Low Temperature Combustion after Treatment Strategy and Particle Emission Correlation with different Ratio of Dual Fuel

Received: 02-Jan-2023 / Manuscript No. ogr-22-81799 / Editor assigned: 04-Jan-2023 / PreQC No. ogr-22-81799 (PQ) / Reviewed: 18-Jan-2023 / QC No. ogr-22-81799 / Revised: 23-Jan-2023 / Manuscript No. ogr-22-81799(R) / Published Date: 27-Jan-2023 DOI: 10.4172/2472-0518.1000280

Abstract

Low-Temperature combustion (LTC) has demonstrated huge potential to simultaneously control nitrogen oxide (NOx) and particle matter (PM) significantly in automotive engines. Hydrocarbons (HCs) and carbon monoxide (CO) are key challenges due to low combustion temperatures in dual fuel combustion. The selection of diesel oxidation catalyst (DOC) and precious group metal (PGM) content is critical for low-temperature combustion (dual fuel) to control HC and CO emissions norms. An experimental test bed study was conducted in a 3.8 litre diesel common rail engine with a gasoline port injection to evaluate the after-treatment strategy in low and high-reactive fuel. Three DOCs with different PGM content were tested along with different dual fuel compositions to understand their effectiveness and particle matter composition. The chemical composition of exhaust particles from engine Out and DOC out are compared. An increase in low reactive fuel (D15G85) and an increase in PGM content highlights a significant reduction in PM from 31 mg/kWhr to 2 mg/kWhr. The major reduction in particle size distribution observed with high PGM loading is 40 nm with a dual fuel configuration of D15G85 as the best approach to meet emission standards. Additionally, a detailed study was made to investigate the characteristics of particle mass and particle size distribution in the engine and after-treatment emissions. The particle number (PN) and their correlation for engine out, DOC Out, and DPF out emission are demonstrated with different dual fuel combinations of D50G50, D25G75, and D15G85 compared with diesel fuel. To comprehend its characteristic of particle number and particle mass correlation, dual fuel is tested in different ratios. A linear correlation of PM and PN emissions is observed between engine out and DOC out as particulate diameter of the particle size with the total number concentration of particles in engine and DOC out. The nonlinear trend is observed for DPF out due to small particle size (around 5nm) with different ratios of dual fuel. Particle matter filter paper analyses were performed to understand chemical composition with different DOCs and dual fuel ratios to understand Soluble Organic Fraction (SOF) and Insoluble Organic Fraction (IOF) content.

Keywords

Particle Number; Particle mass; Diesel Oxidation Catalyst; Diesel Particle Filter; Precious Group Material; Hydrocarbon; Carbon monoxide

Abbreviations

HC- Hydrocarbon; CO - Carbon Monoxide; PM - Particle Matter; NOx - Oxides of Nitrogen; LTC - Low temperature combustion; PN - Particle Number; Nm – Newton Meter; nm- Nanometer; mmmillimetre; CI- Compression Ignition; EMS- Engine Management System; EGR- Exhaust Gas Recirculation; CO2 - Carbon Dioxide; ECU – Electronic Control Unit; NABL - National Accreditation Board for Testing and Calibration Laboratories; IOCL – Indian Oil Corporation Limited; D100- Diesel Fuel Only; D50G50 – Diesel 50% and Gasoline 65%; D25G75 – Diesel 25% and Gasoline 75%; D15G85 – Diesel 15% and Gasoline 85%; DOC – Diesel Oxidation Catalyst ; DPF – Diesel Particle Filter; SCR – Selective Catalyst Reduction; BSVI – Bharat Stage VI Emission; PGM – Precious Group Material; SOF – Soluble Organic Fraction; IOF – Insoluble Organic Fraction; GVW – Gross Vehicle Weight

Introduction

LTC is advanced dual fuel combustion having different reactivity of fuel to get optimised emission in different engine operating points [1-3]. This is a proven technology and demonstrated in multiple diesel engines operated with a different blending of fuel of low and high reactive fuel along with the different compositions of dual fuel [4-6]. LTC reduces significantly both NOx and PM during combustion with dual fuel due to low temperature [7-8]. Lower in-cylinder temperature leads to incomplete combustion of premixed low reactive fuel-air combination and prevents stored or trapped fuel-air mixture from participating in combustion, which is the cause of greater CO and HC emissions [9-10]. The major challenge is HC and CO emissions from LTC combustion, which can be only addressed with DOC [11- 13]. DOC contains different amounts of PGM content like Platinum (Pt) and Palladium (Pd) to reduce both HC and CO emissions [14- 15]. The selection of DOC and PGM is the most important factor to meet the emission level of Bharat Stage VI (BSVI) with dual fuel combustion. This can be optimised based on application, cost, and emission durability requirements for any engine. Particle number and particle mass from diesel engine emissions attract attention due to health-related concerns. Particle size with a diameter of 10 microns or less (PM10) can cause lung-related problems in the human body. Fine particle matter (PM2.5) is defined as a particle with a diameter of 2.5 millimetres or less. This results in PM2.5 making up a fraction of PM10. The composition of particulates PM10 and PM2.5 are made up of distinct chemicals and come from diverse sources of pollution. This is causing casualties from air pollution-related causes such as heart disease, lung cancer, and other respiratory disorders [16].

