Research Article Open Access

Fed-Batch Bioconversion of Glycerol to 1,3-PD by Using Immobilized Citrobacter freundii Cells

Malgorzata Mizielinska*, Urszula Kowalska, Magdalena Labuda, Joanna Furgala and Artur BartkowiakWest Pomeranian University of Technology, Szczecin, Poland

- Corresponding Author:

- Malgorzata Mizielinska

Faculty of Food Sciences and Fisheries

West Pomeranian University of Technology

Center of Bioimmobilisation and Innovative Packaging Materials

Janickiego 35, 71-270 Szczecin, Poland

Tel: 0048914496132

E-mail: Malgorzata.Mizielinska@ zut.edu.pl

Received date: June 06, 2015; Accepted date: August 13, 2015; Published date: August 20, 2015

Citation: Mizielinska M, Kowalska U, Labuda M, Furgala J, Bartkowiak A (2015) Fed-Batch Bioconversion of Glycerol to 1,3-PD by Using Immobilized Citrobacter freundii Cells. J Biotechnol Biomater 5:193. doi:10.4172/2155-952X.1000193

Copyright: © 2015 Mizielinska M, et al. This is an open-access article distributed under the terms of the Creative Commons Attribution License, which permits unrestricted use, distribution, and reproduction in any medium, provided the original author and source are credited.

Visit for more related articles at Journal of Biotechnology & Biomaterials

Abstract

This work was especially concerned with the effectiveness of immobilization of C.freundii strain on surface of PU foams (PUFs) modified by peanut shells. The aim of the work was to check the efficiency of immobilization process in 1,3-PD production in comparison to 1,3-PD bioconversion by using free bacterial cells. The results of the study showed that the immobilized C.freundii cells were more efficient than the free culture was. It is the thesis of the present work that reiterated a fed-batch bioconversion by using immobilized strain could be not so time-consuming and not as an expensive as a conversion in bioreactor containing free cells was. The immobilization was also important because the cells attached to the materials became more adapted to the environment, and could be used many times for the conversion of 1,3-PD. Based on the results presented in the study, it could be concluded that the immobilization could help to decrease the cost of 1,3-PD synthesis and shorten the time of the process.

Keywords

Bioimmobilization; Foam; Bacterial adhesion

Introduction

The 1,3-propanediol (1,3-PD) is a platform chemical presenting several industrial applications. Due to its special properties, PD has an important role in many synthetic reactions, especially polycondensations [1]. The microbial production of 1,3-propanediol has been widely researched and considered as a competitor to the traditional petrochemical routes [2-4]. The crude glycerol as a major byproduct of the biodiesel industries can be a prospective feedstock for PD production. The utilization of the byproduct glycerol promises an opportunity to capitalize on the surplus of waste [5,6].

In literature, fermentation optimizations of the glycerol-converting route include a batch and fed-batch cultures, a continuous culture, a micro aerobic culture, co-substrate fermentation and a two-stage continuous fermentation. The continuous culture has an advantage of relatively high concentrations of the 1,3- propanediol (35.2–48.5 g/L) at a low dilution rates [7-9], but the maximum concentrations of the 1,3-propanediol (50–70 g/L) were obtained in batch and fedbatch cultures [1]. Taking the advantage of the higher end-product concentration of the batch culture and the benefits of a permanent slight glycerol excess, the most efficient cultivation method appears to be a fed-batch variant which uses automatic pH correction by alkali addition for growth-adapted glycerol supply. The bacterial cells would be immobilized to improve the productivity of 1,3-PD [10]. The polyurethane (PU) foams have been widely used as a carrier for microorganism’s immobilization before batch and fed-batch variants of bioconversions. This immobilization material was found to provide a successful immobilization matrix through a long-term fermentation [11]. The other reason to use immobilization is that the microorganisms are very sensitive to their microenvironment and a small variation can alter cell growth and production rate [12,13]. This process may imply some modifications in the microenvironment of the cells, what can be an expected effect. For the industrial fed-batch and batch applications, immobilized cells offer an added important advantage as these can be used again and again for the production of desired molecule and can be easily removed from the production medium [10,14-16].

The work described here involved the immobilization of Citrobacter freundii strain by adsorption on polyurethane foams that were modified by using peanut shells. This material was chosen by taking into consideration the possibilities for the microorganisms to be adsorbed on the porous surface of the modified material. The aim of the work was to check the effectiveness of immobilization process in 1,3-PD production in comparison to 1,3-PD bioconversion by using free bacterial cells. The waste glycerol was used as carbon source. It was the thesis of the present work that bioconversion process using immobilized microorganisms can be carried out repeatedly as well as the modified PU foams with bacterial cells can be used many times. It would be appear that immobilization can eliminate the step of redundant preparing of new culture of bacteria for new bioconversion process.

