Review Article Open Access

Occupational and Environmental Health Hazards in the Brick Manufacturing Industry in Kathmandu Valley, Nepal

Steven M Thygerson1*, Seshananda Sanjel2 and Sally Johnson3

1Department of Health Science, Brigham Young University, Provo, Utah, USA

2Department of Medicine, Kathmandu University School of Medical Sciences, Dhulikhel, Nepal

3Department of Health Science, Brigham Young University, Provo, Utah, USA

- Corresponding Author:

- Thygerson SM

Department of Health Science

Brigham Young University, Provo, Utah, USA

Tel: 801-422-1891

E-mail: steven.thygerson@byu.edu

Received Date: September 23, 2016; Accepted Date: October 06, 2016; Published Date: October 13, 2016

Citation: Thygerson SM, Sanjel S, Johnson S (2016) Occupational and Environmental Health Hazards in the Brick Manufacturing Industry in Kathmandu Valley, Nepal. Occup Med Health Aff 4:248. doi:10.4172/2329-6879.1000248

Copyright: © 2016 Thygerson SM, et al. This is an open-access article distributed under the terms of the Creative Commons Attribution License, which permits unrestricted use, distribution, and reproduction in any medium, provided the original author and source are credited.

Visit for more related articles at Occupational Medicine & Health Affairs

Abstract

The ever expanding traditional brick industry in Nepal is a labour intensive, low technology activity found in the Kathmandu Valley and Terai regions of Nepal. Various studies have characterized the environmental pollutants associated with brick making, few studies have focused on the effects of these pollutants on the workers themselves. This review attempts to summarize recent evidences characterizing the occupational hazards associated with the brick industry and provide evidences for control of these hazards.

Keywords

Brick kiln; Occupational exposure; Hazards; Injury; Musculoskeletal disorders

Introduction

Brick manufacturing has become one of the fastest growing industrial sectors in Nepal with increasing numbers of brick kilns spreading across the three districts of Kathmandu Valley: Kathmandu, Bhaktapur, and Lalitpur. Since the year 2000, the amount of brick kilns in the Valley has increased by 200%. There are now roughly 500 brick kilns in operation during the dry season from December to May [1]. A rise in the numbers and capacity of brick kilns has caused an influx of migrant workers filling the job openings. The migrant workforce also includes women and children as young as eight years old assisting in clay production, green brick formation and transportation. There are four main operations of brick manufacturing in Nepal: mixing, molding into shape, sun-drying, and baking [2].

While the rise in the brick industry has brought more work opportunities to Kathmandu Valley, it has also become one of the top contributors to air pollution and related health problems among workers and others in the community. This industry spike, coupled with the topography of the valley that restricts air movement, makes it a place vulnerable to air pollutant accumulation [3]. Along with vehicle emissions and re-suspended road dust, brick industry dust particles reduce air quality substantially and can cause chronic obstructive pulmonary disease (COPD), asthma, bronchitis, silicosis, and other pulmonary complications [2,4]. One of the greatest threats of brick dust inhalation is crystalline silica exposure. Silica is commonly found in quartz rock and minerals; when cut, crushed and ground, particles small enough to respire are released into the air. As a known carcinogen, prolonged inhalation of above-threshold values of crystalline silica can destroy the breathing capacity of the lungs [4]. Workers and community members in Kathmandu Valley are consistently exposed without protection to silica- containing brick dust and other air pollutants capable of causing illness.

Many industrial hazards are associated with brick manufacturing beyond that of brick dust exposure. The main risks posed to workers in Kathmandu Valley involve chemical, physical, and physiological hazards. While brick dust and silica exposure fit under the “chemical” classification, other toxic chemicals are present in the brick kilns including carbon monoxide (CO), sulfur dioxide (SO2), fluoride compounds, and nitrogen oxides (NOx). The main physical hazard associated with brick formation, based on working conditions and hours on the job, is heat stress. Physiological hazards are present in workers as young as eight years old and include concerns in ergonomics. Heavy work load transportation, postural issues and repetitive movements are prevalent among workers and lead to acute and chronic musculoskeletal disorders [5]. In an effort to anticipate, recognize, evaluate and control the environmental and occupational hazards, this paper will detail the importance of occupational health and safety (OSH) practices among brick manufacturers in Kathmandu Valley.

