Energy Optimization of Light Naphtha Isomerization Unit at PGSOC1 Using by Pinch Analysis

Received: 01-Mar-2023 / Editor assigned: 03-Mar-2023 / PreQC No. jabt-23-90080 / Reviewed: 17-Mar-2023 / QC No. jabt-23-90080 / Revised: 21-Mar-2023 / Manuscript No. jabt-23-90080 / Accepted Date: 27-Mar-2023 / Published Date: 28-Mar-2023 QI No. / jabt-23-90080

Abstract

Energy efficiency is improved by Heat Exchanger Network (HEN) and Pinch Analysis (PA). In this research, the retrofitting of HEN of Light Naphtha Isomerization (LNI) was carried out to decrease the utility consumption and cost using by PA. Data extraction was needed to calculate the hot and cold utility consumption in target and actual by Aspen Energy Analyzer (AEA) to indicate the Composite Curve (CC) and Grand Composite Curve (GCC). The base case shows that at Δ𝑇𝑚𝑖𝑛 = 10˚C that has the minimum total cast, the approach pinch was 92-102˚C. Also, an energy pocket on GCC existed between 140 to 170˚C, and the target can be optimized up to 19.17%. Five retrofitting cases were carried out on HEN of LNI to approach the target of utility consumption. The results indicated that, the hot and cold utility consumption 2.78 e7 Kj and 5.08 e7 Kj decreased, respectively. Also by retrofitted on a base case the utility consumption and total cost decreases by 11.3% and 3.7%, in order.

Keywords

Isomerization unit; Pinch Analysis; Energy Optimization; Heat Exchanger Network; Refinery

