Research Article Open Access

Nutraceuticals from Olives Plain Water Extraction, Identification and Assay by LC-ESI-MS/MS

Cinzia Benincasa1*, Enzo Perri1, Elvira Romano1, Ilaria Santoro2 and Giovanni Sindona2

1Consiglio per la ricerca in agricoltura e l'analisi dell'economia agraria, Centro di ricerca per l'olivicoltura e l'analisi dell'economia agraria, Italy

2Department of Chemistry and Chemical Technology, University of Calabria, Italy

- *Corresponding Author:

- Cinzia Benincasa

Consiglio per la ricerca in agricoltura e l'analisi dell'economia agraria,

Centro di ricerca per l'olivicoltura e l'analisi dell'economia agraria, Italy

Tel: +39-0984-49284

E-mail: cinzia.benincasa@entecra.it

Received date: August 12, 2015; Accepted date: September 03, 2015; Published date: September 11, 2015

Citation: Benincasa C, Perri E, Romano E, Santoro I, Sindona G (2015) Nutraceuticals from Olives Plain Water Extraction, Identification and Assay by LCESI-MS/MS. J Anal Bioanal Tech 6:274. doi:10.4172/2155-9872.1000274

Copyright: © 2015 Benincasa C, et al. This is an open-access article distributed under the terms of the Creative Commons Attribution License, which permits unrestricted use, distribution, and reproduction in any medium, provided the original author and source are credited.

Visit for more related articles at Journal of Analytical & Bioanalytical Techniques

Abstract

Ancient olive trees are widespread in many countries of the Mediterranean area, including the Calabria region located in southern Italy. They have adapted to environments, climates and soil conditions and represent an ecosystem heritage. The use of their drupes for manufacturing both table olive and oil is not often economically and/or commercially attractive. The future to preserve the environment and to develop new jobs in this area is the evaluation of alternative strategies to foster the establishment of small medium enterprises (SMEs) involved in the production of high value added products which might be obtained from these now endemic trees, in an environmental safe way. High-value active principles can be recovered from wastes of agri-food farms. Olive manufacturers are spread throughout the Mediterranean area, where incomes from this particular food industry represent an important fraction of the gross domestic product (GDP). A typical business of existing SMEs is represented by the commercialization of table olives; the necessary debittering process, traditionally performed by plain water is usually carried in alkaline conditions. The bitterness of freshly harvested olives is due to the presence of antioxidants and anti inflammatory active principles, which belong to the family of the most popular nutraceuticals. The development of a production line whereby olive wastewaters could be used to produce end products suitable for food, pharmaceutical and cosmetic industries might induce the establishment of new SMEs. Accordingly, waste products of plain water processing of table olives were monitored by Liquid Chromatography (LC)-Electro Spray Ionization (ESI)-tandem mass spectrometry (MS/MS) over a 10-day period to assess the content of the expected phenolic compounds responsible for bitterness and generally recognized for their healthy properties.

Keywords

Table olives; Wastewater recycling; Nutraceuticals; Tandem mass spectrometry

Introduction

Old and environmentally friendly procedures might be reconsidered in olive debittering [1,2] as a green strategy in the production of goods in the interest of nutritional, pharmaceutical and cosmetic industries from wastes. The recovering of bergamot albedo from wastes of cosmetic industries has been recently proposed as a source of statinlike active principles [3]. Table olives are the most popular fermented agri-food in Mediterranean countries. Their composition depends on several factors such as genetics, ripening, processing technologies and storage. Standard processing technologies affect the physicochemical features of olive fruits such as color, texture, volatile compounds and phenol contents and, consequently, the organoleptic and nutritional properties of the final product. Any processing method aims, in general, at removing the natural bitterness of the fruit, caused by phenols, especially by the glucosyde known as oleuropein [4]. Oleuropein and its metabolites have powerful antioxidant activity both in vivo and in vitro making virgin olive oil a functional food. This secoiridoid is able to confer resistance to diseases and insect infestation [5], and offers antioxidant protection due to the catechol moiety [6]. It is also accumulated as a defense mechanism against phytophatogens [7,8]. In particular, when olive tissues are injured by diseases or by mechanical damage, a specific enzyme producing highly reactive molecules [7] hydrolyzes oleuropein. The antioxidant and antimicrobial activities of oleuropein derivative molecules against herbivores and insect attacks have been also demonstrated either in plants as well as in vitro against bacterial strains [9].

β-glucosidase (E.C. 3.21.1.21) [9,10] is involved during fruit ripening in the progressive degradation of oleuropein with concomitant releasing of glucose and the aglycones with a concomitant reduction in bitterness of the fruit [11,12]. The detected changes in β-glucosidase activity, thus in the products of enzymatic hydrolysis at different stages of fruit ripening [10] are strictly associated with product quality; in fact, good-tasting table olives and olive oil are greatly influenced by phenolic compound content [13-16]. Thus, debittering of green olives is a major challenge in the industrial processing of fruit. The most commonly employed methods involve dilute NaOH and/or NaCl at low concentrations. The alkaline treatment modifies the ester moieties of phenolic compounds present such as oleuropein and its derivatives. The waste produced cannot be safely and easily eliminated [17,18] while the quality of the recovered food is deeply affected. The recovering of antioxidants from olive wastes is an important issue in the Mediterranean area [19].

