Minimizing Waste in Neonatal Intensive Care Units by Effective bedside Supply Management: Application of Lean Six Sigma in Neonatal Intensive Care Unit

Received: 23-Oct-2018 / Accepted Date: 16-Jan-2019 / Published Date: 24-Jan-2019 DOI: 10.4172/2572-4983.1000175

Abstract

Objectives: The primary objective of the study was to minimize the waste because of stocked supplies at the bedside cabinet in NICU. The aim was to find alternative options to stock, and to educate care providers about the increase in cost of the patient care arising because of the waste associated with inadequate inventory management.

Material and Methods: A pilot study was conducted by formulating new protocols of supply indentation and removing all excess supplies from bedside cabinet to a moving trolley which was kept outside infected area. The study lasted 12 weeks and cost savings on consumables were compared with historic data of past 12 weeks for the same beds. The response time for procuring endotracheal tube from moving trolley was compared with other bed where the new protocols were not applied. The data was compared in appropriate statistical test.

Results: Data was collected for 12 week time period. There was significant cost saving at the end (Average saving Rs 4383 vs. 1771, value of p was highly significant) without significant change in patient care, the time taken for procurement of an endotracheal tube was found to be 71.3 s vs. 68 s with a p value more than 0.9.

Conclusion: Storing consumables and supplies in moving trolley rather than on bedside cabinet resulted into waste reduction because storing at bedside cabinets rendered supplies potentially infected leading to their discarding and resulting in more waste and cost incurred on patient bills. While storing excess supplies on a moving trolley which can quickly be moved to patients bedsides in case of an emergency situation, resulted in less potential of supplies being infected and thus saving on patients costs on consumables because leftovers can be returned to stores.

Keywords: Lean six sigma; Waste reduction; Indent protocols; Supply management; Inventory management; Neonatal; Intensive care unit

Abbreviations

NICU: Neonatal Intensive Care Unit; ICU: Intensive Care Unit; SMVDNSH: Shri Mata Vaishno Devi Narayana Superspecialty Hospital; ARO: Antibiotic Resistant Organisms; CSSD: Central Supply Sterility Unit

Introduction

Lean six-sigma are methodologies to reduce waste and decrease errors and they can be effectively applied in healthcare to improve efficiency by minimizing waste and errors [1]. The NICU at Shri Mata Vaishno Devi Super-specialty Hospital (SMVDNH), Kakryal (Jammu) harbors one store which serves as supply storage unit and has all the essential materials viz. consumables and drugs which are needed for treatment of the neonates admitted in NICU. Neonatal care is an acute care specialty and necessitates availability of lifesaving drugs and equipment right at the infant’s cot, so that it is handy to the care provider [2]. Although these supply cabinets provide the convenience of availability of material in critical situation yet they are a reason for waste in the NICU [3]. Because in our NICU maximum number of patients are admitted with neonatal sepsis/other forms of infections and to maintain the sterility current practice is either to discard or sterilize all the unused articles present on the bedside of the neonates who has been found to be positive or suspected to be suffering from infection, this adds cost to the patient care and may be hazardous to the environment. The leftover supply is assumed to be infected in case the baby is found positive for infection and all unused supplies are discarded when such a baby is discharged or they die.

The option of keeping all the drugs in store and no drug at bedside is also not feasible because that will add time delay consumed in moving to store, doffing and donning of the NICU sterilized suits, cap and mask, thus may severely compromise patient care. By and large the NICU store is present at around 10 meters from the main patient care area but getting an medicine or consumable from the store every time is not feasible this is because the nurse will have to doff the protective gown and don her usual clothes, she will have to cross three barricades which have been created to impede direct entry of unwashed/ungowned person into patient care area, then she would enter the store, Vcollect the article, come back to patient care area after crossing the three barricades and doffing her usual clothes and donning the NICU sterilized suits, cap and mask. The whole process would be very time consuming and can compromise the patient care significantly. Therefore, we designed this study in order to find some way to reduce waste while not affecting the patient care.

Literature Review

A literature review was undertaken looking at the major concept of waste reduction; reducing the amount of discarded unused medical supplies is believed to reduce costs, help protect the environment and reduce infectious transmission.

It is understandable that cost incurred can be decreased by minimizing the quantity of discarded consumables, drugs and other supplies [4]. In addition, it would have environment friendly benefits because of lesser chemical waste. Lauer et al. found that hospitals in USA on an average produce more than 13000 pounds of waste daily [5]. NHS alone is responsible for emission of more than 20 million metric tons of carbon waste every year [6]. Lean and six sigma principles can help organizations to minimize the waste and hence cost, and environmental hazards. Chapman et al found that hospital waste is a major contributor to landfills [7].