Introduction

An isomerization unit is a process to increase the gasoline quality and decrease environmental issues. Isomerization carries out the conversion from hydrocarbons to their isomers. The interest in the isomerization process has grown to limit the amount of benzene, aromatic, and olefin in gasoline for improving the Research Octane Number (RON) of gasoline and also to decrease the amount of gasoline benzene with the benzene saturation. The isomerization process has been commercialized due to its wide application to gasoline production with high quality by some commercial technology, the most important are GTC, Axens, and UOP. GTC technology for isomerization of n-butane, Light Straight Right (LSR), and c+ hydrocarbons uses various processes. The isomalk-3SM process use a mixed metal oxide catalyst for the isomerization of n-butane, the isomalk-4SM process for the isomerization of c+ hydrocarbons and for the isomerization LSR uses a platinum mixed metal SI-2 catalyst. Axen technology uses chlorinated alumina (ATIS-2L) catalysts for the isomerization of LSR that are, once- through, DIH, IPSORB, and HEXORB. HEXORB that combination of DIH and molecular sieves, have the highest RON, and once through gives the lowest RON. UOP process has been used for different technics, that is including Buatmar, Penex, and Par-ISOM process. Chlorinated Pt/Al2O3 catalyst is used at Penex1Persian Gulf Star Oil Company. Process for the isomerization of LSR, Buatmar process is taken for isomerization of n-butane, and non- chlorinated alumina catalyst used for isomerization of LSR. Recently, energy consumption has been increased, and studied of LNI units to optimization of energy consumption, and energy recovery and also present appropriate solutions to reduce energy consumption are important. Process Integration (PI) improved energy recovery and reduced loss of energy in chemical processes. PI is a methodology for continuous processes started and developed in the 1970s. There are three approaches to PI: 1) graphical methods including Pinch Analyses (PA), 2) computer-aided mathematical programming methods, and 3) two methods. PA is a graphical technique for HEN analyses, and also PA improves energy saving and heat recovery in the process industry. PA can be used to reduce [1-9] energy costs and increase the efficiency of HEN design through innovation and creativity in an energy-based industry. Identifying the location of the pinch is taken by PA systematic. Composite Curve (CC) for cooling and heating, which drowns on a temperature-enthalpy, and represents the thermal energy, is one of the applications of PA. Gadalla proposed a new graphical method of PA that is based on plotting the temperature of hot streams versus cold streams to analyze the HEN. Each exchanger is illustrated by a straight line and the slop is indicated the ratio of heat capacity. The exergy and PA were carried out to optimize heat integration and recycling heat flow by Chang et al. The results show that utility energy efficiency is saved at 81.97%, and the total exergy efficiency for products in the process was 92.24%. Dagda and Piagbo monitored refinery data to analyze HEN of crude distillation unit in Port Harcourt of Nigeria, West Africa by Aspen Energy Analyzer (AEA). The analyses showed that the cross-pinch of HEN was 5.52 e7 KJ/h above the target, then the retrofit of HEN can be used. To achieve maximum energy saving of the Continuous Catalytic Regeneration Reformer process (CCRRP), the retrofit of HEN was studied by, using PA. The result showed that utility consumption and costs were reduced by 3.2% and 4.5%, respectively. Investigation of HEN on Column Distillation Unit (CDU) to save energy and reduction of emission of co2 is carried out by Gadalla at a refinery. The result showed that energy and Colling Water can be saved by 17% and 39%, respectively. Liu XG, et al., investigated the HEN of a complex refinery with crude oil feed to recover energy and reduce cost by PA using Aspen Plus V 7.2. They obtained that, by adding a condenser, condensed oil tank, and side reboiler, efficiencies improved and the capital cost was reduced. The results showed that, hot and cold utility and annual operating costs improved by 17.98%, 25.65%, and $346,617, respectively. Modification of the HEN in the LNI unit is done by using the Pinch Design Method (PDM) to reduce the hot and cold utility consumption. They proposed scenarios to modify LNI unit that increased heat transfer and reduced energy consumption. They found that, the heat transfers from cooling water cold utility at 29.5 ° C to Medium pressure Steam (MPS) hot utility at 150°C has been increased by the heat pump. Reduced the energy consumption of LNI units using PA. Their results show a decrease in hot and cold utility consumption (34.2%) and (26.2%) respectively. Al-Mutairi and Babaqi demonstrated the thermal integration of HEN to energy storage and saving energy costs in the new design by PA. To optimize the control parameters on separation, the simulation of the splitter and comparison between the design and the actual was investigated by Malfi. Recently used a new algorithm and methodology to analyze HEN and reduced cost. Stampfli. suggested a two-level algorithm for HEN retrofit: 1) a Genetic algorithm for to determine optimization and 2) a differential algorithm for heat loads. They achieved, this algorithm applied to industry and reduced the total annual cost by about 66%. Optimization of LNI was carried out in a petroleum refinery with a combined direct and indirect hybrid methodology. Kinetic and surrogate were applied for a direct and indirect model, respectively. The results showed that the accuracy of an indirect model is not good for the solution, but the directed model decreases the computational time. Some studies in the LNI unit on RON were carried out by Can. Also, some investigations on reaction and catalysts in LNI units were studied by Injongkol. PGSOC, is the biggest refinery in the Middle East, and the biggest refinery with condensate gas feed in the world, that located in the south of Iran, Bandar abas. PGSOC is established in 2006, but with the presence of boycotts, this company operated all three-phase in 2018. The total gas condensate feedstock to the new refinery is 360,000 BPSD in design, which will be processed in three parallel crude distillation columns, and now is worked at 450,000 bbl/day or 125% of design. PGSOC is included: Column Distillation Unit (CDU), Naphtha HydroTreater (NHT) unit, Octanaizer and Continuous Catalytic Regeneration (CCR) unit, liquid Pressure Gas (LPG) unit, Isomerization unit, Kerosene HydroTreater (KHT) unit, and Gas Oil HydroTreater (GOHT) unit, that produce Gasoline, Gas oil, LPG, Kerosene with 5 Euro standard. The feedstock is provided with pipes from south pars gas refineries. Before operating PGSOC, all of the gas condensates were sold in the market, and Iran Government should import gasoil from aboard. PGSOC is the first refinery with condensate gas in Iran. With operating all three phases of PGSOC, Iran Government exports extra gasoil to other countries. Thus, operating the PGSOC is very important in Iran and in the Middle East. The extra value of gas condensate refineries is more than oil refineries, and on the other hand, the production of more than 75% of gasoline and gasoil from gas condensate refinery feed, is one of the economic justifications of this company. The first time, we studied the HEN of the LNI process at PGSOC by PA in this research. Up to now, there aren’t any research studies on the HEN of LNI at PGSOC, that fed with condensate gas. Also, there are a few investigations on the HEN of LNI of the refinery with gas condensate feed. Thus the investigation of this refinery and optimization of the LNI unit is very important and necessary. PA is a very important and simple method among others, thus we use the PA method for analyses of HEN. The LNI unit is licensed by UOP company with the Penex process. Five retrofitting cases have been studied on the HEN of LNI and compared with the base case (the design process). CC, GCC, hot and cold utility energy consumption, and costs (Operating, Capital, and Total Costs) were studied using Aspen HYSYS and AEA V9.