The alternative approaches providing both debittering and fermentation [16] through the action of bacterial β-glucosidase, interferes, unfortunately, with the antioxidant properties of the products.

A great number of studies describe the phenolic composition of olives [20-24]; their recovering by low cost innovative technologies in concentrated solutions might be of commercial interest in view of the accepted use of these natural compounds as nutraceuticals [25-30]. Nutraceuticals possess the special role of preventing or even supporting medical therapies [31].

This work aims at identifying and assessing active compounds, such as oleuropein, hydroxytyrosol, tyrosol, verbascoside, luteolin and rutin, accumulating in wastes during the simplest debittering processing of olives with plain water. Solutions containing whole, pitted and crushed olives were prepared and target phenols assayed using tandem mass spectrometry. Tandem Mass spectrometry has been extensively used in the field of structure evaluation of natural products [32].

Experimental

Chemicals

Pure samples of rutin, luteolin and verbascoside were purchased from Extrasynthese (Nord B.P 62 69726 Genay Cedex France) and tyrosol, 3-hydroxytyrosol and oleuropein from Sigma–Aldrich (Riedelde Haën, Laborchemikalien, Seelze). Methanol, ethanol, formic acid were LC/MS grade and purchased from VWR International; aqueous solutions were prepared using ultrapure water, with a resistivity of 18.2 MΩ cm, obtained from a Milli-Q plus system (Millipore, Bedford, MA, USA).

Olives sampling and maceration process

Hand-picked olives of Coratina cultivar, allegedly very rich in antioxidant compounds [33], were collected during the crop year 2013 from an olive grove located in the Basilicata region (Italy) and stored immediately at -25°C. Three different forms of olives, whole, pitted and crushed, were considered for the debittering process. Ultrapure water and ultrapure water-ethanol 80/20 (v/v) were used in two distinct protocols. In a typical experiment, 12 g of olives were placed in stoppered flask containing 100 ml of debittering solution; the maceration process was carried out in the dark at 4°C, except for the first day when the olives were subjected to two thermal shocks caused at first by passing from -25°C to room temperature in the aqueous solutions and then being frozen again. This was to promote the disintegration of the cell membranes and the release of any active compounds. After which, every day for 10 days, aliquots of supernatant were collected and the solution pH was checked. The samples thus prepared were submitted to LC-MS/MS analysis.

Preparation of standard solutions

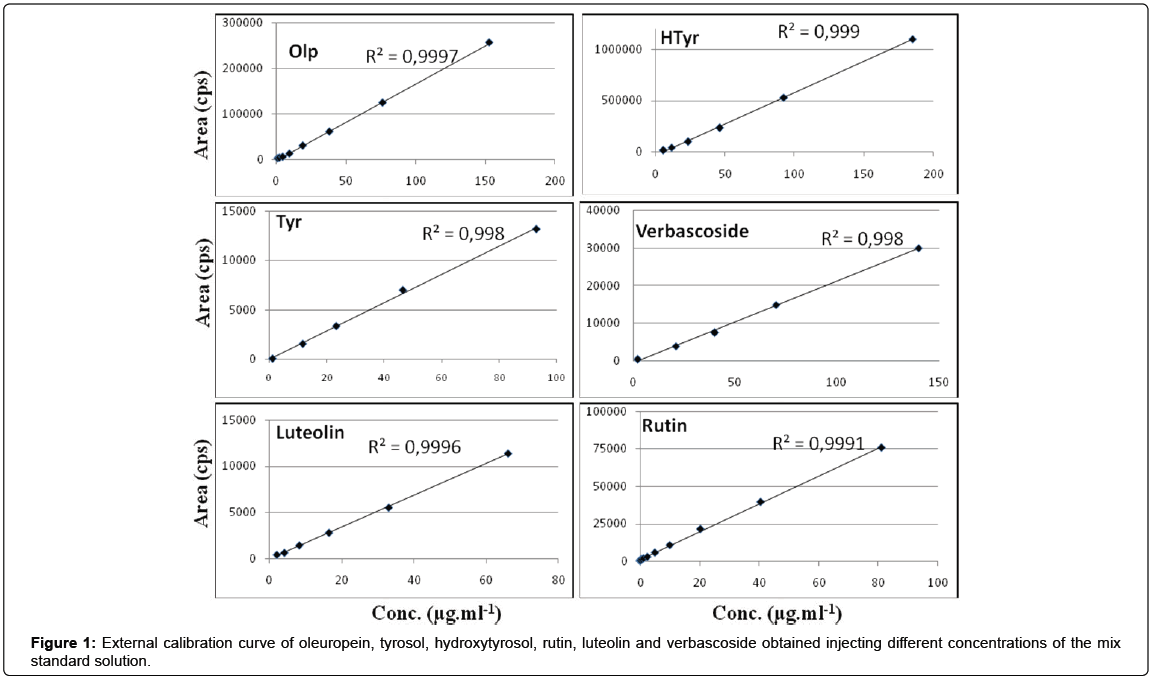

Standard stock solutions were prepared by dissolving reference compounds in ethanol. Aliquots of these solutions were further diluted with water/0.1% formic acid to obtain calibration standards at concentrations between 1-200 μg/ml for oleuropein and hydroxytyrosol, 1-100 μg/ml for tyrosol, luteolin and rutin, and 1-150 μg/ml for verbascoside.