Materials and Methods

• The one C. freundii strain used in this study was obtained from the collection of Department of Biotechnology and Food Microbiology of Poznan University of Life Sciences Poznan (Poland).

• The culture media (M) that has been used for the studies consisted of 50 g/L (gram per liter) of waste glycerol (Trzebinia Rafinery), 2,4 g/L of K2HPO4, 0,6 g/L of KH2PO4, 2 g/L of (NH4)2SO4, 0,4 g/L of MgSO4*7H2O, 0,1 g/L of CaCl2*2H2O, 0,004 g/L of CoCl2*H2O, 2 g/L of yeast extract, 2,5 g/L of bactopeptone, 1,5 g/L of meat extract. All other reagents that have been used to compose medium were from Merck and CHEMPUR companies. The medium was prepared according to Barbirato et al. composition [17,18]. The amount of substrates was modified to obtain the high yield of process.

• The peanut shells (Lidl) were used as an organic additives during PU foams preparation

• The Mixture of polyols (PCC Prodex) (density=1.02 g/cm3, viscosity=2800 mPas) was used as component A, and the mixture of polyisocyanates (density=1.21 g/cm3, viscosity=150 mPas) was used as a component B. The foams without additives were prepared according to PCC Prodex protocol.

• Set for static process: Bioreactor biostat A plus (Sartorius, Germany) with a proper software.

The modified foam synthesis: The foam composites were obtained from a conventional formulation for flexible polyurethane foams containing the component A (polyethylene glycol, polypropylene glycol, triethylenediamine as the catalyst for the reaction and less than 1% of ethylene glycol as the extending-agent). The composition of the component B, with respect to the polyols content, was 4,4-diisocyanate methylenediphenyl. The peanut shells as a modification were added into component B (0,56 g of peanut into 2 g of polyols). The conventional procedure for the foams preparation was adopted. It consisted of vigorously mixing of 1,2 g of the component A and 2,56 g of component B about 15 s. The modified foams were prepared in a falcon test-tube 1,2 cm in a diameter and 12 cm in length before an expansion started to take place. Later during polymerization (5 min) the polyurethane foams were left to rest for 24 h at room temperature to complete solidification of PUF. The prepared foams were cut into disks and tested.

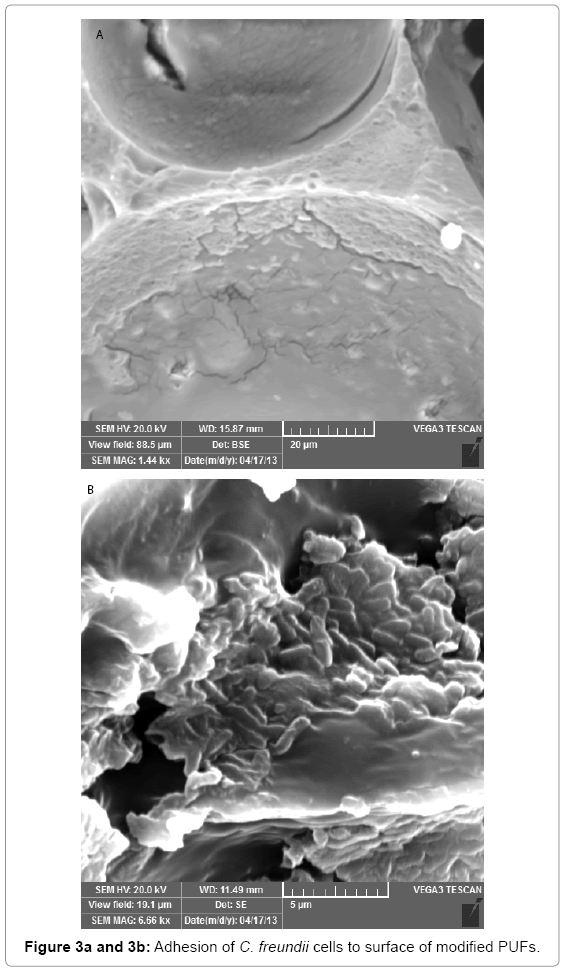

SEM: Before and after immobilisation, microscopic analysis was performed using a microscope Vega 3 LMU (Tescan) scanning electron microscope (SEM). The tests were necessary to examine the porous structure of carriers and to confirm the adhesion of C. freundii cells to the surface of the carriers. Analysis was performed at room temperature with tungsten filament, and an accelerating voltage of 20 kV was used to capture SEM images for both of the pure carrier’s samples and immobilised carriers. All specimens were viewed from the top.

Immobilization: In the first step of the experiments, C. freundii cells were pre-grown on a Medium ’’M’’ with agar for 24 h at 30ºC. After incubation the biomass was suspended in sterile 0.85% NaCl solution (1.3x107 CFU/mL). Then the suspended biomass was added to a sterile flask with broth ’’M” (in a ratio of 1:10) and stirred using a magnetic stirrer (DragonLab, China) for 15 minutes. After stirring, the medium with bacteria culture was added to sterile flasks with sterile modified PU foams and incubated at 30ºC for 24 h. After immobilization 100 mL of PUFs (with bacteria) were used in the bioconversion process. The immobilization effectiveness was evaluated by checking of bacterial cells adhesion using three samples of the PU foams.

