Letter to Editor Open Access

Gas-Cylinder Handling Tasks in Taiwan

Yi-Lang Chen*Department of Industrial Engineering and Management, Ming Chi University of Technology, New Taipei, Taiwan

- *Corresponding Author:

- Chen YL

Department of Industrial Engineering and Management

Ming Chi University of Technology

84 Gung-Juan Road, Taishan 24301, New Taipei, Taiwan

Tel: +886-2-29089899

Fax: +886-2-29085900

E-mail: ylchen@mail.mcut.edu.tw

Received date: March 12, 2016; Accepted date: March 28, 2016; Published date: April 4, 2016

Citation: Chen YL (2016) Gas-Cylinder Handling Tasks in Taiwan. Occup Med Health Aff 4:232. doi: 10.4172/2329-6879.1000232

Copyright: © 2016 Chen YL, et al. This is an open-access article distributed under the terms of the Creative Commons Attribution License, which permits unrestricted use, distribution, and reproduction in any medium, provided the original author and source are credited.

Visit for more related articles at Occupational Medicine & Health Affairs

Dear Editor-in-Chief,

Work-related musculoskeletal disorders (WMSDs) have become a critical topic, especially among people who must handle heavy objects in unsuitable postures to fulfill job requirements [1]. The manual handling of gas cylinders is a typical example of such operations in Taiwan and many Southeast Asian countries. Gas cylinders are used frequently in Taiwan because of the dietary and living conditions of Taiwanese people, such as cooking meals and providing heat for water heaters.

In Taiwan, the estimated number of gas stores is 10,000 and approximately 40,000 people are employed in gas distribution. Nearly 8,000,000 gas cylinders weighing 40 kg each are currently used in Taiwan (an empty weight of 20 kg).

Particularly in rural areas or villages and towns where natural gas pipelines have not been developed, numerous individual gas stores operate and maintain designated service areas.

Lin reported that handling gas cylinders over 40 kg induces risks of shoulder and back injury [2]. For example, lifting a cylinder onto the shoulders requires supporting the cylinder by using the right hand, which may cause severe injury to the hands and shoulders (Figure 1).

Devereux et al. evaluated the effectiveness of using auxiliary devices to handle small gas cylinders (16-22 kg), and discovered that these devices increased handlers’ physical loads [3]. Therefore, we investigated potentially risky factors by in-depth interviews and provided suggestions for improving these tasks. Semi-structured onsite in-depth interviews with four gas-cylinder handlers were conducted, and the interviews were recorded verbatim to identify the similarities and differences among the interviewees.

The major similarities are summarized as follows:

All interviewees belonged to the disadvantaged working group because of the financial conditions of their families and they did not work on only 2-3 days per month.

None of the interviewees had former experience in handling gas cylinders before engaging in this work, and the companies did not provide pre-occupational training. The primary job requirement was that applicants must be able to ride motorcycles with manual transmissions. The interviewees learned skills to prevent injuries through experience and considered handling skills more essential than body size.

The interviewees perceived that the most dangerous actions or postures were lifting from a lower level, shoulder carrying, and unloading and the most frequently performed actions or postures were shoulder carrying, lifting from the bottom, and placing down (Figure 1).