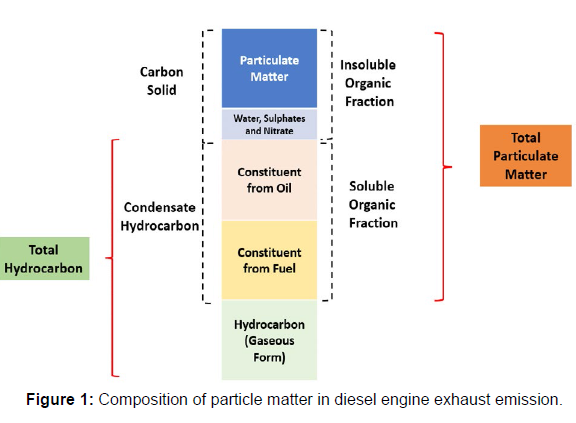

Multiple pieces of literature highlighted the impact of particle matter health effects depending on its composition, particle size, and particle nature [17-18]. Particle emissions concentration is very high in a diesel engine in comparison to gasoline engines because of the high carbon content in the exhaust gas. This is very important to understand the formation of particle matter with gasoline and diesel fuel with respect to particle number and size distribution characteristics. Diesel exhaust particle matter emission composition contains carbon soot with compounds of absorbed organic which increase during gas to particle conversion method [19]. PM consists of the composition of fine particles, and liquid drops including ash, water SOF, nitrates, and oil and fuel content (SOF) from diesel engines [20]. Smoke opacity indicates the amount of soot in the exhaust gas. The majority of particle matter is generated by incomplete combustion of fuel hydrocarbons and oil with lubricating oil playing a minor role.

Particle Emission formation in High Reactivity Fuel Combustion

Due to high injection pressure and temperature in diesel engines, there was better fuel atomisation and spray penetration which leads to better mixing of air and fuel with better combustion efficiency. Due to the non-uniform dispersion of these droplets, the excess air ratio value changes at every position of the combustion chamber. This is relatively low near the droplet surface and increases as you get further away from it. The local excess air ratio is particularly low near droplets, indicating that incomplete combustion is caused due to a lack of oxygen. PM is formed mostly due to incomplete combustion. Particle matter consists of an Insoluble organic fraction (IOF) and a soluble organic fraction (SOF) as explained in Figure.1 [Figure 1]

Particle Emission formation in Low Reactivity Fuel Combustion

In an SI engine, achieving optimum combustion and temperature require the presence of liquid fuel and oxygen to ignite the mixture, and determine particle formation in a heterogeneous phase reaction. Particle matter in gasoline engines is strongly influenced by air /fuel ratios of both global and local ratios. To achieve minimum particle mass concentration and PN, the ratio of global air/fuel ratio should be below 10% of the stoichiometric ratio. Multiple experiments and researchers highlighted from PM are lowest when the stoichiometric air/fuel ratio is 10-20% lean and further increases when the ratio is rich or extremely lean in SI engines [21-22].

Particle Emission formation in Low-Temperature Combustion

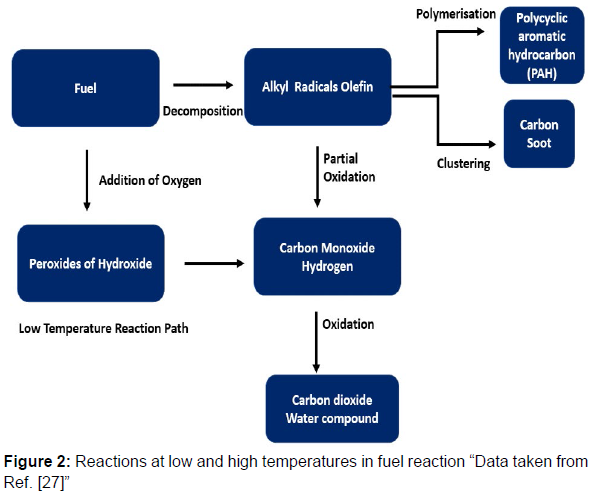

Many studies have shown that reduction of combustion temperature can reduce both levels of soot formation and NOx emissions simultaneously with dual fuel [23]. Soot production in LTC mode occurs mainly downstream in the jet’s head as opposed to the upstream soot-producing core found in traditional jets in diesel combustion engines [24]. The charge dilution as well as mixing between the end of injection and second-stage ignition account for this change used in LTC. The relationship between soot reduction and NOx reduction is more complicated in LTC combustion. At about 48 percent EGR, PCI combustion conditions achieved by late injection have been documented to produce very low amounts of particle matter in engine out emission [25]. Denbratt and Alriksson [26] experiment data mention that 50% of EGR with 25% load found the lowest peak combustion temperature. They have observed an increase of soot up to 50% EGR and abruptly decreased due to soot oxidation in this condition. Figure 2 shows the reaction pathway of diesel combustion in low and high-temperature combustion and its related emission products. [Figure 2] “Data taken from Ref. [27]”

Dual fuel combustion results in a significant reduction of NOx and PM emissions. However, it also leads to an increase in HC and CO emissions. A Diesel Oxidation Catalyst (DOC) can play an important role in reducing HC and CO emissions. The selection of DOC and its PGM loading content is very important to meet the stringent emission norms. DOCs with different PGM loading are evaluated to understand their impact on SOF and HC reduction. The major motivation for this study is to understand the correlation between particle matter and particle number from the engine out, DOC out, and DPF out with different dual-fuel configurations. This correlation assists in optimising EATS selection to meet emission norms. The novelty of the work is the study of particle matter behaviour and composition with low reactivity and high reactivity dual-fuel in low-temperature combustion. Filter paper analysis was conducted to understand the SOF and IOF content in soot with a dual-fuel engine.