There is a school of thoughts which believes in analysis and reduction in waste in critical care zones inside the hospital so that the cost incurred by the patient can be minimized because these area are already very expensive. The cost effectiveness brought in by reducing the inventory at the bedside of the infected patients [8]. Waste reduction protocols were found to be very useful, causing approximately 60% reduction in medical waste and 50% decrease in costs by saving on waste and indirectly by decreasing transmission of infections [9]. The patients who are positive for antibiotic resistant organisms (AROs) should be isolated to curtail the infection spreading to other patients. The environment around the patient should be disinfected and all the items and leftovers should be discarded or disinfected. In any case the environment, instrument, consumables or any other leftover of such patient must not come in contact with other patients [10]. These infection control measures has resulted in inflation of the costs for treatment. Hence, it is required to find strategies to decrease waste, so that minimum inventory exists in direct contact of the patient decreasing the need of discard at the discharge. The implementation of protocols depends upon the staff motivation [11]. Staff involvement and support is solicited at every level.

Aims and Objectives

The primary objective of the study was to minimize the waste accumulated because of stocked supplies at the bedside cabinet in NICU. The aim was to find alternative options to stock, and to educate care providers about the increase in cost of the patient care arising because of the waste associated with inadequate inventory management.

Material and Methods

A team of infection control nurse, infection control officer (microbiologist), central sterility supply department (CSSD) manager and hospital inventory and supply chain in charge was constituted. The team undertook a cost analysis of the discarded supplies once the patient was discharged/died, the result of the analysis were shared with all the members.

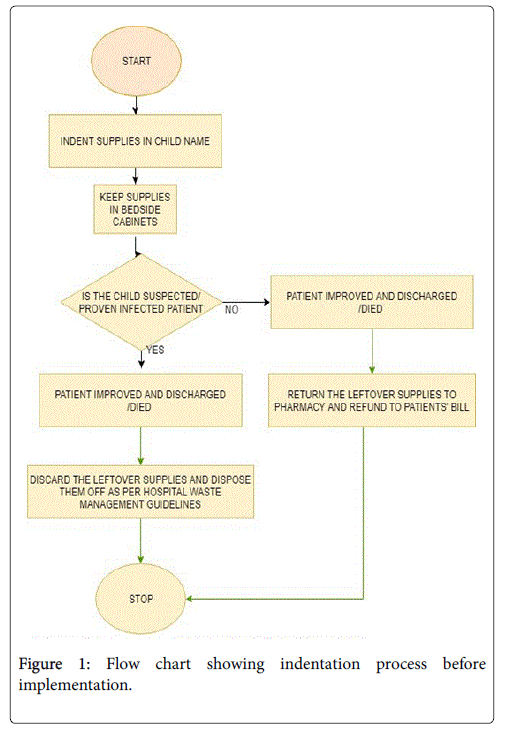

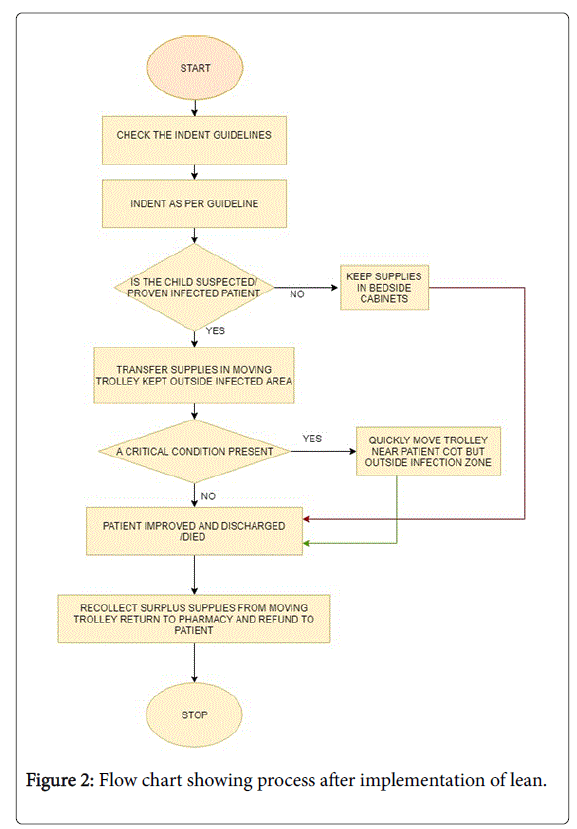

The infection control officer was the doctor incharge of whole system of processes and he was responsible for formulating the guidelines about how to use supplies and linen at bedside cabinets. The indents were reviewed and surplus was omitted and sent to a moving trolley close to patients’ cot but outside the infective zone. After a general accord on the recent changes about what and how much to keep, the new indent lists and photos were created and posted to every bedside cabinet. The new rules were implemented in phases gradually. The moving trolley helped by making the supply handy while preventing it from being contaminated thus decreasing need to discard it later and preventing an unopened supply to become waste. These efforts combined with motivation of staff to practice the changes paved the way to success. Although the waste reduction and cost reduction were primary focuses, efficiency improvement was also been solicited. The group met biweekly to brainstorm, plan and evaluate the objectives. Meetings were held in the traditional setting of a conference room, followed by walking through NICU. Informal walkabouts facilitated visualization of problem areas and provided an open venue for innovative solutions. Front-line staffs were asked to contribute their thoughts and ideas to grow their interest (Figures 1 and 2).