High performance liquid chromatography (HPLC)

HPLC was performed using an Agilent Technologies 1200 series liquid chromatography system equipped with G1379B degasser, G1312A pump, and G1329A autosampler. The analytes were separated on an Eclipse XDB-C8-A HPLC column [5 μm particle size, 150 mm length and 4.6 mm i.d. (Agilent Technologies, Santa Clara, California)] at a flow rate of 350 μl/min and an injection volume of 10 μl. A binary mobile phase made up of 0.1% aqueous formic acid (A) and methanol (B) was programmed to increase B from 10% to 100% B in 10 minutes, hold for two minutes and ramp down to original composition (90% A and 10% B) in eight minutes. The total elution time was 20 min per injection.

Mass spectrometry

The ESI-MS/MS analyses were performed using a MSD Sciex Applied Biosystem API 4000 Q-Trap mass spectrometer in negative ion mode using multiple reactions monitoring (MRM). The experimental conditions were set-up as follow: ionspray voltage (IS) -4500 V; curtain gas 20 psi; temperature 400°C; ion source gas (1) 35 psi; ion source gas (2) 45 psi; collision gas thickness (CAD) medium. Entrance potential (EP), declustering potential (DP), collision energy (CE) and collision exit potential (CXP) were optimized for each transition monitored.

Results and Discussion

Method validation

Calibration curves reported in Figure 1 were constructed using a least-squares linear regression analysis. For each analyte the calibration curves were linear in the concentration range 0-150 μg/mL with correlation coefficients ranging between 0.9990 and 0.9997. Recovery tests were carried out injecting three times two standard solutions at different concentration of the six active molecules. Results from recovery experiments at levels of 25 and 50 μg/ml gave mean recoveries ranging from 91–116% with satisfactory precision (relative standard deviation (RSD) from 0.1-0.5%). Limits of quantitation (LOQs) from 1.258-2.847 μg/ml (Table 1).

| Spiked solutions | |||||

|---|---|---|---|---|---|

| (a) | (b) | ||||

| Active compound | LOD | Found | Recovery | Found | Recovery |

| (µg/ml) | mean ±RSDa | (%) | mean ±RSDa | (%) | |

| Oleuropein | 1.258 | 58.0 ± 0.1 | 116 | 25.3 ± 0.2 | 101 |

| Hydroxytyrosol | 1.479 | 52.5 ± 0.1 | 105 | 24.5 ± 0.3 | 98 |

| Tyrosol | 2.418 | 49.5 ± 0.2 | 99 | 26.0 ± 0.3 | 104 |

| Verbascoside | 1.215 | 45.5 ± 0.5 | 91 | 27.3 ± 0.1 | 109 |

| Luteolin | 1.658 | 50.5 ± 0.3 | 101 | 24.8 ± 0.2 | 99 |

| Rutin | 2.847 | 51.5 ± 0.1 | 103 | 22.5 ± 0.1 | 90 |

Table 1: LOD, recoveries and precision (RSD) of the active compounds analysed by LC-ESI-MS/MS. a Each value is the mean of three determinations; RSD=relative standard deviation; Spiked solutions (a) 50 μg/ml; and (b) 25 μg/ml.

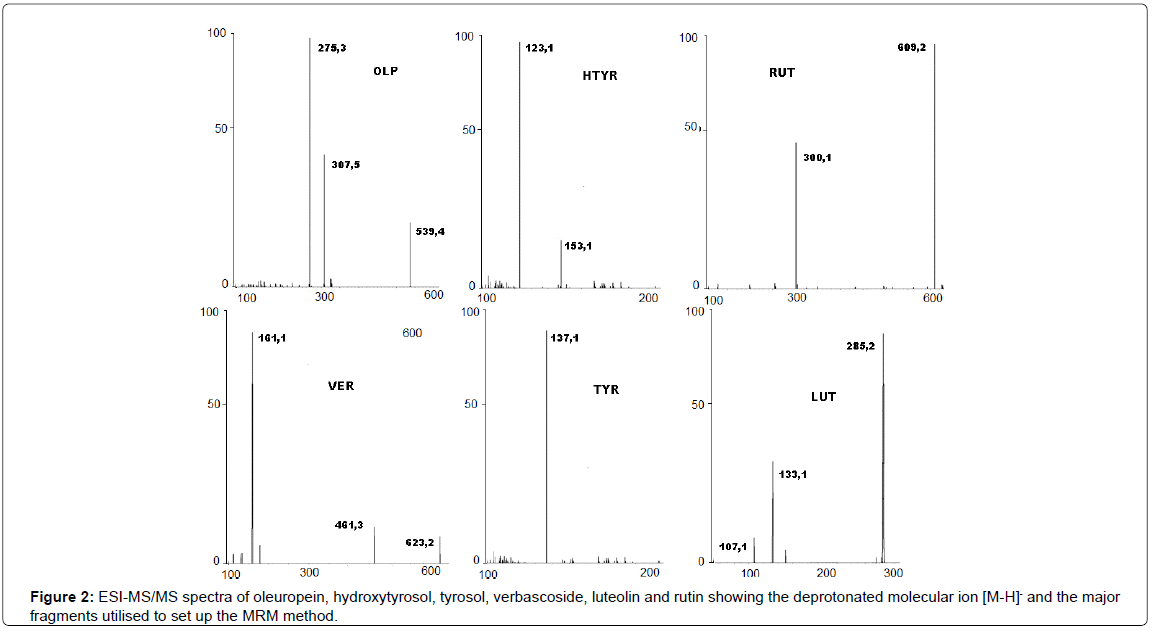

The MS instrument operating parameters were optimized for each analyte of interest by direct injection of the analyzed solution. The CID-MS/MS spectra of the deprotonated molecular ion [M-H]-1 are shown in Figure 2. MRM analyses were carried out by monitoring the transition reported in Table 2.

