Evaluation Design Scheme of Emission from Point Sources of Petroleum Gas Process Industrial in Nigeria

Received: 03-Oct-2018 / Accepted Date: 03-Nov-2018 / Published Date: 12-Nov-2018 DOI: 10.4172/2472-0518.1000158

Abstract

This paper deals with evolution design scheme for emission from point source of petroleum gas process industry in Nigeria. In this aspect attempt is made to have engineering design of treatment of process of waste water the treated effluent can be reused in process for floor in washing cooling towel and for green belt development.

Keywords: Point source petroleum; Gas industry; Greenbelt

Introduction

Emissions from point sources gas process industrial projects complex

The pollution of major concern from point sources identified are NOx and hydrocarbons. In order to control their emissions measures are recommended. Reduction of Nox levels in proposed installations can be achieved by modifying operating conditions or changing design features of process units. The following steps are recommended to be initiated for modification in the operating conditions: (a) Low excess air firing (b) Multistage combustions, (c) Flare gas recirculation, (d) Selective catalytic reduction measures are preferred for achieving more than 60% reduction in NOx.

Material and Method

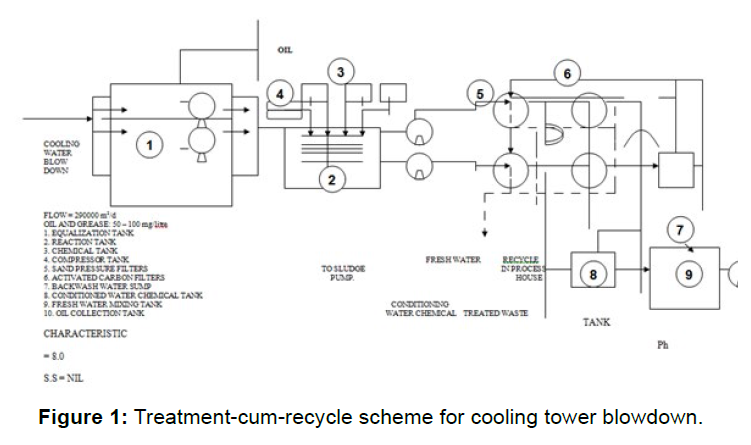

It may be noted that the fluidized bed combustion and selective catalytic reduction are preferred options. In flare starch, the burner and steam injection system should be so designed that maximum reduction in smoke and NOx is achieved. In the water environment, the scheme for treatment of waste water and before discharging into the sea is revealed. The recommend treatment scheme for treatment plants for process waste water spent caustic involves equalization, free oil removal by manual and mechanical means, chemical coagulation and flocculation, classification by activated carbon filter and disinfection before discharge into sea is shown in Figure 1. The scheme illustrates collection as well as treatment of waste water from various sources. Four collection systems have been proposed upon characteristics and quantities of various waste water streams. The different categories are: (a) Cooling tower blow down, pump house spills and effluent from oil skimming facilities. (b) Chemical wastes containing acid spillage from cooling tower area, caustic spillage from caustic storage tank area neutralized waste from DM plant, (c) Contaminated rain water plant are, and (e) Process wastes from the units [1]. In recent research, study, the US EPA regulates the emissions and effluent discharges from certain manufacturing industries and highlighted the emission routs for the process waste water and air emissions. The US EPA has defined process waste water as any water that during manufacturing or processing comes into direct contact or results from the production or use of any raw material, intermediate, product finished product by product or waste product. According to the US EPA 1998 process waste water includes surface runoff from the immediate process area that has the potential to become contaminated [2]. The Government of India 1993 sponsored symposium on emission from point sources and the government of Nigeria Federal Ministry of Environment 2000 initiated control of nox and hydrocarbon emission from point source. Green belt is proposed for checking points source emission of petroleum gas Industry.

Results

Figure 1 shows schematic process flow diagram of treatment cum-recycle plant for cooling tower blow down. Raw sewage after preliminary treatment will be subjected to anaerobic fixed film reactor system to recover useful methane gas. Sludge filtrate will be subjected to chlorination. The treated effluent can be reused in process for floor washing, cooling tower make up water and used for greenbelt development. A detailed schematic representation flow scheme of the proposed treatment (Figure 1). Through the implementation of these two scheme of recycle and reuse in plant about 85% of waste water can be recovered to replace fresh water. These schemes will further minimize the load on water discharge system in sea and adverse impact on quality of coastal sea water [3-5].

Conclusion

Environmental audit programme is a basic management tool comprising of systematic documentation and periodic evaluation of performance of environmental organization, management systems and equipment. Various activities from offshore structures involve potential environmental pollution resulting from a wide variety of causes such as smoke, gas emissions and discharge of waste water when drilling oil wells and extracting oil. The transport of crude oil and refined products on tankers and through pipelines involves the possibility of accidental oil spills that may pollute land and water body. It is very essential for petroleum industry to preserve the ecological environment surrounding its operational facilities and measures for reducing the risk to the environment. This can be accomplished by suitable auditing of operating conditions that prevails at the facilities.

Two stages mitigation approach need be planned for control of fugitive emissions firstly, at the source itself and secondly by attenuating the dispersion of pollutants through green belt around the plant. In order to control fugitive emissions of hydrocarbons from storage tanks and process leaks, the following measures are suggested (a) close systems should be planned during design stage to avoid occupational exposition to hydrocarbons (b) prevention maintenance of valves and other equipments be done on regular basis (c) use of submerged filling in product loading stage is recommended to be developed around the plant sites to attenuate the fugitive emissions of proposed scheme of plantation incorporate related plants species that are resistant to hydrocarbons and dusts.

References

- Paul CN (2003) System Approach to Petroleum Energy Process Engineering and Environmental in Nigeria a DSC Engineering Thesis submitted to Faculty of Engineering Department of Mechanical Engineering. M.M.M.E. and College Gorakhpur India.

- US Environmental Protection Agency (1998) Pharmaceutical Manufacturing Category Effluent Limitations Guidelines, Pretreatment Standard and New Source Performance Standards: final role.

- Federal ministry of Environment (2000) Control Nox and Hydrocarbons Emissions Lagos.

Citation: Paul CN (2018) Evaluation Design Scheme of Emission from Point Sources of Petroleum Gas Process Industrial in Nigeria. Oil Gas Res 4: 158. DOI: 10.4172/2472-0518.1000158

Copyright: © 2018 Paul CN. This is an open-access article distributed under the terms of the Creative Commons Attribution License, which permits unrestricted use, distribution, and reproduction in any medium, provided the original author and source are credited.

Share This Article

Recommended Journals

Open Access Journals

Article Tools

Article Usage

- Total views: 3254

- [From(publication date): 0-2018 - Apr 05, 2025]

- Breakdown by view type

- HTML page views: 2418

- PDF downloads: 836