Exploration of Indigenous Pineapple-Acrylic Blend: A Future Prospect for Sustainable Luxury Textiles

Received: 10-Apr-2017 / Accepted Date: 28-May-2017 / Published Date: 06-Jun-2017 DOI: 10.4172/2168-9717.1000195

Abstract

Utilization of underexploited, unexplored natural fibres from crop waste are not only critical issues in the international scenario but are also the need of the hour in developing countries like India. Pineapple leaf fibre extracted from the green pineapple leaf, an agro waste reveals its immense potentiality in the field of textiles particularly due to the disposal problem after harvesting for cleaner and green environment. Blending of indigenous PALF with acrylic will help development of textiles with better functional properties by combining positive features of both the fibres. Blending of PALF/acrylic did not pose any problem in conventional jute processing system. Wet spun yarn exhibits better characteristics compared to dry spun one. The optimum stage of blending of the above fibres is carding stage. The critical blend level for 3 denier acrylic fibre and indigenous PALF has been found to be 74/26. The theoretical and actual blend composition estimated by chemical method reveals close matching with each other. The PALF/acrylic blended yarn has a bright future prospect for sustainable luxary textiles like fancy apparel products.

Keywords: Agricultural waste, Indigenous pineapple and acrylic, Blended yarn, Tensile properties, Critical Blend

76988Introduction

India is primarily an agricultural country producing a variety of cash crops. In spite of this, a shortage of raw materials is a notable hindrance limiting the industrial growth of our country. In 1493, Colombus and his crew were the first Europeans to taste pineapple fruits at Guadeloute Island. The name pineapple itself is derived from the Spanish word “Pina” which means cone shaped. The Pineapple (Ananas Comosus Merr. appertained to the Family-Bromiliaceae) is most popular tropical fruits widely cultivated in tropical and subtropical regions around the globe. The unutilized leaves, a major part of the plant needs global attention for its commercial exploitation after harvesting of fruits creating wastage. Either the leaves are disposed by burning or decomposed and lead to the arising some environmental issues, a global alarming issue. Proper utilization of indigenously available agricultural waste like PALF will not only solve the problems of their disposal, environmental and technical issue but improve the economy of cultivation and give new employment potential under “Make in India Mission”. Besides it will also open up reservoirs of natural resources for various requirements of the country [1,2]. Wealth from waste is no more a slogan in 21st century but achieved successfully turning pineapple leaves into wealth which not only creates green environmental sense but also turns waste into wealth (Figure 1).

Global production of pineapple was around 24.79 million tonnes in 2013. Philippines has the first position is the list of pineapple producing countries, which generates about 2200 thousand metric tons. Despite the fact that it is a little nation when contrasted with others yet land and climate is best for pineapples to cultivate. Thailand and Costa Rica are additionally the largest pineapple producer in the world. The fibre is extracted from the leaves either manually with scrapper or mechanically with decorticator or by retting the leaves in water. The fibre exhibits silky lustre, creamy colour, finer than jute, good antibacterial and dyeing properties, and the yield is confined to about 2.5-3.5% only of total leaf biomass. Thus, extraction alone is not economically viable and hence does not arouse interest to the farmers. Even the leaves are not suitable for cattle feed and hence after harvest of fruit, the disposal creates a headache leading to potential for the mass consumption of these resources with applying some technologies besides generate additional income for the farmers and entrepreneurs. The residual sludge can be utilized successfully for vermicomposting to make a total integrated package economically viable. Pina fabric made from fibres extracted from pineapple leaves has occupied a pride of place in Philippines. In 2008, India produced 1.2 million tonnes of pineapple and the major pineapple producing states in India are West Bengal (23%), Assam (16%), Karnataka (12%), Bihar (11%), Tripura (10%) Kerala (8%), Meghalaya (7%), Manipur (6%). In India, there are around 80,000 hectares of land under pineapple cultivation and given the average yield of around 2 tonnes of fibre per hectare, the total potential for production of pineapple fibre in the country is around 1,60,000 tonnes. PALF in view of its unique inherent features like high strength, natural colour, biodegradability and cheaper price may be explored to manufacture of a variety of home textiles by binary or multi blending [1-3]. Dey, et al. reported that a magic yarn is born out of golden fibre blends with pineapple (15-25%) which is impossible from 100% golden fibre alone. The fibre is best used as decorative material. The findings of Dey, et al. reveals that when blended with synthetic material, the product is an extra fine material which can be promoted to apparel textiles. It can work wonders with jute. If pineapple leaf fibre is blended with jute up to 20-25%, fine yarn of linear density of 69 tex or less can be created which is very difficult to achieve with Indian jute alone [4,5].

