Offshore Gas Well Flow and Orifice Metering System: An Overview

Received: 04-Dec-2017 / Accepted Date: 11-Dec-2017 / Published Date: 18-Dec-2017 DOI: 10.4172/2576-1463.1000163

Abstract

This research presents a concise account of offshore surface well test from objective, organization, to practical approach and in relation to orifice metering system of natural gas; against the perspective of regulatory standards. With reference to reliability, availability, affordability and including control measures governing the design, the orifice meter sometimes called a head loss flow meter is chosen most often because of its reputation in the oil and gas industry. Alternative metering system of natural gas, including robust and cost effective innovations within the industry which addressed some key limitations of orifice meter was examined. The advanced flow computer with transducers suited for orifice measurement installations is a cost effective electronic flow real time measurement system. It has telemetry features and improved accuracy under fluctuating flow conditions based on functional differential pressure root mean squared volume calculation principles. These new developments and their capabilities have reduced the market share of the mechanical orifice chart meters. Except that Electronic flow meters has environmental limitations; thus, the proven mechanical orifice metering systems are still an effective solution for many flow measurement applications.

Keywords: Well test; Orifice metering system; Innovative metering system

Introduction

The cost of exploration activities, drilling and completions, surface and subsurface production operations would be futile if the wells are not specifically and routinely tested within its productive life. The understanding of the actual well flow rates and other critical factors will enhance production allocation, well management and optimum field development. In Nigeria, many of the new findings in oil and gas fields are on deep water. Accurate metering of gas flow rates is an important issue in offshore production.

Surface flow meter is fundamentally changing the way we measure complex flow from producing wells. Most of these transformations are driven by new technology that can accurately measure rapid variations associated with gas flow. The ability to measure gas flow in real time will increase operational efficiency by saving both time and money. According to Leigh [1], metering costs are often included in the tariff that field pays or may be allocated on a shared basis amongst different fields as part of an operating services agreement. It was also noted that this approach affects the way future value can be generated. It was suggested that, ensuring a linkage between metering cost and field cost helps reinforce the link between the commercial and technical management of the asset and so will assist in future development options.

The measurement of gas purchases and deliveries is made on a flowing stream of gas. Accurate measurement of the total quantity of gas that has passed through a given section of pipe over a period of time is of utmost importance to the gas industry [2,3]. The type of differential metering system often used in Nigeria gas fields is the orifice meter. This metering system consists of a thin flat plate with an accurately machined circular hole that is centered in a plate holding device in a straight section of smooth pipe. The selection of the measurement method or system to be used should be made only after careful analysis of several factors, which includes;

1. Accuracy desired

2. Expected useful life of the metering system

3. Flow rate

4. The required maintenance of the metering system

5. Compactness

6. Conformance with accepted standards and regulations

Initially, there was a strong emphasis on the areas of accuracy and conformance with standards and regulations. Currently, it has become necessary to weigh needs in different areas against each other. This is because there has been a number of changes in the area of field economy and field development. This research reviews the emerging developments in offshore field practice with technical illustrations and insights into natural gas metering system with particular reference to the orifice plate flow obstruction device.

