Research Article Open Access

Integrating Exposed Structural Steel Plate Shear Walls into the Architectural Design Process

Adam R Phillips1*, Helene Renard RA2 and Matthew R Eatherton3

1Graduate Research Assistant, Virginia Tech, Department of Civil and Environmental Engineering, 105D Patton Hall, 750 Drillfield Drive, Blacksburg, VA 24061-1051, USA

2Virginia Tech, Interior Design Program, USA

3Virginia Tech, Department of Civil and Environmental Engineering, USA

- *Corresponding Author:

- Adam R. Phillips

Graduate Research Assistant, Virginia Tech

Department of Civil and Environmental Engineering

105D Patton Hall, 750 Drillfield Drive, Blacksburg

VA 24061-1051, USA

Tel: 757-395-0469

E-mail:arp12@vt.edu

Received Date: September 20, 2016; Accepted Date: September 25, 2016; Published Date: September 30, 2016

Citation: Phillips AR, Helene Renard RA, Eatherton MR (2016) Integrating Exposed Structural Steel Plate Shear Walls into the Architectural Design Process. J Archit Eng Tech 5: 171. doi: 10.4172/2168-9717.1000171

Copyright: © 2016 Phillips AR, et al. This is an open-access article distributed under the terms of the Creative Commons Attribution License, which permits unrestricted use, distribution, and reproduction in any medium, provided the original author and source are credited.

Visit for more related articles at Journal of Architectural Engineering Technology

Abstract

Historical precedent shows that advancements in structural engineering technology can facilitate novel architectural forms. Consideration of a recently conceived shear wall panel through an aesthetic lens prompted the authors to investigate the potential of the panel as an architectural design element and as a tool for collaboration between architects and engineers. The innovative shear panels, called Ring Shaped – Steel Plate Shear Walls (RS-SPSW), are characterized by a pattern of circular rings cut into a solid web plate. The resulting shear wall panel has a strong presence as a sculptural object, acts as a visual screen and defines spatial boundaries while providing lateral load resistance. This study develops this shear wall type into an architectural design element by identifying the variables in the shear wall panel design, creating a common vocabulary that encourages architect/ engineer collaboration, and outlining a design method based on the interior design vision. The design methodology addresses what elements can be modified, and to what degree, while preserving structural performance. A sample narrative explores the use of the proposed vocabulary to showcase how this new piece of architectural technology can be used to foster a more integrated and collaborative design process resulting in a contemporary interior space.

Keywords

Exposed structure; Steel plate shear wall; Ring shaped; RS-SPSW

Introduction

Architecture can be described as the art of designing buildings that are both functional and beautiful. Modernist architects articulated ideas about the relationship between functional and beautiful form that remain influential today. The philosophical convictions of both Le Corbusier and Adolf Loos were grounded in the conviction that order provides a foundation for beauty. In Le Corbusier’s case, geometry was the order from which beauty arose, whereas Loos’s writings emphasized honesty in building materials. Originally published in 1927, Le Corbusier’s manifesto Towards a New Architecture appeals to architects to create order and beauty through the laws of geometry [1]. Le Corbusier expressed the idea that the engineer “puts us in accord with universal laws” and “attains harmony” [2]. He asserted that architecture is beyond construction, which is for “making things hold together,” whereas architecture is for “stirring emotion.” In his 1898 essay, “The Principle of Cladding,” Loos formulated the idea that materials should not imitate other materials, but should be true to their own nature [3].

Architectural critic and writer Jonathan Glancey states that, “one of [architecture’s] purposes, from the smallest well-put-together building to the highest skyscraper, is to lift the human spirit. In architecture we find a way of celebrating our humanity and of raising ourselves above the concerns of the matter-of-fact, the here and now” [4]. Glancey expresses that good architecture elicits feeling from people who are around it. Exposed structural elements incorporated into the architectural form can evoke a sense of strength and security for its inhabitants. Furthermore, integrating exposed steel elements into the structural system of a building is in keeping with the modernist tradition, as stated by Loos (1982), of utilizing materials for their natural strengths. Steel can be shaped to fit many different forms while retaining high levels of strength, ductility, and stiffness.

Modern buildings that incorporate exposed structural elements into the architectural design require an efficient and well-defined dialogue between the architect and the engineer. This dialogue is critically important because it allows the architectural form to be a balance between artistic vision and structural function. In his book Structure in Architecture, structural engineer and architecture professor Mario Salvadori expresses this idea as a need for a “common vocabulary” between architects and engineers [5].