The findings of Dey, et al. reveal that PALF / Ramie blended yarns spun in wet spinning system shows better performance than dry spun yarns due to better inter fibre friction in the wet spinning system. PALF/Viscose blends by Dey, et al. reveal that gradual increase of PALF in the blend brings improvement in the tenacity of the blended yarns due to higher strength of PALF [6,7]. The wet spun blended yarn from PALF-viscose show better performance than corresponding blended yarns spun on the dry spinning system. Binary blending of PALFPolypropylene by Ghosh et al. for its use in sophisticated area of textiles indicate that the performance of PALF-Polypropylene blended yarns reveal that 100% PALF yarn is better than polypropylene yarn though latter is stronger than the former. Ghosh et al. reported that yarn from PALF: Wool blend processed in semi worsted spinning system can be suitably used for carpet face yarns and home furnishing fabrics. The recent development on PALF by Yusri, et al, showed that PALF extracted using M1 has higher tensile compared to PALF extracted by hand scrapping [8]. Jalil, et al. reported that physical properties of jute- PALF blended yarn (5 and 7 lbs/spy) of 70:30 and 80:20 respectively are better than those of 100% jute yarn while there is no significant surface appearance properties like color strength (K/S value) and whiteness, yellowness and brightness indices of the blended yarns [9,10].

Performance of Pine apple leaf fibres in Jute and Worsted spinning by Palit, et al. reveals that for every 1% addition of PALF, the strength of jute/PALF blended yarn increases by about 0.38%.Polyester/wool/ PALF blended yarns (45%/45%/10%) spun on worsted spinning system are inferior to polyester/wool yarn (50%/50%) in major tensile characteristics [11-15]. However, very scanty literatures are available for the apparel quality textile thread from blends of PALF/Acrylic, the reported work is an endeavour for PALF characterization, and conversion into luxury textiles by using existing fibre processing system since there is no specialized spinning system available for PALF and their possible commercial utilization [16].

Materials and Methods

Evaluation of fibre properties

Materials: Acrylic fibres (nonshrinkable), Top of 3 denier, 120 mm length were supplied by an indigenous company at Baroda, India and Pine apple leaf fibre (PALF) was collected from ICAR-Central Research Institute for Jute and Allied Fibres, Sorbhog, Assam.

Chemicals: All chemicals used in this research work were analytical grade.

Methods

Evaluation of fibre properties: The tensile properties of fibres were measured using Instron Tensile tester (Model 5567, UK made) following standard parameters for fibres (ASTM D 3822) maintaining 10 gauge length and 300 m/min traverse. The moisture regain of PALF and acrylic were measured by oven dry method following ASTM-D 2654-76 under standard testing atmosphere of 65% relative humidity and at 27°C.

The gravimetric fineness expressed in mass per unit length was ascertained by cutting and weighing method. Small lengths of fibres/ filaments were cut into 2 mm length and 500 pieces were counted and weighed in precision micro balance. The results are expressed in gm/ km i.e., tex.

Spinning of yarn: Three sets of experiments were designed to conduct the spinning trials in the present research work are as follows.