Adhesion: After 24 h of incubation, medium “M’’ was taken off the flasks. The PUFs were placed in new flasks and rinsed with a sterile NaCl solution. In the next step the samples were suspended in a sterile broth “M”, and squeezed/homogenised with a sterile glass rod about 1 minute and vortex about 4 minutes. From each suspension serial dilutions were made. The cell concentration was expressed as colony-forming units (CFU) per mL and determined by making a serial decimal dilutions and plating on a Medium “M’’ with agar. Results were presented as an average of three samples. The adhesion of bacterial cells onto surface of the foams was checked before their transfer into the bioreactor and after the bioconversion process.

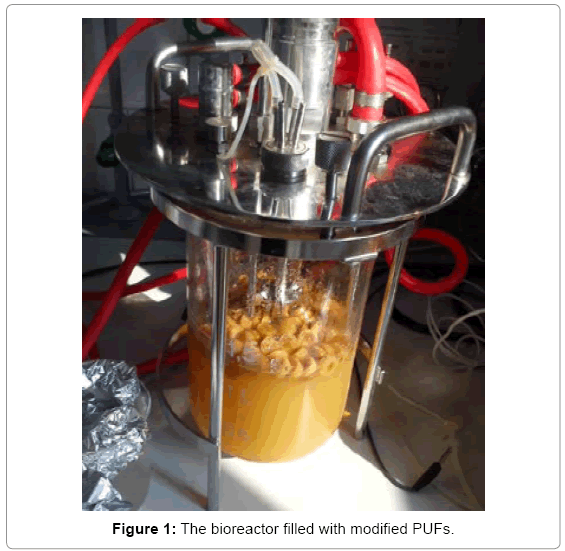

Bioconversion of glycerol to 1,3-PD by using immobilized bacterial cells: After the immobilization, 100 PUF’s were rinsed with sterile 0.85% NaCl solution and transferred to a sterile bioreactor and filled broth “M” (900 mL). The temperature was kept at 30°C using a thermo blanket. The static culture in the bioreactor was started with stirring 150 rpm for 292 hours (Figure 1). The glycerol was added to the medium after 24 and 48 hours of the bioconversion. The samples of an effluent were taken of the bioreactor every day. The amount of glycerol and 1,3-PD in these samples was analyzed. The viability of bacterial cells in effluents was examined as well. After 144 hours of process the medium was completely replaced and the three polyurethane foams have been taken of the bioreactor. The adhesion of bacterial cells onto the surface of this foam was determined.

Bioconversion of glycerol to 1,3-PD by using free bacterial cells: The 1 L of broth “M” containing free bacterial cells was transferred to a sterile bioreactor. The temperature was kept at 30°C using a thermo blanket. The static culture in a bioreactor was started with stirring 150 rpm for 292 hours. The glycerol was added to the medium after 24 hours of the bioconversion. The samples of the effluent were taken of the bioreactor every day. The amount of glycerol and 1,3-PD in these samples was analyzed. The viability of the bacterial cells in the effluents was examined as well. After 144 hours of process ½ of the medium was replaced by a new sterile broth “M”.

Chromatography analysis: The total 1,3-PD and glycerol content was determined by HPLC (Knauer, Germany) using Aminex HPX-87H organic acid analysis column and RI detector. The injection volume of the sample was 10 μL. The column, maintained at 25ºC, was eluted with 5 mM H2SO4 at a flow rate of 0.6 mL/min, samples ran for 30 minutes. Samples for chromatography analysis were taken every day after 24 h. The production of 1,3-PD and consumption of glycerol were obtained by dividing the final concentration (g/L) by the fermentation process time (h).

Microorganism viability: Samples from the effluent were taken and analyzed for viability of C. freundii cells. 100 μL of each sample was put into 900 μL of media “M” and mixed using vortex. From each suspension serial dilutions were made. Cell concentration was expressed as CFU per mL and determined by making serial decimal dilutions and plating on Medium “M’’ with agar. Results were presented as the average of three samples.