Brick manufacturing, a traditional craft in Nepal for centuries, largely influenced the rise in industry. Under the 2693 category entitled, “Manufacture of non-refractory clay and ceramic products,” includes brick manufacturing companies that totaled 429 units employing 42,003 persons in the 2006/2007 census. Today, there are over 500 brick kilns in operation, with more unregistered kilns in use under the radar [6] (Figure 1).

Both transitional and stationary kilns are in use. Transitional kilns are generated as local farmers in Kathmandu Valley lease their lands during the dry season to brick manufacturers and soil excavators for profit [3].

Brick Kiln Technology

As Nepal’s industrial sector continues to progress, technological advancements within the industry similarly progress. Brought over from India where it was later banned, the Bull Trench Kiln (BTK) was the original brick technology used in Nepal [8].

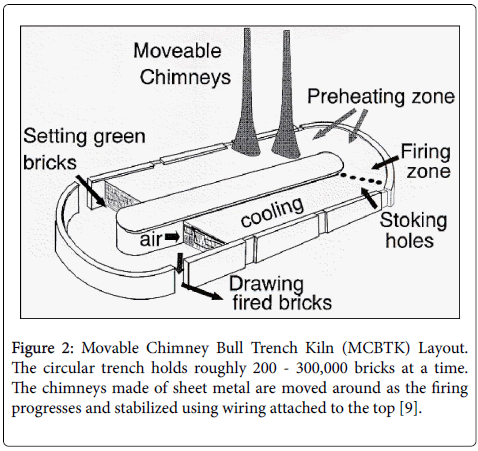

BTKs are now outdated and inefficient, causing ambient air pollution to increase in the surrounding areas where they are stationed. Currently, there are two main types of BTKs used in Nepal: Moving Chimney Bull Trench Kilns (MBTK) outlined in Figure 2, and Fixed Chimney Bull Trench Kilns (FCBTK).

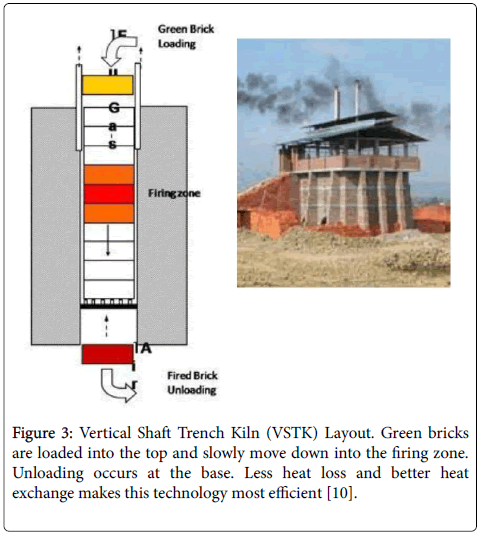

Other kilns in operation, but in far fewer numbers, include Vertical Shaft Trench Kilns (VSTK) and Hoffman brick technology [8]. VSTKs, as shown in Figure 3, and Hoffman brick kilns are known for using cleaner technology and producing better quality bricks, features that make these kilns favored among those pushing for cleaner air in Kathmandu Valley [3].

Rapid industry and technological development spurs novel risks and hazards for employees and others in the community. The Society for Environment and Economic Development in Nepal reports on their hazard analysis among brick manufacturers in regards to industry hazards: “It has been observed that due to the lack of legal provisions and enforcements in the country and the adequate awareness, the employees are working in this hazardous situation without using minimum protection in most of the industrial establishments” [5]. Implicating new methods of industrial waste management from solid, liquid and gaseous derivatives produced in the brick kilns of Nepal is necessary to combat the rapidly increasing manufacturers and capacity within the kilns. While the Occupational Safety and Health Administration (OSHA) regulates worker’s health and safety conditions in the United States, Nepal’s government has yet to establish such measures on workplace hazards. No specific standards have been imposed, leaving a legislative approach to mitigating the hazards, while vitally important, less significant [5].

Brick Kiln Hazards

To better understand how to approach mitigation and control of hazards in the workplace, general identification and assessment of potential risks is necessary. The hazards specific to the brick manufacturing industry can be organized into three categories: workplace hazards, community hazards, and environmental hazards.