Experimental Set Up

Engine testing is performed on a four-cylinder diesel engine with a common rail diesel injection system for this experiment test in engine dyno. A gasoline injection system is installed in the intake manifold, which is controlled by EMS. The specifications of engine base hardware are given in Table 1. [Table 1]

| Engine | 3.8 L, 4-cylinder |

|---|---|

| Diesel fuel injection system | Electronic–Direct Injection System |

| Compression ratio | 17:05 |

| Maximum torque | 450 Nm @ 1200-1600 rpm |

| Maximum power | 100 kW @ 2600 rpm |

| Maximum peak combustion pressure | 160 bar |

| Bore x Stroke (mm) | 100x 120 |

| Swirl Ratio | 2.0 |

Table 1: Engine specification.

ECU is used to control gasoline and diesel injectors. Table number 2 provides technical specifications of diesel and gasoline injectors, respectively. Both injectors are precisely controlled in fuel flow demand and actual as physically verified before the engine tests. [Table 2]

| Injector Specification | Diesel Fuel Injector | Gasoline Fuel Injector |

|---|---|---|

| Type of Actuation | Solenoid Actuated | Saturated operated |

| Injector make | CRIN Bosch Injector | Bosch Injector |

| Hydraulic Through Flow | 600 mm3/30 sec | 7.2 kg/hr |

| Number of holes | 9 | 6 |

| Diameter of Hole | 0.18 mm | 65 μm |

| Injector Spray Angle | 148° | 30° |

| Maximum injection pressure | 1800 bar | 9 bar |

| Injection Strategy | Multiple Injection | Single Injection |

Table 2: Diesel and Gasoline Injector Specification.

Engine tests are conducted in AVL transient test bed dynameter. The temperature of the coolant is maintained at 80+2°C and the lubricating oil temperature is kept constant during the testing. Intake air is conditioned at 1000 millibar pressure, 25°C temperature, and 40% humidity during the tests. EGR is precisely controlled with electronic control EGR valve based on ECU input. EGR rate is expressed as the ratio of the concentration of CO2 in intake and exhaust gases. AVL AMAi60 emission analyser to measure NO, NOx, HC, CO, CO2 and O2 concentrations independently. Filter Smoke Number (FSN) and Soot Concentration are measured at engine out using AVL 415S (SM) and AVL Micro Soot Sensor (MSS). The Particle Number (PN) concentration in exhaust gas was measured using an AVL Particle Counter (APC). AVL Micro Soot Sensor uses a photoacoustic technique to measure solely solid components of particle matter (mainly soot). Smokemeter measures the blackening of filter paper through which exhaust gases flow in the measurement line. A detailed description of test bed instrumentation and its accuracy is mentioned in Table 3. [Table 3] Diesel (High Reactive) and gasoline (Low Reactive) fuels are considered for this experimental study as this widely used across the world. Both these fuels are hydrocarbon derivative fossil fuels used for the internal combustion engine. The fuel ignition delay period and selfignition temperature properties of both fuels differentiate them and impact combustion behaviour. The physical and chemical properties of fuels verified in IOCL Lab (NABL Certified) are compared in Table 4. [Table 4]

| Instrumentation Unit | Model Type | Operating principle | Accuracy |

|---|---|---|---|

| Dynamometer | AVL | Transient Dyno | +2% |

| Speed Measurement | Magnetic Pick-Up | Inductive Principle | +5rpm |

| Torque | Load Cell | Strain gauge type load cell | +1% |

| Fuel mass flow meter | AVL – 735 | Coriolis mass flow meter | +0.5% |

| Air mass flow meter | KVG G100 | Hot film anemometer | +0.5% |

| Pressure Sensor | Piezo-resistive Transducers | Resistance-based Whitestone Type | +25 mbar |

| Temperature Sensor | Thermocouple – Type K | See-back effect | +2.5 deg C |

| FSN | Smoke Meter – AVL415S | Exhaust measurement in Filter Paper | +0.001 FSN |

| Particle Size and number | SMPS – AVL Make | Bio Polar Aerosol Charger | +3.5% |

| NOx | AVL AMAi60 | Chemiluminescence detector | 2% |

| HC | Flame ionization detector | ||

| CO | Infrared detector |

Table 3: Instrumentation and Accuracy of Test Bed Measurement Units.

| Fuel Property | Gasoline | Diesel |

|---|---|---|

| Motor Octane Number | 82 | - |

| Cetane Number | 6 | 52 |

| Molecular Weight | 110 | 190 |

| Low Caloric Value (MJ/kg) | 44.5 | 42.5 |

| Boiling Point(˚C) | 190 | 320 |

| Auto-Ignition Temperature(˚C) | 450 | 250 |

| In Flammability limit | 6.9 | 7.7 |

| Latent heat(kJ/kg) | 310 | 270 |

| Viscosity(20˚C) (cP) | 0.29 | 3.9 |

Table 4: Major important Fuel Chemical Properties (Gasoline and Diesel) used in trials.

