Research Article Open Access

Mechanical, Interfacial and Thermal Properties of Different Chemical Structures of Epoxy Resin

Pyeong-Su Shin1, Jong-Hyun Kim1, Ha-Seung Park1, Yeong-Min Baek1, Dong-Jun Kwon1, K. Lawrence DeVries2 and Joung-Man Park1,2*1Department of Materials Engineering and Convergence Technology, Center for Creative Human Resource & Convergence Materials, Research Institute for Green Energy Convergence Technology, Gyeongsang National University, Jinju 660-701, Korea

2Department of Mechanical Engineering, The University of Utah, Salt Lake City, Utah 84112, USA

- *Corresponding Author:

- Park JM

Department of Materials Engineering and Convergence Technology

Center for Creative Human Resource & Convergence Materials

Research Institute for Green Energy Convergence Technology

Gyeongsang National University, Jinju 660-701, Korea

Tel: +82-55-772-1656

Fax: +82-55-772-1659

E-mail: jmpark@gnu.ac.kr

Received Date: June 18, 2017; Accepted Date: June 20, 2017; Published Date: June 22, 2017

Citation: Shin PS, Kim JH, Park HS, Baek YM, Kwon DJ, et al. (2017) Mechanical, Interfacial and Thermal Properties of Different Chemical Structures of Epoxy Resin. J Powder Metall Min 6: 169. doi:10.4172/2168-9806.1000169

Copyright: © 2017 Shin PS, et al. This is an open-access article distributed under the terms of the Creative Commons Attribution License, which permits unrestricted use, distribution, and reproduction in any medium, provided the original author and source are credited.

Visit for more related articles at Journal of Powder Metallurgy & Mining

Abstract

Optimal glass fiber/epoxy composite conditions were investigated as functions of different epoxy resin structures. Bisphenol-A and novolac type epoxies were used as composite matrices. TGA and DSC measurements were used to investigate thermal stability and glass transition temperatures of these resins. A UTM was used, at room and high temperatures, to preform tensile and compressive tests as well microdroplet pull-out tests to investigate the mechanical and interfacial properties of the resins and their composites. Novolac epoxy resin and its composites exhibited better mechanical and interfacial properties than bisphenol-A and its composites. It was also observed that the shape of microdroplet on the glass fiber was significantly narrower for the novolac resin than it was for the bisphenol-A epoxy resin.

Keywords

Composites material; Glass fiber; Heat resistance; Epoxy resin

Introduction

Epoxy resins are among the most important thermosetting polymers and are used extensively as adhesives in many applications including aerospace [1]. The recent development of epoxy resinbased renewable organic materials has attracted a lot of attention [2]. It is also noteworthy that, cardanol-based novolac resins have been investigated for use as modifiers and curing agents for commercial epoxy resins improving toughness and other mechanical properties [3]. The mechanical properties of epoxy resin are affected by the ratio of curing agent to epoxy resin; this mixing ratio has very important practical implications. Recently, composite materials have been developed for applications in severe environments, such as cryogenic and high temperatures, water repellency, corrosion resistance and ultraviolet radiation [4,5]. The “microdroplet pull out test” has been developed and used to evaluate interfacial properties. In this test a single fiber is embedded in a microdroplet (40-300 μm diameters) of the polymer. The interfacial shear strength (IFSS) is calculated using the measured pull out force and the contact area between the fiber and the microdroplet [6,7]. In this study, the optimal conditions for glass fiber/epoxy composites were investigated using two different composite matrices (bisphenol-A type epoxy and novolac type epoxy). TGA and DSC instruments were used to investigate thermal stability and glass transition temperature. AN UTM was used to facilitate measurements of tensile and compressive properties of the resins and their composites at room and high temperatures. The microdroplet pull-out test was used to evaluate interfacial properties between the resins and glass fibers.

Experimental

Materials and specimens

Novolac type epoxy (YDPN-638, Kukdo chemical Co., LTD, Korea) and bisphenol-A type epoxy (YD-128, Kukdo chemical Co., LTD, Korea) were used as epoxy resin matrices. Acid anhydride (KFH- 1089, Kuk do chemical co, LTD, Korea) was used as the hardener. Glass fiber (SE1500, Owens Corning, USA) was used for composite reinforcement.