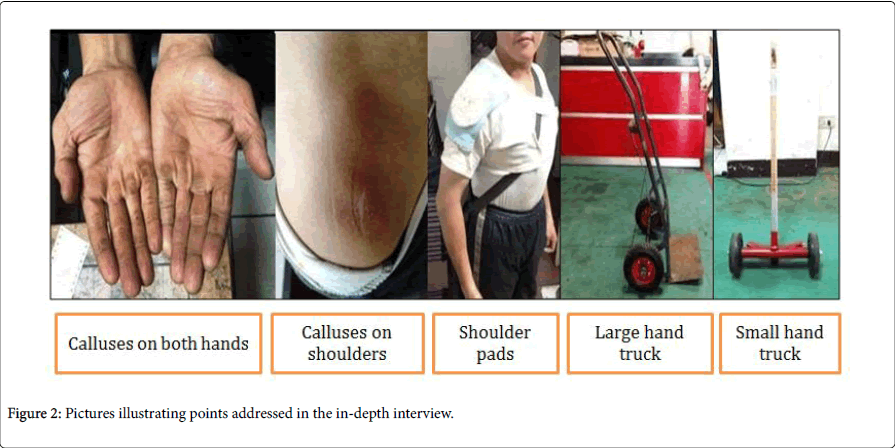

Gloves are commonly worn during winter to prevent the hands from bleeding and becoming chapped. In addition, shoulder carrying results in calluses on the shoulders; therefore, the interviewees sometimes used shoulder pads. The interviewees rarely used other auxiliary devices, such as carts, because using them was inconvenient or did not improve the handling efficiency (Figure 2).

Initially, the interviewees experienced fear when riding motorcycles to deliver heavy gas cylinders that contained dangerous chemicals. Accidents even occurred when only two cylinders were loaded on the motorcycle because the riders could not firmly hold the handlebars due to shaking.

Most consumers of gas live in old apartments, of which only 10%-20% are equipped with elevators. Delivery to the third floor or above requires additional charges of US$0.6-2.0.

Peak hours in a day are 8:00-10:00, 12:00-14:00 and 17:00-20:00 (especially during dinner preparation and showering). Approximately 20 gas cylinders can be delivered in 1 hour during peak hours, and over 100 cylinders per day can be delivered during periods of cold weather.

Handling gas cylinders is more dangerous on rainy days than on sunny days, because wet roads or shallow tire treads can cause accidents such as loss of control and collision. In addition, skid proof shoes should be worn when handling gas cylinders to prevent slipping and falling, especially when ascending stairs.

Most interviewees feared ascending the stairs while carrying a gas cylinder on the shoulders. They felt tremendously stressed when a delivery to the fourth floor or above was requested. This stress was less serious when they were young, but grew with age.

We investigated the current situation regarding task characteristics among gas cylinder handlers and the possible risk factors by using indepth interviews. The preliminary results are provided as follows. Most of the gas-cylinder handlers were older and began handling gas cylinders when employed in other job positions or unemployed. This result revealed that, considering the work characteristics and social identity evaluations, this job was not the first choice for applicants looking for their first job and that gas-cylinder handlers are a disadvantaged working group who require additional concern and assistance. Moreover, the environment and delivery circumstances influenced the perceptions and physical loads of gas-cylinder handlers. Therefore, the working conditions and level of handling difficulty should be considered when analyzing workers’ physical and psychological loads.

References

- Keyserling WM (2000) Workplace risk factors and occupational musculoskeletal disorders, Part 1: A review of biomechanical and psychophysical research on risk factors associated with low-back pain. Am IndHygAssoc J 61: 39-50.

- Lin YH (2004) In-depth review on a CTS case. Bulletin ILOSH, Taiwan, 66.

- Devereux J, Buckle P, Haisman M (1998) The evaluation of a hand-handle interface tool (HHIT) for reducing musculoskeletal discomfort associated with the manual handling of gas cylinders.Int J Ind Ergonom21: 23-34.

Relevant Topics

- Child Health Education

- Construction Safety

- Dental Health Education

- Holistic Health Education

- Industrial Hygiene

- Nursing Health Education

- Occupational and Environmental Medicine

- Occupational Dermatitis

- Occupational Disorders

- Occupational Exposures

- Occupational Medicine

- Occupational Physical Therapy

- Occupational Rehabilitation

- Occupational Standards

- Occupational Therapist Practice

- Occupational Therapy

- Occupational Therapy Devices & Market Analysis

- Occupational Toxicology

- Oral Health Education

- Paediatric Occupational Therapy

- Perinatal Mental Health

- Pleural Mesothelioma

- Recreation Therapy

- Sensory Integration Therapy

- Workplace Safety & Stress

- Workplace Safety Culture

Recommended Journals

Article Tools

Article Usage

- Total views: 11562

- [From(publication date):

April-2016 - Dec 04, 2024] - Breakdown by view type

- HTML page views : 10831

- PDF downloads : 731