Results and Discussion

In order to reduce the high costs of glycerol fermentation to 1,3-PD and to keep the process stable it was necessary to immobilize an active biomass of C. freundii. The fed-batch bioconversion of the glycerol in which free cells are adopted is an expensive and limited even if the partial exchange of the medium is used. It is important that at the time in which free bacterial cells include another metabolic pathway and stop to produce 1,3-PD, the fermentation process should be stopped. The new inoculum of bacterial cells and new medium should be prepared to repeat the 1,3-PD production. The sterilization of a bioreactor is also important. These steps are time-consuming and expensive. The immobilization can be used to reduce the costs and to shorten the time of the process. In the case of bioconversion of glycerol to 1,3-PD using immobilized bacterial cells the medium can be partially exchanged as well, and the glycerol can be added during the process. The conversion should be also stopped at the moment in which bacterial cells stop to produce 1,3-PD. In contrast to the process in which free cells are used in the case of immobilized bacterial strain there is no need to prepare new inoculum of bacterial cells and there is no need to open the bioreactor (Figure 1). When the first bioconversion process is stopped there are still the carriers with bacterial cells inside the bioreactor, even if it is devoid of the medium. In that case the bioreactor can be filled with new medium and the second process can start. The elimination of sterilization and new inoculum preparation steps can decrease the total costs and time of the process. This study was especially concerned with the influence of the immobilization on repeated bioconversion of the glycerol to the 1,3-PD. The polyurethane foams have been chosen as carriers during bacteria immobilization. Additionally the adhesion of bacterial cells to PUF’s surface was increased by the addition of the peanuts shells during the foams preparation what was proved during the tests within the project (Figure 2).

The results of the study using scanning electron micrographs revealed the porous structure of the modified PUFs (Figure 3a and 3b). A network of bacteria rapidly colonized the polyurethane matrix (Figure 3a and 3b). After 24 h of immobilization the biofilm on the PUFs was macroscopically visible. Similarly, the porous structure of the carrier was determined using SEM by Pflugmacher et al. [12]. The authors used PUR 90/16 to immobilize C. freundii strain to converse glycerol to 1,3- PD. In this case also a network of bacteria was macroscopically visible (Figure 3a and 3b).

In the effluent from the bioreactor containing free and immobilized C. freundii, viable cells were detected throughout all the experiments (Table 1-4). The amount of the bacteria on the surface of the foams was also examined to indicate that the C. freundii cells were still immobilized on PUFs. The results of the experiments showed that there were 1.36x107 CFU/mL of C. freundii cells on the surface of the polyurethane foams before the process run. After the first 144 hours of the bioconversion, before medium exchange there were 1.65x107 CFU/mL of bacterial cells on the surface of modified carriers and 6.5x106 CFU/mL in effluents (Table 1). After 292 hours, the process of conversion of the glycerol to the 1,3-PD was finished, and decrease of the amount of C. freundii in effluents was observed. There were 9.67x103 CFU/mL of bacteria in the effluent from the bioreactor containing foams and 4.5x106 CFU/mL on the surface of carriers. The higher number of cells on carriers than in the effluent as well as SEM images proved that microorganisms have been still immobilized on PUFs (Table 2) (Figure 3a and 3b). The decrease of the amount of bacteria in effluents during the process was observed. Gurgonmusler et al. [16] obtained similar results. As the authors say the decrease of the number of bacterial cells in bioreactor can be explained by the fact that C. freundii was in a lag phase. The results of fed-batch bioconversion using free bacterial cells demonstrated that there were 1.12x109 CFU/mL of C. freundii in the effluent before process run. During the first 145 hours the number of microorganism’s cells decreased to 2.5x109 CFU/mL (Table 3). After 292 hours of conversion of glycerol to 1,3-PD the amount of bacteria decreased to 0.22x108 CFU/mL (Table 4). It should be said that the decrease of the number of bacterial cells in the effluent from bioreactor containing free C. freundii was lower than decrease of the number of bacteria in the effluent from bioreactor containing immobilized cells what could be caused by immobilization (Table 1-4). It would appear that the use of the modified peanuts shells to modify PU foams caused the adhesion of the high number of C. freundii cells on the surface of PUFs (Table 1-4) what was proved by the higher number of bacterial cells on the surface on carriers than in the effluent. The effective adhesion could be the reason of very low number of bacterial cells in effluent from bioreactor containing immobilized bacteria.

| Time [h] | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| 0 | 6 | 24 | 48 | 72 | 96 | 120 | 145 | 0 | 145 | |

| Concentration of C. freundii in effluent [*106CFU/mL] |

Concentration of C. freundii on PUFs [*106CFU/mL] |

|||||||||

| 0 | 63.7 | 330 | 154 | 99.7 | 243 | 38.0 | 6.5 | 13.6 | 16.5 | |

| Standard deviation [*106CFU/mL] | ||||||||||

| 0 | ±2.08 | ±17.3 | ±3.79 | ±11.5 | ±30.6 | ±0.14 | ±0.42 | ±0.15 | ±0.32 | |

Table 1: The concentration of C. freundii cells in the effluent and on the surface of carriers before complete exchange of medium (avarage values of triplicates).