Process Description

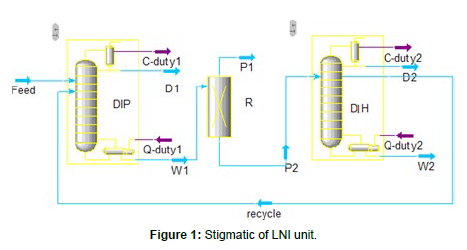

The feedstock at PGSOC is gas condensate, that lighter than crude oil. It means the heavy hydrocarbon ( c+ ) is the less and the light hydrocarbon is the more in gas condensate feedstock. Thus, the product specification of gas condensate feedstock, like RON, benzene, and sulphur is the best. In this research, the LNI unit is licensed by the UOP Penex process. The Penex process has served as the primary isomerization technology for upgrading C5/C6 light straight-run naphtha feeds since 1958. Penex process in the feedstock stream can bear up to 5 vol% benzene. The Penex/DIH Process Units shall be designed to each process 30,000 BPSD of light naphtha derived from South Pars condensate. The three-phase Penex/DIH Process Units shall each include a Deisopentanizer Column (DIP) and a Deisohexanizer Column (DIH). The DIP will produce an overhead product rich in isopentane and the bottoms will be routed to the Penex reactor section. The DIH [6-9] will produce overhead and bottom products, as well as a recycle stream which shall be routed back to the reactor section to maximize the product RON, that indicated in Figure 1. The DIP overhead product when mixed with the DIH overhead and bottoms product, will form the isomerate product which shall meet the following target specification:

C5+RONC 88.5

The feed to the Penex/DIH Process Units is light straight run naphtha and derived directly from the overhead system of a Naphtha Splitter that has the properties in (Table 1 & 2). The isomerization unit consists of these sections: DIP Section, Feed and make-up gas driers, Reactor exchanger circuit, Isomerization reactors, Stabilizer, Net gas scrubber, DIH, and Methanator.

| Component | wt% | Component | wt% |

|---|---|---|---|

| n-Butane | 0.01 | 3-Mpentane | 6.84 |

| i-Pentane | 22.25 | n-Hexane | 15.59 |

| n-Pentane | 21.58 | Mcyclopentan | 5.85 |

| Cyclopentane | 1.22 | Cyclohexane | 3.3 |

| 22-Mbutane | 1.28 | Benzene | 6.08 |

| 23M-1-butene | 2.05 | C7+Paraffins | 2.11 |

| 2-Mpentane | 11.45 | C7+Naphthenes | 0.39 |

| Total | 100 | Flowrate Kg/hr | 132296 |

Table1: Feedstock Component to the isomerization unit.

Contamination |

Value |

|---|---|

| Total sulfure, ppm | 0.5 |

| Total nitrogen, ppm | 0.1 |

| Bromine number | 4 |

| Total oxygenate | 0.5 |

| Hcl, ppm | 0.5 |

| Fluoride,ppm | 0 |

| Copper, ppb | 20 |

| Lead, ppb | 10 |

| Arsenic, ppb | 1 |

| Mercury,ppb | 1 |

Table2: Feedstock Component to the isomerization unit.

DIP section

The light Naphtha with the temperature of 40ºC and pressure of 6 barg, will be entered to DIP column (CC- 1801) through E-1801. The purpose of this column is to remove isopentanes with a high RON from the reactor feed. Heat input to the column is provided by a steam reboiler (E-1802 A/B) serviced by Low Pressure Steam (LPS) on condensate flow control. The overhead product which is mainly isopentane is sent to storage on flow control reset by the DIP tower. In order to maximize the product RON, the recycle stream will be routed back from DIH side draw pumps and will be mixed with DIP bottom product to route to the feed drier section after cooling through E-1801, E-1806, E-1807 down to 40°C. The DIP section shown in makeup gas driers

Due to the extreme sensitivity of the Penex catalyst with water and other containments, the feedstock and the makeup hydrogen for the Penex unit must be routed through molecular sieve driers. These driers are designed to remove containments before they can reach to the Penex catalyst and deactivate the catalyst.