Workplace Hazards

Poor OSH conditions result in a variable amount of workplace hazards. Many of the processes involved in brick production present hazards that are known to detrimentally affect worker’s health. These hazards directly influencing the health and safety of the workers are further classified into chemical hazards, physical hazards, and physiological hazards.

Chemical hazards

Dust inhalation is the main chemical concern among those working in the brick kilns of Kathmandu Valley. Brick dust particles contain known irritants and carcinogens that deteriorate the breathing capacity of the lungs. One of the carcinogenic chemicals contained in brick dust is crystalline silica. Silica is a baseline component of granite rock, sand, soil, and several other minerals. It is most commonly found in quartz rock and minerals, and also found in tridymite and cristobalite rock [4].

Silica becomes hazardous when rock minerals are chipped, cut, blasted, drilled, or ground in any way to produce respirable fractionsized particles. These particles are small enough to enter the bronchiole and alveolar regions of the lungs and disrupt the tissue causing irreversible scarring. According to ACGIH, the threshold limit value (TLV) of respirable dust is 3 mg/m3, 0.1 mg/m3 for quartz, 0.05 for tridymite and 0.05 mg/m3 for cristobalite (8-hr time-weighted average) [11]. Workers in Kathmandu Valley are consistently exposed to clay dust containing silica as high as 19.51 mg/m3 in the baking sections of brick production, and 10.08 mg/m3 in the mixing and molding sections [12].

Despite the silica exposure threat to the brick kiln workers, researchers assessing the occupational exposure in the brick kilns of Kathmandu Valley have yet to effectively sample for silica. Presently, researchers at Kathmandu University are involved in assessing crystalline silica exposure among brick kiln workers in Kathmandu Valley, a sampling feat that has never before been performed. These efforts in deriving conclusions on worker’s exposure to silica will help in understanding the level of risk posed to the workers and publicize the need for greater intervention. Regardless of the current lack of data quantifying the exposure levels of silica, we can safely assume that dust samples extracted from the kilns contain silica at hazardous levels [5].

Other chemical exposures among workers include high levels of coal dust and kiln smoke containing sulfur oxides, nitrous oxides, fluorine compounds, hydrocarbons and carbon monoxide. The type of chemical exposure depends primarily on the type of fuel used to fire the kilns.

The main fuel used in Nepal’s brick kilns includes coal and firewood; however, motor oils, plastic, saw dust and other wood products are used [1,8]. These combined fuels produce the toxic gases and vapors that pollute the air in the kilns and the surrounding environment. Assam coal, containing large amounts sulfur, is also used and once fired, releases sulfur dioxide into the air that is not only harmful to human health, but can damage the metallic layer on the inside of kiln chimneys [8].

Carbon monoxide, the main byproduct of incomplete combustion of coal, is prevalent throughout the kilns, but accumulates primarily in the firing/loading sections included in the baking operation [1,5]. Studies on occupational exposures among female brick kiln workers in India indicated that carbon monoxide was the primary culprit for the increased accounts of headaches, body aches, vision impairments, breathlessness and coughs that were observed [13].

In Kathmandu Valley, coal handlers and crushers within the kilns are among the most exposed workers, repeatedly inhaling heavy coal dust on top of the other chemical aerosols in the workplace. In some cases, where rubber tires are used as fuel, carcinogenic dioxins can be released into the atmosphere and inhaled [5].

Adding to the pollution problem was the destruction and reconstruction of the brick kiln chimneys following the 2015 earthquake. Most of the chimneys in the Kathmandu Valley were either destroyed or deems unsafe and subsequently demolished. The majority of these chimneys were 50 to 80 meters high in order to disperse the flue gases into the upper airstream of the valley.

However, following the earthquake, chimneys were built to the lowest allowable height of 30 meters. This has potentially resulted in higher concentrations of hazardous air remaining in around the brick kilns and in the community. Post-earthquake environmental monitoring should be completed to compare to pre-earthquake concentrations.

Physical hazards

Physical hazards in the workplace are those that can harm the body without directly touching it including ionizing and non-ionizing radiation, sunlight, ultraviolet (UV) rays, temperature and loud noises. Although temperatures in the valley are fairly moderate, the main physical hazards of concern among brick manufacturers are heat and exposure to UV rays.