| Time [h] | ||||||||

|---|---|---|---|---|---|---|---|---|

| 0’ | 168 | 192 | 216 | 244 | 268 | 292 | 0’ | 292 |

| Concentration of C. freundii in effluent [106CFU/mL] |

Concentration of C. freundii on PUFs [106CFU/mL] |

|||||||

| 0 | 85.3 | 124 | 113 | 28.0 | 35.3 | 0.00967 | 16.5 | 4.5 |

| Standard deviation [*106CFU/mL] | ||||||||

| 0 | ±10.20 | ±3.61 | ±9.90 | ±1.00 | ±4.04 | ±0.00115 | ±0.32 | ±0.17 |

Table 2: The concentration of C. freundii cells in the effluent and on the surface of carriers after complete exchange of medium (avarage values of triplicates).

| Concentration of C. freundii in effluent [108CFU/mL] | |||||||

|---|---|---|---|---|---|---|---|

| Time [h] | |||||||

| 0 | 6 | 24 | 48 | 72 | 96 | 120 | 145 |

| 11.2 | 2.1 | 21.5 | 25.0 | 9.1 | 10.0 | 5.3 | 2.5 |

| Standard deviation [*108CFU/mL] | |||||||

| ±0.12 | ±0.05 | ±0.14 | ±0.13 | ±0.02 | ±0.01 | ±0.02 | ±0.02 |

Table 3: The concentration of free C. freundii cells in the effluent before repleacment of the medium (avarage values of triplicates).

| Concentration of C. freundii in effluent [108CFU/mL] | |||||

|---|---|---|---|---|---|

| Time [h] | |||||

| 168 | 192 | 216 | 244 | 268 | 292 |

| 1.7 | 2.2 | 2.0 | 2.1 | 2.2 | 0.22 |

| Standard deviation [*108CFU/mL] | |||||

| ±0.02 | ±0.03 | ±0.02 | ±0.01 | ±0.02 | ±0.05 |

Table 4: The concentration of free C. freundii cells in the effluent after the repleacment of the medium (avarage values of triplicates).

Tables 5 and 6 show the average 1,3-PD concentrations obtained from each bioreactor (containing free cells of C. freundii and the cells immobilized on the surface of modified PUFs). As seen in tables the highest 1,3-PD concentrations for each bioreactor were found to be 31.9 g/L and 28.8 g PD/L for PUFs bioreactor, and for free cells bioreactor, respectively. During the first 24 hours of process, the immobilized C. freundii strain consumed 96.6% of waste glycerol (Table 5). In the same time free cells of bacteria used 79.8% of waste carbon source (Table 6). These results demonstrated that bioconversion in which immobilized microorganisms were used caused the more efficient utilization of waste products than the bioconversion with free cells. The experiments carried out by Metsoviti et al. [1] demonstrated that only 50% of crude glycerol was consumed by C. freundii after 24 hours of the process. The results of this work showed that during the first day of process, immobilized cells produced 16 g/L of 1,3-PD and free microorganisms synthesized 13.8 g/L of this product. It is a proof that immobilization of bacteria is advantageous. Comparing the yield and the productivity of the bioconversion for bioreactors containing immobilized and free cells separately, it should be said that after first 24 hours of the process their yield values were similar. However the productivity values were better for the bioreactor containing immobilized cells (Table 5 and 6). After 24 hours of process the concentration of glycerol in the bioreactor with immobilized cells and in bioreactor containing free cells were 1.63 g/L and 8.9 g/L as well. The utilization of the glycerol caused the addition of this substrate to the medium for both of bioreactors during 25 hour of bioconversion. Similarly Metsoviti et al. [1] have added crude glycerol to the medium when its concentration was lower than 5 g/L. After next 24 hours immobilized microorganisms utilized 64% of glycerol. In the same time free cells consumed only 21.3% of waste product. It is why glycerol was added only to the medium from bioreactor containing immobilized cells. Comparing these two processes during next 100 hours it should be said that better results were obtained for the free cells than for immobilized. It was proved by the yield and the productivity values. It should be added that immobilized cells utilized the glycerol slower and partially. From the other hand free cells used all glycerol. In the case of 1,3-PD, after 144 hours of process, the concentration of this product was higher for free than for immobilized cells. It was also important that after 120 hours immobilized cells started to consume 1,3-PD. After 145 hours of bioconversion a half of the medium from bioreactor included free cells was replaced with new one. In the case of bioreactor containing immobilized cells it was possible to exchange all medium. The total replacement of medium had many advantages as total removal of process by-products that could inhibit bacterial growth and 1,3-PD synthesis. After partial replacement of medium free bacterial cells utilized crude glycerol very slow. As has been demonstrated, after 240 hours of the new process they have stopped to converse this substrate to 1,3-PD. They have utilized only 0.98 g/mL of glycerol between 240 and 292 hour and they have started to consume 1,3-PD (Table 6). Analyzing the yields of both of processes (Table 5 and 6), the 1,3-PD yields ranged between 0.23 and 0.79 (g 1,3-PD/g glycerol) there is compatible with the theoretical expected ranges [19]. Similarly results of study of Gungormusler et al. [16] showed that values of yields ranged between 0.23 and 0.79 that was compatible with the theoretical expected ranges.