Objectives of Surface Well Testing

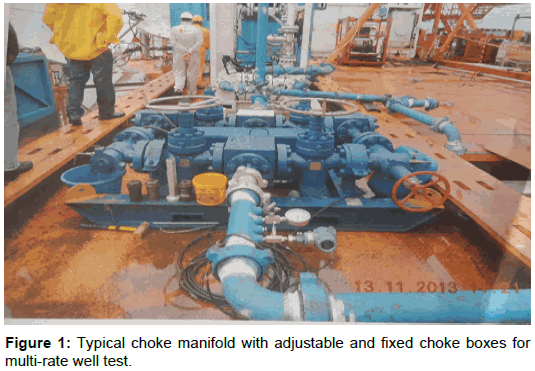

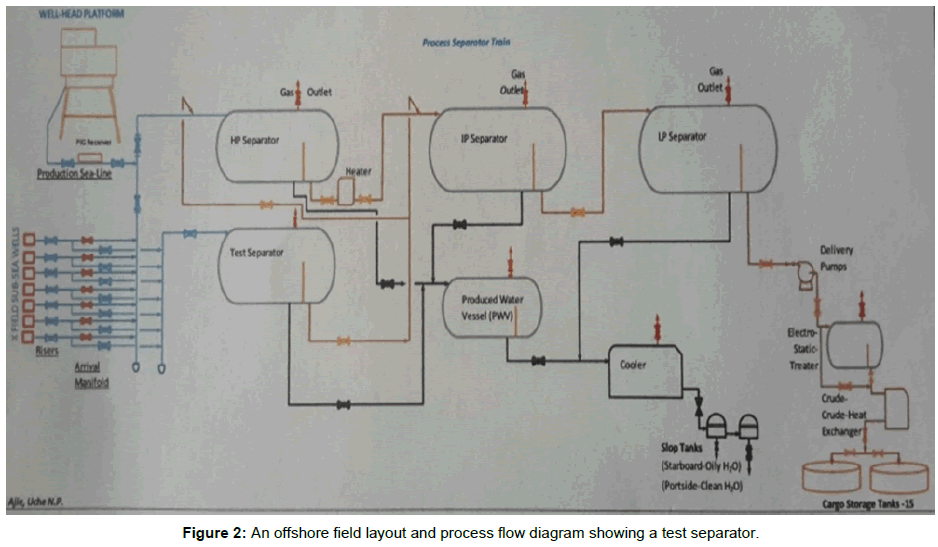

The frequency of planned production flow test increases as the oil and gas field mature. A properly conducted well test can be defined as a temporary completion of a well to acquire dynamic rate through time, pressure and fluid property data. The well test often indicates how the well will perform when it is subjected to various flow conditions. After well test, the performance of each producing well string under different back pressure conditions, Well Head Choke Size and metering can be comprehensively determined through computer well test report programs. From the results obtained and documented for immediate or future improved drilling, completion and production decisions can be made on the well and other wells in the field. When conducting routine internal flow test, the equipment will not alter from the standard field development top-side production facilities originally designed and laid out after an initial assessment of reservoir potentials, production philosophy and field development plan or conceptual studies transformed into reality (Figures 1 and 2).

Orifice Metering System

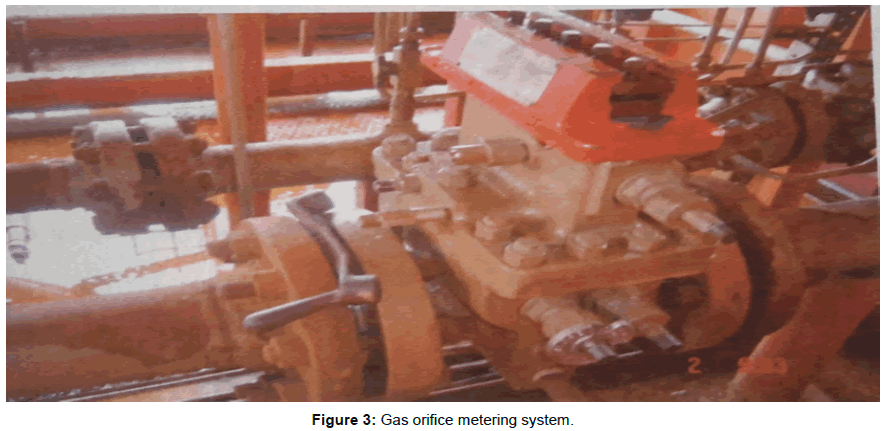

The orifice metering is an extremely well documented and regulated metering system in gas industry. There are two main standards for Orifice plate metering; American Gas Association (AGA) and International Organization for Standardization (ISO). The primary consideration in the design, fabrication and field installation of gas orifice metering system is accuracy (Figure 3).

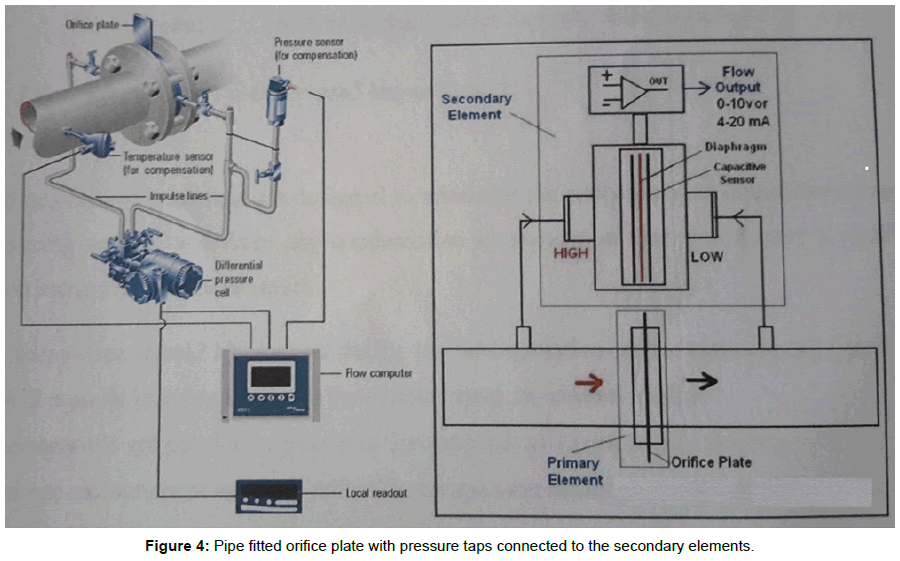

It is habitual to consider a complete orifice metering system as composed of two major elements.

1. The primary element: This section consists of the orifice plate, the plate holder with its associated differential pressure sensing taps and the meter tube. They are all designed to produce a difference in pressure as the flow increases. Provided that the standard mechanics of construction are followed no further calibration is required for the orifice plate.

2. The secondary element: This section is the differential pressure transmitter. It is designed to measure the differential pressure produced by the primary element as accurately as possible (Figure 4).

Natural Gas metering stations are designed to minimize the probability of liquid carry over into the metering section and from any condensation or separation that would have a significant effect on measurement uncertainties.