| Analyte | 1stquadrupole (M-H)- | 2ndquadrupole | EP | DP | CE | CXP |

|---|---|---|---|---|---|---|

| (A) Hydroxytyrosol | m/z 153 | m/z 123 | -55 | -7 | -25 | -5 |

| (B) Luteolin | m/z 285 | m/z 133 | -70 | -8 | -35 | -8 |

| (C) Oleuropein | m/z 539 | m/z 307 m/z 275 |

-65 | -10 | -30 | -5 |

| (D) Rutin | m/z 609 | m/z 301 | -65 | -8 | -45 | -10 |

| (E) Verbascoside | m/z 623 | m/z 161 m/z 461 |

-70 | -8 | -35 | -8 |

| (F) Tyrosol | m/z 137 | No scan | -45 | -8 | -25 | -5 |

Table 2: Data set for the assay of active principles A-F. Optimized entrance potential (EP), declustering potential (DP), collision energy (CE) and collision exit potential (CXP).

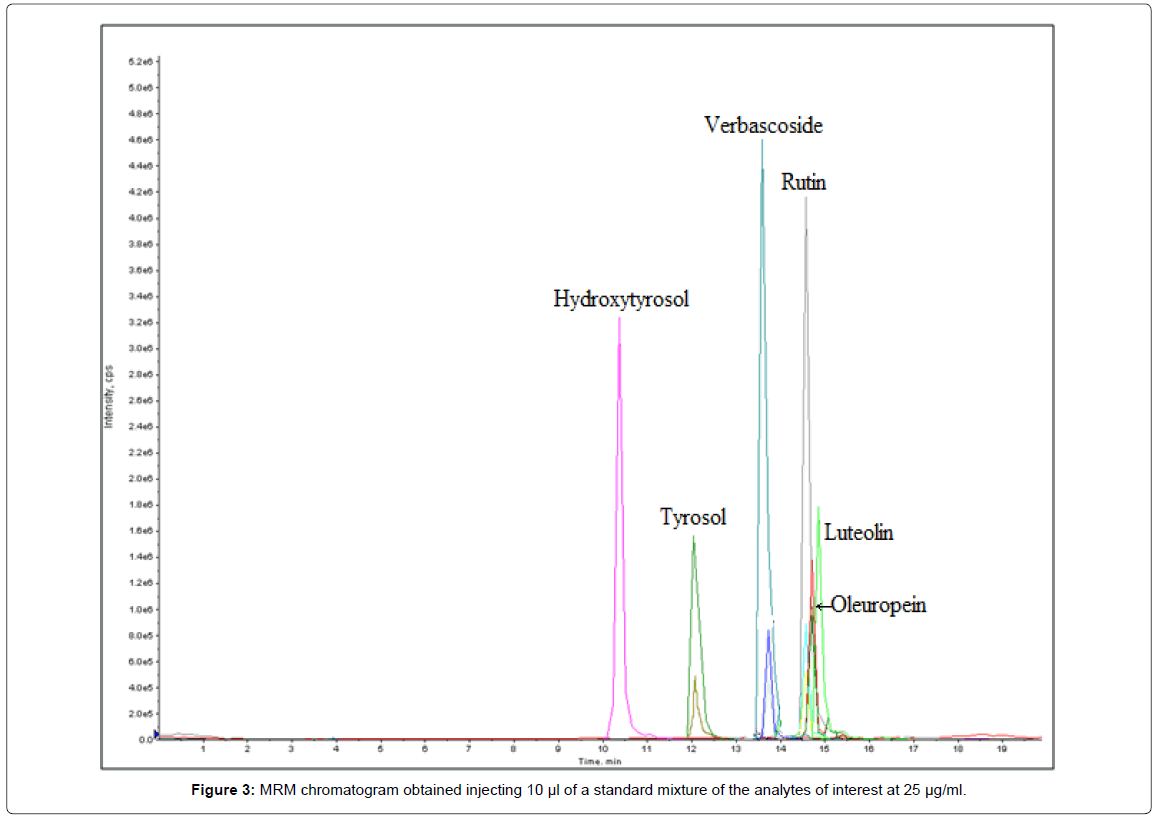

A SIM-like analysis was considered for tyrosol (F) since its product ion spectrum under the experimental conditions adopted for the other analytes did not produce any important fragments. The MRM measurements were, therefore, carried out by modulating the first quadrupole scanning for the transmission of the (M-H)- value of the six analytes (Table 2) and scanning the third analyzer according to Table 2. A MRM chromatogram obtained by injecting 10 μl of a standard mixture of the compounds under investigation at 25 μg/ml is shown in Figure 3.