Upon discharge of the patient, all leftover supply indented in the name of the child were collected from the moving trolley, analyzed for cost, photographed and result mailed to all members and healthcare providers to feed them about the current state of wastage. The unused supplies were returned to the pharmacy and the cost refunded to patient’s guardian. Final cost analysis and quality improvement was done every fortnightly. Initially, we implemented the changes on 2 beds only, the beds designated for septic patients only.

Results And Discussion

Data collection and outcome measures

The study was conducted over a period of 12 weeks, two NICU beds designated for children suspected of neonatal sepsis (infection) were chosen for implementation of lean protocols. The weekly meetings were conducted on Mondays for cost analysis and cost and quality analysis of patient care was done for the patients discharged in previous week (Sunday to Saturday). The saving on the patient bills by returning unused supplies to pharmacy in case of those beds which were using moving trolleys were compared to same beds (when they were using bedside cabinets) by using historic data of preceding 12 weeks. The results were compared using appropriate statistical tests (Mann-Whitney U test) [12]. The compromise on patient care was measured by comparing the time needed in procuring a endotracheal tube in event of crisis for a bed which is using moving trolley versus a bed which is using a bed side cabinet, The outcome (time taken in seconds) were compared using Mann-Whitney U test. IBM SPSS® version 21 was used for analyzing the results and calculating the value of ‘p’, a value less than 0.05 is taken as a significant impact because of intervention.

The primary outcome measure: Cost of unused supply for patient who has been discharged till Saturday of last week.

Secondary outcome measure: Delay in getting the supply in case of a critical event.

Value of p using Mann-Whitney U test << 0.05.

Value of p=0.945 which is insignificant statistically using Mann- Whitney U test (Table 2).

| Week | Avg Refund on unused supply per week after lean in INR | Avg Refund on unused supply per week before lean (from historic data) in INR |

|---|---|---|

| 1 | 4612.00 | 1709.00 |

| 2 | 5068.00 | 2302.00 |

| 3 | 4109.00 | 1762.00 |

| 4 | 3850.00 | 1876.00 |

| 5 | 7436.00 | 1023.00 |

| 6 | 8093.00 | 2324.00 |

| 7 | 4084.00 | 1806.00 |

| 8 | 3098.00 | 1434.00 |

| 9 | 4127.00 | 2449.00 |

| 10 | 5098.00 | 1528.00 |

| 11 | 4389.00 | 1437.00 |

| 12 | 4023.00 | 1609.00 |

| Average | 4832.25 | 1771.58 |

Table 1: Refund on unused supply before and after implementation of lean.

| Week | Avg time taken in procuring endotracheal tube in critical event from moving trolley in seconds | Avg time taken in procuring endotracheal tube from bedside cabinets in seconds |

|---|---|---|

| 1 | 67 | 64 |

| 2 | 54 | 59 |

| 3 | 112 | 69 |

| 4 | 58 | 89 |

| 5 | 77 | 60 |

| 6 | 64 | 68 |

| 7 | 87 | 54 |

| 8 | 73 | 83 |

| 9 | 58 | 65 |

| 10 | 63 | 71 |

| 11 | 81 | 60 |

| 12 | 62 | 74 |

| Average | 71.3 | 68 |

Table2: Average time taken to procure an endotracheal tube in critical events in septic beds (from moving trolley) and non-septic beds (bedside cabinets).

Challenges

This study imposed many challenges because attitude and practice change were difficult to achieve. Staff resistance needed quite an effort in terms of education, motivation and direct involvement. Also, doctors were insisting on not changing the current scenario. Initially the nurses and the doctors felt that the decreased storage of supplies in the bedside cabinet would severely compromise patient care in emergency. Ongoing staff education was a necessary component to justify the need of reducing supplies and to communicate strategies that would alleviate negative effects on patient care. Finding additional storage space close enough to quickly procure the supply so that patient care is not hampered was another challenge which was solved by availability of moving trollies which would be kept in a demarcated zone away from contamination zone but close to patients’ cots. The last challenge was to ensure continuous education and dialogue with staff for continuous sustainability of the practice. This would be achieved by continuous posting of pictures and posters showing positive outcomes.