Noise is also a hazard present in the kilns; however, according to studies published by the International Labour Organization (ILO) in the Bhaktapur district, the average noise levels in the brick kilns were all under the TLV for noise exposure (85 dBA, 8-hr TWA), with the highest average noise level in the kilns being 68.5 dBA for an 8-hr TWA [14]. Although exposure to noise is present in the kilns, overexposure is unlikely with the current kiln technologies in use.

Excessive heat exposure is the most common physical hazard present in the kilns and can lead to heat exhaustion or heat stroke. Heat exposure in the kilns comes from two sources: process heat from kiln operations and excessive, unprotected sun exposure. Research at Kathmandu University investigated occupational concerns among brick workers in Kathmandu Valley and reported that “much of the activities are carried out under conditions where there is exposure to excessive sun and inadequate water” [2].

Without adequate water stations or job rotations, the effects of excessive heat can compound; indirect effects of heat exhaustion such as unfocused, delirious behavior increase the risk of secondary injuries and illnesses within the workplace and pose an additional hazard to the workers [5].

Physiological hazards

Disorganized layout of the workplace leading to poor use of ladders, hazardous pathways, and inadequate or damaged equipment are a few of the physiological hazards currently present in the kilns [5].

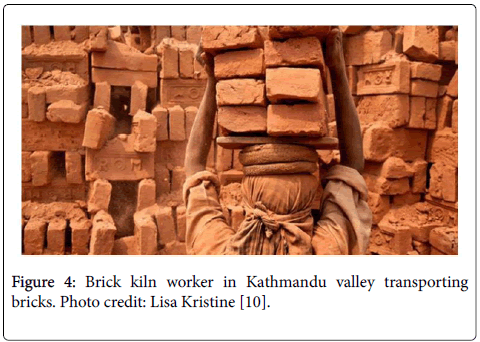

Another area of concern involves ergonomic hazards. Women and children in the kilns, who are worked in excess of 10 hours per day, transporting 50lbs or more of bricks repetitively, are especially at risk of developing these chronic physiological disorders. Many female workers are required to transport the green brick as well as the fired brick by hand [2].

In the Bhaktapur district, bricks are carried using a back-board supported by a head strap to lessen the impact and distribute force throughout the back (Figure 4). Other kilns in Kathmandu Valley have workers that carry as many as 18 bricks stacked methodically on top of a board resting on the head, with each brick weighing roughly 1.5-2.0 kilograms. Children are also hired on as brick transporters and have been witnessed carry loads heavier than their own weight [14].

With a majority of the brick manufacturing workforce lacking education, implementation of hazard prevention within the kilns is also lacking. Studies have shown that injuries among children in the kilns are more frequent because of their age and lack of knowledge in the production process [14]. Better training and education within the industry would aid employers and workers in identifying hazards and mitigation solutions within the workplace.

Environmental hazards

Kathmandu Valley carries a natural hazard to pollutant air accumulation. The topography of the Valley is bowl-shaped, restricting air flow in and out of the Valley and allowing for pollution accrual inside. This natural landscape places Kathmandu Valley at higher risk for environmental consequences and suggests that emission-prone industries should have limitations and stricter regulations. In 1996, the World Bank conducted a study assessing contributions of air pollution in Kathmandu [15]. They found the main contributing sources for total suspended particles (TSP) were cement factories (36%), brick kilns (31%), domestic fuel combustion (14%), suspended road particles (9%), and exhaust from vehicles (3.5%). However, the World Bank more accurately deduced the culprit for negative health effects in the Valley by sampling for particulate matter (PM) of less than 10 μm, or PM10. High PM10 concentrations are more concerning as it includes particles that are small enough to respire and enter the deep regions of the respiratory system. Brick kilns contained the highest PM10 concentrations: brick kilns (28%), domestic fuel combustions (25%), cement factories (17%), exhaust from vehicles (12%) and suspended road particles (9%). With brick kilns at the helm of inducing concerning health effects, it is also a major contributor in the production of nitrous oxides and sulfur oxides. These chemicals not only affect worker’s health, but in large enough quantities can contribute to the production of acid rain, black smoke and deterioration of the ozone, pushing away pollinating species that damage agricultural and farming production [1,16].

