Review Article Open Access

Esthetic Archwires in Orthodontics- A Review

Devinder Preet Singh*

Department of Orthodontics & Dentofacial Orthopedics, Dr Harvansh Singh Judge Institute of Dental Sciences & Hospital, India

- *Corresponding Author:

- Dr. Devinder Preet Singh

Mohali Medical Centre, Phase 2

Opposite Bassi Cinema

Mohali, Punjab, India

Tel: +919316557350

E-mail: ahluwalia147@gmail.com

Received Date: November 12, 2015; Accepted Date: December 28, 2015; Published Date: January 04, 2016

Citation: Singh DP (2016) Esthetic Archwires in Orthodontics- A Review. J Oral Hyg Health 4:194. doi: 10.4172/2332-0702.1000194

Copyright: © 2016 Singh DP. This is an open-access article distributed under the terms of the Creative Commons Attribution License, which permits unrestricted use, distribution, and reproduction in any medium, provided the original author and source are credited.

Visit for more related articles at Journal of Oral Hygiene & Health

Abstract

The archwire has been an integral part of the orthodontic appliance, ever since Dr. Edward Angle placed the first appliance into the patient’s mouth. The high esthetic demand by the patient, along with the introduction of composite and ceramic brackets initiated research for esthetic archwires to go with these brackets. Esthetic archwires available are composite, optiflex and coated archwires. In orthodontics, composite prototypes of archwires, ligatures and brackets have been made from S-2 glass fibers (a ceramic) and acrylic resins (Polymer). Optiflex archwires are made of clear optical fiber comprises of three layers: a) silicon dioxide core b) silicon resin middle layer and c) nylon outer layer. Coated archwires can be teflon coated, epoxy coated or the nitanium tooth toned archwire. Appropriate use of all the available wire types may enhance patient comfort and reduce chairside time as well as the duration of treatment. The individual clinician must always know and understand the needs and options at every stage of therapy.

Keywords

Coated archwire; Esthetics; Composites; Optiflex

Introduction

The development of an optimum, predictable and effective orthodontic force system is predicated on the knowledge of mechanics, biomaterials and their interaction. The archwire has been an integral part of the orthodontic appliance, ever since Dr. Edward Angle placed the first appliance into the patient’s mouth. Then, the preferred materials for making these wires were gold and other precious metals. The high esthetic demand by the patient, along with the introduction of composite and ceramic brackets initiated research for esthetic archwires to go with these brackets. One promising approach toward achieving an esthetic archwire with excellent overall properties involves the use of composites, which can be composed of ceramic fibers that are embedded in a linear or cross-linked polymeric matrix. When compared with nickel titanium alloy, the resilience and spring back are comparable. Moreover, when failure finally does occur, the wire loses its stiffness, but it remains intact. Research work is ongoing to see whether low coefficients of friction and enhanced biocompatibility are possible by modifying the surface chemistry of the polymer.

Thus, a new face of orthodontic mechanotherapy, guided by the recent technological advancements and better understanding of physiology of tooth movement, has emerged. The introduction of newer archwire materials has necessitated alterations in appliance design, construction and clinical manipulation. Hence, it is imperative on the part of the clinician, to make an informed decision in wire selection & manipulation based on the wire characteristics.

In view of the aforesaid, the following endeavor is to compile information on orthodontic archwires of the present era of fiber reinforced composites.

Review of Literature

Lim et al. [1] started to assess the springback and stiffness of two esthetic archwires (1) A Teflon coated stainless steel (SS) round wire and (2) round Optiflex wire. They found that Optiflex wire had low stiffness, resilience and poor springback and the archwire remained bent on activation. The stiffness for the Teflon coated archwire was found to be higher and more in line with the stiffness of the control. Both the Teflon coated and SS archwires displayed good springback properties.

Burstone and Kuhlberg [2] studied the use of fiber-reinforced composites in Orthodontics. The new concepts of mechanics and application of fixed appliances through the use of a pre-impregnated material, a partially polymerized fiber-matrix complex that is later fully polymerized in a clinical setting was demonstrated. The advantages were a significant enhancement of mechanical properties, better control of the final cross-sectional shape, and simplification of steps performed by the clinician. They mentioned that the greatest clinical potential lay in active applications, where long-fiber composites can be used as adjuncts for active tooth movement.