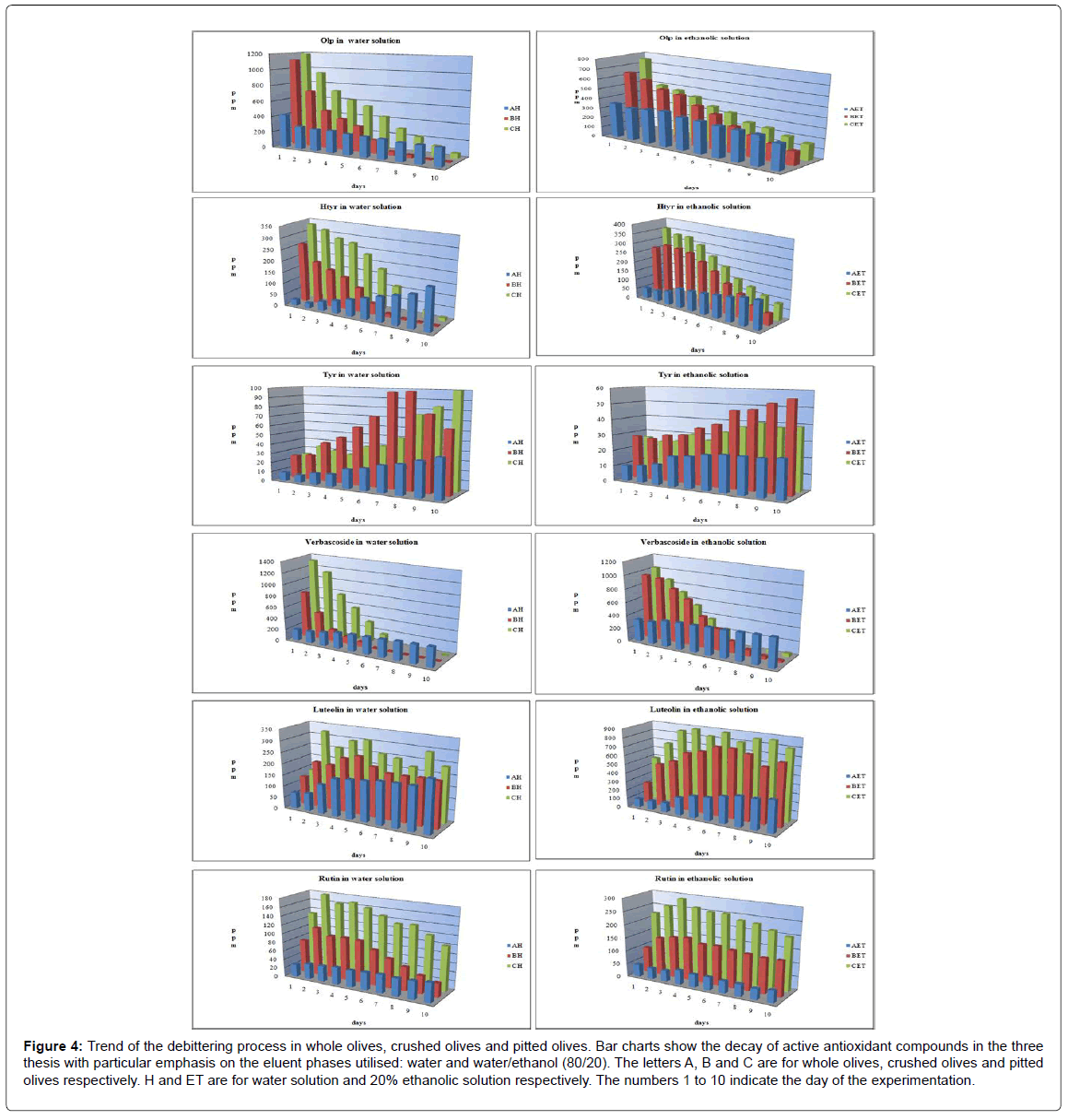

LC-ESI-MS/MS analysis was performed on aliquots of each sample collected. Aqueous solutions containing whole and crushed olives gave a pH value of 6 regardless of whether water/ethanol (80:20) or pure water was used. However, the aqueous solutions containing pitted olives was pH 5 suggesting the presence of the stone was involved in this variation. The results obtained and a discussion for each compound analysed (below) are also presented in Figure 4.

Figure 4: Trend of the debittering process in whole olives, crushed olives and pitted olives. Bar charts show the decay of active antioxidant compounds in the three thesis with particular emphasis on the eluent phases utilised: water and water/ethanol (80/20). The letters A, B and C are for whole olives, crushed olives and pitted olives respectively. H and ET are for water solution and 20% ethanolic solution respectively. The numbers 1 to 10 indicate the day of the experimentation.

Oleuropein (Olp)

The ESI mass spectrum of the negative (-) ions shows the (M-H)- species together with the known diagnostic fragments at m/z 275 and m/z 307 [34,35] (Figure 2). Olp, as expected, was one of the major components of wastes. The maximum concentration of this secoiridoid (409 mg/kg), reached after the first day when plain water is used, slowly decreases to half (228 mg/kg) in the subsequent days (Figure 4). A similar trend was observed when water/ethanol (80:20) was used although the maximum concentration observed after one day (369 mg/ kg) reaches the mean value 264 mg/kg.

A marked difference was observed when crushed and pitted olives were debittered (Figure 4). The maximum concentration achieved after one day was 1187 mg/kg and 1118 mg/kg for pitted and crushed drupes, respectively. This value decreases according to enzymatic kinetics to reach a value of 8 mg/kg on the last day. The solution containing water/ ethanol (80:20) since day one gave a lower content of olp (665 mg/ kg for crushed olives and 754 mg/kg for pitted olives). These values decrease during the days until they reached the mean values 139 mg/ kg and 162 mg/kg for crushed and pitted olives, respectively (Figure 4).