Operating principles of gas orifice metering system

The orifice flow meter consists of a thin, flat plate usually clamped between a pair of socket or weld-neck flanges known as orifice Flange Union or installed in a dedicated mechanical fitting. The plate has a precise sharp-edge orifice and bored concentric with the pipe axis. Applying the principle of Daniel Bernoulli conservation of energy, a constriction of orifice plate installed or inserted in a pipe will reduce the cross sectional area of the flow stream. The change across the orifice produces a differential pressure which is a function of the gas flow rate. It continues to drop until the “vena contracta” is reached and then gradually increases until at approximately 5 to 8 diameters downstream a maximum pressure point is reached that will be lower than the pressure upstream of the orifice. The pressure drop across the orifice increases when the rate of natural gas flow increases and is proportional to the square of the flow velocity. Thus, the flow rate of natural gas is proportional to the square root of the pressure difference across the line obstruction.

Orifice flow meters have been extensively used offshore and it is the most popular meter type for both liquid and gas [4]. Other meter types using newer technology, such as ultrasonic and coriolis meters are now widely specified in preference to orifice meter types [5].

Innovations in Natural Gas Metering System

Considering design limitation of orifice metering system of natural gas and in order to minimize uncertainties, errors and enhance reliability of fiscal flow measuring system and acceptability of measured volume; the search for alternative metering system remains a critical preference and decision.

Fluid meters are divided into two functional groups. The first measures quantity (positive displacement); while the second measures rate of flow (Inferential). All metering system consists of two different parts, each of which has different functions to achieve. The first is the primary element, which is in contact with the gas or fluid, resulting in some form of interaction. This interaction may be that of imparting motion to the primary element; the fluid may be accelerated etc. The second or secondary element translates the interaction between gas or fluid and primary element into a signal that can be converted into volume, weights or rates of flow and indicates or records the results. This same combination of primary and secondary elements will be observed in almost all other types of meters.

Presently, alternative metering systems flourish but they are not as industrially accepted as the orifice metering system.

Direct inferential metering system

This group of metering systems eliminates the requirement to quantify gas at flow conditions; that is, it eliminates the need to measure flow pressure, temperature and calculate a flowing compressibility.

The most common cause of damage in rotating or oscillating element of flow meters is high rates of change which causes over speeding. This over speeding often causes mechanical damage or loss of measurement in the use of rotary and oscillating metering systems. Most of these alternative and innovative metering systems are constructed with high blend metal alloys. These materials prevent the metal material from being eroded by moisture in the gas.

The justification for designing or proposing the use of these innovative metering systems over traditional gas metering systems are based on improved materials that reduced eroding rate, installation and calibration/maintenance cost. Most of the innovative metering systems have a significant advantage because of their;

1. Large turndown

2. Negligible pressure loss and

3. No requirement for upstream and downstream straight pipe length.

Conclusion

Flow measurement is a complex and application related discipline. It borders on being an art rather than a science, and as such it has developed its own mystique, traditions and customs. While it is true that no meter is universally applicable to all situations, the orifice has been more widely used in industrial settings than any other now meter. Differential pressure metering systems are ideally appropriate for the harsh environment of wet gas. The most vital reason will be due to no moving parts and they are less likely to experience mechanical failures or challenges. Many innovative technologies depend on sensors in the flow stream. These sensors can be destroyed or filled with liquids which can cause loss of signal.

The orifice metering system has served industry well over the years, and it will continue to do so in applications that do not require wide range of now, and can afford shutdown or by-pass lines. In other applications, predominantly metering for energy accountability, innovative metering system with actual or observed volume flow meters should be applied.

References

- Leigh M (1998) Fiscal flow measurement in the millennium: An operator’s view. 15th North Sea Flow Measurement Workshop.

- Ikoku CU (1992) Natural Gas Production Engineering. Pennsylvania State University, Florida.

- Danielsen H, Jacobsen E (1998) Present and future oil company needs in the area of flow measurement.

- Hossain MS, Faroque G, Rahman M (2011) Comparative study on orifice versus turbine meters for gas flow measurement. Proceedings of the International Conference on Mechanical Engineering, Dhaka, Bangladesh.

- DTI (2007) Uncertainty Assessment of Quality Measurements in Relation to EU ETS Requirements- Guidance for Offshore Oil and Gas Production Facilities- Proposals for Flow Meter Uncertainty Values. EU ETS Support Technical Note.

Citation: Emeka EO, Kevin I, Angela M, Charles O, Evelyn EB (2017) Offshore Gas Well Flow and Orifice Metering System: An Overview. Innov Ener Res 6: 163. DOI: 10.4172/2576-1463.1000163

Copyright: © 2017 Emeka EO, et al. This is an open-access article distributed under the terms of the Creative Commons Attribution License, which permits unrestricted use, distribution, and reproduction in any medium, provided the original author and source are credited.

Share This Article

Recommended Journals

Open Access Journals

Article Tools

Article Usage

- Total views: 5160

- [From(publication date): 0-2017 - Nov 24, 2024]

- Breakdown by view type

- HTML page views: 4448

- PDF downloads: 712