In that spirit, the authors have formed an interdisciplinary team to develop a steel plate shear wall panel design that can become part of modern architectural form and that encourages collaborative design based on a collective terminology. This paper, based on ongoing structural steel research, explores the intersection of formal aesthetics and structural function in the context of exposed Ring Shaped - Steel Plate Shear Walls (RS-SPSW). Variations on an initial panel design are investigated through a set of parameters that include both aesthetic and structural criteria. The structural design criteria ensure that the panels serve their intended function as the primary lateral load resisting system, providing earthquake resiliency, while the formal design criteria allow an architect to understand the variables that are at play for modifying the aesthetic presence of the panels. Design principles and other visual criteria may be applied at the object (wall panel) and spatial scales, influencing both the distribution of the rings-and-links pattern and the proposed functionality of the wall within the space as a spatial divider, a visual screen, or a sculptural element.

The proposed panel designs can take on a range of formal variations that have the same basic structural properties in common. First, they are well suited for high seismic areas. Second, they possess high initial stiffness and can be tuned to meet the necessary strength and ductility requirements. Lastly, they are capable of undergoing large inelastic loading cycles and can dissipate large amounts of seismic energy.

The following sections provide a broader context for this iteration of the RS-SPSW through historical precedents of architectural forms fashioned in response to advancements in architectural technology, background information on the development and use of steel plate shear wall systems, the design principles and methods for the proposed shear wall panels, and examples of the RS-SPSWs in various architectural spaces. During the discussion of the design principles for the RSSPSW panels a “common vocabulary” is proposed that is intended to facilitate collaboration between the architect and engineer in pursuit of a form that serves the design goals of each. The shared vocabulary is used throughout the design examples, in a variety of scenarios, showing where exposed structural shear walls can be utilized. The demonstration illustrates the possible results of an effective dialogue between architect and engineer.

Historical Background

Throughout history, there are examples of architectural form and structural integrity intersecting. These intersections are described by architecture professor and author Andrew Charlesson as places, “where structure is given a voice, and it contributes architectural meaning and richness” [6]. An early example of structural innovation influencing and defining architectural form is the use of stone arches and masonry columns in Roman structures. Although the Greeks knew about the properties of the arch, it wasn’t until Roman times that they were utilized as part of architectural form. The Romans used the arch to create some of the most iconic structures known to man such as the Colosseum and multi-tier aqueducts. Additionally, the Romans expanded the theoretical foundation of arches in order to pioneer barrel vaults and groin vaults, which appeared in many Roman basilicas [4].

Professor Remo Pedreschi describes the idea of structural function being intertwined with architectural form by stating, “The disciplines of structural art are efficiency and economy, and the freedom lies in the potential it offers for the expression of a personal style motivated by a conscious aesthetic search for engineering elegance” [7]. By refining how materials and structural form carry load, new forms, shapes, and systems can be created. During Gothic times, the use of stone to create arches, vaulted ceilings, and domes facilitated the creation of historic cathedrals across Europe. The Gothic architects, supported by master craftsmen, expanded the limits of the arch by adding support through creative means such as flying buttresses and complex patterns of supporting groins [4]. This example shows how new architectural forms were created by searching for ways to design structures with greater spans and load carrying capacity.

More recent examples of the elegant synthesis of structural innovation and architectural form may be found in the works of Pier Luigi Nervi, Fazlur Khan, Bruce Graham, and Santiago Calatrava.

Historical Examples of Structural Design Innovation Leading to Novel Forms

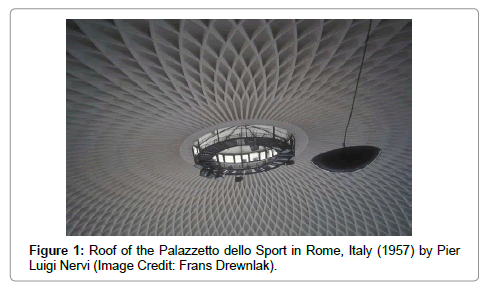

In the forward to Salvadori’s Structure in Architecture, Nervi is quoted as saying, “In order to invent a structure and give it exact proportions, one must follow both the intuitive and the mathematical paths” [6]. The theory of letting the load path define the exact structural and architectural proportions led Nervi to create world-renowned long-span roofs (Figure 1). Nervi’s use of concrete for thin, long roofs represents some of the most significant advancements in structure of the early 20th century. His process for designing roofs was different from his contemporaries’ because he combined double curvature with a pattern of stiffened ribs that followed the stress contours of the roof. The end result of this state-of-the-art patterning of ribs is a unique and impactful architectural form. David Billington states that, “Nervi saw that structure could be art when it arose out of correct form, careful construction practice, and a conscious aesthetic intention” [8]. Architecture students still study Nervi’s works today as an example of elegant structural form.