Brick kilns in Nepal also utilize fertile soil during production. Studies on the fertile lands leased to the brick industry indicate that essential nutrients in the soil such as nitrogen, phosphorus and potassium are running low as kilns continue to eat away at the fertile top soil [3]. This top soil takes roughly 25 to 30 years to regenerate, further declining local farm production and posing a threat to the agricultural advances in the Valley [1].

While many of the hazards among brick manufacturers in Kathmandu Valley have been identified, the level of risk associated with many of the hazards has not. Though we may understand the individual risks associated with chemical, physical, physiological, community and environmental hazards, the cumulative effects have yet to be thoroughly investigated and pose a complex hazard worthy of governmental and societal attention.

As brick production in Kathmandu Valley rises and the surrounding air quality continues to degrade, related health problems consequentially increase in workers and community members. Few studies have been performed detailing the respiratory health effects and other medical concerns specific to brick workers in Kathmandu Valley. However, a study on kilns using similar coal and firewood fuel in Pakistan gives insight into the health effects brick workers observe under similar conditions. Shaikh et al. [17] relayed that high counts of COPD hospitalizations and other respiratory symptoms among brick workers have been reported: 22.4% of workers experience a chronic cough; 21.2% have chronic phlegm; 13.8% have experienced attacks of shortness of breath with wheezing; 17.1% have chronic bronchitis; 8.2% have physician-diagnosed asthma; and among non-smokers, 8.9% have chronic bronchitis. The study also found that workers in the baking sections of brick production were also at higher risk for developing asthma and bronchitis than workers in other areas of brick production. These findings can be expected in the population of brick workers in Kathmandu Valley undergoing similar working conditions.

Excessive dust, gas and vapor exposure in the brick kilns can likewise lead to irreversible chronic diseases. Crystalline silica is a known lung carcinogen. Beyond its classification as a lung carcinogen, silica can cause scarring of the lung leading to silicosis. Silicosis occurs when scarring prevents oxygen take-up of the lung and can be severely debilitating as the body becomes vulnerable to secondary illnesses such as tuberculosis [4]. Although the main route of exposure for these toxicants is inhalation, the lungs are not the only target organ susceptible to disease. Carbon monoxide levels above permissible exposure limits inhaled over a long term period are linked with increased incidence of cardiovascular disease [8]. Even relatively low levels of dust particles that are inhaled affect lung function leading to respiratory and cardiovascular diseases [5].

Hazards present in the kilns migrate out into the ambient air to affect individuals living near the kilns. Among community members, the rise in particulate matter concentration from brick kiln emissions has been associated with increased accounts of asthma in the community. The World Bank estimated in 1996 that 18,863 accounts of asthma and roughly 4,847 accounts of bronchitis in Kathmandu Valley each year were due to the PM10 concentrations calculated [5]. Based on the sharp increase in the brick industry over the years, we can assume these estimated numbers have similarly increased, posing a larger threat of respiratory illness to the community.

Physiological hazards in the kilns are an additional risk faced among the workers. Poor posture, frequent heavy lifting involved in transportation of the bricks, and repetitive body movements in hand mixing and molding of clay without properly adjusted workstations are a few examples present in the kilns; these ergonomic hazards subsequently lead to acute and chronic work-related musculoskeletal disorders (WMSDs) that cause muscle, tendon and nerve damage leading to chronic illnesses such as tendonitis, carpal tunnel syndrome and tension neck syndrome [18]. Sixteen year old Tilak Pun, a worker in the Bhaktapur district, provided insight into kiln work in Kathmandu Valley and the consequences of improper ergonomic conditions:

Tilak Pun, 16 hailing from Rolpa ferries brick in the kiln of Bhaktapur. Tilak previously used to work as a helper in the transportation industry. With few peer pressure and the debt taken from the labor contractor Tilak comes to Bhaktapur to have a bitter experience of carrying heavy loads all day. He feels that his previous work was easier and provided much freedom than current work. Tilak feels that the world of kiln is like a bondage with very little to offer and much to exploit. He claims to be suffering from severe pain in his legs due to the heavy loads he carries every day. Tilak has taken a vow for not coming to the brick world ever again in his life [14].

