Energy Requirements and Performance of Different Soil Tillage Systems on the Yield of Maize Crop

Received: 11-Jan-2018 / Accepted Date: 19-Jan-2018 / Published Date: 26-Jan-2018 DOI: 10.4172/2329-8863.1000334

Abstract

Here we are presenting a research study on maize production in Islamabad, Pakistan for the season spring-2013. Impact of tillage methods and input-output energy on maize crop yield have been investigated. Input energy consumption and outputs energy gained for maize crop production have also been evaluated. Grain harvest was found maximum under deep tillage compared with conventional and no-till. The total energy was found comparatively higher under deep tillage than that with conventional tillage, while the least in the no-till. Net energy gain was observed highest under deep tillage.

Keywords: Tillage; Energy; Grain yield; Net energy gain

Introduction

Tillage is the most important activity in the crop production but due to uncertain fuel supplies and increasing fuel costs farmers, agricultural engineers and researchers are forced to examine methods that can conserve energy and yield high agricultural production. Thus, there is a need for research to explore possible ways and means so that energy consumed by different tillage practices could be conserved. Very little attention has been given on energy consumption by farmers in Pakistan; as a result energy consumption in mechanized agriculture is quite high. The shortages of fuel supplies coupled with rapidly increasing food and fibre demands has stimulated the development of sustainable mechanized agriculture around the world [1]. In Pakistan, maize is the staple food for a large population especially in hilly areas. This top is capable of producing the greatest amount of grain per unit area [2], and can be grown twice a year during the spring season and the summer. Keeping in view, this investigation was carried out to determine the input energy requirements and performance of different soil tillage systems on yield of maize crop.

Materials and Methods

In present study, experimental field was selected from the capital city of Pakistan-Islamabad. The selected area included nine plots. The length and width of each plot was kept same and measured as 10 m each. Three replications were made to organize and randomize complete block design. Maize seeds were dibbled 5 cm depth. The row to row and seed to seed distance was kept 75 cm and 20 cm respectively. 25 kilogram of maize was sown per hectare with a complete dose of nitrogen, phosphorous and potassium fertilizer (NPK) at the time of sowing.

The remaining doses of nitrogen were added in two splits. Furthermore, the procedure has been applied before the first tapering of irrigation in order to keep the plants at a distance suitable five stations at random from each plot and tagged.

All the data was subjected to analyze the variance (ANOVA) by using the variance procedure [3]. The division of treatment mean was made by using least significant difference (LSD) at level of 0.05 probability. For tillage operation, a MF diesel tractor (75 hp) was used. Implements included in different tillage systems were deep tillage (sub soiler+moldboard plow), conventional tillage (disc harro+cultivator) and zero tillage (drill).

All the trial plots were fertilized at the same levels in order to decrease the significance difference of fertility on maize crop yield. Energy investigations were carried out on the bases of field operations including tillage, fuel, human labor, seed, fertilizing and harvesting.

All these sources involved in the production process. For every field operation, energy used per hectare was calculated by following three equations [4]:

(1)

(1)

Where, ED, h, AFU, PEU and RU respectively are specific direct energy use (fuel) for a field operation (MJ/ha), specific working hours per run (h/ha), average fuel use per working hour (L/h), specific energy value per litre of fuel runs (MJL) and number of applications in the considered field operation.

(2)

(2)

Where, EID, RATE and MATENF respectively are indirect energy input (MJ/ ha), application rate of input (kg/ ha) and energy factor of material used (MJ. kg).

(3)

(3)

Where, LABEN, Labour, Time Area and Labenf respectively are labor energy (MJ/ ha), number of working laborers, operating time (h), operating area (ha) and labor energy factor (MJ/ h).

Energy equivalents of the input used in maize production along with references are given in Table 1.

| Input | Energy Equivalents(MJ) | Reference |

|---|---|---|

| Human Labour(h) | 2.3 | [5] |

| Diesel fuel (L) | 47.80 | [6] |

| Chemical fertilizers (kg) | ||

| i.Nitrogen | 61.53 | [7] |

| ii. Phosphorus | 12.56 | [7] |

| iii. Potassium | 6.7 | [7] |

| Maize seed (kg) | 14.7 | [8] |

Table 1: Energy equivalent data for different input and output used in field crop production.

Results and Discussion

Yield

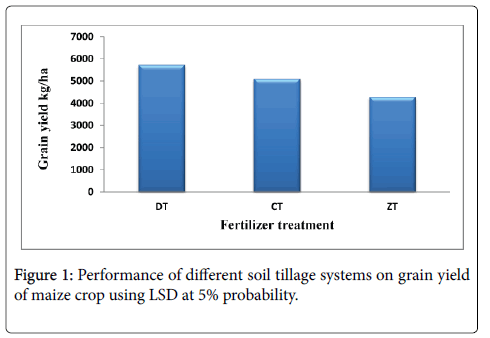

The productivity of each tillage methods was evaluated by performing field experiment and related with input energy consumption. The mean grain yields were obtained from the performance of different soil tillage systems and results are shown in Figure 1. The results have shown significant rise in yield with deep tillage, Figure 1. The yield of 5727 kg/ha was obtained with deep tillage which was highest as compared to (5108 kg/ha) in conventional tillage, while the lowest yield (4281 kg/ha) was obtained in zero tillage. Present results revealed that deep tillage is beneficial for maize and these results were found compatible with the findings reported by Arora et al. [9]. However, in another study reported by Kersten and Hack [10] no till cultivation was suggested best for ploughing.

