Integration of Quality Safety Health and Environment Management Systems based on Construction Design Management 2015 (Case Study of Construction Projects in Jakarta)

Received: 01-Feb-2023 / Manuscript No. omha-23-87294 / Editor assigned: 03-Feb-2023 / PreQC No. omha-23-87294 / Reviewed: 17-Feb-2023 / QC No. omha-23-87294 / Revised: 23-Feb-2023 / Manuscript No. omha-23-87294 / Published Date: 28-Feb-2023 DOI: 10.4172/2329-6879.1000451

Abstract

Background: Construction accidents are a catastrophe in the construction of buildings and infrastructure in Indonesia. According to PUPR Ministry data in 2017, the construction sector is the largest contributor to accident cases in Indonesia with an average incidence of around 32% each year. Facts on the ground show that the quality management system and safety management system in construction are still fragmented. In Indonesia, the integration of the Quality Safety Health and Environment (QSHE) management system has been carried out since 2018, but the implementation of the integrated QSHE system is still questionable.

Methods: The purpose of this research is to produce an operational system that integrates quality, safety, occupational health and environmental management systems to create good quality, safe, useful and sustainable construction products. This research is based on the policies and best practices of the Construction Design and Management Regulation 2015 management system (CDM Regulation 2015). The research methodology uses literature studies, distribution of questionnaires to academics and construction practitioners, the Delphi method and case studies of construction projects in Jakarta and its surroundings.

Results: The result of this research is an operational system that is effective in integrating quality, safety, health and environmental sustainability in construction.

Conclusion: Operational system integration of quality, safety, health, and sustainability environment (QSHE) is a unity of various supporting elements which must be applied consistently in construction projects to achieve the goal of no defects and no accident.

Introduction

Construction accidents become catastrophic in infrastructure development. Evidence shows that quality failures such as system failures, services failures, procedural failures, materials, and equipment failures as well as human failures within the business process of project delivery systems are contributing causes of construction accidents to lead to a negative impact on worker safety, public safety, building, and environmental safety [1]. The Ministry of Public Works & Housing (2017) shows that the construction sector is the largest contributor to accident cases in Indonesia with an average incident rate are about 32% annually. Social Security Administration/BPJS in Indonesia (2019) reckons that occupational accidents in construction increased from 114,000 cases in 2019 to 177,000 cases in 2020.

Through the management system, organizations try to improve product quality, worker safety and health and environmental sustainability, but in practice management system integration still faces problems such as the absence of a framework and operational system for an integrated system that has the potential to cause accidents [2].

The advantages of QSHE integration are avoiding duplication of many standards used by organizations, reducing/eliminating overlapping activities, jobs, policies and systems, resource efficiency, costs and time, document efficiency such as reducing policies, procedures, manuals, instructions and records, expanding the functional scope of each standard used by the organization, streamlining organizational documents and communication lines, unifying internal and external audits, and enhancing the image of the company/organization [3,4], [figure 1].

The Labour Force Survey in UK estimated around 2.4% of workers in construction sector suffered from an injury and this is statistically significantly higher than all industry rates. When the CDM Regulation came into force from 1994 to 2015, there was a trend towards a reduction in fatal injuries in the construction area and this was an improvement in the application of SHE [6]. Based on these facts, this study uses the 2015 CDM Regulations as a reference for proposing the integration of the QSHE operational system to be used in the construction sector in Indonesia.

Materials and Method

The general definition of quality as it relates to manufacturing and construction is meeting user needs and creating products that are fit for use and meet requirements. However, the definition of quality for construction projects differs from that of the manufacturing industry in that the products are non-repetitive and are unique works with specific requirements. Quality in construction projects is not just the quality of products and equipment used in construction, but rather a total management approach to completing a construction project [7] [figure 2].

In construction, product quality is improved by managing individual components/suppliers, ensuring their quality system, eliminating defects, and fixing them from the start. Process quality is about using product intelligently in design and assembly so that it is compatible, protected from damage, and installed in the manner and best tolerances to prevent defects. Service quality is about working with clients and paying attention to details as discussed in the SERVQUAL customer satisfaction model [8]. The integrated approach requires effective collaboration between designers, contractors and clients [9].

Construction quality depends on construction control which is the main responsibility of the contractor. Quality must be planned into the project to prevent unnecessary rework, waste, costs, and delays. Any design/engineering errors or quality discrepancies may also result in incidents if not identified and corrected. The plan should form an integral part of the project management system and define how quality will be managed throughout the project life cycle. Quality assurance and quality control activities are required in procedures and practices that result in acceptable quality levels in the construction work process and in the final construction product.