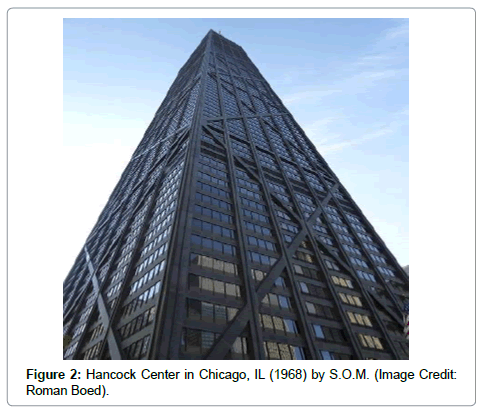

A significant technological advancement that allowed architects and engineers to build higher into the sky was the development of structural steel from iron ore (Glancey 2006). For much of the 20th century, most tall buildings were constructed out of steel due to its strength and relative lightness. An example building that uses the material benefits of structural steel in conjunction with bold structural and architectural form is the Hancock Center in Chicago (Figure 2). The Hancock Center was designed by structural engineer Fazlur Khan and architect Bruce Graham, both partners at Skidmore, Owings and Merrill (SOM). The Hancock Center is characterized by strong, multi-floor exterior bracing that is the main structural support for the building. It was one of the first tall buildings for which the designers developed and implemented a tubular structural system, allowing for the interior of the building to be open and free of columns.

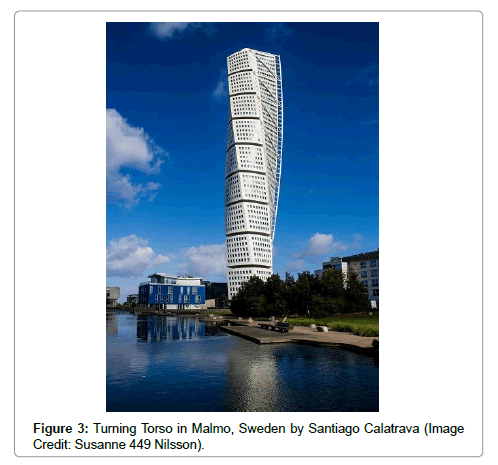

Structural steel lends itself well to the blending of architectural and structural function because it can be fabricated for complex and curved geometries more easily than concrete. Architect, structural engineer, sculptor and painter Santiago Calatrava effectively combines his knowledge of structural and aesthetic principles to create form that is a graceful creative expression of structure. His designs take on unique architectural form while also embodying the lines of the structural system that are used to carry the loads. One of his buildings that showcases his unique method for design is the Turning Torso in Sweden (Figure 3). This form of the building symbolizes a twisted human torso. Exposed concentric steel bracing constitutes the primary structural system, which represents the “spine” of the torso. He does not use the steel frame as a concealed, reinforcing framework but rather celebrates its contribution to the sweeping lines of the structure [4].

