Estimating Effect of Vinasse on Sugarcane through Application of Potassium Chloride at Metahara Sugarcane Plantation

Received: 27-Sep-2014 / Accepted Date: 10-Nov-2014 / Published Date: 11-Nov-2014 DOI: 10.4172/2329-8863.1000154

Abstract

A study was conducted at Metahara Sugar Estate in Ethiopia to assess effect of vinasse disposal on sugarcane fields. The experiment was laid out in a randomized complete block design with five replications. To simulate the amount of vinasse to be disposed, three levels of potassium chloride (0, 340, and 580 kg ha-1) were tested on three different soil types (brown clay loam, black non-vertic clay and black vertic clay). Soil analysis result showed that available K in the soil was ranged from 311-547 ppm. Potassium chloride application on cane fields had nonsignificant (p<0.05) effect for cane and sugar yields. Similarly, non-significant (p<0.05) effect was found for juice K2O and leaf nutrient contents (N, P and K%). Therefore, the level of potassium chloride applied at the proposed vinasse disposal rates didn’t affect nutrient uptake, yield, and juice quality in the subsequent crop; thus at Metahara Sugar Plantation, sugarcane fields can be used as disposing site for vinasse. However, long-term effect of vinasse to sugarcane crop and dynamics of K in relation to availability and fixation in the soils of the plantation should be further investigated through vinasse application to sugarcane fields.

Keywords: Sugarcane; Ratoon crop; Vinasse; Juice quality; Cane yield; Sugar yield

405056Introduction

Biocomposts have gained importance since the fertilizers and pesticides cause a lot of environmental problem and health hazards and soil degradation [1]. Sugarcane being a multiple product commodity, recycling of sugar industry wastes as composts can be gainfully utilized to enhance sugar productivity and reduce cost of cane production on account of fertilizers [2]. Effective use of industrial by-products and crop residues require sound composting program by considering combinations of different by-products that give good compost with adequate nutrients, free from pathogens and that matures in reasonable period of time [3]. The rise and fall of temperature, and changes in nutrient concentrations and carbon to nitrogen (C/N) ratios over time are reliable indicators for the progress of composting process in establishing biological stability and maturity of compost [4]. Many organic wastes from home industries can be composted. However, the composition and quality of the compost produced depends on the choice of composting materials, method of composting, time and effort invested to manage the heap [5].

At Metahara Sugar Estate, different by-products such as filter cake, boiler furnace ash, and molasses are produced in large quantities during each sugar production season. Moreover, huge amount of cane tops from harvested fields and cane trash from seed cane fields are left unused. Changing these materials into more usable form for sugarcane production can help the Sugar Estate to reduce cost incurred to purchase fertilizers and also contribute to improve productivity of sugarcane fields by enriching soil organic matter. Moreover, enriching soil organic matter contributes to better nutrient retention by the soil and efficient utilization of the nutrients by the crop from chemical fertilizers. Therefore, this study was executed with the objective to evaluate composting materials for quality compost production.

Materials and Methods

Metahara Sugar Estate is located at about 200 km southeast of the capital city, Addis Ababa, Ethiopia. It is situated at 80 53’ N, 390 52’ E and an altitude of 950 m.a.s.l. The area has a semi-arid climatic condition. Most of the Estate soils are alkaline with pH normally above 8.0.

Pit composting was used, as it is preferred for dry land areas [6- 8]. The pit size was 1.5 m3 (1 m length × 1 m width × 1.5 m height). The experiment was laid out in a factorial randomized complete block design with three replications. The tested composting materials were sugarcane trash (cane tops), farm yard manure (FYM), boiler furnace ash (residue left after burning of bagasse) (BFA), and molasses which is co-product of sugar factory. FYM refers to naturally decomposed mixture of dung and urine of farm animals along with their bedding material. Each composting material was tested at two levels: cane tops (4 and 6 kg/m2), FYM (0 and 3 kg/m2), BFA (0 and 1 kg/m2) and molasses (0 and 6.75 Lt/1.5 m3) (Table 1). One spade arable soil per m2 was added at each layer for all treatments [9].

| Composting materials | Treatments | |||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| A | B | C | D | E | F | G | H | I | J | K | L | M | N | O | P | |

| Trash (kg/m2) | 6 | 6 | 6 | 6 | 6 | 6 | 6 | 6 | 4 | 4 | 4 | 4 | 4 | 4 | 4 | 4 |

| FYM (kg/m2) | 3 | 3 | 3 | 3 | 0 | 0 | 0 | 0 | 3 | 3 | 3 | 3 | 0 | 0 | 0 | 0 |

| BFA (spade/m2) | 1 | 1 | 0 | 0 | 1 | 1 | 0 | 0 | 1 | 1 | 0 | 0 | 1 | 1 | 0 | 0 |

| Molasses (Lt/1.5m3) | 0 | 6.75 | 0 | 6.75 | 0 | 6.75 | 0 | 6.75 | 0 | 6.75 | 0 | 6.75 | 0 | 6.75 | 0 | 6.75 |

Table 1: Treatment combinations.