Construction projects that are unique and non-repetitive require special attention to maintain quality. Each project must be designed and built to serve specific needs. Total Quality Management (TQM) in construction projects involves adherence to minimum standards of materials and workmanship to ensure construction products conform to design. TQM in construction projects is a form of cooperation in running a business that relies on talent, workforce expertise and management to continuously improve quality [10][figure 3].

The successful management of QSHE will result in the ability to manage business risks in construction projects including risks to people/workers, risks to the public, risks to the environment, and risks to property. Figure 3 illustrates the elements of leadership, management, competence, legal compliance, risk profile and employee involvement which are units that support the successful management of QSHE [11].

This research will use the Delphi method by compiling concepts operational system based on CDM Regulation 2015, verification, validation, testing and updating the operational system concept so that it will be obtained operational system that integrates quality, safety, health, and environment in construction projects. The research methodology to be carried out such as the following: [figure 4]

From the literature study, the authors compiled a diagram of the supporting elements of the QSHE integration which would then be verified, validated, and evaluated by academics and construction project teams. The elements in the supporting integration diagram will then be verified, validated and tested in construction projects carried out by 5 contractors in Jakarta and its surroundings [figure 5][12,13]

The operational system verification research stage used a questionnaire which was disseminated via Google form to construction practitioners with more than 5 years of work experience. This questionnaire uses the Guttman scale to get firm and consistent answers to a problem posed. The operational system validation research stage using the Delphi method with a Likert scale questionnaire distributed via google form to academics and construction practitioners with more than 10 years of work experience. The evaluation stage of the QSHE integration operational system research is carried out by distributing Google form questionnaires to the project team consisting of 5 contractors to obtain confirmation of the implementation of the elements of the QSHE integration operational system in construction projects. In the process of updating the operational system of QSHE integration is carried out by changing and adding elements according to input/responses from academics and construction practitioners starting from the verification, validation and evaluation stages of the operational system QSHE integration.

Results and Discussion

Verification Stage

The results of the questionnaire for the verification stage of construction practitioner respondents obtained that most respondents agreed with the supporting elements of QSHE integration. Following are the profiles of 22 respondents at the verification stage [figure 6].

The results of the verification phase questionnaire on 22 construction practitioners with more than 5 years’ experience obtained a reproducibility coefficient = 0.9943 which is greater than 0.9 and a scalability coefficient = 0.9875 which is greater than 0.6 so that elements P1-P32 are valid and continue to proceed to the validation stage of the QSHE integrated operational system.

Validation Stage

The research stage for validating the operational system of QSHE integration uses the Delphi method with a Likert scale questionnaire distributed via goggle form to academics and construction practitioners with work experience of over 10 years. Following are the profiles of respondents at the validation stage [table 1]

| No | Respondent | Age | Position | Working Experience | Education Degree |

|---|---|---|---|---|---|

| 1 | Academics | 51 - 60 tahun | Professor | > 25 years | Doctor |

| 2 | Practitioner | 41 - 50 tahun | General Manager | 21 - 25 years | Master |

| 3 | Practitioner | 51 - 60 tahun | Deputy Dept. Head QHSE | 21 - 25 years | Master |

| 4 | Academics | 30 - 40 tahun | Lecturer | 16 - 20 years | Doctor |

| 5 | Practitioner | 30 - 40 tahun | Project Manager | 11 - 15 years | Master |

| 6 | Practitioner | 41 - 50 tahun | Operation Manager | 16 - 20 years | Master |

| 7 | Practitioner | 51 - 60 tahun | Director | > 25 years | Bachelor |

Table 1: Profile of Respondents for Operational System Validation.

Delphi as a research method is very good for obtaining consensus from groups that have certain expertise where the information sought is subjective and participants are separated by physicality and distance [14, 15]. From the results of the stage 1 validation questionnaire, it was found that several respondents did not give relatively the same assessment, so a stage 2 questionnaire was needed for respondents 3, 4 and 6 to obtain a consensus. After compiling the stage 2 validation questionnaire, the questionnaire was distributed to respondents 3, 4 and 6. Then after the respondents gave a reassessment the table of results of the stage 1 validation was updated and the following results were obtained [table 2].