The hazards within the brick kilns result in life-long health consequences. These notable health effects sustained by the workers and individuals in the community validate the need for mitigation and control.

Methods of Evaluation and Control

The increased rates of pulmonary symptoms among workers and community members warrant continued evaluation and control measures in the Kathmandu Valley brick kiln industry. The primary method of evaluating dust exposure in the workplace includes testing for levels of respirable dust, particulate matter, gases and vapors. Personal sampling pump monitors are worn by employees to assess measurable doses of dust, silica, sulfur dioxide, nitrogen dioxide, or other toxicants identified in the preliminary risk assessment and identification process. Real-time monitors are stationary area samples that are used to assess particulate matter sizes and concentrations. These are also used to better understand which locations in the workplace need extra precautions. The sampling values are then compared with their respective TLV and control measures deemed appropriate are implemented. Other evaluation assessments include general worksite evaluations, household environmental surveys, and general health and school health examinations among workers and others in the community. Many household and community surveys have been completed in Kathmandu Valley; the greater need is evident in areas of minimal data collection including personal breathing-zone samples of silica, gases and vapors, and surveys on the respiratory health status of workers [2].

Measures of Control

After assessment, mitigation and control methods deemed appropriate should be implemented. General OSH practice involves a hierarchy of hazard controls including: elimination or substitution of the hazard; engineering controls including plant design or equipment modification; administrative controls including training, timing on the job, or enforcement of policies and procedures; and implementation of personal protective equipment including wearing of respirators. The hierarchy of hazard controls emphasizes the importance of utilizing elimination or substitution methods where possible before seeking engineering or administrative control solutions. PPE is present at the bottom of the hierarchy because a user must actively engage in protection. PPE can also be uncomfortable to wear, reduce efficiency of the work process, or be worn improperly. However, workers who are educated on maintenance and proper usage of PPE can effectively control for the present hazards. Using these intervention strategies to reduce environmental and occupational health hazards, improve ergonomics and subsequent worker exposure will prove to benefit workers’ health and safety and improve economic growth of the community. In Kathmandu Valley, the greatest areas of concern and necessity of control include:

• poor quality fuel used in the kilns

• outdated brick kiln technology

• use of illegal kilns in the Valley

• long hours on the job leading to greater risk of high-level exposure to hazards

• infrequent job rotations and ergonomic concerns

• minimal personal protective equipment and education

Substitution of kiln technology and fuel/illegal kilns in the valley

According to studies performed by the World Bank, 8.06 kg of suspended particulate matter (SPM) per 1,000 bricks produced were emitted from MBTKs [1]. Only 1.71 kg and 0.55 kg of SPM per 1,000 bricks produced were emitted from FBTKs and VSTKs, respectively. Because MBTKs emit far more particulate matter and largely contribute to the environmental pollution in Nepal, the government banned them from use in 2001 [5]. This state-wide ban has been disregarded by some as unregistered kilns using old traditional technology continue to surface. Since 2001, many dignified and concerned members of the community have continually called for illegal kilns in the Valley to be closed [1,7]. Petitioners submitted a request in 2007 to the Supreme Court of Nepal to focus efforts in quantifying and assessing the laxity of illegal kiln operators:

Due to negligence of the [illegal kiln] respondents, the number of brick kilns in operation has more than doubled as compared to those with the legal entities.

Currently, the number of legally operating brick kilns is 6 in number in Kathmandu, 47 in Lalitpur and 45 in Bhaktapur, totaling 98. But the number of illegally operating brick kilns are twice the number of the legally operating kilns [19].

Although brick kilns are registered with the Nepali government and are meant to abide by the regulations set for labor laws and illegal kilns, they continually remain “outside the arms of the government [20]. However insignificant the legalities stand in Nepal, continuing to educate and promote awareness of the hazards is crucial in the process of mitigation. Society’s educated influence may subsequently improve legislative impact within the country.

Another legislative area of focus that would assist in controlling the hazards posed for the community involves increasing the distance between residences and kiln furnaces [13]. This would aid in confining the toxic levels of dust and vapors to remain within the vicinity of the kilns and prevent migration towards the nearby communities. Providing emission standards for the brick kiln manufacturers is an additional area of control and would promote a better balance of cleaner fuels, such as natural gas, along with solid coal and wood products to reduce combustion byproducts released [8]. Increased efforts focused on quantifying and reducing the number of illegal kiln operators in the Valley, promoting legislation in favor of increasing distance between kilns and community residences, and providing emission standards are vital pieces of the puzzle in approaching the environmental hazards produced by the kilns.