Optimum twist factor of yarns: For evaluation of optimum twist factor of PALF, Acrylic and PALF/Acrylic (50:50) blended yarns, PALF was processed in jute spinning system along with roving and Rove spinning frame with wet spinning attachment. PALF was sprayed with 2% oil in water emulsion, passed through Frasers Jute Softener machine(63 pairs of heavy fluted helical rollers) to maintain moisture management level at 35% and kept in a closed bin for 48 hours to penetrate the emulsion inside the fibre matrix and conditioning. During this piling period, the fibre gets softened and lubricated which facilitates for mechanical processing. It was then manually cut into 200 mm staple length and slivers of PALF was prepared in full circular double doffer knife doffed finisher card (Mackie, UK). The carded slivers of PALF and Acrylic top were blended at first drawing stage in the blend ratio of 50:50 and processed in three passage of gill drawing frame (Mackie). Liner density of 84 tex were spun from 100% PALF, 100% Acrylic and 50:50:: PALF/acrylic blend with a varying twist factor ranging from 6-12 (Jute System) (Table 1) [6-12].

| Fibre properties | PALF | Acrylic |

|---|---|---|

| Fineness(Tex) | 2.67 | 0.33 |

| Breaking load(Gm) | 74.0 | 8.2 |

| Breaking extension (%) | 3.0 | 12.4 |

| Tenacity (gm/Tex) | 27.71 | 24.62 |

| Initial modulus (gm/tex) | 10.83 | 2.46 |

| Specific gravity (g/cc) | 1.48 | 1.17 |

| Moisture regain(%) 20°C and65% R.H | 11.8 | 1.6 |

Table 1: Physical properties of PALF and acrylic fibre.

Effect of blend composition on the quality of yarn: Slivers of PALF and acrylic top were blended in Mackie’s Screw gill first drawing frame in five different blend compositions viz, 87:13, 67:33, 50:50, 33:67 and 13:87. Linear density of yarns having 84 tex were spun in dry and wet spinning system from all PALF, all acrylic and 50:50 PALF: Acrylic blended material. During wet spinning, the rove was processed through hot water bath (Temp 800c to 1000c) before spinning (Table 2).

| S. No | Stage of blending | Nominal linear density | Actual linear density | Tenacity (Gm/tex) | Breaking Extension (%) | Strength C.V % | |||

|---|---|---|---|---|---|---|---|---|---|

| (Tex) | (Tex) | Dry Spg | Wet Spg | Dry Spg | Wet Spg | Dry Spg | Wet Spg | ||

| 1 | Carding | 84 | 81 | 15.93 | 20.07 | 3.05 | 3.5 | 21 | 20 |

| 2 | First Drawing | 84 | 92 | 12.37 | 12.55 | 3.52 | 3.5 | 17 | 17 |

| 3 | Second drawing | 84 | 93 | 10.54 | 12.15 | 2.84 | 3.5 | 33 | 20 |

| 4 | Third Drawing | 84 | 89 | 9.25 | 11.37 | 1.83 | 4.12 | 39 | 17 |

Table 2: Performance of PALF-Acrylic (50:50) blend at different stages of jute processing.

Optimum stage for blending PALF and acrylic: PALF; Acrylic: 50:50 blended yarns having linear density of 84 tex with a T.P.I of 7.5 were prepared in jute spinning system in dry and wet spinning conditions. Four blended yarns were spun by blending PALF and acrylic at four different stages of Jute processing Viz, carding and three drawing frames [17,18].

Determination of yarn linear density: The linear density of the yarn was determined by following standard method IS 685(1962) and expressed in tex. Density is the mass per unit volume expressed in g/cm3. The diameter of the yarn was analysed using Projection Microscope at 50X magnification. The bulk density of the yarn is calculated using the equation:

Bulk density of yarn=Dy. 4.10-5/Πd2 gm/cc,

Where Dy=Yarn linear density in tex and d=yarn diameter in mm,

Packing fraction of the yarn is calculated using the formulae,

P=Bulk density of yarn /fibre density.

The tensile properties of the yarn viz, tenacity, breaking strain are measured on Zwick tensile tester following standard parameters for yarn IS: 1670-1970.