Input-output energy

The input and output energy values used in maize production were evaluated and presented in Table 2. The total input energy was found maximum under deep tillage (12530 MJ/ha) followed by conventional tillage (10554 MJ/ha) while lowest input energy was evaluated in zero tillage as 9945 MJ/ha. Similar order was observed for output energy and the net energy (Table 2).

| Input energy | Deep tillage |

Conventional tillage |

Zero tillage |

|---|---|---|---|

| Human labor (MJ/ ha) | |||

| Sowing | 184 | 184 | - |

| Harvesting | 368 | 368 | 368 |

| Diesel (MJ/ ha) | |||

| Sub soiler | 1740.8 | - | - |

| Mould board plow | 1331.6 | - | - |

| Disc harrow | - | 586.5 | - |

| Cultivator | - | 510.4 | - |

| Zero tillage | - | - | 671.6 |

| Fertilizer (MJ/ ha) | |||

| Nitrogen (120 kg/ ha) | 7383 | 7383 | 7383 |

| Phosphorus (60 kg/ ha) | 753 | 753 | 753 |

| Potassium (60 kg/ ha) | 402 | 402 | 402 |

| Seed (MJ ha-1) | 367.5 | 367.5 | 367.5 |

| Total input energy (MJ/ ha) | 22293 | 20317 | 19708 |

| Output energy (MJ/ ha) | 84187 | 75088 | 62931 |

| Net energy gain (MJ/ ha) | 61894 | 54771 | 43223 |

Table 2: The energy input-output for spring-2013 sown maize.

Output energy and net energy were obtained higher in deep tillage (84187 MJ/ha and 71657 MJ/ha respectively), followed by conventional tillage (75088 MJ/ha and 64534 MJ/ha respectively) and minimum (62931 MJ/ha and 52986 MJ/ha respectively) in zero tillage.

Conclusions

On the basis of yield, input and output energy of maize crop, we evaluated different tillage methods. Maximum input and output energy was gained with deep tillage and revealed it a best method over conventional tillage, while zero tillage treatment gave the lowest values of input and output energy. Since deep tillage used high energy as compared to conventional and zero tillage; the conventional tillage method will be the best choice to those farmers who cannot afford much input cost. On these bases, we may suggest farmers to preferentially adopt conventional tillage method for successful growth of maize crop.

References

- Swanton CJ, Murphy SD, Hume DJ, Clements DR (1996) Recent improvements in the energy efficiency of agriculture: Case studies from Ontario, Canada. Agricultural Systems 52: 399-418.

- Akbar M, Shakoo S, Hussain A, Sarwar M (2008) Evaluation of maize 3-way crossed through genetic variability, broad sense heritability, characters association and path analysis. J Agric Res 46: 39-45.

- Steel RG, Torrie JH (1980) Principles and procedures of statistic. 2nd edn, Mc Graw-Hill, New york.

- Moerschner J, Gerowitt B (2000) Direct and in-direct energy use in arable farming in northern germany. In: Weidema BP, Meeusen MJG (eds.), Agricultural Data for Life Cycle Assessments. The Hague, Agricultural Economics Research Institute, p: 195.

- Yaldiz O, Ozturk HH, Bascetincelik A (1990) The determination of energy outputs/inputs rates at some products of the Cukurove region. International conference on agricultural engineering, technical papers and posters, Berlin, pp: 391-392.

- Safa M, Tabatabaeefar A (2002) Energy consumption in wheat production in irrigated and dry land farming. Proc Intl Agric Engg Conf, Wuxi, China.

- Pimentel D, Pimental M (1979) Food, energy and society. Resource and Environmental Science Series, Edward Arnold, London.

- Panesar BS (2002) Energy norm for input and output for agricultural sector. In: SR Verma, JP Mittal and S Singh (eds). Energy management and conservation in agricultural production and food processing. USG Publishers and Distributors, Ludhiana, Punjab, India, pp: 5-16.

- Arora VK, Gajra PR, Prihar SS (1991) Tillage effect on corn in sandy soil relation to water retentivity, nutrient and water management and seasonal evaporability. Soil and Tillage Res 21: 1-21.

- Kersten M, Hack F (1991) Effect of four tillage methods on growth of maize in Zambia. AMA 22: 34-38.

Citation: Menon SQ, Arshad N (2018) Energy Requirements and Performance of Different Soil Tillage Systems on the Yield of Maize Crop. Adv Crop Sci Tech 6: 334. DOI: 10.4172/2329-8863.1000334

Copyright: © 2018 Arshad N, et al. This is an open-access article distributed under the terms of the Creative Commons Attribution License, which permits unrestricted use, distribution, and reproduction in any medium, provided the original author and source are credited.

Share This Article

Recommended Journals

Open Access Journals

Article Tools

Article Usage

- Total views: 6264

- [From(publication date): 0-2018 - Apr 29, 2025]

- Breakdown by view type

- HTML page views: 5346

- PDF downloads: 918