are used on outer side over 345 mm thick external brick wall

Model B: Aerogels insulated panels are used on outer side over 345 mm thick brick wall

Model C: Rigid Polyurethane foam panels are used on outer side over 345 mm thick brick wall

Model D: Polystyrene panels are used on outer side over 345 mm thick brick wall

From all the models, the maximum heat gain reduction is achieved by Model A with VIP insulation panels over external brick wall (U value 0.08 W/m2 ⋅K) is tested to prove to be a better insulation material among all models.

In summary, the use of advanced energy-efficient materials and insulation on building facades can significantly reduce heat gain and promote the development of high-efficiency buildings. As demonstrated by the findings of this research, the implementation of various energy-efficient materials can effectively decrease heat gain through a building's structure, particularly when the building's longer side faces north-south in a composite climate. Model A, which utilizes VIP insulation panels over the external brick wall, resulted in the greatest reduction in heat gain among all the models tested, making it the most effective insulation material. It is clear that the construction industry must prioritize the development and implementation of such energy efficient materials and continuously improve their technology to ensure a better future for humanity.

References

- https://issuu.com/akarshan/docs/academic_dissertation_-_akarshan_chauhan_-.docx

- Corridor Budiati (2020) Building Material in the Perspective of Energy Efficiency and Thermal Environment in TOD Area.

- https://issuu.com/akarshan/docs/academic_dissertation_-_akarshan_chauhan_-.docx.

- Ahmed N, Memon SA, Asif M, Rashid A (2020) A review on thermal comfort and energy efficient materials for buildings. Energy Reports 6: 1293-1312.

- Serway RA, Jewett JW (2018) Principles of physics Cengage Learning.

- Chauhan A, Chandel S (2017) A review on thermal performance of walls for energy efficient buildings. Renewable and Sustainable Energy Reviews 75: 1130-1146.

- Cengel YA, Ghana AJ (2014) Heat and mass transfer: Fundamentals and applications. McGraw-Hill Education.

- Pescatore P (2022) Building Heat Gain | Animal & Food Sciences. Retrieved October 27, 2022.

- https://www.academia.edu/45155353/ASHRAE_Handbook_Fundamentals_SI

- https://aceupdate.com/10-energy-efficient-building-materials/

Citation: Sharma U, Tariq SMN (2023) Reducing Heat Gain in Building throughWalls with Energy Efficient Materials – A Case Study of Frank & DebbieManagement Complex, A.M.U.. J Archit Eng Tech 12: 347. DOI: 10.4172/2168-9717.1000347

Copyright: © 2023 Sharma U, et al. This is an open-access article distributed underthe terms of the Creative Commons Attribution License, which permits unrestricteduse, distribution, and reproduction in any medium, provided the original author andsource are credited.

Share This Article

Recommended Journals

Open Access Journals

Article Tools

Article Usage

- Total views: 1208

- [From(publication date): 0-2023 - Apr 07, 2025]

- Breakdown by view type

- HTML page views: 958

- PDF downloads: 250