Chemical analysis of blends: The actual blend proportions were determined chemically as per the method IS: 3421-1966 for blend estimation [19]. All samples were extracted with a benzene-methanol (3:2) mixture to remove oil and any finishing materials that had been added during processing. Each blended sample was analyzed twice and the average value was reported.

Results and Discussion

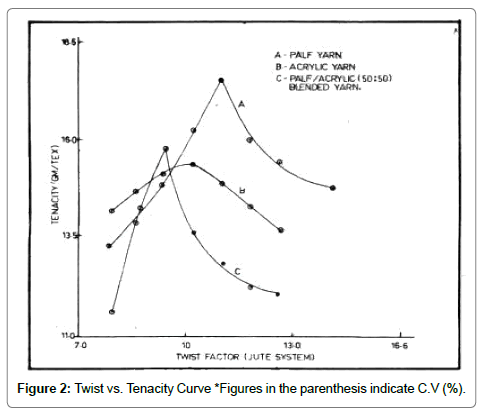

Optimum twist factor of yarns: The optimum twist factor of PALF, acrylic and PALF/acrylic blended yarn were evaluated in jute spinning machinery with the technical know-how developed to process this special natural fibre. There was no difficulty encountered to process acrylic top in jute screw gill drawing, roving and rove spinning frame. The carded slivers of PALF and Acrylic top were blended at first drawing stage in the blend ratio of 50:50 and processed in three passage of gill drawing frame (Mackie). Liner density of 84 tex were spun from 100% PALF, 100% Acrylic and 50:50. PALF/acrylic blend with a varying twist factor ranging from 6-12 (Jute System). The tenacity of different yarns with varying twist factor was plotted graphically in Figure 2 to evaluate optimum twist factor. It is observed from the figure that the optimum twist factor on the basis of maximum strength of the above three yarns are achieved as follows. PALF Yarn: 11.07, Acrylic yarn: 10.28 and PALF/Acrylic (50:50) Yarn: 9.49.

Optimum stage of blending of PALF and acrylic fibre

PALF:Acrylic :: 50:50 blended yarns having linear density of 84 tex with a T.P.I of 7.5 were developed in jute spinning system in dry and wet spinning conditions. Four blended yarns were spun by blending PALF and acrylic at four different stages of Jute processing Viz, carding and three drawing frames. The performance of the blended yarns was studied to evaluate the optimum stage of mechanical processing for binary blending of PALF and acrylic.

It reveals from Table 2 that the performance in respect of strength and regularity properties was better when blended at carding stage compared to blending at drawing stages [20,21]. The probable reason may be that in carding stage of blending, the fibres might have got scope to mix intimately to make a homogenous mixture of fibres so that each fibre component contribute their own share proportionately in the yarn structure which ultimately helps to achieve a good quality yarn blended at carding stage. During wet spinning, yarn strength increases considerably. This can be attributed to the higher wet strength of PALF and increase of fibre friction on wetting. A similar increase of yarn strength due to wetting was observed by Lawson, et al. and Chakraborty, et al. while studying the properties of cotton and pineapple leaf fibre respectively [22-24].