Hydroxytyrosol (HTyr)

The mass spectrum for this compound in negative ion mode gave the deprotonated molecule at m/z 153 and the fragment at m/z 123 due to the loss of the CH2OH group (Figure 2).

HTyr is frequently detected in olive pulp and has been widely studied, in particular its anti-oxidant activity and its health-beneficial properties [36]. The concentration of HTyr in the solution containing pure water and whole olives on the first day was 21 mg/kg. This content increases during the next nine days of experimentation to reach the mean value of 171 mg/kg. The solution containing 20% of ethanol gave an initial value of HTyr double than the solution of pure water (50 mg/ kg). Moreover, the concentration of the compound at the end of the experimentation was found to be less than in the previous one (149 mg/kg). The solutions containing pure water and either crushed and pitted olives showed a high content of HTyr already in the first day of the experimentation (261 and 334 mg/kg, respectively). These values decrease over time to almost zero (2 and 14 mg/kg, respectively). It is to be noted that by using 20% of ethanol the content of HTyr is preserved over time and, in fact, the concentration of the compound found at the end of the experimentation was 60 and 87 mg/kg in the solution containing crushed and pitted olives, respectively. The patterns observed in the three cases (whole, pitted and crushed olives) in the two solutions (pure water and water/ethanol (80:20)) are quite different. In the case of the solution containing whole olives the concentration of the compound increases over time and this increment is due both to its initial content and both to the degradation of secoiridoid compounds. This low accumulation observed could be attributed to the fact that in whole olives the membrane is not damaged and the release of the active compound is slowed down. In the case of the solution containing crushed and pitted olives the concentration of HTyr decreases over the time. The presence of the stone seems to favour a faster degradation of the compound under investigation (Figure 4).

Tyrosol (Tyr)

In all cases analysed the content of Tyr increases (Figure 4). This increase can be attributed both to its initial content and to the degradation processes of higher molecular weight molecules. In the solutions containing whole olives the concentrations of Tyr on the first day was found to be 8 mg/kg in pure water and 9 mg/kg in water/ ethanol (80:20). At the end of the debittering process these contents were 39 and 31 mg/kg, respectively. The concentration of Tyr in crushed olives on the first day of the debittering process was 25 mg/ kg in pure water and 27 mg/kg water/ethanol (80:20). At the end of the experimentation these contents were 65 and 56 mg/kg respectively. The solvent in these two cases does not affect the Tyr content. The situation appears different in the solutions containing pitted olives. In fact, the Tyr content varies from 24 to 100 mg/kg in pure water and from 25 to 40 mg/kg in water/ethanol (80:20).

Verbascoside

The ESI mass spectrum in negative ion mode was represented by the deprotonated ion at m/z 623 with few other fragments of lower intensity (Figure 2). Particularly, two ions characteristic of verbascoside at m/z 461 and m/z 161 were observed. The loss of caffeic acid produced an ion at m/z 461 and a ketene as a neutral fragment, while the peak at m/z 161 resulted from a proton transfer and production of an anionic ketene [35].

The trend observed for all the solutions was similar to the one observed for HTyr: the verbascoside tends to increase during the process of debittering. In the solutions containing whole olives the content of the active compound varies from 196 to 365 mg/kg on the first and last day, respectively. In water/ethanol (80:20) its content varies from 338 to 441 mg/kg on the first and last day, respectively.

The solution containing crushed and pitted olives in pure water showed a high content of verbascoside already on the first day of the experimentation (802 and 1319 mg/kg for crushed and pitted olives respectively). These values decrease over the time to almost disappear (1 and 4 mg/kg respectively) (Figure 4).

Luteolin

The ESI mass spectrum was characterized by an intense ion at m/z 285 and a fragment of m/z 133 of lower intensity (Figure 2).

In several studies this flavonoid has been detected in olive fruits of different cultivars and has proved to possess important biological properties, such as anti-oxidant, anti-inflammatory, anti-microbial and cardio-tonic activity, ability to scavenge free radicals and to inhibit low-density lipoprotein oxidation [34]. Luteolin is responsible, along with other carotenoid compounds, for the colour of the drupes. Fermentation and debittering processes promote its release into solution that is pronounced if olives are damaged. Moreover, in the presence of solvents such as ethanol, this release is marked. Also, the absence of light preserves the colour of the final solutions.

During the ten days of experimentation, depending on the olives utilized, different gradients of colour were obtained. Whole olives gave, at the end of the experimentation, a dark green colour, whereas crushed and pitted ones gave a browny green colour that was more evident in the ethanolic solutions. All solutions analysed showed an increase of the active compound. In particular, in aqueous solution containing whole olives the luteolin content varies from 66 to 218 mg/kg during the experimental period, whereas in the ethanol solution from 83 to 287 mg/kg. The solutions containing crushed and pitted olives in pure water showed a higher content of luteolin during the first days of the experimentation; these values will not vary significantly over the period of the debittering process. In fact, the content of luteolin for crushed olives varies from 126 to 202 mg/kg whereas for pitted olives from 110 to 190 mg/kg. The ethanol solutions have a different pattern with respect to the previous ones examined. In fact, from day one the solutions are very rich in luteolin and increases during all the debittering process. At the end of the experimentation almost 700 mg/kg were found in the solution containing crushed olives and almost 800 mg/kg in the solution containing crushed ones (Figure 4).

