Image Open Access

Lobo System Scaffold

Robert Bokros*LOBO Systems Ltd, UK

- *Corresponding Author:

- Robert Bokros

Managing Director, LOBO Systems Ltd, UK

Tel: +44(0)1332 365666

E-mail: r.bokros@lobosystems.com

Received Date: January 31, 2017; Accepted Date: February 01, 2017; Published Date: February 02, 2017

Citation: Bokros R (2017) Lobo System Scaffold. Oil Gas Res 3: i104. doi: 10.4172/2472-0518.1000i104

Copyright: © 2017 Bokros R. This is an open-access article distributed under the terms of the Creative Commons Attribution License, which permits unrestricted use, distribution, and reproduction in any medium, provided the original author and source are credited.

Visit for more related articles at Oil & Gas Research

Abstract

Further to our visit to LOBO’s premises to witness demonstrations of the systems being erected. A site visit by LOBO to Bacton Gas plant to demonstrate the system was carried out on Wednesday, 28/09/2016. LOBO was provided with five different scenarios to which they provided detailed drawings in preparation to erect on site. A site visit was arranged and LOBO attended site to demonstrate erecting and dismantling the system. This report details the type of scenario where LOBO can be used and provides advantages/disadvantages of the system. This report goes into detail on erect and dismantles times where major cost savings can be gained. The LOBO system also has the added benefits that it doesn’t need to be erected by trained scaffolders. Training can be carried for any individual to be competent to erect and dismantle.

Introduction

Further to our visit to LOBO’s premises to witness demonstrations of the systems being erected. A site visit by LOBO to Bacton Gas plant to demonstrate the system was carried out on Wednesday, 28/09/2016. LOBO was provided with five different scenarios to which they provided detailed drawings in preparation to erect on site. A site visit was arranged and LOBO attended site to demonstrate erecting and dismantling the system. This report details the type of scenario where LOBO can be used and provides advantages/disadvantages of the system. This report goes into detail on erect and dismantles times where major cost savings can be gained. The LOBO system also has the added benefits that it doesn’t need to be erected by trained scaffolders. Training can be carried for any individual to be competent to erect and dismantle.

Who Attended?

Paul Timson,

National Sales Manager,

Jason Currie, LOBO Technician,

Andrew Roznowski, Senior LOBO Technician.

Bilfinger,

B*** G***, Operations Manager, S**** D*****, Bacton maintenance Focal Point.

A*** F********, Jacobs BRP Focal Point, E**** B****, Multi- Discipline Foreman.

D*** R******, Scaffold Foreman.

Shell,

M*** H***, FM Coordinator, C**** C***, FM QA/QC Engineer.

AJS J** P*****, Senior Work Prep.

What was Built?

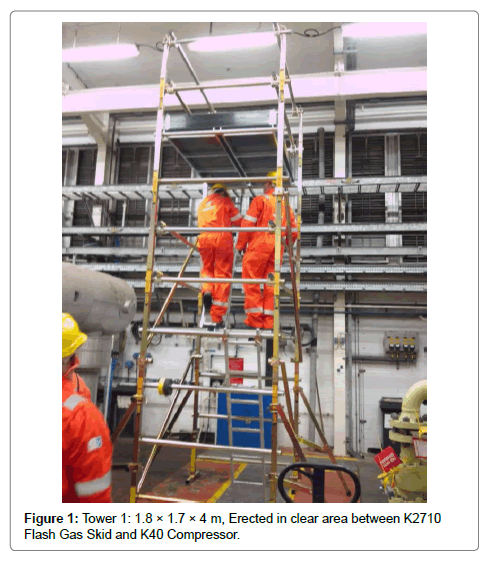

Tower 1: 1.8 × 1.7 × 4 m, Erected in clear area between K2710 Flash Gas Skid and K40 Compressor:

• LOBO Scaffold;

2 men × 1 hour to erect

2 men × 15 minutes to dismantle

Total hours 2.5 man hours

• Conventional Scaffold; Tube and fitting would take;

3 men × 5 hours to erect

3 men × 2.5 hours to dismantle

Total hours 22.5 man hours

No problems apart from the recurring issue of WAH controls during the transition of placing the guard rail on from the seated/ kneeling position when the boards are placed. A discussion was held with the team and this can be alleviated by using an advanced guard rail (Figure 1).