Effect of blend proportions of PALF-acrylic blended yarns

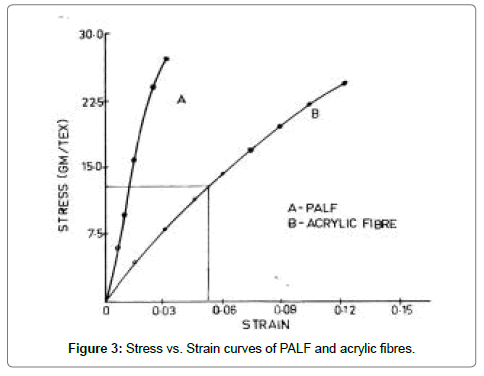

It is clear from Table 1 that there is a remarkable difference in fineness between indigenous PALF and acrylic fibre. The fineness of PALF is eight times coarser than acrylic.. The breaking stress of PALF is higher as compared to acrylic fibre. Blending of finer acrylic fibre with PALF helps to improve the spinnability resulting more number of fibres per yarn cross section irrespective of the Hamburgers theory [21]. It reveals from Figure 3 that stress-strain curve of PALF follows hooks law whereas acrylic is nonlinear. The breaking extension of PALF is only 3% which is comparatively low to that of acrylic fibre. It is evident from Table 1 that there is a considerable difference in initial modulus between PALF and acrylic fibre which will reflect on the tensile properties of the blended yarn (Table 3).

| Property | Proportion of Acrylic in the blended yarn (%) | ||||||

|---|---|---|---|---|---|---|---|

| 0 | 17 | 33 | 50 | 67 | 83 | 100 | |

| Fibre linear density (Denier) | 24 | 3 | |||||

| Yarn linear density | 132 | 141 | 139 | 133 | 155 | 156 | 145 |

| Diameter µ (×10-4cm) | 0.34 | 0.35 | 0.4 | 0.39 | 0.48 | 0.5 | 0.4 |

| Tenacity (Gm/tex) | 16.86 | 12.78 | 12.69 | 12.37 | 12.17 | 12.12 | 10.97 |

| (32.59)* | -25.96 | -22.25 | -21.04 | -17.16 | -16.42 | -15.07 | |

| Breaking Elongation (%) | 1.2 | 2.7 | 2.81 | 3.52 | 3.56 | 5.55 | 6.82 |

| Weight C.V(%) on 2″cut length | 26 | 18 | 15 | 18 | 13 | 12 | 8 |

| Packing co-efficient | 0.63 | 0.63 | 0.61 | 0.57 | 0.52 | 0.41 | 0.85 |

Table 3: Effect of blend composition on yarn quality- dry spun yarn.