Liquid feed drier

The liquid feed driers that showed in are loaded with molecular sieves adsorbent HPG-250 for the removal of water and trace levels of oxygenates or sulfur compounds. The driers are operated in series except when they are in the regeneration mode. In this mode, only one drier will be in service. The hydrotreated stream is introduced to liquid feed drier (VV-1805, 6) at the bottom and passes upflow through the molecular sieve desiccant and exits at the top. The flow is then routed through one of the drier crossovers to the other liquid feed drier. The flow through the second liquid feed drier is also in the upflow pattern. The dried hydrocarbon is then routed to feed surge drum (VV-1807). The purpose of this drum is to provide liquid feed surge capacity for the Penex unit. The spent drier is taken out of service by closing the appropriate block valves. The second drier is now alone in service as the only drier drying the feed. After the drier regeneration has been completed, it is now ready for service.

Makeup gas drier

The pressure of the treated hydrogen is less than the pressure required at the Penex reactors, so the gas from the methanator is routed to the makeup compressor suction drum VV-1803, as shown in. It is compressed up to the about 40 barg by the reciprocating compressors C-1801 A/B and cooled in discharge cooler E-1805. To remove any liquid drops the cooled gas is sent to VV- 1804 and then sent to the gas driers. Makeup gas must be dried to remove water and potential co/co2 which are extremely poisonous to the reactor catalyst. The two gas driers (VV-1801, 2) operate in the same manner as the liquid feed driers. The driers operate up flow, in series. The dried hydrogen is then sent to the reactor circuit.

Regeneration

A part of the isomerate, DIH overhead liquid product is used for driers regeneration, as shown in. The regenerant vaporizer E-1810 is used to heat the regenerant stream before it reaches the electric superheater (H-1801). The vaporizer is an upright heat exchanger which uses bayonet type tubes that have been strength welded and fully rolled. MPS on the inside of the bayonet tubes transfers heat to the regenerant on the outside of the bayonet tubes. This arrangement allows hot steam in the tip of the bayonet tube to transfer heat to the vaporized regeneration stream, giving it several degrees of superheat. This prevents the regenerant from condensing which could damage the electric bundles in the superheater. The regenerant superheater raises the temperature of the vaporized regenerant from 146 to 316ºC. The regenerant stream is heated by inconel electric elements. The regenerant enters to spent drier (feed or gas dryer) that is taken out of service by closing the appropriate block valves. Regenerant is flow down from the drier and absorb moistures and other contaminates from molecular sieves. Spent regenerant from driers are combined and cooled through E-1808 and E-1809 to 40ºC and back to product line to join the material sent to storage.

Reactor exchanger circuit

The reactor exchanger circuit consists of the cold combined feed exchanger (E-1811), the hot combined feed exchanger (E-1812) and the reactor charge heater (E-1813). Prior to the entry of the liquid hydrocarbon into the cold combined feed exchanger, it combines with the makeup and recycle hydrogen streams. After exiting the reactor charge heater, the heated combined stream then flows to the first reactor. The combined feed is finally brought up to the desired temperature (146°C at SOR and 188ºC at EOR) in the reactor charge heater by a temperature controller which resets the exchanger heating medium flow. After exiting the reactor charge heater, the heated combined stream then flows to the first reactor.

Isomerization Reactors

These reactors are the heart of the process. Although not essential to the success of the process, the Penex system employ two reactors in a series flow configuration. The catalyst type is “Amorphous Chloride Alumina containing platinum”; “I-8 catalyst. Isomerization and Benzene hydrogenation reactions are both exothermic and the temperature increases across the reactor. Upon exiting the first reactor, the stream then passes to the hot combined feed exchanger (E-1812) where the first reactor’s heat of reaction is partially removed. The partially cooled stream is then routed to the second reactor (R- 1802) where the final process reactions are completed. Upon exiting the second reactor, the stream then passes to the cold combined feed exchanger (E-1811) to remove heat of reaction at the second reactor. The effluent after cooling to temperature of 53ºC through E-1814 and E-1815 enters to a separator (VV-1808) to separate hydrogen and liquids. The liquid outlet of the separator enters to the stabilizer.