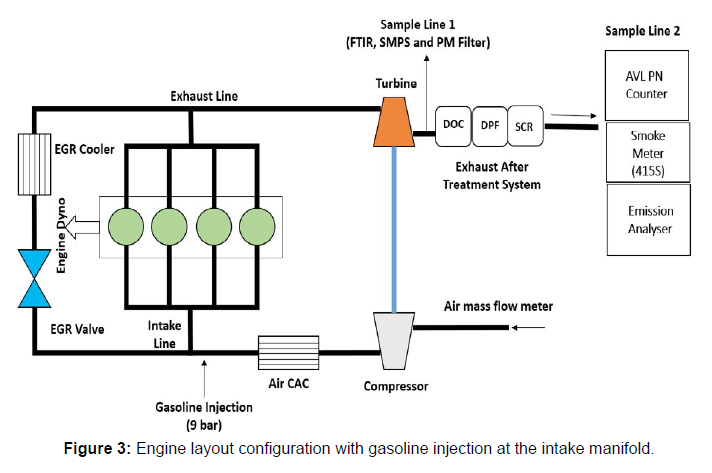

A schematic of the engine and instrument layout is given in Figure 3. Single-point gasoline injection is used in the intake manifold of the engine for this experimental test. Two sample line emission analysers are used pre and post-after-treatment systems to understand their emission characteristic and behaviour. Different configuration of DOCs samples was used to understand particle matter and particle number behaviour. Filter paper analysis is done to understand the characteristic of IOF and SOF content with different content of the dual-fuel composition. [Figure 3]

Filter paper analysis is performed on particle mass emissions on filter paper. The primary, secondary and blank filter papers holding particle matter are separately weighted and both filters are taken together with Soxhlet solvent extraction in the laboratory. For SOF analysis, chromatographic is analysed to determine fuel compostion and oil-derived hydrocarbon fractions in SOF using the method of standard IP 442 testing conditions. IOF Contents were analysed by Thermo Gravimetric Analysis (TGA) method. Particle matter collected on primary, secondary and black filter paper is subjected to a TGA test after solvent extraction. The Thermo grams are evaluated for weight loss over the defined temperature range of 40- 540°C and 540-700°C to determine (sulphates +nitrates+ water) and (carbon soot and metal oxide + others). AVL Smoke meter is used for measurement of FSN (Filter Smoke Number). FSN is an index that measures the number of carbon particles (soot) available in exhaust gas.

Three configurations of DOCs were evaluated with different PGM content to understand particle mass and particle number trend. Filter paper analysis was carried out to understand SOF and IOF with a different configuration of the dual fuel composition. Technical specification of three numbers of different configurations of the diesel oxidation catalyst is compared in Table no. 5. [Table 5]

| Specification | DOC 1 (Configuration 1) |

DOC 2 (Configuration 2) |

DOC 3 (Configuration 3) |

|---|---|---|---|

| Diameter | 9.5" | 9.5" | 9.5" |

| Length | 3" | 3" | 3" |

| Volume (lts) | 3.48 | 3.48 | 3.48 |

| Substrate Material | Cordierite | Cordierite | Cordierite |

| Nobel Material |

Platinum and Palladium | Platinum and Palladium |

Platinum and Palladium |

| PGM loading | 10 g/cft3 | 15 g/cft3 | 20 g/cft3 |

| Pt: Pd Ratio | 4:1 | 4:1 | 4:1 |

| CPSI | 300 | 300 | 300 |

Table 5: Technical Specification of Diesel Oxidation Catalyst Configuration.

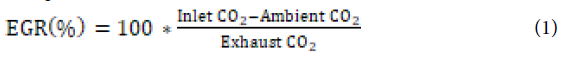

The technical specification of DPF is given in Table 6. [Table 6] To measure EGR , inlet CO2 is mounted in intake manifold and exhaust CO2 is measured after turbo out during test bed trials and EGR is calculated as per equation 1.EGR is measured as per below equation for all experimental trials:

| Specification | DPF Specification |

|---|---|

| Diameter | 9.5" |

| Length | 6" |

| Volume (lts) | 7.55 |

| Substrate Material | Recrystallized Silicon Carbide (RSiC) |

| Nobel Material | Platinum and Palladium |

| PGM loading | 4 g/cft3 |

| Pt: Pd Ratio | 4:1 |

| CPSI | 300 |

Table 6: Technical Specification of Diesel Particle Filter.