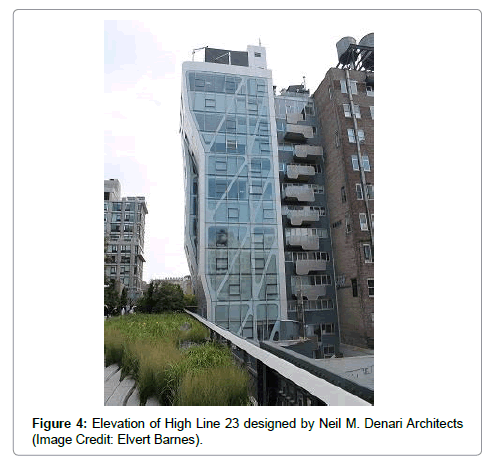

Case Study of Steel Plate Shear Walls being used in a Modern Building

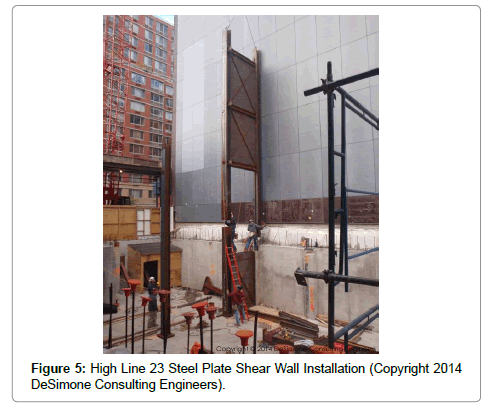

An example of a building that uses steel plate shear walls (SPSW) and exposed diagonal bracing is the High Line 23 (HL23) in New York City (Figure 4). The HL23 was designed by Neil M. Denari Architects with structural design by DeSimone Consulting Engineers. Many modern high-rise buildings are constructed using cast-in-place flat plate reinforced concrete to maximize floor-to-ceiling heights, so it is unusual to see SPSWs as part of a dual lateral load resisting system in New York City [9]. Due to the unsightly characteristics of conventional SPSWs they were the only parts of the structural lateral load resisting system that were hidden from view (Figure 5). SPSWs were used because of the buildings relatively thin width, only 38 feet at the base. The thin width made anchoring the structure and providing sufficient lateral resistance challenging. Utilizing SPSWs in the structural design saved two feet of width as compared to comparable wide-flange bracing [10].

Even though conventional SPSWs were a good choice for this building due to the space and loading constraints, they didn’t fit organically into the otherwise exposed structural system. The Ring Shaped - Steel Plate Shear Wall (RS-SPSW) might have been better integrated into the architectural design by continuing the theme of exposing the structural elements. DeSimone Engineering Consultants state on their website that the exposed perimeter bracing is, “A true sign of synergy between form and function” [11]. The RS-SPSW infill panels could have been designed to add another layer of dimensionality to the design.

Steel Plate Shear Wall Background

Steel plate shear walls (SPSWs) are a commonly used structural system in North America since they appeared in U.S. building codes in 2005 [12]. They can be deployed in earthquake prone regions or in situations where it is desirable to use relatively short lengths of wall to resist lateral loads. SPSW systems are characterized by a thin steel web plate surrounded by stiff boundary elements. The system resists lateral loads by yielding of the web plate along tension diagonals; this is commonly referred to as tension field action. However, despite their popularity, SPSWs also present several challenges. The first is that they can buckle at relatively small shear loads. The second is that SPSWs exhibit pinched cyclic (hysteretic) behavior due to small lateral resistance during load reversals. This results in relatively small amounts of energy dissipation and low stiffness. The last challenge is that the building code (AISC 2010) requires moment resisting connections at all of the beam-to-column joints of the SPSW boundary frame to supplement the buckling challenged web plates. This adds cost and complexity to the fabrication and erection of SPSW structures [13].

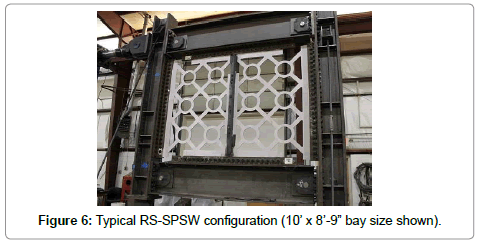

The Ring Shaped – Steel Plate Shear Wall (RS-SPSW) is a novel structural system that can bring an industrial or modern feel to a building while also improving upon conventional SPSW performance [14]. The RS-SPSW system can act as both the lateral load resisting system and as an architectural element. RS-SPSW’s are typically characterized by cutting ring shaped patterns into a solid steel web plate. The size, distribution, and orientation of the rings can be manipulated to support the design intention within a given space. The pattern of ring shapes enhances the RS-SPSWs hysteretic performance by preventing buckling behavior. This means that RS-SPSWs have good stiffness during load reversals, high amounts of energy dissipation, and do not need supplementary moment connections.