Rutin

The ESI mass spectrum was characterized by an intense deprotonated molecular ion at m/z 609 and a fragment at m/z 301 which is diagnostic of quercetin derivatives (Figure 2). Many biological effects have been attributed to this flavonoid, which shows anti-oxidant, anti-inflammatory, anti-thrombotic, cytoprotective, vasoprotective and anti-microbial activity [37]. This glycoside flavone is stable in aqueous solution at neutral or alkaline pH; in an acid or by the action of enzymes specific hydrolase, the glycosidic bond is broken with the formation of anomeric hemiacetals. In the aqueous solutions analysed the concentration of rutin, from the first to the last day of experimentation, does not change much and remains constant when whole olives are used (from 40 to 44 mg/kg). A decrease in the concentration can be observed for crushed olives (from 110 to 31 mg/ kg) and for pitted olives (from 179-101 mg/kg). The difference that can be noticed when ethanol is added is that the content of rutin released is far greater, but constant throughout the experimentation period. For whole olive the content of rutin is the same as in the aqueous solution (from 41 to 49 mg/kg). The solutions containing pitted olives showed an increased content of the compound than those containing crushed olives (from 144 to 132 mg/kg and from 221 to 200 mg/kg, respectively) (Figure 4).

Conclusion

The results discussed above show, from a chemical point of view that, as expected, the glycosidic antioxidants are less stable in water than the other detected active principles, even in the absence of chemical catalysts that could affect the process. The observed behaviour is, therefore, probably driven by those deglycosylation enzymes which are extracted from the drupes together with the active species listed in Table 1 [24]. This observation allows the choice of the experimental conditions to be applied to favour the recovering of a particular family of nutraceuticals from olive drupes.

In conclusion, the results presented above provide evidences on the possibility of devising new strategies in the recovering of active principles from olives. They can be obtained either by mild procedures applied to the debittering of table olives or by treatment of wild olive drupes widespread in the Mediterranean area.

Acknowledgements

This work was supported by MIPAAF, Italian Ministry of Agricultural, Food and Forest Policies under the projects of RIOM, OPERO e OLIGAS and by the Calabrian region APQ-RAC QUASIORA project. Ilaria Santoro thanks the doctorate school of Translational Medicine for a fellowship.

References

- Romeo FV (2012) Microbiological Aspects of Table Olives: Olive Germplasm - The Olive Cultivation, Table Olive and Olive Oil Industry in Italy. Edited by Innocenzo Muzzalupo. Publisher: InTech. pp. 321-342.

- Benincasa C, Muccilli S, Amenta M, Perri E, Romeo FV (2015) Phenolic trend and hygienic quality of green table olives fermented with Lactobacillus plantarum starter culture. Food Chem 186: 271-276.

- Di Donna L, Gallucci G, Malaj N, Romano E, Tagarelli A, et al. (2011) Recycling of industrial essential oil wastes: Brutieridin and Melitidin, two anticholesterolaemic active principles from bergamot albedo. Food Chem 125: 438-441.

- Sindona G (2010) A Marker of Quality of Olive Oils: The Expression of Oleuropein, in Olives and olive oil in health and disease prevention. Preedy V, Watson R (Eds) Academic Press.

- Soler-Rivas C, Espin JC, Wichers HJ (2000) Oleuropein and related compound. J Sci Food Agric 80: 1013-1023.

- Visioli F, Galli C (1994) Oleuropein protects low density lipoprotein from oxidation. Life Sci 55: 1965-1971.

- Konno K, Hirayama C, Yasui H, Nakamura M (1999) Enzymatic activation of oleuropein: a protein crosslinker used as a chemical defense in the privet tree. Proc Natl Acad Sci U S A 96: 9159-9164.

- Briante R, La Cara F, Tonziello MP, Febbraio F, Nucci R (2001) Antioxidant activity of the main bioactive derivatives from oleuropein hydrolysis by hyperthermophilic beta-glycosidase. J Agric Food Chem 49: 3198-3203.

- Briante R, Patumi M, Limongelli S, Febbraio F, Vaccaro C, et al. (2002) Changes in phenolic and enzymatic activities content during fruit ripening in two Italian cultivars of Olea europaea L. Plant Sci 162: 791-798.

- Morello JR, Motiva MJ, Tovar MJ, Romero MP (2004 b) Changes in commercial olive oil (cv Arbequina) during storage with special emphasis on phenolic fraction. Food Chem 85: 357-364.

- Ryan D, Antolovich M, Prenzler P, Robards K, Lavee S (2002) Biotransformations of phenolic compounds in Olea europaea L. Scientia Horticulturae 92: 147-176.

- Morelló JR, Romero MP, Motilva MJ (2004) Effect of the maturation process of the olive fruit on the phenolic fraction of drupes and oils from Arbequina, Farga, and Morrut cultivars. J Agric Food Chem 52: 6002-6009.

- Ciafardini G, Marsilio V, Lanza B, Pozzi N (1994) Hydrolysis of Oleuropein by Lactobacillus plantarum Strains Associated with Olive Fermentation. Appl Environ Microbiol 60: 4142-4147.

- Angerosa F, D’Alessandro N, Cornara F, Mellerio G (1996) Characterization of phenolic and secoiridoid aglycones present in virgin olive oil by gas chromatography-chemical ionization mass spectrometry. J Chromatogr A 736: 195-203.