Results and Discussion

Effect of PGM Loading in DOC with Dual Fuel

The particle number and size distribution are important aspects to meet the standards set by Bharat Stage VI (BSVI) legislative emissions. Limits on particle number are added in BSVI emission regulation to protect the environment and human health. Emission limits of BSVI emission norms for PN are 6x 10^11 and PM is 0.02 g/kWhr in WHTC cycle above 3.5 Ton vehicle GVW condition [GSR No. 510(E)]. Selection of DOC and PGM content is critical for low-temperature combustion (dual fuel) to control HC and CO indirectly reducing particle mas through SOF content. SOF content in particle exhaust is critical to increasing both particle size and number. Particle mass emission is reduced compared to base engine out emission with the use of DOC system due to reduction of SOF in exhaust particle emission. Technical evaluation of DOC was done with the configuration of PGM loading. Diesel oxidation catalyst reduces hydrocarbon and carbon monoxide from exhaust along with reduction of the soluble organic fraction. Conversion efficiency majorly depends upon exhaust mass and temperature along with the PGM loading of the catalyst. An increase of noble metal content (Platinum) in DOC wash coat leads to improving the light-off property at the lower temperature required for conversion of HC and CO along with better efficiency to reduce SOF content from particle matter. No selective catalyst reduction (SCR) is required to control NOx and a diesel particulate filter (DPF) for PM norms is required with dual fuel due to the very low value (Below 0.001 g/kWhr) observed during testing with dual fuel in this engine mode. Hence, the technical approach for after treatment with dual fuel will be the only requirement of DOC to control HC and CO. Engine out PM and NOx is negligible. Tested all 3 samples of DOCs (different PGM loading) can control both HC and CO. This has an impact on the particle number and particle size behaviour due to different content of PGM loading in DOCs.

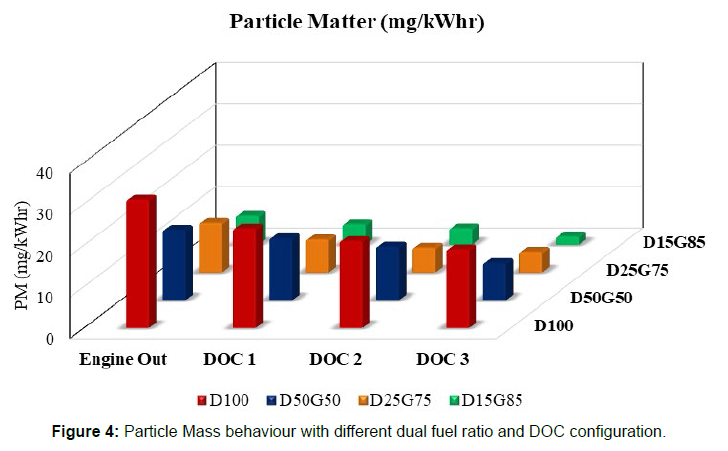

An experiment was conducted with different compositions of dual fuel (Diesel and Gasoline) from D50G50, D25G75 and D15G85. The results were compared with emissions for pure diesel fuel. The engine was tested at an engine speed of 1500 rpm and a torque of 250 Nm with a constant EGR of 20% across all tests. Dual fuel composition was varied maintaining the same torque to understand its particle matter behaviour. Engine out particle mass reduced from 31 mg/kWhr to 19 mg/kWhr with different DOC configurations. DOC3 showed a high reduction in particle mass due to the high content of noble material (Platinum) that helps in better oxidation of HC, CO and SOF. The increase of low reactive fuel (D15G85) along with an increase of PGM (Platinum) in DOC3 is giving the best result which leads reduce significantly from 31 mg/kWhr to 2 mg/kWhr as per Figure 4.

Effect of composition with Dual Fuel on Particle Mass Emission Particle mass decreased with an increase in low reactive fuel (gasoline) as highlighted in Figure 4. Increase of low reactive fuel in dual fuel reduced particle mass from 31 mg/kWhr for (D100) to 7 mg/ kWhr for (D15G85). The presence of a homogeneously mixed gasoline elongates ignition delay due to lower temperatures of intake charge which also leads to lower combustion temperature. The strategy to increase low reactivity fuel (gasoline) in diesel engine combustion is a methodology to reduce particle mass from exhaust emission. [Figure 4]

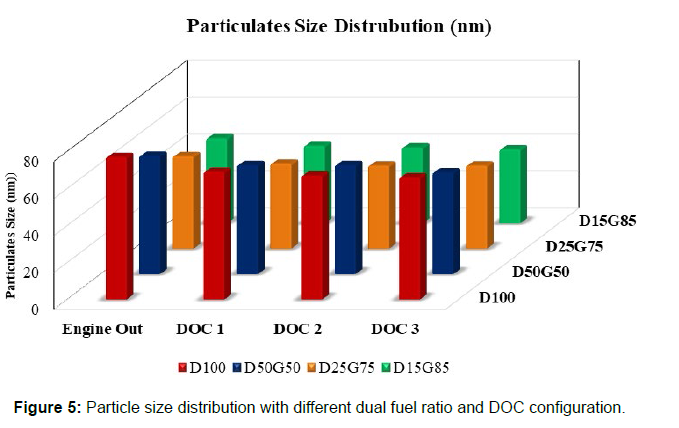

Effect of composition with Dual Fuel on Particle Size distribution

Particle size distribution in different dual fuels from D50G50, D25G75 and D15G85 is compared with diesel fuel (D100). The test condition was kept at 1500 rpm engine speed and a torque of 250 Nm with fixed EGR content of 20% was applied. In test data, particle size distribution reduced from 71 nm to 46 nm with an increase of gasoline content from 0% to 85% in dual fuel. No major particle size distribution impact was observed with DOC out with all three DOCs tested during the experiment. The increase of PGM content in DOC plays is having a minor impact on particle size distribution between engine out and DOC out. The behaviour of particle size distribution with different ratios of dual fuel and DOCs is highlighted in Figure 5. The major reduction in particle size distribution observed with DOC3 is 40 nm with a dual fuel configuration of D15G85. The possible cause of this minor reduction in particle size distribution is due to very less soot oxidation taking place inside DOC with dual fuel combustion. [Figure 5]