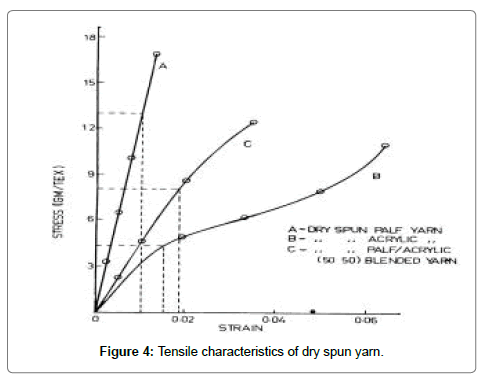

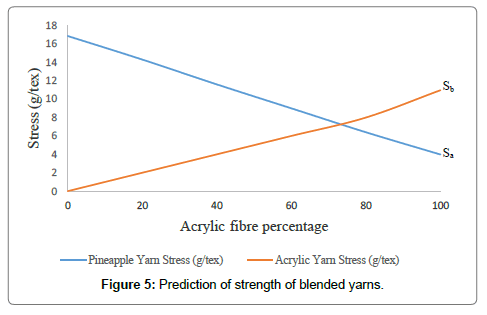

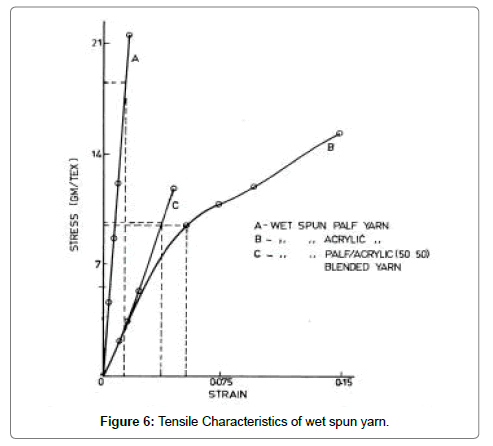

It is clear from Table 3 that C.V% of yarn parameters goes on decreasing with increase in proportion of acrylic component in the blends. The reason may be the better fineness of acrylic fibre which provides more number of fibres per unit cross section of yarn. The yarn diameter increases with increase in acrylic component in the blend. This can be attributed to higher specific volume of acrylic fibre compared to pineapple leaf fibre. The findings of Dey [14], and Mukhopadhyay states that diameter of ramie yarn is lower than acrylic or cotton yarn of same linear density [23]. The findings of Gupta et al. on ramie-polypropylene and ramie-tasar blends reveals the same result [17,18]. The theoretical breaking stresses for different blends were computed from stress-strain curves of the yarns made out of one component fibres (Figure 4) instead of individual fibres. The predicted curves are presented in Figures 5 and 6. The critical blend level for 3 denier acrylic fibre and PALF has been found to be 74:26.

Wet spinning technology

Wet spinning brings about improvement in short-term weigh irregularity of the yarns resulting in better regularity of yarn diameter. This is chiefly due to better control of fibres in the drafting zone of the spinning frame during wet spinning. The diameter of wet spun PALF yarn of equivalent linear density is lower and its packing coefficient is also higher than that of the dry spun one. The tenacity of the wet spun yarn (Figure 5) is higher than that of the dry spun one as the regularity of wet spun yarn is better and the higher packing coefficient is expected to generate transverse pressure during tensile loading. The strength C.V% of wet spun yarn was also lower compared to dry spun yarns. There was no significant difference in breaking elongation of dry and wet spun yarns (Table 4).

| Property | Proportion of Acrylic in the blended yarn (%) | ||||||

|---|---|---|---|---|---|---|---|

| 0 | 17 | 33 | 50 | 67 | 83 | 100 | |

| Fibre linear density (Denier) | 24 | 3 | |||||

| Yarn linear density | 132 | 141 | 139 | 133 | 155 | 156 | 145 |

| Diameter µ (×10-4cm) | 0.32 | 0.35 | 0.36 | 0.4 | 0.49 | 0.49 | 0.43 |

| Tenacity (Gm/tex) | 21.4 | 15.15 | 13.44 | 11.85 | 11.96 | 12.76 | 14.92 |

| (31.68) | -23.21 | -18.75 | -17.68 | -17.58 | -12.46 | -9.73 | |

| Breaking Elongation (%) | 1.39 | 2.84 | 3.79 | 4.09 | 4.72 | 10.46 | 14.92 |

| Weight C.V(%) on 2″cut length | 28 | 19 | 18 | 16 | 14 | 14 | 14 |

| Packing Co-efficient | 0.79 | 0.83 | 0.71 | 0.58 | 0.47 | 0.48 | 0.52 |

Table 4: Effect of blend composition on yarn quality-wet spun yarn.

Chemical analysis of blends

Blend compositions of the yarns based on the theoretical blend compositions of PALF/acrylic yarns spun on the jute spinning system analysed by chemical method are given in Table 5. The results obtained show the true compositions as estimated by chemical method to a high degree of accuracy. Dey, et al. Reported that the blend compositions of ramie-acrylic blends can be unambiguously assessed using infrared spectra with the help of calibration plot. These compositions match those obtained by chemical methods.

| Theoretical blend | Actual blend compositions by chemical method (%) | |||

|---|---|---|---|---|

| Percentage | Without added moisture | With added moisture | ||

| Acrylic/PALF | Acrylic | PALF | Acrylic | PALF |

| 1 | 18.57 | 81.43 | 17.73 | 82.27 |

| 2 | 35.12 | 64.88 | 34.46 | 65.54 |

| 3 | 48.74 | 51.26 | 47.67 | 52.33 |

| 4 | 65.48 | 34.52 | 64.26 | 35.74 |

| 5 | 82.17 | 17.83 | 81.02 | 19.98 |

Table 5: Blend estimation by chemical method.