- Marsilio V, Lanza B, Pozzi N (1996) Progress in table olive debittering: degradation in vitro of oleuropein and its derivatives by Lactobacillus plantarum. J Am Oil Chem Soc 73: 593-597.

- Panagou EZ, Tassou CC (2006) Changes in volatile compounds and related biochemical profile during controlled fermentation of cv. Conservolea green olives. Food Microbiol 23: 738-746.

- McDonald S, Prenzler PD, Antolovich M, Robards K (2001) Phenolic content and antioxidant activity of olive extracts. Food Chem 73: 73-84.

- Halliwell DJ, Barlow M, Nash DM (2011) A review of the effects of wastewater sodium on soil physical properties and their implications for irrigation systems. Aust J Soil Res 39: 1259-1267.

- Agalias A, Magiatis P, Skaltsounis AL, Mikros E, Tsarbopoulos A, et al. (2007) A new process for the management of olive oil mill waste water and recovery of natural antioxidants. J Agric Food Chem 55: 2671-2676.

- Aziz NH, Farag SE, Mousa LA, Abo-Zaid MA (1998) Comparative antibacterial and antifungal effects of some phenolic compounds. Microbios 93: 43-54.

- Perri E, Raffaelli A, Sindona G (1999) Quantitation of oleuropein in virgin olive oil by ionspray mass spectrometry-selected reaction monitoring. J Agric Food Chem 47: 4156-4160.

- Benincasa C, De Nino A, Lombardo N, Perri E, Sindona G, et al. (2003) Assay of aroma active components of virgin olive oils from southern Italian regions by SPME-GC/ion trap mass spectrometry. J Agric Food Chem 51: 733-741.

- Di Donna L, Mazzotti F, Napoli A, Salerno R, Sajjad A, et al. (2007) Secondary metabolism of olive secoiridoids. New microcomponents detected in drupes by electrospray ionization and high-resolution tandem mass spectrometry. Rapid Commun Mass Spectrom 21: 273-278.

- De Nino A, Di Donna L, Mazzotti F, Sajjad A, Sindona G, et al. (2008) Oleuropein Expression in Olive Oils Produced from Drupes Stoned in a Spring Pitting Apparatus (SPIA). Food Chem 106: 677-684.

- Benevante-Garcia O, Castello J, Morente J, Ortuno A, Del Rio J (2000) Antioxidant activity of phenolics extracted from Olea europea L leaves. Food Chem 68: 457-462.

- Caruso D, Colombo R, Patelli R, Giavarini F, Galli G (2000) Rapid evaluation of phenolic component profile and analysis of oleuropein aglycon in olive oil by atmospheric pressure chemical ionization-mass spectrometry (APCI-MS). J Agric Food Chem 48: 1182-1185.

- Visioli F, Poli A, Gall C (2002) Antioxidant and other biological activities of phenols from olives and olive oil. Med Res Rev 22: 65-75.

- Gordon MH, Paiva-Martins F, Almeida M (2001) Antioxidant activity of hydroxytyrosol acetate compared with that of other olive oil polyphenols. J Agric Food Chem 49: 2480-2485.

- Carluccio MA, Siculella L, Ancora MA, Massaro M, Scoditti E, et al. (2003) Olive oil and red wine antioxidant polyphenols inhibit endothelial activation: antiatherogenic properties of Mediterranean diet phytochemicals. Arterioscler Thromb Vasc Biol 23: 622-629.

- Lorraine Heller. U. S. Patent 7,713,569, Jun-22-2010.

- Ritieni A, Rastrelli L, Novellino E (2013) Special Issue: Food Quality Evaluation. Food Chemistry 140: 613.

- Banoub J, Delmas GH Jr, Joly N, Mackenzie G, Cachet N, et al. (2015) A critique on the structural analysis of lignins and application of novel tandem mass spectrometric strategies to determine lignin sequencing. J Mass Spectrom 50: 5-48.

- Gambacorta G, Faccia M, Previtali MA, Pati S, La Notte E, et al. (2010) Effects of olive maturation and stoning on quality indices and antioxidant content of extra virgin oils (cv. Coratina) during storage. J Food Sci 75: C229-C235.

- Ryan D, Robards K, Prenzler P, Jardine D, Herlt T, et al. (1999) Liquid chromatography with electrospray ionisation mass spectrometric detection of phenolic compounds from Olea europaea. J Chromatogr A 855: 529-537.

- de la Torre-Carbot K, Jauregui O, Gimeno E, Castellote AI, Lamuela-Raventós RM, et al. (2005) Characterization and quantification of phenolic compounds in olive oils by solid-phase extraction, HPLC-DAD, and HPLC-MS/MS. J Agric Food Chem 53: 4331-4340.

- Paiva-Martins F, Gordon MH, Gameiro P (2003) Activity and location of olive oil phenolic antioxidants in liposomes. Chem Phys Lipids 124: 23-36.

- Raj Narayana K, Sripal Reddy M, Chaluvadi MR, Krishna DR (2001) Bioflavonoids classification, pharmacological, biochemical effects and therapeutic potential. Indian Journal of Pharmacology 33: 2-16.

Relevant Topics

Recommended Journals

Article Tools

Article Usage

- Total views: 14824

- [From(publication date):

December-2015 - Apr 03, 2025] - Breakdown by view type

- HTML page views : 10196

- PDF downloads : 4628