| No | QSHE Integration Elements | R1 | R2 | R3 | R4 | R5 | R6 | R7 | Average |

|---|---|---|---|---|---|---|---|---|---|

| 1 | Owner | 5 | 4 | 5 | 5 | 5 | 5 | 4 | 4.71 |

| 2 | Designer | 5 | 4 | 5 | 5 | 5 | 4 | 5 | 4.71 |

| 3 | Principal Contractor | 5 | 4 | 5 | 5 | 5 | 5 | 5 | 4.86 |

| 4 | Consultant | 5 | 4 | 5 | 5 | 5 | 5 | 5 | 4.86 |

| 5 | P1 | 5 | 4 | 5 | 5 | 5 | 5 | 5 | 4.86 |

| 6 | P2 | 5 | 4 | 5 | 5 | 5 | 5 | 5 | 4.86 |

| 7 | P3 | 5 | 4 | 5 | 5 | 5 | 5 | 5 | 4.86 |

| 8 | P4 | 5 | 4 | 5 | 5 | 5 | 5 | 5 | 4.86 |

| 9 | P5 | 5 | 5 | 5 | 5 | 5 | 4 | 4 | 4.71 |

| 10 | P6 | 5 | 5 | 5 | 5 | 5 | 5 | 4 | 4.86 |

| 11 | P7 | 5 | 5 | 5 | 5 | 5 | 5 | 5 | 5.00 |

| 12 | P8 | 5 | 5 | 5 | 5 | 5 | 5 | 5 | 5.00 |

| 13 | P9 | 5 | 4 | 5 | 4 | 5 | 5 | 4 | 4.57 |

| 14 | P10 | 5 | 4 | 5 | 4 | 5 | 5 | 5 | 4.71 |

| 15 | P11 | 5 | 5 | 5 | 4 | 4 | 5 | 4 | 4.57 |

| 16 | P12 | 5 | 5 | 5 | 4 | 4 | 5 | 5 | 4.71 |

| 17 | P13 | 5 | 5 | 5 | 4 | 5 | 5 | 4 | 4.71 |

| 18 | P14 | 5 | 4 | 5 | 4 | 5 | 5 | 5 | 4.71 |

| 19 | P15 | 5 | 4 | 5 | 3 | 5 | 4 | 5 | 4.43 |

| 20 | P16 | 5 | 4 | 5 | 4 | 5 | 4 | 4 | 4.43 |

| 21 | P17 | 5 | 4 | 5 | 4 | 4 | 4 | 4 | 4.29 |

| 22 | P18 | 5 | 4 | 5 | 4 | 5 | 5 | 4 | 4.57 |

| 23 | P19 | 5 | 4 | 5 | 5 | 5 | 5 | 4 | 4.71 |

| 24 | P20 | 5 | 5 | 5 | 4 | 5 | 5 | 5 | 4.86 |

| 25 | P21 | 5 | 5 | 5 | 4 | 5 | 4 | 5 | 4.71 |

| 26 | P22 | 5 | 4 | 5 | 4 | 5 | 4 | 5 | 4.57 |

| 27 | P23 | 5 | 4 | 5 | 4 | 5 | 4 | 4 | 4.43 |

| 28 | P24 | 5 | 4 | 5 | 4 | 5 | 4 | 5 | 4.57 |

| 29 | P25 | 5 | 4 | 5 | 4 | 5 | 4 | 4 | 4.43 |

| 30 | P26 | 5 | 5 | 5 | 3 | 5 | 3 | 4 | 4.29 |

| 31 | P27 | 5 | 4 | 4 | 4 | 5 | 4 | 4 | 4.29 |

| 32 | P28 | 5 | 4 | 4 | 5 | 4 | 4 | 4 | 4.29 |

| 33 | P29 | 5 | 5 | 5 | 3 | 5 | 5 | 5 | 4.71 |

| 34 | P30 | 5 | 5 | 3 | 4 | 5 | 4 | 4 | 4.29 |

| 35 | P31 | 5 | 5 | 5 | 4 | 5 | 4 | 4 | 4.57 |

| 36 | P32 | 5 | 5 | 5 | 4 | 5 | 5 | 5 | 4.86 |

| 5.00 | 4.39 | 4.89 | 4.31 | 4.89 | 4.56 | 4.53 | 4.65 | ||

Table 2: Validation Questionnaire Result.