Zufall and Kusy [3] tested the viscoelastic behavior of prototype composite archwire materials using bend stress relaxation test. The results showed that the stress relaxation behavior was strongly correlated to archwire reinforcement level. The final relaxation varied, with decreasing reinforcement, from 2 to 8 percent. Archwire recovery was not related to reinforcement level and revealed a final viscous loss of only 1 percent. The relaxed elastic moduli of composite archwire were similar to that of various conventional archwire materials. The losses associated with viscoelastic behavior with decreasing reinforcement level varied from 1.2 to 1.7 GPa. Because these modulus losses were minimal, each archwire retained sufficient resilience to be applicable to the early and intermediate stages of orthodontic treatment.

Elayyan et al. [4] conducted a study to examine the mechanical and physical properties of retrieved coated nickel-titanium (NiTi) archwires compared with unused samples. Ultraesthetic 0.016 inch coated archwires (G&H(R) Wire Company) were investigated. They found that only 75 per cent of the coating was present in retrieved coated archwires. Retrieved coated archwires produced lower unloading force values than as-received coated archwires with conventional ligation. Surface roughness of coated archwires increased after use. Coated archwires have a low aesthetic value, with 25 per cent of the coating lost within 33 days in vivo.

Goldberg et al. [5] evaluated the time-dependent viscoelastic properties of an aesthetic orthodontic archwire which was based on a recently developed translucent polyphenylene thermoplastic, whose rigid molecular structure provides high strength. They concluded that the relaxation behaviour was proportional to the initial tensile strain and therefore these data were combined into a single curve using regression. Deformation of the samples placed in the bracket pairs increased with increasing vertical displacement and time, evaluated with analysis of variance, but 19-100 per cent of the deformation was recoverable. The force systems from polyphenylene wires could vary with time and activation, but this behaviour is predictable.

Da Silva et al. [6] evaluated the color stability of six esthetic archwires at different time periods and their fluorescence. Samples were evaluated after 7, 14, and 21 days of immersion in staining solution. They found that all brands showed statistically significant color change after 21 days. The Optis archwire (fiber-reinforced composite) presented the highest color alteration, although staining was observed only near its ends. The Trianeiro archwire (coated nickel-titanium) and the Ortho Organizers archwire (coated stainless steel) presented with less color change. The Optis archwire was the only one that presented with fluorescence similar to that of bovine teeth. They concluded that all esthetic archwires assessed showed clinically noticeable color change after 21 days in staining solution. The optical properties of currently available esthetic archwires may not yet be ideal.

Da Silva et al. [7] evaluated the coating thickness of four brands of as-received esthetic coated rectangular archwires and their surface characteristics and coating stability after 21 days of oral exposure compared to those of conventional stainless steel (SS) and nickel titanium (NiTi) ones. They concluded that coated archwires had a low esthetic value as they presented a nondurable coating. The remaining coating showed a severe deterioration and a greater surface roughness than postclinical control counterparts (conventional SS and NiTi wires).

Materials and Methods

Esthetic archwires are of three main types namely, Composite plastics, Optiflex archwires, and Coated archwires.

Composite plastics

One promising approach toward achieving an esthetic archwire with excellent overall properties involves use of COMPOSITES [8].

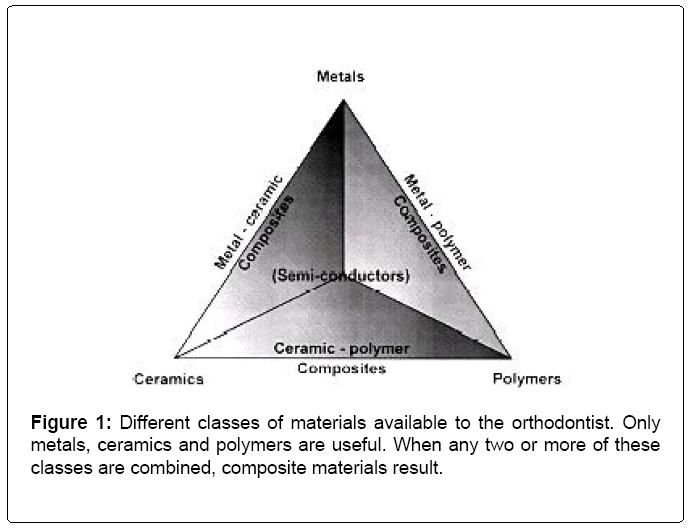

Composite: The term “Composite Material” may be defined as a compound of two or more distinctly different materials with properties that are superior or intermediate to those of individual constituents. Composites will play an increasingly important role in orthodontic treatment as two or more classes of engineering materials are combined at a time. e.g., Polymers and metals, metals and ceramics or ceramics and polymers may be combined in such a way that advantages of each class of a material may be realized and disadvantages minimized; thereby yielding a unique final product that is superior to either of its principal components alone (Figure 1).