Design Methodology

Concepts

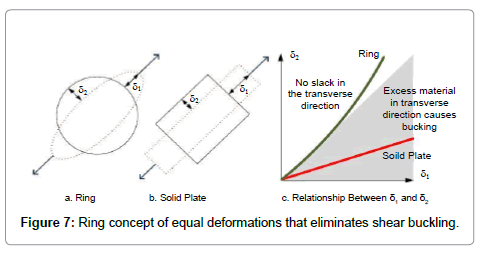

The Ring Shaped – Steel Plate Shear Wall (RS-SPSW) concept uses a combination of rings and connecting links to create a plate that is both aesthetically pleasing and structurally resilient (Figure 6). The ring shapes are responsible for mitigating buckling and producing favorable cyclic behavior. Figure 7a shows how a circle deforms into an ellipse when load is applied to it. For a circle, the longitudinal elongation, δ1, will approximately equal the transverse shortening, δ2. This eliminates slack, or buildup of material, in the transverse (compression) direction. Slack material along the compression diagonal is one way to think about the cause of shear buckling and it has been shown that the ring shape is capable of preventing this shear buckling [14]. For a solid plate subjected to a tension elongation, δ1 (Figure 7b), the transverse shortening, δ2 is approximately equal to δ1 multiplied by the Poisson’s ratio, which is 0.3 for steel. Therefore, a solid steel plate will have a buildup of material along the compression diagonal that results in shear buckling. Shear buckling is less desirable for structural performance because it causes a sharp reduction in stiffness, decreases energy dissipation, and increases the likelihood of localized tearing or fracture of the web material. The web plate of conventional SPSWs may buckle during large wind loads or earthquakes with intermediate return period.

As previously mentioned, it is necessary to develop a uniform vocabulary for the RS-SPSW system to support effective communication between the architect and structural engineer. A formal vocabulary allows the architect to describe the intended form to the structural engineer, who can then set the geometric parameters that provide sufficient strength and seismic performance. The RS-SPSW formal vocabulary is comprised of the compositional parameters that define the architectural form and the geometric parameters that define the structural properties. The following sections describe the vocabulary and design method for each set of parameters.

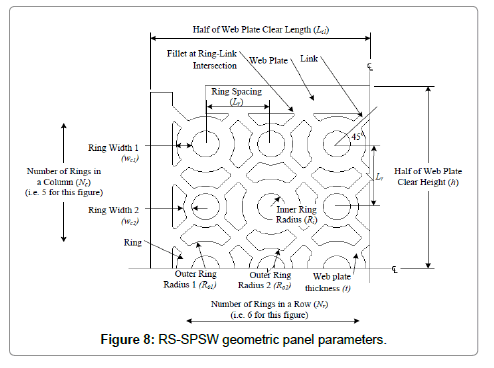

Geometric parameters governing structural behavior

The geometric parameters define the exact dimensions of the rings and links which control the strength, initial stiffness, and hysteretic (cyclic) behavior. The RS-SPSW geometric parameters (Figure 8) include the clear height of the web plate between structural beams, h, the clear width of the web plate between columns, Lcl, the number of rings in a row, Nr, the number of rings in each column, Nc, the ring spacing, Lr, outer ring radius, Ro, inner ring radius, Ri, and ring width, wc. It is assumed that the links connecting the rings will always be oriented at a 45° angle because that is the ideal angle to facilitate the RS-SPSW concept described in the previous section. If multiple ring geometries are used in a single panel, the parameter designations will have an additional number in the subscript. For example, if two different ring sizes are used in one panel, then the ring radius and ring width variables for the first ring size would be Ro1 and wc1 and for the second ring size would be Ro2 and wc2.

The number of rings in a row and column is dictated by the overall size of the wall panel and the ring spacing. There cannot be a greater number of rings in a row or column than there is space to fit them. For example, if the width of the web plate (Lcl) is 120 inches and the ring spacing (Lr) is 12 inches, then the number of rings in a row (Nr) cannot be greater than nine. The following equations give the maximum number of rings that can fit in a column or row line.

(rounded down to nearest whole number) – 1.

(rounded down to nearest whole number) – 1.

(rounded down to nearest whole number) – 1.

(rounded down to nearest whole number) – 1.

The geometric parameters of ring radius (Ro), ring width (wc), link width (wl), plate thickness (t), and number of rings in a row (Nr) are used to tune the RS-SPSW structural behavior to fit the desired performance objectives [15,16]. The strength and cyclic behavior can be individually tuned for desired levels of performance. In general, rings that are wider and thicker have greater cross-sectional area and therefore result in a stronger panel. The initial stiffness is also controlled by similar ring parameters; however it is also influenced by the link geometry, such as link width and link length. For additional information regarding methods to predict strength and stiffness see Phillips and Eatherton and Maurya, respectively [17,18].

An important characteristic of a structure’s cyclic performance during earthquakes is the amount of energy dissipated. Controlling the amount of energy dissipation is related to controlling the hysteretic behavior of the panel. Full hysteretic behavior is capable of dissipating large amounts of seismic energy and thus helps control peak lateral drifts. Pinched hysteretic behavior produces low amounts of energy dissipation and may result in a system less equipped to control drifts. The RS-SPSW hysteretic behavior is primarily controlled by panel (h/t) and ring slenderness (Ro/wc) ratios; which are ratios that describe how susceptible the panel is to buckling. These ratios can be selected by the structural engineer to limit buckling degradation and are further described in Phillips and Eatherton (2015a and 2015b).