Administrative controls

Assignment of administrative controls in the workplace is largely influenced by the employer. As the employer comes to understand the health and safety needs within the workplace, implementation of methods derived on mitigation become a reality. Necessary administrative controls in the brick kilns include timing on the job to reduce cumulative exposure to toxicants, job rotations, adjusting workstations, providing PPE for the workers and installing proper hygiene and water facilities. Monga et al. [12] performed studies on brick workers in Nepal and noticed hesitation with safety equipment “…most of [the] industrial workers showed reluctance in use of safety equipment which indicates lack of safety awareness and appropriate managerial steps. This is either due to negligence of the company or due to them being uneducated”. Workers displaying reluctance with safety equipment emphasizes the need and importance of education involved in all safety controls implemented. Protecting the workers by providing the PPE as well as training on proper usage will also prove to be profitable to the industry as workers understand their health and safety matters to the employer.

Personal protective equipment (PPE)

Little or no PPE is used to mitigate for dust or toxic gases and vapors present in the kilns [5]. These toxicants can irritate the skin and mucous membranes, as well as the lungs. Providing proper PPE would not only help workers initial comfort but prevent the accumulation of toxicants in the body leading to chronic effects. Controlling for dust can include using a wet method technique of spraying down dusty areas, and respiratory protection through mandatory dust mask usage. Proper hand, face, and eye PPE in the baking sections could also be implemented to reduce burns and visual impairment from the heat of the fires and gases and vapors emitted.

Education on OSH practice

Educated employers have an obligation to discuss the risks involved in the workplace. If the employers misunderstand or are unaware of the risks present within their workplace, the likelihood that workers are trained and educated on the hazards before an incident or health outcome occurs is slim. While these occupational control measures would prove to benefit the industry and surrounding communities, not all brick manufacturers have the resources necessary to meet these needs. Although using the legislative approach to mitigate brick kiln hazards in Kathmandu Valley is currently falling behind, as public awareness increases of the health and environmental impacts, governmental assistance may not be far off. Regardless, education provided on the risks within the workplace can help existing employers look past the lack of resources and see a way forward. A greater focus must be placed on educating the brick manufacturing employers and their workers in occupational health and safety methods and the specific hazards present within the kilns.

Conclusion

Anticipation, recognition, evaluation and control of the industrial hazards presented in the brick kilns of Kathmandu Valley, Nepal can provide a healthy and safe workplace and community environment. Brick manufacturers continue to dominate the industrial sector of Nepal with over 500 kilns in use during the dry season from December to May [1]. This rise in the brick industry has flooded the Valley with work opportunities in the kilns; however, this increase has also contributed to notable amounts of particulate matter pollution in the air. Health effects associated with the rise in particulate matter concentrations have similarly increased among workers in the kilns and individuals in the community.

Brick dust exposure is the greatest threat posed to workers in the kilns. Exposures above threshold limit values are extensive throughout the kilns and include exposure to crystalline silica, a known human lung carcinogen. Other hazards present in the kilns include chemical, physical and physiological hazards. These hazards have correlative health effects that lead to acute and chronic debilitating diseases including musculoskeletal disorders, silicosis, respiratory and cardiovascular diseases. Measures of evaluation are important in deriving conclusions on measures of control. There is a resounding need for improved evaluation of the hazards within the kilns in the Valley and the risks posed to the workers and the community. Control areas of focus in the brick kilns include: poor quality fuel used in the kilns; outdated kiln technology leading to toxic emission levels; illegal kilns in the Valley; long hours on the job leading to greater risk of overexposure to toxicants in the workplace; and minimal personal protective equipment (PPE). No governmental standards on emission have been promulgated yet [5]. A reactive legislation approach to control is falling behind, with occupational safety and health standards unenforced throughout the Valley; nevertheless, priorities geared towards the health of the community and the workers in the brick kilns are increasingly pertinent with the rise in industry.