Structure of Fiber Reinforced Composites (FRC): In Orthodontics, composite prototypes of archwires, ligatures and brackets have been made from S-2 glass fibers (a ceramic) and Acrylic Resins (Polymer). Commercially reinforcement of polymers with long continuous fibers has been established as an effective means of developing engineering materials for a wide range of Aerospace, Automotive, Recreational and other uses.

Fiber reinforced composites as archwire: Fiber reinforced composites (FRC) can change the concept, mechanics and application of fixed appliances through the use of ‘pre-preg’ or partially polymerized fibermatrix complex that fully polymerizes in the clinical setting. Its greatest clinical potential lies in the active applications where they are used as adjuncts for active tooth movement. They have the potential to replace metals in orthodontics as they have good bonding characteristics not only to the tooth but also to the appliance itself. An FRC can be bonded to another and attachments added directly [2].

Structure: Three configurations of FRC are available:

i. Rope type- 2 mm wide, round strips

ii. Can be wrapped around corners of an arch and thus is useful in cuspid-to-cuspid retainers.

iii. Unidirectional parallel configurations have best mechanical properties for bending

FRC can be bonded by direct and indirect technique with good bond strength, as polymeric matrixis the same as the bonding adhesive. The advantage of indirect technique being shorter curing time needed intra-orally. If attachments such as brackets tubes or hooks, they can be directly bonded on the FRC.

Advantages:

i. Esthetic as the connecting bar is clear or translucent.

ii. Biocompatibleand less hypersensitivity reported as compared to stainless steel and other metals.

iii. High modulus of elasticity in flexure (70% greater than highly filled dental composite), six times greater yield strength and 2 times greater resilience.

iv. Option to join pieces together with an adhesive to make a string structural unit.

v. Attachments can be added for inter-maxillary tooth movement without bands or brackets, making it simple to position hooks with ideal direction and point of force application respective to maxillary and mandibular center of resistance.

vi. Vertical elastics can be applied directly to FRC bars, either on full arches or on segments for closure of an open-bite.

vii. Intra-arch movements such as space closure, with bonded tubes on FRC bars, which can be positioned to increase the inter-bracket distance.

viii. Correction of poorly erupted second molars after completion of orthodontic therapy can be done by uprighting the tooth using full-arch FRC as an anchorage unit. Active force applied by straight wire segment, T-loop or wire with differential bend.

ix. Ease of modification as more layers can be added if greater rigidity required. Attachments can be repositioned, repaired or replaced any time.

x. Passive applications such as bonded tooth-to-tooth retainer can be made with ideal esthetics as compared to metal wire bonded retainers.

Limitations:

i. FRC bars are strong and rigid in tension but less in bending mode and are weakest in shear and torsion.

ii. Unlike metals, they are not homogenous materials so shear loads need to be minimized.

iii. Sound bonding technique is required.

Availability: ‘Splint-it’, a commercially available long-fiber-reinforced composite, uses strong S-glass fibers. The matrix is light cured thermoset bisGMA with the fibers correctly oriented gives excellent coupling

Fabrication of Fiber Reinforced Composites (FRC): FRCs are produced in two steps. In the first step, “Amount, distribution and wetting of fibers by resin is closely controlled” and in the second step “Composite is formed into desired final shape”.

Two important processes associated with fabrication of FRCs, i.e., Pultrusion and Beta staging.

Pultrusion: It is the process of manufacturing components having continuous lengths and a constant cross sectional shape such as in archwire. In this bundle of continuous fibers are impregnated with polymeric resin and are then pulled through a Sizing Die that performs composite and establishes resin/fibre ratio. The bundles are then passed through Curing Die which imparts precise shape as it cures the resin.

Beta Staging: It is an intervening process in which partially cured resin and its bundles of continuous fibers are deformed into another form (e.g. preformed archwire) after which the curing is completed. Preformed arch wires and rectangular cross-section is possible by this process.