The layering was made in the following order from bottom to top: cane tops (cane trash), BFA, FYM, a thin layer of arable soil, and molasses. These layers were repeated until the heap reached 1.5 m height. Each layer was watered until the pile attained adequate moisture (50% moisture). Finally, the pit was covered with cane trash to avoid water loss. Hollow plastic pipe was placed at the middle of the pit to improve aeration. Every two weeks, all the contents of the pit were turned over into another empty pit until maturity. Temperature, particles size, and color change were used for determination of maturity and stability of compost. Matured compost was analyzed for its chemical composition mainly for pH (1:10) measured in water suspension, electrical conductivity (EC1:10), organic carbon (OC), total N, phosphorus (P), and potassium (K). These analyses were carried out using standard methods [4].

Statistical analysis of the variance was performed using MSTATC computer software. Mean separation for significant parameters was also done at 1% probability level by Duncan Multiple Range Test (DMRT).

After mean separation, best treatments were identified through ranking as shown in Table 5. Ranking was used for significant parameters and the best compost was selected based on overall rank scored by treatments. Treatments having the same letter were given the same rank. For each parameter, the highest value was ranked 1st and the lowest was ranked last. Accordingly, except for EC, the treatment with highest value was ranked 1st. The overall rank was obtained by summation giving equal weight for all parameters. The treatment with the lowest summation was taken to be the best quality compost while with the highest summation was considered to be the lowest. Therefore, EC, OC, total N, P and K were considered. For ranking, lowest EC value was given the first rank but for organic C, total N, P and K, the highest value of each parameter was given the first rank.

Result and Discussion

Chemical composition of composting materials

Boiler furnace ash was low in N, P, and K as compared to farm yard manure and molasses. Farm yard manure and molasses were found to be high in K content as compared to N and P (Table 2).

| Composting materials | N (%) | P (%) | K (%) |

|---|---|---|---|

| FYM | 1.80 | 0.09 | 3.38 |

| BFA | 0.19 | 0.12 | 0.25 |

| Molasses | 0.42 | 0.09 | 3.24 |

Table 2: Nutrient content of composting materials.

Temperature of the heap

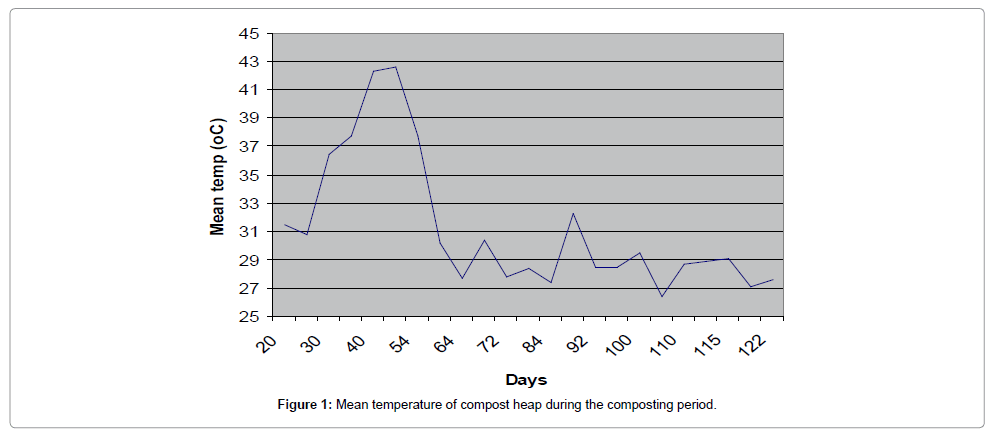

After 100 days, a major drop in the activity of the compost heap was found as seen in the figure below. Thus, this period (100 days) was considered as the time in which the composting process was completed and matured (Figure 1).