| Time [hours] | Glycerol [g/L] |

1,3-propanodiol [g/L] |

|---|---|---|

| 0h | 48.07 (±0.4) | 0 |

| 24h | 1.63 (±0.1) | 16 (0.75) |

| Yield [g/g] | 0.34 (±0.17) | |

| Q [g/Lh] | 0.67 (±0.2) | |

| 25h | 32.70 (±0.9) (addition of 31.07g of glycerol) | 15.29 (±1.45) |

| 48h | 11.74 (±1.12) | 20.72 (±1.22) |

| Yield [g/g] | 0.26 (±0.04) | |

| Q [g/Lh] | 0.23 (±0.09) | |

| 49h | 45,30 (±0.87) (addition of 33,56g of glycerol) | 20.58 (±1.98) |

| 72h | 38.09 (±1.14) | 22.27 (±1.15) |

| 96h | 36.00 (±2.11) | 23.42 (±2.21) |

| 120h | 39.49 (±1.43) | 28.38 (±0.99) |

| 144h | 34.11 (±0.75) | 25.00 (±0.81) |

| Yield [g/g] | 0.39 | |

| Q [g/Lh] | 0.05 | |

| 145h | 51,3 (±0.5) (complete replacement of the medium ) | 6.2 (±0.11) |

| 168h | 38.11 (±1.23) | 12.49 (±0.76) |

| 192h | 18.89 (±2.28) | 21.68 (±0.75) |

| 216h | 1.87 (±0.15) | 27.86 (±0.55) |

| 240h | 3.48 (±0.11) | 31.09 (±0.56) |

| 264h | 6.98 (±0.14) | 31.90 (±0.34) |

| 292h | 0 | 31.90 (±0.34) |

| Yield [g/g] | 0.50 (±0.01) | |

| Q [g/Lh] | 0.17 (±0.01) |

Table 5: The concentration of the glycerol and 1,3-PD during 292 h of the bioconversion using immobilized C. freundii cells.

| Time [hours] | Glycerol [g/L] |

1,3-propanodiol [g/L] |

|---|---|---|

| 0h | 44.00 (±0.97) | 0 |

| 24h | 8.9 (±0.01) | 13.8 (±0.18) |

| Yield [g/g] | 0.39 (±0.05) | |

| Q [g/Lh] | 0.58 (±0.05) | |

| 24h* | 28.52 (±1.12) (addition of 19.62g of glycerol) | 7.05 (±0.02) |

| 48h | 22.45 (±0.11) | 22.13 (±0.08) |

| 72h | 27.90 (±0.19) | 16.12 (±0.12) |

| 96h | 12.36 (±0.19) | 22.34 (±0.75) |

| 120h | 8.72 (±0.12) | 27.24 (±0.5) |

| 144h | 0 | 28.8 (±0.75) |

| Yield [g/g] | 0.76 (±0.01) | |

| Q [g/Lh] | 0.18 (±0.01) | |

| 145h | 40,35 (replacement of 1/2 of the medium) | 14.9 (±1.12) |

| 168h | 41.51 (±0.99) | 20.9 (±1.23) |

| 192h | 35.28 (±1.25) | 19.0 (±0.75) |

| 216h | 35.00 (±0.98) | 19.2 (±0.5) |

| 240h | 34.01 (±0.35) | 18.5 (±0.61) |

| 264h | 33.90 (±0.77) | 18.2 (±0.6) |

| 292h | 33.03 (±0.75) | 18.2 (±0.6) |

| Yield [g/g] | 0.45 (±0.01) | |

| Q [g/Lh] | 0.022 (±0.01) |

Table 6: The concentration of the glycerol and 1,3-PD during 292 h of the bioconversion using free C. freundii cells.