Properties of experimental prototypes of FRCs:

i. Tooth coloured.

ii. Vary in stiffness from that of most flaccid multi-stranded wire to nearly that of β-Ti archwire. These characteristics can be varied during manufacture without any change in wire slot engagement by pultrusion.

iii. Mechanical tests show that such archwires are elastic until failure occurs and when failure does occur the wire loses its stiffness but remains intact.

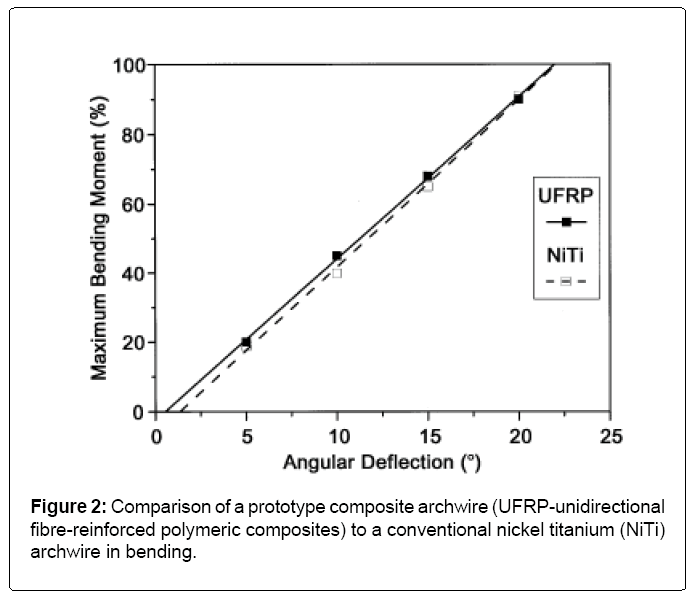

When compared with NiTi, resilience and springback are comparable (Figure 2). Specifics of other characteristics such as formability, weldability and frictional coefficients are unknown at this time. Low coefficients of friction and enhanced biocompatibility should be possible by modifying the surface chemistry of polymer. Like the advanced metal wires, their shape is very difficult to change once the manufacturing process is completed which leads to a number of practical problems for clinical applications.

Optiflex archwire

New Orthodontic archwire designed by M.F. Talass [9] in 1992. It combines unique mechanical properties with a highly esthetic appearance.

• Structure: Made of clear optical fiber comprises of three layers (Figure 3):

i. Silicon Dioxide Core: Provides the force for moving teeth

ii. Silicon Resin Cladding: Protects core from moisture and adds strength and

iii. Nylon Coating: It is stain resistant and prevents damage to the wire and further increases strength.

• Properties:

i. Wide range of action.

ii. Ability to apply light continuous forces.

iii. Sharp bends must be avoided since they could fracture the core otherwise optiflex has practically no deformation.

• Application: Applications are similar to those of coaxial archwire.

• Availability: Optiflex (Ormco Corporation) in sizes 0.017” and 0.021”.

Coated archwires [10]

Teflon coated:

• Structure: Coating on archwire material has been introduced to enhance esthetics and decrease friction. These wires are designed to be esthetically more acceptable by the patient. They are given a plastic tooth colored coating so that it can blend with the tooth color and also of ceramic brackets. Normally the coating is 0.002” thick. The coating frequently used is TEFLON (Figure 4). Teflon coating is applied in two coats by conventional airspray or electrostatic techniques.

• Availability: These are available in natural tooth shades or in blue, green and purple colors as Lee White Wire (Lee Pharmaceuticals).

Epoxy coated: Epoxy coated archwire is tooth colored and has superior wear resistance and color stability of 6-8 weeks.

• Availability: It is available in nickel titanium and stainless steel in preformed arches of different sizes such as round 0.016” to 0.022” Niti, rectangular 0.018” x 0.024” to 0.021” x 0.027” NiTi and round 0.014” to 0.018, rectangular – 0.18” x 0.024” to 0.021” x 0.027” stainless steel. Epoxy coated archwires are available under the trade name of Filaflex (American Orthodontics), have high tensile stainless steel core and durable tooth coloured plastic coating. This is available in preformed round 0.018” arches. They are available under another brand name of Orthocosmetic Elastinol (Masel Orthodontics) which is esthetically coated high performance NiTi superelastic archwires and blends exceptionally well with ceramic or plastic brackets and doesn’t stain or discolor plus they resist cracking or chipping.