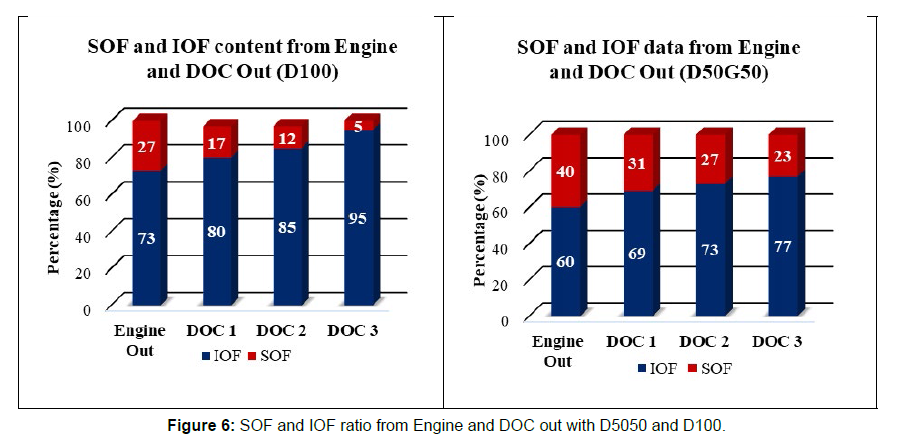

SOF and IOF distribution percentage from Engine and DOC Out with Dual Fuel

Filter paper analysis conducted on particle mass emissions emitted from the engine. IOF and SOF analysis are performed from the engine out emission and all three DOC’s out to investigate SOF and IOF content from exhaust emission with dual fuel composition of D50G50 and compared with D100 engine. SOF is formed with hydrocarbon derived from lube oil and diesel fuel. Figure 6 highlights that DOC is useful to reduce SOF content in particle matter from D50G50 and D100 fuels. An increase of Platinum content in DOC from DOC1 (10 g/cft3) to DOC3 (20 g/cft3) helps in the reduction of SOF content from 17% to 5% in D100 fuel. A similar pattern was observed with D50G50 composition where SOF content is reduced from 31% to 23% with an increase in PGM content. The amount of SOF content is high with D50G50 fuel due to the increase of unburnt hydrocarbon observed in this combustion. However, the total particle mass and particle number are less with D50G50 fuel. [Figure 6]

The selection of DOC configuration and its precious material content is crucial for low-temperature combustion as this reduces both the high content of hydrocarbon and passive soot oxidation in SOF. It can be observed that BSVI emission can be achieved only from DOC with this low-temperature combustion technology.

Correlation of Particle Mass and Particle Number with Dual Fuel Ratio

Kittelson [27] highlighted the relationship between particle mass and particle number with respect to particle size distribution. Test results described in this work highlight that the contribution of smaller particle size is very low for particle mass formation and larger particle size is having fewer particle numbers with an increase of particle mass. An experimental study was performed to understand the behaviour and correlation of particle number size distribution, particle mass, and particle number emissions trend after engine out, DOC out and DPF out with D50G50, D25G75 and D15G85 dual fuel in comparison to conventional diesel fuel. In the experiment test, it was observed that particle number and particle mass follow an almost linear correlation in engine out found with diesel and different dual fuel ratios. This leads to PM to PN correlation being only stable when the agglomeration rate is low as per results shown in Figure 7. This relationship between particle number and particle mass emissions pattern gets changed after DPF out in comparison with the engine out. This characteristic and behaviour pattern between particle number and particle mass emission characteristics could be useful to work in areas of the after-treatment solution. No correlation was observed for PN with PM emissions in DPF out both for diesel and dual fuels. An increase of low reactivity fuel in diesel fuel leads to a very small particle number size due to a homogeneous mixture inside combustion. [Figure 7]

Diesel engine out emission contains large mass concentration from the exhaust as found during test data. From DOC out, due to the reduction of SOF part, the PN number is reduced from the engine out test data as shown in Figure 7. The best approach to control PM and PN is to increase low reactive fuel in dual fuel combustion.

Conclusion

The experimental investigation on engine emission was performed to understand particle mass and particle size distribution with different compositions of dual fuel. Particle emissions from the engine out, DOC out, and DPF out are compared to understand the correlation among these. The PM emission and PN characteristics are studied with dual-fuel combustion. High-reactive diesel fuel is combined with low-reactive gasoline port injection. Test results show that the dualfuel concept can escape from NOx, a smoke trade-off, reducing both to near zero values but leading to the challenge of increasing HC and CO emissions. This analysis of particle mass and particle size experimental study was performed in a single operating condition. In the future, further studies need to be performed across all engine mode points to have similar emission trend.