Comparing the productivities of the fed-batch conversion using free bacterial cells it was noticed that their values decreased during process and after 292 hours it was 0.022 g/Lh. These results were tempting to suggest that fed-batch conversion using free cells should be stopped. It would appear that a next partial exchange of medium would not be sufficient. Gungormusler et al. [16] explained it by the fact that C. freundii produces 1,3-PD in the primer metabolism during logarithmic phase. Later on, in the stationary phase 1,3-PD is produced slower than it is consumed. Only when the microorganisms are kept in log phase, the product concentration reaches its maximum value [9]. The better results were obtained for immobilized bacteria. The C. freundii utilized all 51.3 g/L of the waste glycerol after 292 hours of bioconversion (Table 5). It could be caused by the total exchange of the medium. It would seem that new medium devoid of by-products could influence on better glycerol utilization and synthesis of 1,3-PD. The reason why immobilized cells did not stop to converse glycerol to 1,3-propanediol could also be that microorganisms formed the biofilm on surface of carrier. The biofilm could protect bacterial cells even if toxic by-products were in the medium. Similarly it was necessary to minimize the concentrations of by-products for Gungormusler et al. [9]. Because, as reported, a crude glycerol broth may contain not only acetate but also some inorganic salts from glycerol fermentation medium, and these substances may cause cell growth inhibition and subsequently a decrease in 1,3-PD production. The 2,3-BD (2,3-bythyldiol) was found to be the by-product produced in high amount, but the accumulation of this substance did not affect negatively the 1,3-PD. As has been confirmed by researchers [20] the C. freundii is not resistant to the various impurities in the crude glycerol derived from biodiesel preparation. The authors said that pretreatment of crude glycerol has proved to be an economical and an easy method to remove the most potent growth inhibitors. In addition, it was also observed that removing of impurities can cause not only the growth inhibition decreased but also 1,3-PD production increased to the level which can be comparable to the pure glycerol. The glycerol that was used in this study was crude glycerol from biodiesel production. The impurities were not removed before using. The solution of impurities problem could be immobilization that was used as well. The results of the work of Wong et al. [13] also demonstrated that the ability of microorganisms (for example Klebsieblla sp. HE-2) to produce 1,3-PD is highly dependent on the composition of the cultivation medium. The authors proved that the immobilized-cell system appeared to be an effective for promoting the operational stability and reusability of cells. They showed that immobilized cells were able to produce 1,3-PD using crude glycerol, achieving the yield similar to that obtained when using the pure glycerol. Their results demonstrated that removing impurities in the case of immobilized cells was not necessary. The results of the study showed that modified by peanut shells foams as carriers had positive influence on the final product synthesis. These considerations have been confirmed by Gungormusler et al. [16]. The authors concluded that the differences in 1,3-PD production were not only dependent on the microorganism but also on immobilization material. The experiments of Casali et al. [21] also showed that concentration of 1,3-PD obtained using immobilized bacterial cells was higher than in the case of the freely suspended culture. The results used in this study showed that maximum concentration of the 1,3-PD that was obtained after bioconversion by using immobilized bacteria was 31.09 g/L (Table 5). The concentration of 12.92 g/L of 1,3-PD measured in packed bed bioreactors, was obtained by Casali et al. [21] when the C. freundii was also immobilized on PUF. Similarly, the maximum concentration obtained with C. freundii, observed in the packed-bed reactor filled with VUK (Vukopor®S10). The results obtained in this study were better (Table 5). The authors mentioned above used pure PUFs and VUK as carriers for immobilization of microorganisms. The polyurethane foams that were used in this work were modified by addition of peanut shells. It was necessary to increase cells adhesion and to increase the yield of the conversion of the crude glycerol to 1,3-PD. As has been argued by Pflugmacher et al. [12] the modified polyurethane foams have been found to be better carriers than not modified PUR 90/16 what was proved the productivity values. The higher concentration of 1,3-PD depended not only on immobilization. As has been emphasized by Misturini Rossi et al. [22] K. pneumoniae DSM 2026 exhibited the highest final concentration of 1,3-PD achieving 61 g/L. On the other hand C. freundii produced only 35 g/L respectively, under the same conditions. The maximal concentration of 35 g/L obtained by the authors was similar to the results presented above.

Summarizing, in this study, it was shown that immobilized C. freundii cells were more efficient than the free culture during the conversion the crude glycerol to 1,3-PD. The carriers with bacterial cells were used to repeat the process after total exchange of the medium devoid of bioreactor opening. It is the thesis of the present work that reiterated fed-batch bioconversion by using immobilized strains could be not so time-consuming and not as expensive as conversion in bioreactor containing free cells was. In addition, the modified polyurethane foams proved to be good carriers. The immobilization was also important because cells attached to the materials became more adapted to the environment, and could be used many times for the conversion of 1,3-PD. Based on the results presented above, it could be concluded that immobilization could help to decrease the cost of the 1,3-PD synthesis and shorten the time of process.

References

- Metsovitia M, Zengb AP, Koutinasa AA, Papanikolaou S (2013) Enhanced 1,3-propanediol production by a newly isolated Citrobacterfreundii strain cultivated on biodiesel-derived waste glycerol through sterile and non-sterile bioprocesses. J Biotechnol 163: 408– 418.

- Zhao YN, Chen G, Yao SJ (2006) Microbial production of 1,3-propanediol from glycerol by encapsulated Klebsiellapneumoniae. BiochemEng J 32: 93–99.

- Saxena RK, Anand P, Saran S, Isar J (2009) Microbial production of 1,3-propanediol: Recent developments and emerging opportunities. BiotechnolAdv 27: 895-913.

- Drozdzynska A, Leja K, Czaczyk K (2011) Biotechnological production of 1,3-propanediol from crude oil. J Biotechnol 92: 92-100.

- Liu H, Xu Y, Zheng Z, Liu D (2010) 1,3-Propanediol and its copolymers: Research, development and industrialization. Biotechnol J 5: 1137-1148.