Methodologies

The epoxy resins were diluted with acetone, and these diluted resins were coated on the glass fibers at 30 wt% by hand lay-up. Solvent evaporation and pre-curing were performed in an oven at 120°C for 7 minutes. Glass fiber/epoxy composites were fabricated using these prepreg using a hotpress (1401, Tetrahedron, USA) at 80°C at 1.5 Kgf/ cm2 for 1 hour followed by 120°C at 3 Kgf/ cm2 for 4 hours. An UTM (H1KS, Lloyd, USA) was used to measure mechanical properties according to ASTM D-638 (for tensile testing) and ASTM D695 (for compressive testing) at room and high temperatures, at a test speed of 1mm/min. The microdroplet test was performed to measure the interfacial (IFSS) properties using the equation:

(1)

(1)

Where Df and L are the diameter and length of fiber embedded in the matrix, resp.

TGA (Q50, TA instrument, USA) and DSC (Q20, TA instrument, USA) were used to investigate the chemical construct and glass transition temperature of epoxies with different epoxy resins. The measuring temperature range was from 25°C to 250°C, with a temperature increase rate of 10°C/min.

Results and Discussion

Thermal properties of the epoxy resins

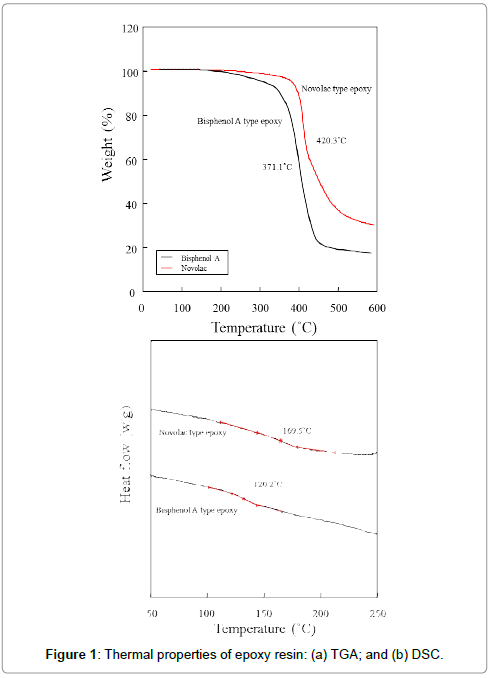

Figure 1 shows TGA and DSC results for the two epoxy resins as: (a) the degrees of thermal degradation and (b) determination of the glass transition temperatures. The thermal properties of novolac type epoxy were generally better than those of the bisphenol-A type epoxy resin. The thermal degradation of the novolac type epoxy started at approximately 420°C whereas it started at approximately 370°C for the bisphenol-A type epoxy. The glass transition temperature of novolac type epoxy was higher at roughly 169°C than it was for bisphenol-A type epoxy resin at approximately 120°C.