Stabilizer

The purpose of this column (CC-1802) is to separate any HCl and light cracked gases (C1, C2, and C3’s) from the isomerate that shown in. The feed to this column, liquids from the separator, is first preheated in the reactor effluent stabilizer feed exchanger (E-1814) up to 98ºC and then by the stabilizer feed bottom exchanger (E-1816) to reach to 134ºC before entering the stabilizer. The column reboiler (E-1817A/B) is serviced by medium pressure steam. The stabilizer column overhead vapor, consisting of the light hydrocarbon components of the column’s feed, is routed to an Air Cooler (AC) condenser (E-1818) and then to the net gas scrubber. Bottoms product is routed to DIH column after first exchanging heat with the incoming stabilizer column feed in the stabilizer feed/bottoms exchangers (E-1816).

Net Gas Scrubber

The function of the Net Gas Scrubber (CC-1803), as indicated in is to neutralize the hydrogen chloride HCl present in the stabilizer off gas. In this vessel, the off gas is contacted with a counter current flow of caustic solution (10 wt% NaOH) which reacts with HCl to form sodium chloride and water. The scrubbed gas leaves the top of the column and goes to the LPG recovery units or the fuel gas system during scrubber upset or emergency.

DIH

The purpose of this column (CC-1804) is to recover product isohexane and pentanes from the stabilized reactor products. The feed to this column is the stabilizer bottoms stream. Heat input to the column is provided by a steam reboiler (E-1820 A/B/C/D), serviced by medium pressure steam. Overhead vapor is totally condensed in an air fin type exchanger (E-1821). The overhead product which is mainly C5’s and di- methylbutanes is sent to isomerate storage. The bottoms product from the column is generally a small and is sent to storage with one AC E-1824 and a Sea Water (SW) exchanger E-1823 are provided to maintain cooling of the product down to 40ºC before storing it. The DIH column operation is fairly straightforward. The basic guidelines are to remove all the pentanes and 2-2DMB overhead while minimizing the overhead 3methyl pentane content. The DIH recycle stream is taken off as a lower side cut. Since the RON of 2MP and 3MP is lower than 2-2DMB and 2-3DMB, then DIH column is designed to limit the amount of methyl- pentanes in the isomerate and recycle back them to the rector section as lower side cut. The lower side cut is pumped back, and mix with the DIP bottom to enter to Penex liquid feed driers. The majority of the cyclo-hexane and co+ material should be rejected out the bottom of the tower. The RON of the overhead product is set by two independent variables. 1) The amount of 2MP and 3MP in the overhead. Since these components have an RON blending value of about 75, the higher their concentration in the overhead product, the lower RON will be. More reflux and more recycle to the reactor section would be required to decrease the methylpentanes. 2) The amounts of 2-2DMB, 2-3DMB in the recycle line to the reactor section. Since these cssomponents have an RON blending value of more than 92, the higher their concentration in the overhead product, the higher RON will be. Less reflux and side draw and more products to the storage would be required in this condition. DIH section indicated in.

Methanator

Methanator system is provided for removal of co and co2 from the hydrogen rich gas. Make up hydrogen feeds from the Octanaizer unit have some contamination that summarized in. By installation of a methanator system the values of co will be decreased to 1 mol.ppm max, that shown in . The main equipment of the methanation system is R-1803. This reactor includes two sections: one for desulphurization and anothre for methanation. The catalyst of the sulphur guard bed is the cooper, zinc oxides on Al. support and the mathanator catalyst layer is nickel on silica support. To protect the catalysts of the R-1803, HCl guard beds are considered at the upstream. Hydrogen is warmed through methanator feed/effluent exchanger (E-1825), plate type, and E-1826 up to 210ºC. Heat input to the mentioned exchangers is provided by the methanator reactor outlet and High pressure Steam (HPS), respectively. The methanation reaction is exothermic and the temperature will increase about 3ºC through the reactor. The reactor outlet will be cooled down to 40ºC through E-1825 and E-1827 routed to make up gas driers section.