Since value of p is less than 0.05 it means there is statistically significant refunds when a patient is being discharged as compared to implementation of lean principles (Table 1).

Positive outcomes

When the new guidelines for stock and indents were implemented, it was expected that the staff nurses would assume responsibility for ensuring that they have planned ahead and are anticipating supply needs before entering NICU. The results were quite convincing after doing the final review after 4 weeks of implementing the guidelines in terms of decreased cost of wastage and decrease in patient bills. Also we noticed a positive change in attitude of the nurses toward indentation. The doctors were happy because the patient care was not hampered while cost of treatment decreased. Finally, we believe we have helped the mother Earth by helping conserve the resources and not polluting the environment unnecessarily. A positive change in knowledge attitude and practice regarding patient care and waste reduction was observed.

Recommendations for institutions undertaking similar future initiatives

• Include front-line staff throughout the process.

• Be expert communicators through a variety of media (email, posters, and face-to-face conversations).

• Consider complete implementation on rollout rather than staggered implementation.

Conclusion

Staff members were effectively adjusting to the practice changes resulting from this initiative. The objective of reducing waste in NICU was achieved, and cost savings potential was realized. We documented the refund on pharmacy bills when the patient was discharged. Furthermore, the reduction in waste helped to promote an environmental awareness and helped alleviate the increasing demand on waste management systems. Additionally, infection control practices were remained consistent. This project provided a real opportunity for staff members to become engaged, drive the project forward and achieve a positive impact at both the micro and macro levels. Individual empowerment enabled staff to take charge of their own practice while feeling they were contributing to greater efforts towards infection control and waste management. Outcomes affected all inter-professional practitioners including leadership, nursing staff and allied healthcare providers; adding a sense of pride and accomplishment that was palpable on the front line.

Recommendations

• All hospitals involved in acute patient care should look forward to developing and implementing lean and six-sigma protocols to eliminate waste and decrease errors in patient care

• The storing consumables in a moving trolley rather than on patient care does not seem to result in an any delay in patient care but significant savings of patients bill were observed

• An increased leadership and responsible behavior is expected in nurses and paramedics toward decreasing the waste if they are actively involved in the process of indent rules and lean six-sigma implementation.

References

- den Heuvel JV, Koning HD (2006) Lean Six Sigma in a hospital. International Journal of Six Sigma and Competitive Advantage 2: 377-388.

- https://www.resus.org.uk/archive/archived-quality-standards/suggested-equipment-for-management-of-paediatric-cardiopulmonary/

- Chasseigne V, Leguelinel-Blache G, Nguyen TL, de Tayrac R, Prudhomme M, et al. (2018) Assessing the costs of disposable and reusable supplies wasted during surgeries. Int J Surg 53: 18-23.

- Lauer M (2009) Reducing health care's ecological footprint. Am J Nurs 109: 56-58.

- Pencheon D, Rissel CE, Hadfield G, Madden DL (2009) Health sector leadership in mitigating climate change: experience from the UK and NSW. N S W Public Health Bull 20: 173-176.

- Kim T, Oh PI, Simor AE (2001) The economic impact of methicillin-resistant Staphylococcus aureus in Canadian hospitals. Infect Control Hosp Epidemiol 22: 99-104.

- Almuneef M, Memish ZA (2003) Effective medical waste management: it can be done. Am J Infect Control 31: 188-192.

- Bagshawe KD, Blowers R, Lidwell OM (1978) Isolating patients in hospital to control infection. Part IV-Nursing procedures. Br Med J 2: 808-811.

- Ferenc J (2010) Going greener. Hospitals continue to make sustainability a priority. Health Facil Manage 23: 24-28.

- Hart A (2001) Mann-Whitney test is not just a test of medians: differences in spread can be important. BMJ 323: 391-393.

Citation: Verma V, Soni P, Jha R, Sharma S, Kumar A (2019) Minimizing Waste in Neonatal Intensive Care Units by Effective bedside Supply Management: Application of Lean Six Sigma in Neonatal Intensive Care Unit. Neonat Pediatr Med 5: 175. DOI: 10.4172/2572-4983.1000175

Copyright: © 2019 Verma V, et al. This is an open-access article distributed under the terms of the Creative Commons Attribution License, which permits unrestricted use, distribution, and reproduction in any medium, provided the original author and source are credited

Share This Article

Recommended Conferences

42nd Global Conference on Nursing Care & Patient Safety

Toronto, CanadaRecommended Journals

Open Access Journals

Article Tools

Article Usage

- Total views: 4552

- [From(publication date): 0-2019 - Apr 02, 2025]

- Breakdown by view type

- HTML page views: 3703

- PDF downloads: 849