Mechanical properties of epoxy resin and composites

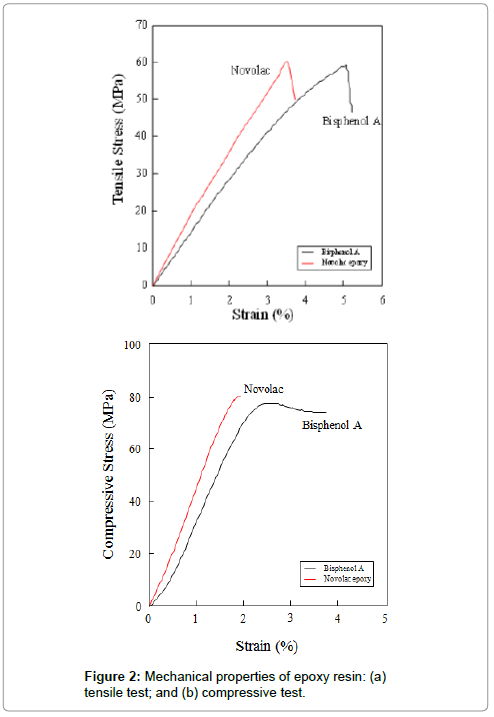

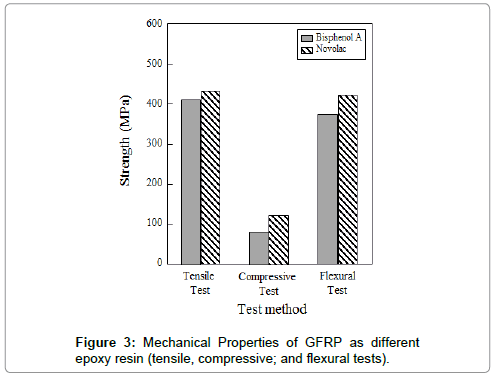

Figure 2 shows the tensile and compression test results for composites of the two epoxy resins. Figure 3 shows a summary the strength results taken from different mechanical tests (tensile, compressive and flexural) on glass fiber/epoxy composites with the different epoxy resin matrices properties). Clearly, the novolac type epoxy composites had superior strength under all three modes of loading.

Interfacial properties between glass fiber and epoxy resins

Figure 4 shows microdroplet test results of the different epoxy resins on glass fibers. When the results of these tests are used in equation (1) it is seen that using the novolac epoxy resin exhibited significantly larger interfacial shear strength than did bisphenol-A type epoxy resin. The shape of the microdroplets for the different epoxy resins was also examined using a reflective microscope. Figure 5 shows photographic results of this examination. The shapes of the novolac resin microdroplets on the glass fibers were narrower than those of the bisphenol-A epoxy resin. The visual differences in the static contact angle between the glass fiber and the two epoxy resins, that is evident in these photographs is consistent with these differences in shape.

Interfacial properties between glass fiber and epoxy resins

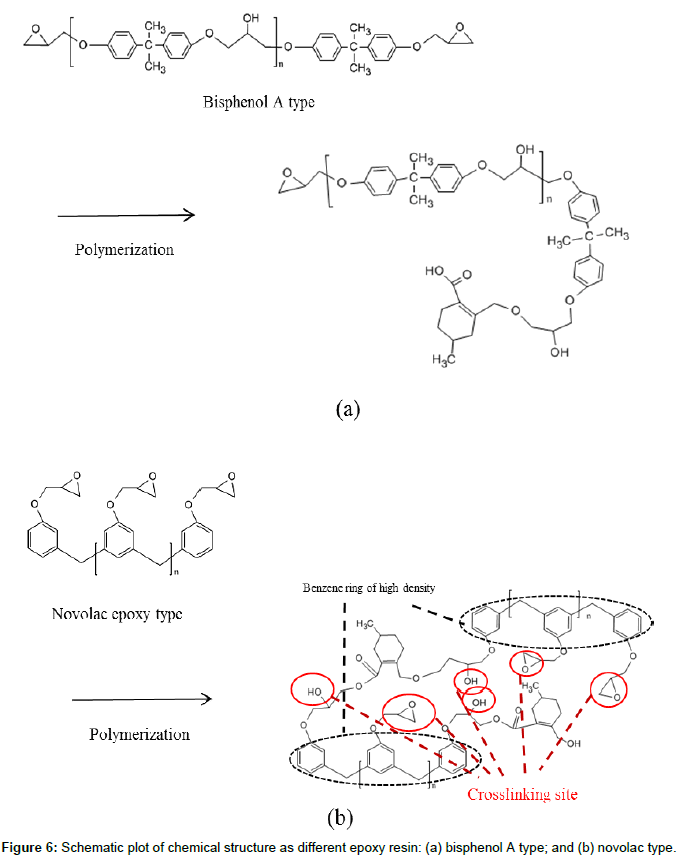

Figure 6 shows molecular structural modeling for the two different epoxy resins showing their functional groups. There are a number of hydroxyl groups and benzene rings in novolac type epoxy whereas the bisphenol-A type epoxy has fewer hydroxyl groups along with several benzene rings. When novolac epoxy resin makes contact with a glass fiber, hydroxyl groups on the surface of novolac and glass fiber form hydrogen bonds and it leading to improvement of interfacial properties. In addition, the novolac epoxy resin contains a number of the amount of benzene rings bringing about a unidirectional alignment of novalac epoxy to resulting in the improvement in mechanical properties of composites. On the other hand the bisphenol-A type epoxy has fewer hydroxyl groups and benzene rings resulting in less mechanical and interfacial properties.