Future prospect and economics of PALF in India

Globally, India is on the top in production of jute, 2nd in cotton, 5th in wool and 7th in pineapple. The global annual production of natural fibres in 2013 is approximately 33 million tonnes. At present pine apple cultivation in India is 1,09,880 ha with annual production of 1,736,740 tons. After harvesting the fruit, the plants are uprooted from soil and either burnt or kept in the field for natural degradation. Assuming an average plant density of 30,000 per hectare, it was estimated 40 matured leaves out of 80-100 leaves per plant annually with an average weight of 70 gm and 50-60 cm length and 2.5% fibre yield, India having a potential for producing around 5.29x 106 tonnes of pineapple leaves per anum from pineapple cultivation.

Banik’s work on vermicomposting reveals that 8 tons of fresh harvested leaves after harvest of pineapple fruit from 1 hectare of land under pineapple cultivation yielded 0.68 tons of vermicompost from 1.5 tons of pineapple leaf scratching residues. Assuming the present Indian market price of vermicompost @ Rs.6 per kg approximately and Pineapple leaf fibre @ Rs. 25 per kg, the fibre yield @ 2.5% is found to be 200 kg under pineapple cultivation. Thus an extra income from pineapple leaf fibre is Rs. 5000 and from vermicomposting is Rs. 4080, i.e., Rs. 9080 from one hectare of land from the integrated system of waste management. The payback period for pineapple leaf scratching machine is 4.5 years with 39.57 break-even point. Accordingly, the combined technology can be adopted by all the pineapple growers for additional income [20].

Conclusion

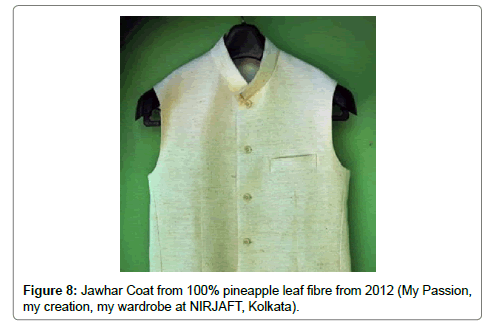

There is no difficulty encountered to process indigenous PALFacrylic blended yarn in conventional jute spinning system. PALF being a less extensible fibre with high strength and high modulus when blended with high extensible indigenous acrylic fibre, the concept of Hamburger theory of blending became invalid. In general, the addition of finer acrylic fibre improves the quality of blended yarn. The optimum stage of blending of the above fibres is carding stage. Wet spun yarns reveal better performance compared to dry spun yarns of the same. The blended yarn has a good scope for development of fancy apparel products. The critical blend level for 3 denier indigenous acrylic fibre and indigenous PALF has been found to be 74:26. Chemical methods can be unambiguously used for estimation blend compositions of acrylic/PALF blends (Figures 7-9).

Acknowledgement

The author wish to acknowledge Indian Council of Agricultural Research, New Delhi and National Institute for Research on Jute and Allied Fibre Technology (ICAR), Kolkata for providing facilities and keen interest for this study. The author is also indebted to Late Asoke Majumdar, Principal Scientist and Late S. K. Ghosh, Senior Scientist of ICAR-NIRJAFT, Kolkata for guidance and suggestions.

References

- Dey SK, Satapathy KK (2013) A combined technology package for extraction of pineapple leaf fibre - An Agrowaste, Utilization of biomass and for application in Textiles, 9thPeople Technology Congress, Kolkata.

- Indra D, Chellamani P (1993) Pineapple leaf fibres, Textile Progress 24: 1.

- Dey SK (2016) Performance of binary blends of Indigenous Ramie-acrylic. J Text Sci Eng 6: 277

- Yahya SAB, Yusof Y (2013) Comprehensive Review on the utilization of PALF. Advanced Materials Research 701: 430-434.

- Dey SK, Nag D, Das PK (2009), New Dimensions of Pineapple leaf Fibre-An agrowaste for Textile Applications New Technologies for rural development having potential of commercialization. Allied Publishers Pvt. Ltd, New Delhi, pp: 115-127.