Temperature variations occurred among the treatments for both maximum and minimum temperatures. Treatments E, G, H, M and N attained a maximum and highest temperature of 50°C, while treatment I attained the lowest minimum and maximum temperature of 34°C (Table 3). Except differences in the maximum temperature of compost, no remarkable difference was detected for minimum temperature among treatments.

| Temperatures (°C) |

Treatments | |||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| A | B | C | D | E | F | G | H | I | J | K | L | M | N | O | P | |

| Minimum | 30 | 30 | 31 | 30 | 31 | 32 | 32 | 33 | 29 | 30 | 30 | 32 | 32 | 33 | 32 | 32 |

| Maximum | 39 | 38 | 41 | 39 | 50 | 46 | 50 | 50 | 34 | 38 | 38 | 45 | 50 | 50 | 45 | 47 |

Table 3: Minimum and maximum temperatures of the heap per treatment.

Chemical properties of the compost

All composts (obtained from different composting materials) were alkaline in reaction. EC values were too low (below 2dS/m) to cause salinity if applied to soil. Organic carbon, total N, P, and K contents ranged from 2.78-5.24%, 0.208-0.335%, 0.006-0.013%, and 0.29-0.60%, respectively (Table 4). All composts were relatively low in contents of P as compared to the other essential elements specifically N and K. However, all composts contained high organic carbon. By the application of the compost, next to K, more N can be released to soil after mineralization. Analysis of variance indicated that except pH, all the parameters including EC, OC, total N, P and K showed highly significant (p<0.01) differences among each other.

| Treatment | pH (1:10) |

EC (dS/m) (1:10 ) | OC (%) |

Total N (%) |

P (%) |

K (%) |

|---|---|---|---|---|---|---|

| A | 7.93 | 0.1960ef | 3.123def | 0.2080b | 0.0060d | 0.2991d |

| B | 8.02 | 0.2180ef | 2.783f | 0.2120b | 0.0063d | 0.3416cd |

| C | 7.94 | 0.2070ef | 4.173abcdef | 0.2130b | 0.0069d | 0.3164d |

| D | 7.97 | 0.2760e | 3.437cdef | 0.2210b | 0.0071d | 0.3842bcd |

| E | 7.88 | 0.5490ab | 4.950ab | 0.3000a | 0.0125a | 0.5301abc |

| F | 7.90 | 0.5800a | 5.243a | 0.3070a | 0.0116abc | 0.6021a |

| G | 7.96 | 0.5550ab | 4.917ab | 0.3350a | 0.0122ab | 0.4363abcd |

| H | 7.97 | 0.4520cd | 4.737abc | 0.3180a | 0.0118abc | 0.5434ab |

| I | 7.91 | 0.1820f | 2.933def | 0.2940a | 0.0057d | 0.2750d |

| J | 7.98 | 0.2160ef | 3.110def | 0.3120a | 0.0057d | 0.3335cd |

| K | 7.92 | 0.2080ef | 2.847ef | 0.3090a | 0.0065d | 0.4168abcd |

| L | 7.99 | 0.2470ef | 3.630bcdef | 0.3120a | 0.0067d | 0.4054abcd |

| M | 8.00 | 0.3870d | 4.367abcd | 0.3230a | 0.0102abc | 0.5286abc |

| N | 7.91 | 0.4960bc | 4.250abcde | 0.3190a | 0.0116abc | 0.5618ab |

| O | 7.87 | 0.4770bc | 4.153abcdef | 0.3110a | 0.0101c | 0.5255abc |

| P | 7.89 | 0.4860bc | 3.990abcdef | 0.3050a | 0.0107bc | 0.3731bcd |

| CV (%) | 1.36 | 12.56 | 18.93 | 8.25 | 10.22 | 23.84 |

Table 4: Major chemical properties of the compost.

Treatment ranking

Based on the chemical composition and temperature, the overall ranking of the treatments indicated that treatments E, F and H were ranked first followed by G (Second), and M and N (Third). The best compost was selected based on the rank combinations of chemical composition and maximum temperature. Thus, based on combined criteria, treatment E (6 kg cane trash/m2 mixed with one spade BFA/m2 per each layer) gave best result (Table 5).