Conclusions

The optimal conditions for glass fiber/epoxy composites were investigated using two different composite matrices (bisphenol-A type epoxy and novolac type epoxy). The thermal properties of novolac type epoxy were generally better than those of the bisphenol-A type epoxy resin. The glass transition temperature of novolac type epoxy was higher than it was for bisphenol-A type epoxy resin. The novolac type epoxy and composites had superior strength under all three modes of loading. The novolac epoxy resin with glass fiber exhibited significantly larger interfacial shear strength than did bisphenol-A type epoxy resin. When novolac epoxy resin makes contact with a glass fiber, hydroxyl groups on the surface of novolac and glass fiber form hydrogen bonds leading to improvement of interfacial properties. In addition, the novolac epoxy resin containing the amount of benzene ring brings about the unidirectional alignment of novalic epoxy resulting in the improvement of mechanical properties of the composites.

Acknowledgements

This work was supported by the National Research Foundation of Korea (NRF) grant funded by the Korea government (MOE) (No. 2016R1D1A1B01012620), 2016-2022, plus by the BK21 Plus Program (Future-oriented innovative brain raising type, 21A20151713274) funded by MOE and NRF, Korea.

References

- Rosu D, Cascaval CN, Musta F, Ciobanu C (2002) Cure kinetics of epoxy resins studied by non-isothermal DSC data. Thermochim Acta 383: 119-127.

- Yadav R, Srivastava P, Srivastava D (2009) Studies on synthesis of modified epoxidized novolac resin from renewable resource material for application in surface coating. Journal of Applied Polymer Science 114: 1471-1484.

- Campaner P, D'Amico D, Longo L, Stifani C, Tarzia A (2009) Cardanol-based novolac resins as curing agents of epoxy resins. Journal of Applied Polymer Science 114: 3585-3591.

- Carra G, Carvelli V (2014) Ageing of pultruded glass fibre reinforced polymer composites exposed to combined environmental agents. Composite Structures 108: 1019-1026.

- Shin PS, Wang ZJ, Kwon DJ, Choi JY, Sung I, et al. (2015) Optimum mixing ratio of epoxy for glass fiber reinforced composites with high thermal stability. Composites Part B 79: 132-137.

- Wong KH, Mohammed DS, Pickering SJ, Brooks R (2012) Effect of coupling agents on reinforcing potential of recycled carbon fibre for polypropylene composite. Composites Science and Technology 72: 835-044

- Kwon DJ, Wang ZJ, Choi JY, Shin PS, DeVries KL, et al. (2015) Interfacial evaluation of carbon fiber/epoxy composites using electrical resistance measurements at room and a cryogenic temperature. Composites Part A 72: 160-166.

Relevant Topics

- Additive Manufacturing

- Coal Mining

- Colloid Chemistry

- Composite Materials Fabrication

- Compressive Strength

- Extractive Metallurgy

- Fracture Toughness

- Geological Materials

- Hydrometallurgy

- Industrial Engineering

- Materials Chemistry

- Materials Processing and Manufacturing

- Metal Casting Technology

- Metallic Materials

- Metallurgical Engineering

- Metallurgy

- Mineral Processing

- Nanomaterial

- Resource Extraction

- Rock Mechanics

- Surface Mining

Recommended Journals

Article Tools

Article Usage

- Total views: 5109

- [From(publication date):

July-2017 - Dec 03, 2024] - Breakdown by view type

- HTML page views : 4264

- PDF downloads : 845