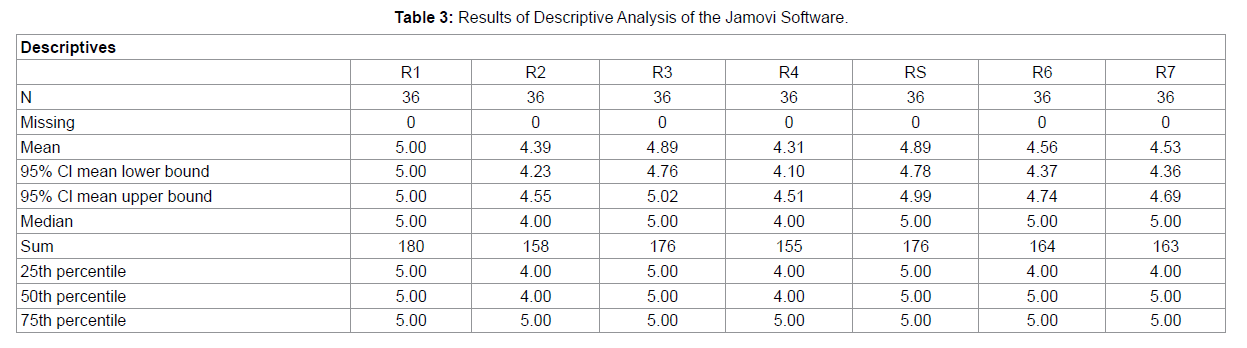

The result of the respondent's assessment in the second stage of validation then was processed into the Jamovi statistical software to see the result of the descriptive analysis. The result can be found in the following table [table 3].

From the results of the descriptive analysis of the Jamovi software, it is known that the average value of the QSHE integration elements for each respondent is more than 4. A value of 4 indicates that these elements positively support the operational system of QSHE integration.

The data from the second stage of validation were analysed and sorted by the average value of each QSHE integration element, and it was found that there were 5 elements with the lowest average value of 4.29 with elements P17, P26, P27, P28 and P30. Furthermore, the elements of QSHE integration that have the lowest score are seen in the assessment of each respondent and it is found that the P26 element has an assessment with a value of 3 out of 2 respondents (R4 and R6). A value of 3 means that the element is considered sufficient to support the operational system of QSHE integration, so that element P26 is considered not to reach a consensus from the validation stage 2. Furthermore, element P26 (Chemical and Biological Substances) will be removed from the operational system of QSHE integration, so that the elements will be reduced from 32 elements to 31 elements.

Evaluation Stage

The stages of evaluation the QSHE integration operational system are carried out by dissemination of the goggle form questionnaire to the project team of 5 contractors for obtain confirmation of the implementation of the QSHE integration operational system elements in construction projects. Following are the profiles of respondents at the evaluation stage [table 4].

| No | Resp. | Age | Education Degree | Company | Position | Experience |

|---|---|---|---|---|---|---|

| 1 | R1 | 31 - 35 years | Bachelor | PT. A | Site Manager | 5 - 10 years |

| 2 | R2 | 31 - 35 years | Bachelor | PT. A | HSE Supervisor | 5 - 10 years |

| 3 | R3 | 41 - 45 years | Bachelor | PT. B | Project Manager | 16 - 20 years |

| 4 | R4 | 41 - 45 years | Bachelor | PT. B | Project Manager | 16 - 20 years |

| 5 | R5 | 36 - 40 years | Bachelor | PT. C | HSE Manager | 11 - 15 years |

| 6 | R6 | 41 - 45 years | Master | PT. C | Site Manager | 21 - 25 years |

| 7 | R7 | 41 - 45 years | Master | PT. D | Project Manager | 11 - 15 years |

| 8 | R8 | 41 - 45 years | Master | PT. D | Deputy Project Manager | 16 - 20 years |

| 9 | R9 | 46 - 50 years | Bachelor | PT. E | Site Operational Manager | 16 - 20 years |

| 10 | R10 | 36 - 40 years | Bachelor | PT. E | HSE Manager | 11 - 15 years |

Table 4: Profile of Respondents for Operational System Evaluation.

Respondents were asked to fill out a confirmation of the implementation of each element of the QSHE integrated operational system on the questionnaire. Respondents explained each of the supporting elements of QSHE integration and were asked to see whether these elements had been implemented in the projects they handled. Respondents were also asked to provide input/response regarding elements of QSHE integration according to experience and knowledge in the field as complementary information.

From the results of field testing conducted by respondents from contractors A, B, C, D and E, it was found that most of the elements had been implemented in the field by the contractor, but there were several elements that had not been implemented because of the stages of construction work, there was no building demolition work. existing, the work location is not near water and does not use explosives in the project.

The results of the questionnaire on the project team with the result "No" were then asked again through the google form questionnaire to contractor respondents B, C, D and E with a scenario when there is demolition work, the project location is near water and using explosives in the project. Respondents from contractors B, C, D and E confirmed that each of these works requires risk management and control, so that each supporting element of the QSHE integrated operational system is valid.

Update Stage

In the process of updating the QSHE operational system integration, it is carried out by changing and adding parts of the elements according to input/responses from academics and construction practitioners starting from the stages of verification, validation, and evaluation of operational systems. The following figure is a diagram of an operational system QSHE integration update based on the research result [figure 7].