Voluntary organizational efforts to promote and educate the workers in the kilns, their employers, and the general public on the necessity of occupational health practice should be considered. These measures to investigate further into the industrial hazards of the brick kilns in Kathmandu Valley, Nepal and mitigation strategies will help promulgate the need for greater intervention. All workers deserve a workplace environment free from extreme health hazards and unsafe conditions.

References

- Pariyar S, Tapash D, Tanima F (2013). Environment and health impact for brick kilns in Kathmandu valley. IJSTR 2: 184-187.

- Sanjel S (2014) Investigating links between environmental pollutions and occupational and environmental health hazards among brick kiln workers in Kathmandu valley.

- Raut A (2006) Brick kilns in Kathmandu valley: Current status, environmental impacts and future options. Himalayan Journal of Sciences 1: 59-61.

- US Department of Labor (USDOL) (2002)Crystalline silicaexposure: Health hazard information. OSHA Fact Sheet.

- SEED Nepal(2013) Report on identification and analysis of hazardous and risky works in brick manufacturing industries of Nepal. Occupational Safety and Health Project: Anamnagar, Kathmandu, Nepal.

- http://cbs.gov.np/sectoral_statistics/manufacturing

- Thapa S (2011) Brick Kilns: A threat to urban agriculture in Kathmandu, Nepal.

- Joshi SK, Dudani I (2008) Environmental health effects of brick kilns in Kathmandu valley. Kathmandu University Medical Journal 6: 3-11.

- http://www.fastonline.org/CD3WD_40/GATE_DL/BUILDING/BK/EN/BK.HTM

- Maity S (2003) Overview of brick industry in Kathmandu valley, Nepal.

- ACGIH (2015) TLVs and BEIs: Threshold limit values for chemical substances and physical agents biological exposure indices. American Conference of Governmental Industrial Hygienists. Cincinnati, OH.

- Monga V, Pal Singh L, Bhardwaj A, Singh H (2012) Respiratory health in brick kiln workers. International Journal of Physical and Social Sciences 2: 226-244.

- Vidya GV, Mamulwar M, Ray SB, Ubale LS (2015) Occupational health hazards of women working in brick kiln and construction industry. JKIMSU 4: 45-54.

- http://www.ilo.org/ipec/Informationresources/WCMS_IPEC_PUB_25297/lang--en/index.htm

- URBAIR (1997) Urban air quality management strategy in Asia: Kathmandu valley report. The World Bank, New York.

- Bhat M, Afeefa Q, Ashok K, Bashir A (2014) Brick kiln emissions and its environmental impact: A Review. J Ecol Nat Environ 6: 1-11.

- Shaikh S, Nafees A, Khetpal V, Jamali A, Arain A, et al. (2012) Respiratory symptoms and illnesses among brick kiln workers: A cross sectional study from rural districts of Pakistan. BMC Public Health 12: 999.

- American Industrial Hygiene Association (AIHA) (2015) Protecting worker health: Discovering industrial hygiene.

- Nepal Supreme Court Decision (2007) Re. Brick Kilns. Supreme Court, Division Bench: Hon'ble Justice Kedar Prasad Giri, Hon'ble Justice Balaram K.C. Order: Writ No.3027 of theyear 2059.

- General Federation of Nepalese Trade Unions (GEFONT) (2007) Nepal: Labour under the chimney.

Relevant Topics

- Child Health Education

- Construction Safety

- Dental Health Education

- Holistic Health Education

- Industrial Hygiene

- Nursing Health Education

- Occupational and Environmental Medicine

- Occupational Dermatitis

- Occupational Disorders

- Occupational Exposures

- Occupational Medicine

- Occupational Physical Therapy

- Occupational Rehabilitation

- Occupational Standards

- Occupational Therapist Practice

- Occupational Therapy

- Occupational Therapy Devices & Market Analysis

- Occupational Toxicology

- Oral Health Education

- Paediatric Occupational Therapy

- Perinatal Mental Health

- Pleural Mesothelioma

- Recreation Therapy

- Sensory Integration Therapy

- Workplace Safety & Stress

- Workplace Safety Culture

Recommended Journals

Article Tools

Article Usage

- Total views: 30844

- [From(publication date):

October-2016 - Apr 21, 2025] - Breakdown by view type

- HTML page views : 29085

- PDF downloads : 1759