Nitanium tooth toned archwire:

• Structure: It is a superelastic Ni-Ti wire with special plastic and friction reducing tooth colored coatings which blends with natural dentition, ceramic, plastic and composite brackets and maintains its original color.

• Disadvantages: However, the coated white colored wires have routinely succumbed to forces of masticationand enzyme activity of oral cavity. On the other hand, the uncoated transparent wires have poor mechanical properties that they function merely as placebo. Esthetics is important to the orthodontist but function is paramount and anything less is unacceptable.

• Availability: It is marketed by Ortho Organizers and is available in round 0.014”, 0.016”, 0.018” and rectangular 0.016” x 0.022” sizes. These wires deliver gentle force.

Conclusion

Recent advances in orthodontic wire alloys have resulted in a wide array of wires that exhibit an amazing spectrum of properties. Until the 1930s, the only orthodontic wires available were made of gold. Since then several other materials with desirable properties have been adopted in orthodontics. These include stainless steel, cobaltchromium, nickel-titanium, beta-titanium and composite wires. These wires demonstrate a wide spectrum of mechanical properties and have added to the versatility of orthodontic treatment.

Appropriate use of all the available wire types may enhance patient comfort and reduce chairside time as well as the duration of treatment. The individual clinician must always know and understand the needs and options at every stage of therapy. The restricted use of only stainless steel wires to treat an entire case from start to finish, therefore, may be indicated in relatively few cases. It may be beneficial instead to exploit the desirable qualities of a particular wire type that is specifically selected to satisfy demands of presenting clinical situation. This, in turn, would provide most optimal and efficient treatment results.

References

- Lim KF, Lew KK, Toh SL (1994) Bending stiffness of two aesthetic orthodontic archwires: an in vitro comparative study. Clin Mater 16: 63-71.

- Burstone and Kuhlberg (2000) Fiber reinforced composites in orthodontics J ClinOrthod 34: 271- 279.

- Zufall SW, Kusy RP (2000) Sliding mechanics of coated composite wires and the development of an engineering model for binding.Angle Orthod 70: 34-47.

- Elayyan F, Silikas N, Bearn D (2008) Ex vivo surface and mechanical properties of coated orthodontic archwires. Eur J Orthod 30: 661-667.

- Goldberg AJ, Liebler SA, Burstone CJ (2011) Viscoelastic properties of an aesthetic translucent orthodontic wire. Eur J Orthod 33: 673-678.

- da Silva DL, Mattos CT, de Araújo MV, de Oliveira Ruellas AC (2013) Color stability and fluorescence of different orthodontic esthetic archwires. Angle Orthod 83: 127-132.

- da Silva DL, Mattos CT, Simão RA, de Oliveira Ruellas AC (2013) Coating stability and surface characteristics of esthetic orthodontic coated archwires. Angle Orthod 83: 994-1001.

- Kusy RP (1997) A review of contemporary archwires: their properties and characteristics. Angle Orthod 67: 197-207.

- Talass MF (1992) Optiflex archwire treatment of a skeletal class III open bite. J ClinOrthod 26: 245-252.

- Vogels DS (1991) Orthodontic archwires. J. ClinOrthod25 : 83-98.

Relevant Topics

- Advanced Bleeding Gums

- Advanced Receeding Gums

- Bleeding Gums

- Children’s Oral Health

- Coronal Fracture

- Dental Anestheia and Sedation

- Dental Plaque

- Dental Radiology

- Dentistry and Diabetes

- Fluoride Treatments

- Gum Cancer

- Gum Infection

- Occlusal Splint

- Oral and Maxillofacial Pathology

- Oral Hygiene

- Oral Hygiene Blogs

- Oral Hygiene Case Reports

- Oral Hygiene Practice

- Oral Leukoplakia

- Oral Microbiome

- Oral Rehydration

- Oral Surgery Special Issue

- Orthodontistry

- Periodontal Disease Management

- Periodontistry

- Root Canal Treatment

- Tele-Dentistry

Recommended Journals

Article Tools

Article Usage

- Total views: 21818

- [From(publication date):

March-2016 - Nov 21, 2024] - Breakdown by view type

- HTML page views : 19277

- PDF downloads : 2541