- Santibáñez C, Varnero MT, Bustamante M (2011) Residual glycerol from biodiesel manufacturing, waste or potential source of bioenergy: A Review. Chil J Agr Res 71: 469-475.

- Boenigk R, Bowien S, Gottschalk G (1993) Fermentation of glycerol to 1,3-propanediol in continuous cultures of Citrobacterfreundii. ApplMicrobiolBiotechnol 38: 453-457.

- Andrade JC, Vasconcelos I (2003) Continuous cultures of Clostridium acetobutylicum: Culture stability and low-grade glycerol utilisation. BiotechnolLett 25: 121-125.

- Gungormusler M, Gonen C, Azbar N (2011) Continuous production of 1,3-propanediol using raw glycerol with immobilized Clostridium beijerinckii NRRL B-593 in comparison to suspended culture. Bioprocess BiosystEng 34: 727-733.

- Silva MF, Rigo D, Mossi V, Dallago RM, Henrick P, et al. (2013) Evaluation of enzymatic activity of commercial inulinase from Aspergillusniger immobilized in polyurethane foam. Food Bioprod Process 91: 54–59.

- Jun SA, Moon C, Kang CH, Kong SW, Sang BI, et al. (2010) Microbial fed-batch production of 1,3-propanediol using raw glycerol with suspended and immobilized Klebsiellapneumoniae. ApplBiochemBiotechnol 161: 491-501.

- Pflugmacher U, Gottschalk G (1994) Development of an immobilized cell reactor for the production of 1,3-propanediol by Citrobacterfreundii. ApplMicrobiolBiotechnol 41: 313-316.

- Wong CL, Huang CC, Chen WM, Chang JSu (2011) Converting crude glycerol to 1,3-propanediol using resting and immobilized Klebsiella sp. HE-2 cells. BiochemEng J 58-59: 177-183.

- De Ory I, Romero LE, Cantero D (2004) Optimization of immobilization conditions for vinegar production. Siran, wood chips and polyurethane foam as carriers for Acetobacteraceti. Process Biochem 39: 547–555.

- Quezada MA, Carballeira JD, Sinisterra JV (2009) Monascus kaoliang CBS 302.78 immobilized in polyurethane foam using iso-propanol as co-substrate: Optimized immobilization conditions of a fungus as biocatalyst for the reduction of ketones. BioresourTechnol 100: 2018-2025.

- Gungormusler M, Gonen C, Azbar N (2011) Use of ceramic-based cell immobilization to produce 1,3-propanediol from biodiesel-derived waste glycerol with Klebsiellapneumoniae. J ApplMicrobiol 111: 1138-1147.

- Barbirato F, Camarasa-Claret C, Grivet JP, Bories A (1995) Glycerol fermentation by a new 1,3-propanediol-producing microorganism: Enterobacteragglomerans. ApplMicrobiolBiotechnol 43: 786-793-793.

- Barbirato F, Himmi EH, Conte T, Bories A (1998) 1,3-propanediol production by fermentation: An interesting way to valorize glycerin from the ester and ethanol industries. Ind Crop Prod 7: 281–289.

- Chen X, Xiu Z, Wang J, Zhang D, Xu P (2003) Stoichiometric analysis and experimental investigation of glycerol bioconversion to 1,3-propanediol by Klebsiellapneumoniae under microaerobic conditions. Enzyme MicrobTechnol 33: 386–394.

- Anand P, Saxena RK (2012) A comparative study of solvent-assisted pretreatment of biodiesel derived crude glycerol on growth and 1,3-propanediol production from Citrobacterfreundii. N Biotechnol 29: 199-205.

- Casali S, Gungormusler M, Bertin L, Fabia F, Azbar N (2012) Development of a biofilm technology for the production of 1,3-propanediol (1,3-PDO) from crude glycerol. BiochemEng J 64: 84-90.

- Misturini Rossi D, Aquino de Souza E, HickmannFlôres S, ZáchiaAyub MA (2013) Conversion of residual glycerol from biodiesel synthesis into 1,3-propanediol by a new strain of Klebsiellapneumoniae. Renew Energ 55: 404-409.

Relevant Topics

- Agricultural biotechnology

- Animal biotechnology

- Applied Biotechnology

- Biocatalysis

- Biofabrication

- Biomaterial implants

- Biomaterial-Based Drug Delivery Systems

- Bioprinting of Tissue Constructs

- Biotechnology applications

- Cardiovascular biomaterials

- CRISPR-Cas9 in Biotechnology

- Nano biotechnology

- Smart Biomaterials

- White/industrial biotechnology

Recommended Journals

Article Tools

Article Usage

- Total views: 14646

- [From(publication date):

September-2015 - Mar 31, 2025] - Breakdown by view type

- HTML page views : 9989

- PDF downloads : 4657