Compositional Parameters Governing Architectural Form

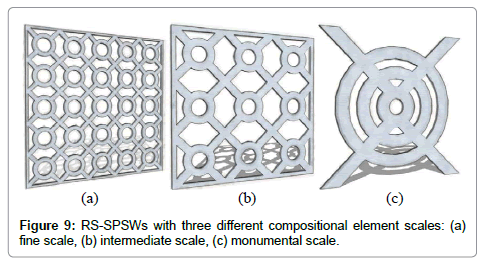

The compositional parameters control the scale of the compositional elements (rings and links), visual depth of the panel, thickness of the panel’s cross section, and overall openness or degree of screening. The scale of the compositional elements refers to the relative size of the rings (Ro) and links (wl) in relation to the size of the full panel (h&L cl). The compositional scale can be varied from fine to intermediate to monumental (Figure 9). Monumental scale walls, which have few very large rings, can create a focal point in an atrium or a lobby. Fine or intermediate scale walls can be used to delineate spaces while allowing visual communication between spaces, and allowing light to penetrate deeper into a space from exterior windows.

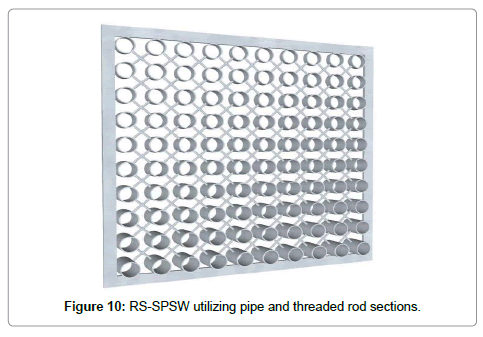

The visual depth of the panel can be modified by using compositional elements with varying depths (Figure 10) or by laying out a uniform depth panel to create the optical illusion of depth. Creating compositional elements with physically varying depths is done by using pipe sections as the rings and circular rod as the links. This is a different method of construction than the previously discussed plates that are water jet cut from a single, solid piece of steel. Panels with visual depth engage the occupant as they move through the space, shifting from opaque to a perforated screen with the changing vantage point of the viewer; these add texture to the boundaries of a room.

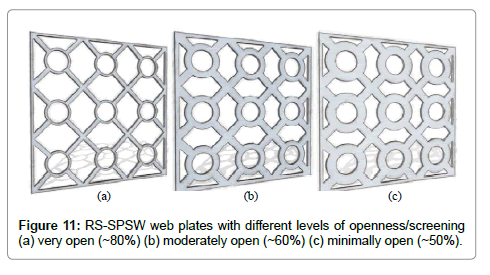

The overall openness or degree of screening of the panel is described by its ratio of positive space to negative space. This is affected by many different parameters including ring density, compositional scale, and ring width (wc). Figure 11 shows three different RS-SPSW panels with the same compositional scale but different amounts of openness. Panels with rings that are spaced far apart and with low values of ring width (wc) appear more open than panels with wide rings that are densely spaced. The degree of panel openness can be used to make spaces feel larger or smaller. They can also be used as visual screens between different spaces. The prevalence of adaptable and multi-functional spaces in contemporary open office design calls for many types of spatial dividers, including those that provide acoustic or visual privacy. The RS-SPSW can provide varying degrees of visual connection and/or privacy depending on the intended function and experience of the space. With the compositional flexibility defined by the parameters presented here (scale, visual depth and openness), the panels can become part of an architectural vocabulary that includes spatial dividers of different materials deployed within a space to provide varying degrees of separation, screening, and visual texture. By providing the architect with the means to use this wall type as a design element, the potential for a more fully integrated design is created.

Even though the compositional parameters (scale, depth and openness) are most typically going to be set by the architect and the geometric parameters are going to be set by the engineer, it is useful for both parties to understand the vocabulary of the RS-SPSW to facilitate collaboration. The next section provides two representative scenarios of how the common vocabulary can be used to create modern, sleek interior spaces with the RS-SPSW system.