1. An advantage to reducing NOx and PM emissions with LTC combustion leads to an increase in HC and CO emissions. This can only be controlled through DOC with PGM contained as an after-treatment device. No SCR and DPF are required to meet BSVI with dual fuel.

All three DOCs with different PGM content can meet HC and CO emissions for BSVI norms limit. SOF content in exhaust gases has a direct relation with particle matter and number. Due to the increase of Pt contained in DOC, the particle size and particle number pattern trend are different with dual fuel ratio.

2. Diesel oxidation catalyst and its PGM content are critical to meet emission levels with dual fuel combustion. Particle mass can be reduced to 99% without DPF with dual-fuel (D15G85) and DOC3 with PGM loading of 20 g/cft3. Nobel material content (PGM) in DOC helps in the reduction of HC and CO emissions along with SOF content from emission. No significant impact was observed in particle number size distribution found with DOCs with an increase in Platinum content.

3. Subsequently, the increase in low reactive fuel (D15G85) and PGM content (DOC3) reflects a significant reduction in PM from 31 mg/kWhr to 2 mg/kWhr as per experimental data. This combination provided the optimised particle size distribution at 40 nm with different dual fuel ratios. In low-temperature combustion (dual fuel), to control HC and CO emissions selection of DOC and PGM content is most critical and important to meet emission standards.

4. High hydrocarbon content is observed reflecting a similar trend followed in SOF content with an increase of gasoline content from G50 to G85 with diesel fuel as a result of extremely low air/fuel ratios. An increase in the amount of gasoline fuel in the combustion chamber leads to unburnt hydrocarbon in form of liquid fuel which cannot fully burn before being discharged into the exhaust.

5. Particle mass and Particle Number show a linear correlation for engine out and DOC out condition emission with diesel and dualfuel due to high particle mass emission from the engine out from the engine. This is due to the low agglomeration rate and high content of non-volatile fractions (soot) emissions from the engine out. Particle mass above 22 mg/kWhr showed linear behaviour with particle number.

6. Particle mass below 10 mg/kWhr displayed a nonlinear behaviour trend with respect to PN number after DPF out emissions. This is nonlinear due to significantly low PM and PN after high filtration efficiency of DPF. Due to the presence of semi-volatile particles from DPF out, the trend and correlation of particle number and particle mass will behave as chemical composition difference between particles mass as well as different size distributions.

7. An increase in the amount of gasoline in dual-fuel leads to a reduction of PM and PN as the mixture becomes a more homogeneous fuel-air mixture resulting in low levels of PN emissions compared to D100 fuel. To meet BSVI emission norms, the limits of NOx (460 mg/ kWhr) and PM (200 mg/kWhr) both SCR and DPF are not required in the after-treatment system with dual fuel combustion. DOC is only required to meet emission for BSVI emission with this low-temperature combustion technology using low and high reactive fuel having low cost after the treatment system.

References

- Kokjohn S, Hanson R, Splitter D, Reitz R (2010) “Experiments and Modeling of Dual-Fuel HCCI and PCCI Combustion Using In-Cylinder Fuel Blending.” SAE Int J Engines 2(2): 24-39.

- Splitter D, Hanson R, Kokjohn S, Reitz R (2011) “Reactivity Controlled Compression Ignition (RCCI) Heavy-Duty Engine Operation at Mid-and High-Loads with Conventional and Alternative Fuels.” SAE Technical Paper 1: 363.

- Hanson R, Kokjohn S, Splitter D, Reitz R (2010) “An Experimental Investigation of Fuel Reactivity Controlled PCCI Combustion in a Heavy-Duty Engine.” SAE Int J Engines 3(1): 700-716.

- Kokjohn S, Reitz R, Splitter D, Musculus M (2012) “Investigation of Fuel Reactivity Stratification for Controlling PCI Heat-Release Rates Using High-Speed Chemiluminescence Imaging and Fuel Tracer Fluorescence.” SAE Int J Engines 5(2): 248-269.

- Kokjohn S, Hanson R, Splitter D, Kaddatz J (2011) “Fuel Reactivity Controlled Compression Ignition (RCCI) Combustion in Light- and Heavy-Duty Engines.” SAE Int J Engines 4(1): 360-374.

- Curran S, Prikhodko V, Cho K, Sluder C (2010) “In-Cylinder Fuel Blending of Gasoline/Diesel for Improved Efficiency and Lowest Possible Emissions on a Multi-Cylinder Light-Duty Diesel Engine.” SAE Technical Paper 1: 2206.

- Curran S, Cho K, Briggs T, Wagner R (2011) “Drive Cycle Efficiency and Emissions Estimates for Reactivity Controlled Compression Ignition in a Multi-Cylinder Light-Duty Diesel Engine.” Proceedings of the 2011 Conference, ICEF2011, Morgantown WV.

- Curran S, Hanson R, Wagner R (2012) “Effect of E85 on RCCI Performance and Emissions on a Multi-Cylinder Light-Duty Diesel Engine.” SAE Technical Paper 1: 0376.