| Treatments | Rank for chemical parameters | Grand Total | Overall rank | Total score | Total rank for the treatments | |||||

|---|---|---|---|---|---|---|---|---|---|---|

| EC | OC | Total N | P | K | Chemical parameters | Maximum temperature | ||||

| A | 2 | 9 | 2 | 6 | 7 | 26 | 9 | 6 | 15 | 8 |

| B | 2 | 11 | 2 | 6 | 6 | 27 | 10 | 7 | 17 | 10 |

| C | 2 | 6 | 2 | 6 | 7 | 23 | 7 | 5 | 12 | 6 |

| D | 3 | 8 | 2 | 6 | 5 | 24 | 8 | 6 | 14 | 7 |

| E | 7 | 2 | 1 | 1 | 3 | 14 | 1 | 1 | 2 | 1 |

| F | 8 | 1 | 1 | 3 | 1 | 14 | 1 | 3 | 4 | 3 |

| G | 7 | 2 | 1 | 2 | 4 | 16 | 2 | 1 | 3 | 2 |

| H | 5 | 3 | 1 | 3 | 2 | 14 | 1 | 1 | 2 | 1 |

| I | 1 | 9 | 1 | 6 | 7 | 24 | 8 | 8 | 16 | 9 |

| J | 2 | 9 | 1 | 6 | 6 | 24 | 8 | 7 | 15 | 8 |

| K | 2 | 10 | 1 | 6 | 4 | 23 | 7 | 7 | 14 | 7 |

| L | 2 | 7 | 1 | 6 | 4 | 20 | 4 | 4 | 8 | 4 |

| M | 4 | 4 | 1 | 5 | 3 | 17 | 3 | 1 | 4 | 3 |

| N | 6 | 5 | 1 | 3 | 2 | 17 | 3 | 1 | 4 | 3 |

| O | 6 | 6 | 1 | 5 | 3 | 21 | 5 | 4 | 9 | 5 |

| P | 6 | 6 | 1 | 4 | 5 | 22 | 6 | 2 | 8 | 4 |

Table 5: Ranking of compost based on chemical composition and maximum temperature.

Conclusion

All composts (obtained from different composting materials) were alkaline in reaction, and had low value of EC indicating that the composts were safe in view of salinity if applied to soil. While, organic carbon contents were found to be high. Nutritionally, all composts were relatively low in P as compared to the other essential elements specifically N and K. By the application of the compost, next to K, more N could be released during mineralization process. The time taken to produce matured compost was found to be 100 days. The result also showed that the first best compost was obtained from composting of 6 kg cane trash/m2 mixed with one spade BFA/m2 per each layer. Therefore, based on present finding, the above combination of composting materials is recommended to be used for producing quality compost.

Acknowledgements

The authors are indebted to the former Ethiopian Sugar Development Agency, Research Directorate, for financing the study.

References

- Chauhan N, Singh MP, Aneg SAK, Singh SS, Chauhan SS, et al. (2008) Effect of biocompost application on sugarcane crop. Short communication. Sugar Tech 10:174-176.      Â

- Singh N (2008) Biocompost from sugar distillery effluent: effect on metribuzin degradation, sorption and mobility. Pest Management Science 64:1057-1062.

- Finstein MS, Hogan JA (1992) Integration of composting process: Microbiology, Facility Structure and Decision making. Proceedings of the International Composting Research Symposium, Renaissance Publications, Columbus.

- Sahlemedhin S, Taye B (2000) Procedures for soil and plant analysis. Technical. Ethiopian Agricultural Research Organization, National Soil Research Center, Addis Ababa, Ethiopi a 74.

- Bollen GJ (1992) Factors involved in inactivation of plant pathogens during composting of crop residues. Proceedings of the International Composting Research Symposium, Renaissance Publications, Columbus.

- Inckel M, Smet PD, Tersmette T, Veedkamp T (1999) Preparation and use of compost. (5th edn). CTA, Wageningen.

- Carucci V (2000) Guideline on water harvesting and soil conservation for moisture deficit areas in Ethiopia. The productive use of water and soil manual for trainers. Addis Ababa, Ethiopia.

- Satisha D, Devarajan J (2007) Effect of amendments on windrow composting of sugar industry press mud: Waste management 27: 1083-1091.

Citation: Dametie A, Fantaye A, Teshome Z (2014) Estimating Effect of Vinasse on Sugarcane through Application of Potassium Chloride at Metahara Sugarcane Plantation. Adv Crop Sci Tech 2:150. DOI: 10.4172/2329-8863.1000154

Copyright: © 2014 Dametie A, et al. This is an open-access article distributed under the terms of the Creative Commons Attribution License, which permits unrestricted use, distribution, and reproduction in any medium, provided the original author and source are credited.

Share This Article

Recommended Journals

Open Access Journals

Article Tools

Article Usage

- Total views: 15264

- [From(publication date): 12-2014 - Apr 02, 2025]

- Breakdown by view type

- HTML page views: 10547

- PDF downloads: 4717