Example design process using RS-SPSW

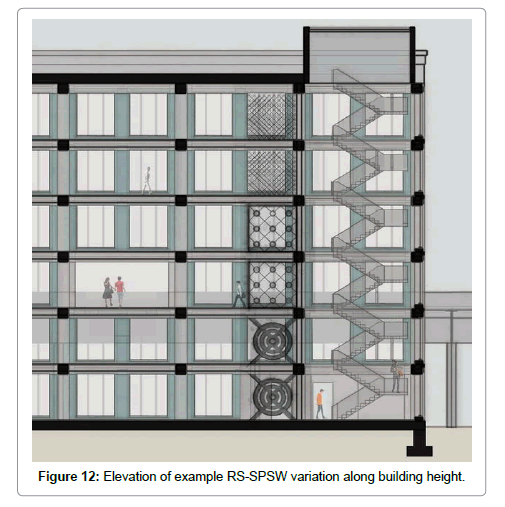

Using the panel vocabulary described in the previous section, it is possible to design many different panel forms. This section discusses two possible scenarios in the same building where an effective architect and engineer partnership can use RS-SPSWs to develop modern building spaces. The first scenario describes how the design of an exposed structural element is incorporated into the design of the lobby of a mixed-use residential building, becoming a sculptural focus within the space and influencing the geometry of other spatial elements such as ceiling planes and furniture pieces. The second scenario describes how the architect can use RS-SPSWs in the upper floors of the same building to define spatial volumes and provide screening in the residential or office spaces. The dialogue between the architect and engineer will facilitate the design of different panel forms to create different spatial and visual effects. Additionally, it will be shown how each floor of the shear wall can have a different infill panel design based upon what the intended usage for each floor is.

After understanding that rings and links (circles and lines) are the basic design elements that make up the panel, the architect recognizes the opportunity to use an RS-SPSW infill panel as a sculptural wall element, creating a focal point in the lobby. The architect describes her concept for the infill panel to the engineer by using the compositional parameters of monumental scale rings that are nested inside each other. She is looking for a lower degree of openness and a slightly thicker plate width to showcase the mass and strength of the base floor exposed plates. The architect also sees the potential to incorporate other nonstructural materials onto the wall panel such as fabric or lighting to change the texture and appearance of the wall from one or both sides. The engineer, using the compositional parameters from the architect, can then specifically design the geometric parameters of the nested rings using the strength equation and buckling slenderness limits given in Phillips and Eatherton (2015a and 2015b).

If the upper floors of this prototype building are mainly office space, then the architect may want to use the RS-SPSW infill panels as dense screens to delineate work spaces. For this use, the compositional parameters would call for fine scaled rings that are spaced densely to provide low amounts of openness. The formal vocabulary of the designed infill panel could be replicated in additional visual screens to be repeated in other locations throughout the space. Conversely, if the middle floors are residential apartments then the architect may use intermediate compositional scale rings with large spacing and thin ring width to create a high amount of openness, allowing for natural light to flood the space. The described variability along the height of the shear wall is displayed in Figure 12.

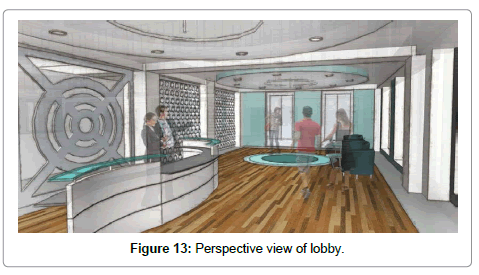

Analogous to multiple compositional configurations of infill plate being used along the height, different configurations of infill plate can also be used in the same space. Figure 13 shows another scenario of a lobby for a professional office utilizing different compositional wall shapes within the same space.

Discussion and Conclusions

The Ring Shaped – Steel Plate Shear Wall (RS-SPSW) system, like many advances in structural systems before it, offers designers a new possibility for architectural form. The RS-SPSW produces substantially improved structural behavior over conventional SPSWs and can be incorporated into the architectural form. Keeping the lateral load resisting system visible in the design of structure aligns with the modernist tradition of celebrating the form’s nature, strength, and purpose.

The common vocabulary developed for RS-SPSWs encourages effective communication between the architect and engineer. Architects will be able to describe what type of panel forms they foresee in the buildings spaces using the compositional parameters and then engineers can create a robust, seismically resilient structural panel that fits the architectural requirements. Advancements in manufacturing techniques, such as CNC controlled laser and waterjet cutting, allow for the RS-SPSW web plates to be fabricated precisely and relatively economically. Additionally, advancements in computer aided drafting, such as Revit 3D and BIM, will allow architects and engineers to visualize, share, and discuss the building’s design more easily. In conclusion, the RS-SPSW system provides a unique avenue to integrate structural functionality into the architectural design process.