- Curran S, Hanson R, Wagner R (2012) “Reactivity controlled compression ignition (RCCI) combustion on a multi-cylinder light-duty diesel engine.” International Journal of Engine Research

- Hanson R, Curran S, Wagner R, Kokjohn S (2012) “Piston Bowl Optimization for RCCI Combustion in a Light-Duty Multi-Cylinder Engine.” SAE Int J Engines 5(2): 286-299.

- Curran S, Szybist J, Wagner R (2012) “Reactivity Controlled Compression Ignition Performance with Renewable Fuels.” ICEF2012-92192, Proceedings of the ASME 2012 Internal Combustion Engine Division Fall Technical Conference

- Prikhodko V, Parks J (2009) “Implications of Low Particle Matter Emissions on System Fuel Efficiency for High Efficiency Clean Combustion.” SAE Technical Paper 1: 2709.

- Prikhodko V, Curran S, Barone T, Lewis S (2010) “Emission Characteristics of a Diesel Engine Operating with In-Cylinder Gasoline and Diesel Fuel Blending.” SAE Int J Fuels Lubr 3(2): 946-955.

- Barone T, Storey J, Prikhodko V, Curran S, Parks J, et al. (2011) “Particle Emissions Reduction by In-Cylinder Blending of Gasoline and Diesel Fuel.” 21st CRC Real World Emissions Workshop San Diego CA

- Prikhodko V, Curran S, Barone T, Lewis S, Storey J, et al. (2011) “Diesel Oxidation Catalyst Control of Hydrocarbon Aerosols from Reactivity Controlled Compression Ignition Combustion.” Proceeding of the ASME 2011 IMECE 11: 64147.

- WHO (2018) Ambient (outdoor) air pollution report.

- Wu Y, Zhang S, Hao J, Liu H, Wu X (2017) On-road vehicle emissions and their control in China: A review and outlook. Science of the Total Environment 574: 332-349.

- Longhin EM, Mantecca P, Gualtieri M (2020). Fifteen years of airborne particulates in vitro toxicology in milano: lessons and perspectives learned. International journal of molecular sciences 21(7): 2489.

- Heywood JB (1988) Internal combustion engine fundamentals. Singapore McGraw Hill

- Northrop WF Assanis D Bohac S (2011) Evaluation of diesel oxidation catalyst of hydrocarbons and particle matter from premixed low temperature combustion of biodiesel. SAE Int 4:1431-1444.

- Rizwanul Fattah IM, Masjuki HH, Liaquat AM, Ramli R, Kalam MA, et al. (2011) Impact of various biodiesel fuels obtained from edible and non-edible oils on engine exhaust gas and noise emissions. Renew Sustain Energy Rev 18: 552-567.

- Pope CA, Dockery DW (2006) Health effects of fine particle air pollution: lines that connect. J Air Waste Manag Assoc 56: 709-742.

- Kittleson DB (1998) Engines and nanoparticles: a review. J Aerosol Sci 29(5-6): 575–588.

- Jacobs TJ, Assanis DN (2007) The attainment of premixed compression ignition low temperature combustion in a compression ignition direct injection engine. Proc Combust Inst 31: 2913-2920.

- Machrafi H (2010) HCCI combustion chemistry reduced kinetic mechanisms and controlling strategies. In: Handbook of combustion. Wiley-VCH Verlag GmbH and Co

- Alriksson M, Denbratt I (2006) Low temperature combustion in a heavy-duty diesel engine using high levels of EGR. SAE technical paper 01: 75.

- Kittelson DB, Dolan DF, Beaver MC (1979) Presented at Central States Section of the Combustion Institute. Paper CSS/CI-79-09.

Indexed at, Google Scholar, Crossref

Indexed at, Google Scholar, Crossref

Indexed at, Google Scholar, Crossref

Indexed at, Google Scholar, Crossref

Indexed at, Google Scholar, Crossref

Indexed at, Google Scholar, Crossref

Indexed at, Google Scholar, Crossref

Indexed at, Google Scholar, Crossref

Indexed at, Google Scholar, Crossref

Indexed at, Google Scholar, Crossref

Indexed at, Google Scholar, Crossref

Indexed at, Google Scholar, Crossref

Indexed at, Google Scholar, Crossref

Indexed at, Google Scholar, Crossref

Indexed at, Google Scholar, Crossref

Indexed at, Google Scholar, Crossref

Indexed at, Google Scholar, Crossref

Indexed at, Google Scholar, Crossref

Indexed at, Google Scholar, Crossref

Indexed at, Google Scholar, Crossref

Indexed at, Google Scholar, Crossref

Indexed at, Google Scholar, Crossref

Indexed at, Google Scholar, Crossref

Indexed at, Google Scholar, Crossref

Citation: Barman J (2023) Low Temperature Combustion after Treatment Strategy and Particle Emission Correlation with different Ratio of Dual Fuel. 280. DOI: 10.4172/2472-0518.1000280

Copyright: © 2023 Barman J. This is an open-access article distributed under the terms of the Creative Commons Attribution License, which permits unrestricted use, distribution, and reproduction in any medium, provided the original author and source are credited.

Share This Article

Recommended Journals

Open Access Journals

Article Tools

Article Usage

- Total views: 2017

- [From(publication date): 0-2023 - Apr 02, 2025]

- Breakdown by view type

- HTML page views: 1682

- PDF downloads: 335