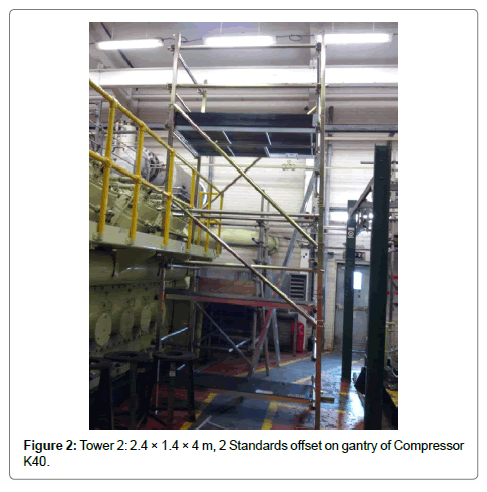

Tower 2: 2.4 × 1.4 × 4 m, 2 Standards offset on gantry of Compressor K40:

• LOBO Scaffold;

2 men × 1 hour, 20 mins to erect

2 men × 20 minutes to dismantle

Total hours 3.3 man hours.

• Tube and fitting would take;

3 men × 5 hours to erect

3 men × 2.5 to dismantle

Total hours 22.5 man hours.

Some minor problems with getting around the obstruction of the guard rail on the gantry, which was eventually overcome by the demo team. Initially I was concerned about the stability, but after climbing the ladders to the top lift I discovered it was no more unstable than a tube and fitting tower of the same size. There is also an option to use longer stabilizers/outriggers to provide added stability (Figure 2).

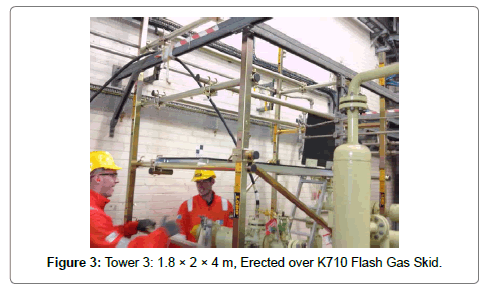

Tower 3: 1.8 × 2 × 4 m, Erected over K710 Flash Gas Skid:

• LOBO Scaffold;

2 men × 50 minutes to erect

2 men × 15 minutes to dismantle

Total hours 2.1 man hours.

• Tube and fitting would take;

3 men × 5 hours to erect

3 men × 2.5 hours to dismantle

Total hours 22.5 man hours.

Task was deliberately set with the obstacle of the skid and low level pipework hindering the base out of the tower, but was duly overcome (Figure 3).

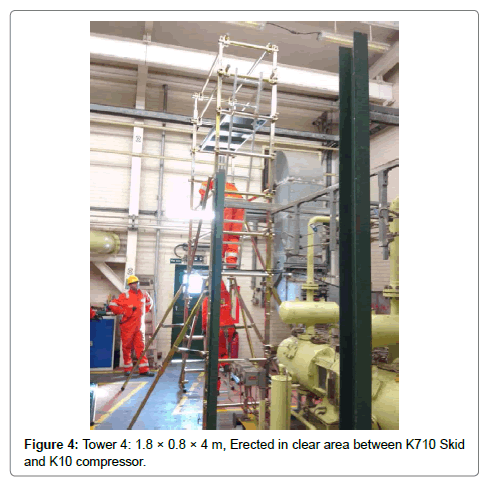

Tower 4: 1.8 × 0.8 × 4 m, Erected in clear area between K710 Skid and K10 compressor:

• LOBO Scaffold;

2 men × 40 minutes to erect

2 men × 15 minutes to dismantle

Total hours 1.8 man hours.

• Tube and fitting would take;

3 men × 4 hours to erect

3 men × 2 hours to dismantle

Total hours 18 man hours.

This tower is an example of where LOBO can be used in narrow areas. There were no issues whatsoever erecting this tower. The fact that we were on our 4th job within a matter of hours gives some indication of how easy the system is to use. LOBO also showed us how we can ‘butt up’ against adjacent structures/walls to make the structure more secure. This was achieved using the components contained with the demo kit with no issues (Figure 4).

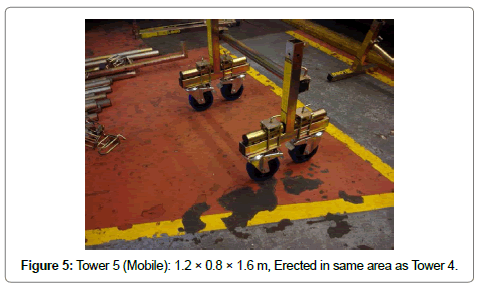

Tower 5 (Mobile): 1.2 × 0.8 × 1.6 m, Erected in same area as Tower 4:

• LOBO Scaffold;

2 men × 30 minutes to erect

2 men × 15 minutes to dismantle

Total hours 1.5 man hours.