Acknowledgements

Special thanks to Matthew Duncan for creating several of the images of RSSPSW designs. The authors acknowledge support from the American Institute of Steel Construction through the Milek Faculty Fellowship Program.

Image Credits

1CC Attribution: https://creativecommons.org/licenses/by/2.0/legalcode

2CC Attribution-ShareAlike: https://creativecommons.org/licenses/by-sa/2.0/ legalcode

1. Drewnlak, Frans. Nervicloseceiling. 2009. Creative Commons Attribution- ShareAlike license2. Web. 22 June 2015. .

2. Boed, Roman. The John Hancock Center in Chicago. 2013. Creative Commons Attribution license1. Web. 22 June 2015. .

3. Nilsson, Susanne. Turning Torso. 2014. Creative Commons Attribution- ShareAlike license2. Web. 22 June 2015. .

4. Barnes, Elvert. 205 HighLinePark.Chelsea.NYC.18June2012. 2012. Creative Commons Attribution-ShareAlike license2. Web. 22 June 2015. .

References

- Le Corbusier (1927) Towards a New Architecture, Translated by Frederick Etchells. Architectural Press, London, UK.

- Le Corbusier (2007) Toward Architecture, Translated by John Goodman. Getty Research Institute, LosAngeles, California.

- Loos A (1982) Spoken In to the Void: Collected Essays 1897-1900. Institute for Architecture & Urban Studies and the Massachusetts Institute of Technology, Chicago Illinois and New York, New York.

- Glancey J (2006) Eyewitness Companions: Architecture. DK Publishing, Inc, New York.

- Salvadori MG, Heller RA (1986) Structure in architecture: the building of buildings. Prentice-Hall.

- Charlesson A (2005) Structureas Architecture. Architectural Press, London,UK.

- Pedreschi R (2008) Form, Force and Structure: A Brief History. Architectural Design, John Wiley & Sons, Ltd 78:12-19

- Billington DP (1983) The Tower and the Bridge-The New Art of Structural Engineering. Princeton University Press, Princeton, New Jersey.

- Anonymous (2013a) 13 Structural Steel Buildings that Dazzle. Building Design + Construction, American Institute of Steel Construction.

- Anonymous (2013b) 2013 IDEAS 2 Awards. Modern Steel Construction, May Issue, American Institute of Steel Construction.

- De-Simone Consulting Engineers (2014) Building on the High Line The Rise of HL23. DeS imone.

- ASCE7 (2005) Minimum Design Loads for Buildings and Others Structures. American Society of Civil Engineers.

- AISC (2010) Seismic Provisions for Structural Steel Buildings ANSI/AISC 341-10. American Institute of Steel Construction, Chicago, IL.

- Egorova N, Eatherton MR, Maurya A (2014) Experimental Study of Ring-Shaped Steel Plate Shear Walls. Journal of Constructional Steel Research 103:179-189.

- Phillips AR, Eatherton MR (2015a) Shear Buckling Stability of Ring Shaped–Steel Plate Shear Walls. Proceeding of the SSRC Annual Stability Conference, Nashville, TN.

- Phillips AR, Eatherton MR (2015b) Ring Shaped–Steel Plate Shear Wall Lateral Torsional Buckling Behavior. Proceedings of the ASCES tructures Congress, Portland.

- Maurya A, Egorova N, Eatherton MR (2013) Development of Ring-Shaped Steel Plate Shear Walls. Proceedings of the ASCE Structures Congress, Pittsburgh, PA

- Maurya A (2012) Computational Simulation and Analytical Development of Buckling Resistant Steel Plate Shear Wall (BR-SPSW). Master’s Thesis,VirginiaTech, Blacksburg,VA.

Relevant Topics

- Architect

- Architectural Drawing

- Architectural Engineering

- Building design

- Building Information Modeling (BIM)

- Concrete

- Construction

- Construction Engineering

- Construction Estimating Software

- Engineering Drawing

- Fabric Formwork

- Interior Design

- Interior Designing

- Landscape Architecture

- Smart Buildings

- Sociology of Architecture

- Structural Analysis

- Sustainable Design

- Urban Design

- Urban Planner

Recommended Journals

Article Tools

Article Usage

- Total views: 13704

- [From(publication date):

September-2016 - Apr 05, 2025] - Breakdown by view type

- HTML page views : 12737

- PDF downloads : 967