Conclusions

Operational system integration of quality, safety, health, and sustainability environment (QSHE) is a unity of various supporting elements which must be applied consistently in construction projects to achieve the goal of no defects and no accident. The figure above is 31 supporting elements QSHE integration as a guide for the operational system integration of QSHE that has been verified, validated and evaluated in the project field. From the process of verification, validation and evaluation of operational systems that have been stated by respondents that the implementation process requires practical steps as follows:

1. The implementation of the QSHE integration policy is carried out consistently with the top management of each stakeholder and establishes a QSHE culture in all organizations involved in construction projects.

2. Leadership and exemplary in implementing QSHE at the construction project scale will be the key which is supported by continuous outreach to the project team.

3. The need for cooperation and commitment to implementing QSHE integration from all construction team from the planning stage to the implementation of construction projects.

4. To increase compliance with the implementation of QSHE integration in the field, it is necessary to apply sanctions/fines in the event of a rule/policy violation that must be complied with by the entire project team, starting from project owners, consultants, contractors and project guests.

5. Good and effective communication is needed between construction team so that the application of QSHE integration can realize the goals of no defects and no accidents in construction projects. 6. Provision of an emergency response team and collaboration with external parties such as hospitals, fire department and police to support the implementation of construction projects.

7. Creating a good QSHE culture requires commitment and becomes company policy from all parties implementing the development, especially the contractor team, both state- owned contractors and private contractors who carry out construction work in Indonesia.

The authors realize that this research is not perfect, so further research is needed to complete this research with the following topics:

1. QSHE operational system integration research is carried out at the pre-construction stage, such as during the feasibility study stage and the design stage to ensure that the constructability factors of a construction project can be identified from the outset.

2. QSHE operational system integration research is carried out at the post-construction stage such as during the operation and maintenance stage to ensure that QSHE implementation is still carried out by users and operators.

3. QSHE operational system integration research that examines the readiness and response of state-owned and private contractors to a sustainable QSHE culture.

References

- Silalahi AP (2022) A Conceptual Framework for Integrating QSHE in Construction. EACEF Conference 2-10.

- Masuin R (2019) Development of knowledge management in integration management systems in order to increase the organisational performance of construction companies. MATEC Web of Conferences 1-10.

- Ahidar I (2018) Approach to Integrating Management Systems. The TQM Journal 183- 204.

- Carvalho K (2015) Benefits in the Implementation of Safety, Health, Environmental and Quality Integrated System. IACSIT Int J Eng Technol 7: 1-5.

- Institution of Civil Engineers (2020) CDM 2015: 3 years on Assessing the Construction (Design & Management). London: Institution of Civil.

- HSE (2021) Workplace Fatal Injuries in Great Britain. London: Crown.

- Henjewele (2019) Construction Project Management An Integrated Approach Third Edition. New York: Routledge.

- Rumane (2018) Quality Management in Construction Projects Second Edition. Boca Raton: Taylor & Francis Group.

- CONIAC (2015) CDM 2015 - Industry Guidance for Clients. Norfolk: CITB.

- Rebelo MF (2014) A generic model for integration of quality, environment and safety management systems. TQM Journal January 683-701.

- Health and Safety Executive (2013) Managing for Health and Safety. Norwich: Crown.

- CDM Regulation (2015) Managing Health and Safety in Construction - Construction (Design and Management) Regulations L153. London: Crown.

- Hughes P (2016) Introduction to Health and Safety in Construction. New York: Routledge.

- Linstone (2002) The Delphi Method Techniques and Applications. California: University of Southern California.

- 5Renzi (2015) The Delphi method for future scenarios construction. AHFE 1-7.

Indexed at, Google Scholar, Crossref

Indexed at, Google Scholar, Crossref

Citation: Silalahi AP, Widjajakusuma J, Suraji A (2023) Integration of Quality Safety Health and Environment Management Systems based on Construction Design Management 2015 (Case Study of Construction Projects in Jakarta). Occup Med Health 11: 451. DOI: 10.4172/2329-6879.1000451

Copyright: © 2023 Silalahi AP, et al. This is an open-access article distributed under the terms of the Creative Commons Attribution License, which permits unrestricted use, distribution, and reproduction in any medium, provided the original author and source are credited.

Share This Article

Recommended Journals

Open Access Journals

Article Tools

Article Usage

- Total views: 1377

- [From(publication date): 0-2023 - Dec 04, 2024]

- Breakdown by view type

- HTML page views: 1239

- PDF downloads: 138