• Tube and fitting would take;

3 × 2.5 hours to erect

3 × 1 hour to dismantle

Total hours 10.5 man hours.

We only got as far as the board on the first lift with this one, as time didn’t permit completion The dual castors however were quick to assemble and easy to attach and detach. During erection the first lift was reached within 15 minutes. The tower was very stable even though it was mobile (Figure 5).

General Overview

A couple of concerns - one was around the components themselves, with the smaller attachments and fittings potentially being lost or mislaid, or even damaged, so we would need to keep the materials in a secure area or use a LOBO Tow store container. The compressor house or generator building where the system might be primarily used would be an ideal area to use LOBO. As a time comparison, only 2 towers would have been erected using tube and fitting, with no dismantle. In the same time span 5 jobs were erected and dismantled with the LOBO system. There were issues with the gap between the top guard rail and the lift you are accessing from the internal ladder. This could easily be overcome with additional components fixed utilising the bracket clamps. The LOBO system, as with any system has its advantages, time factor, easy to assemble etc. it really comes into its own when there are no obstructions to negotiate on upper levels, however the system is versatile to work around obstructions if the erection is planned (Tables 1 and 2).

Summary in between Lobo vs. Conventional

| Man Hours | LOBO System | Conventional Scaffold | ||

|---|---|---|---|---|

| Erect | Dismantle | Erect | Dismantle | |

| Tower 1 | 2 | 0.5 | 15 | 7.5 |

| Tower 2 | 2.7 | 0.6 | 15 | 7.5 |

| Tower 3 | 1.6 | 0.5 | 15 | 7.5 |

| Tower 4 | 1.3 | 0.5 | 12 | 6 |

| Tower 5 | 1 | 0.5 | 7.5 | 3 |

| Total Hours | 11.2 | 96 | ||

Table 1: Man Hours it takes to erect, LOBO vs. Conventional.

| Labour Cost | LOBO System | Conventional Scaffold | ||

|---|---|---|---|---|

| Erect | Dismantle | Erect | Dismantle | |

| Tower 1 | $62.00 | $15.50 | $465.00 | $232.50 |

| Tower 2 | $83.70 | $18.60 | $465.00 | $232.50 |

| Tower 3 | $49.60 | $15.50 | $465.00 | $232.50 |

| Tower 4 | $40.30 | $15.50 | $372.00 | $186.00 |

| Tower 5 | $31.00 | $15.50 | $232.50 | $93.00 |

| Total Cost | $347.20 | $2,976.00 | ||

Table 2: Labour Cost, based on $31.00 per man hour (this rate is used for comparison only).

LOBO Scaffolding Cost’s

To build all five towers without dismantle

Tower 1 $5,805.00

Tower 2 $6,317.00

Tower 3 $4,556.00

Tower 4 $3,688.00

Tower 5 $2,254.00

Total: $22,620.00.

The cost to purchase enough LOBO materials to erect and dismantle each tower on an individually (to build all platforms duplication of all components would be required - $7,907.00, Train the trainer course, up to 8 delegates - $3,045.00.

Galvanised Scaffolding

There is currently 9 tonne erected in this location.

Benefits of LOBO

The benefit of using LOBO is the labour time saved to erect and dismantle. Based on the towers erected an average saving of $525 per tower was achieved on man hours. At a purchase price of $7,907 to purchase the materials a total of 15 towers would need to be completed for the cost saving to be realised. The hire cost of the conventional scaffold would also not apply during this period. In addition to the labour time saved any trade can be trained in erecting and dismantling the system which reduces manpower numbers on site.

--Relevant Topics

Recommended Journals

- Oil & Gas Research Journal

- Renewable Energy and Applications Journal

- Oceanography Journal

- Industrial Pollution Control Journal

- Coastal Zone Management Journal

- Climatology & Weather Forecasting Journal

- Geoinformatics & Geostatistics Journal

- Engineering and Technology Journal

- Petroleum & Environmental Biotechnology Journal

- Polymer Sciences Journal

Article Tools

Article Usage

- Total views: 3965

- [From(publication date):

March-2017 - Mar 31, 2025] - Breakdown by view type

- HTML page views : 3087

- PDF downloads : 878