- Dey SK (2013) Processing technology for the utilization of pineapple leaf fibre (PALF) An Agro-waste Diversification of Jute and Allied Fibres Some Recent Developments. NIRJAFT ICAR, Kolkata, pp: 239-250.

- Dey SK, Nag D, Das PK (2009) New Technologies for rural development having potential of Commercialization. Allied Publishers Pvt Ltd, New Delhi, pp: 115-127.

- Yusof Y, Yahya SA, Adam A (2014) A new approach for PALF productions and spinning system The role of surface treatments. Journal of Advanced Agricultural Technologies 2: 161-164.

- Ghosh SK, Sinha MK, Dey SK (1979) Utilization of pineapple leaf fibre in Textile sector. Text Ind and Trade Jr, 17: 5-6.

- Abdul JM, Chandra R, Mahabubzzaman AKM, Hossain M, Idris M, et al. (2016) Study on physical and Structural properties of Jute-Palf Blended yarn spun by Apron draft spinning. Research Journal of Textile and Apparel.

- Ghosh SK, Dey SK, Ghosh A (1989) Pineapple leaf fibre/Wool blend in semi-worsted processing. The Ind Text Jr p: 152.

- Ghosh SK, Dey SK, Sinha MK, Ghosh RN (1982) Pineapple leaf fibre in conveyor belting. The Ind Text Jr p: 65.

- Ghosh SK, Dey SK (1983) Designing an industrial fabric from pineapple leaf fibre. Jr Inst of Engrs p: 16.

- Dey SK, Bhattacharyya SK (2005) Magic yarns from ramie and pineapple- A new dimension in 21st century. 20th Indian Engineering Congress, p: 69.

- Sinha MK, Ghosh SK (1977) Processing of pineapple leaf fibre in jute machine. The Ind Textile Jr p: 105.

- Palit S, Chakraborty TN, Sarkar A, Doraiswamy I, Chelamani P (1992) Performance of Pineapple Leaf Fibres (Palf) In Jute & Worsted Spinning Systems. Textile Trends p: 33-38.

- Gupta NP, Dasgupta PC (1983) Chemical Texturization of Ramie-Polypropylene Blended Yarns. Indian Journal of Textile Research. 8: 71-74.

- Gupta NP, Bhattacharya GK, Roy D, Dasgupta PC, (1983) Semi-worsted Blended Yarns of Ramie-tasar waste. The Indian Textile Journal p: 67-72.

- ISI Handbook of Textile Testing (1966) Quantative Chemical Analysis of Binary Mixtures of Acrylic and certain other fibres. Method p: 430.

- Banik S, Nag D, Debnath S(2011)Utilization of pineapple leaf agro-waste for extraction of fibre and the residual biomass for vermicomposting. Indian journal of fibre and Textile Research 36: 172-177.

- Hamburger WJ (1949) The Tensile properties of blended yarns. J Text Ins, p: 700.

- Lawson R, Ramey HH, Krowki RS (1976) Cotton Fiber Tenacity and Elongation in Rapidly Changing Humidity. Text Res J 46: 715.

- Mukhopadhyay SN (1980) Properties of cotton-ramie blended yarn. Ind Text J 12: 125.

- Chakraborty AC, Sinha MK, Ghosh SK, Das BK (1978) Tensile behaviour of pineapple leaf fibre in wet condition. Â Â Ind Textile J 88: 95.

Citation: SK (2017) Exploration of Indigenous Pineapple-Acrylic Blend: A Future Prospect for Sustainable Luxury Textiles. J Archit Eng Tech 6: 195. DOI: 10.4172/2168-9717.1000195

Copyright: © 2017 Dey SK. This is an open-access article distributed under the terms of the Creative Commons Attribution License, which permits unrestricted use, distribution, and reproduction in any medium, provided the original author and source are credited.

Share This Article

Recommended Journals

Open Access Journals

Article Tools

Article Usage

- Total views: 4908

- [From(publication date): 0-2017 - Apr 21, 2025]

- Breakdown by view type

- HTML page views: 4030

- PDF downloads: 878