Methodology

One of the main tools of PA is the graphical representation of CC that indicated enthalpy-temperature simply but powerful, as indicated in. CC illustrated the minimum hot QHmin and cold utilities QCmin required in addition to the minimum driving force required for the process [K Gu and Vassiliadis VS, 2014]. Any change in process parameters will change the pinch position and as a result the hot QHmin and cold QCmin utilities requirements. The minimum vertical distance between hot and cold stream is indicated the minimum approach temperature ΔTmin and sink and source of energy are in above and below the pinch point, respectively. In the CC, if we close the hot and cold curves to each other, that ΔTmin reaches zero, the driving force due to temperature becomes zero. At this point, we will have the maximum energy recovery, which is called the pinch point. If there is heat transfer around the pinch point, QHmin and QCmin, increase from its minimum value, in other words, it increases the consumption of hot and cold utility. The pinch point divides the process into two systems: upper pinch, and lower pinch. The upper part of the pinch shows the required heat for system QHmin, that is called heat sink part, and the lower part of the pinch shows the surplus energy from system QCmin, that is called heat source part. In the heat sink section, the energy required for process is provided from hot utility, therefore, there is usually no cold utility in the heat sink section. In the heat source section, the excess heat in the process is taken by cold utility, in other words, if there is hot utility in this section the consumption of cold utility is increase. The GCC shown in, is created from the composite curve. If the cold streams are shifted up by ½

ΔTmin and hot streams are shifted down by ½ ΔTmin in CC, at pinch temperature, the two curves touch each other. On this occasion, by transferring the distance between hot and cold steam, the GCC is created. The GCC showed the heat recovery pockets that related to utility level in a range of temperature that produces energy or another utility. As it was said, during the last 2 or 3 decades, the use of CC and GCC graphs in PA are very important. In this research, PA is used to analyses the HEN, and CC and GCC were used to analyses the Target and improve the energy consumption and costs.

Result and Discussion

In the evaluation of the LNI unit, Aspen HYSYS software was used to simulation unit, and AEA software was used to PA. Usually, a base case is considered in optimization studies. Here, the isomerization unit, that designed by the UOP company is considered as a base case. With the studies done on the HEN, five retrofiring cases have been considered on the base case, to calculate and compare the amount of reduction in energy consumption and Total cost for optimization. In following, we provided explanations regarding simulation and energy analysis. In the energy analysis section, data extraction, heat exchanger network analysis, and then retrofitting cases are discussed and analyzed, respectively.

Simulation

As mentioned in the introduction, Aspen HYSYS V9 software was used to simulate the process. The main parts of the isomerization unit are DIP, Reactors, and DIH. For design the unit, columns of the process are designed and simulated, separately. First, the tower pressure is calculated using component splitter and case study. A distillation shortcut has been used to calculate the minimum tray number (Nmin), and the minimum reflux ( Rmin). Finally, the column has been used to simulate the total of the column with the exact solution method. After the simulation of the towers, the reactors of the process are simulated, and then the whole process is simulated using Process Flow Diagram (PFD). Simulation of the isomerization unit shown in.

Energy Analysis of HEN 4-2-1 Data Extraction

HEN analysis is a studied field in PA in order to increase energy efficiency, by retrofitting energy consumption of designed networks. To analysis the HEN, first, all the data from streams of the exchangers are collected in, and then imported the data into the AEA software. The LNI unit has 28 heat exchangers, which 6 exchangers are processto- process and the other exchangers heat transfer with utility, that 14 streams heat exchange with cold utility (AC & SW) and 7 streams heat exchange with hot utility (which are: HPS, MPS and LPS), and one stream heat exchange with electrical heat exchanger.Data extraction of HEN

Grid diagram analysis

Grid diagram of the HEN is shown in. The direction of the streams, in grid diagram was be consider, cold streams flow from right to left, and Hot streams flow from left to right. Pinch point is located at 92- 102˚C that showed in AEA software. Close observation of grid diagram of the HEN, showed that, heat exchangers E1811, E-1812, E,1824, E-1825, E-1810 and E-1808 are inappropriately placed in the existing network, that results in waste of energy in the refinery. Also these situations offered the opportunity for retrofitting of the existing HEN to recover heat in the process.

Cross-Pinc

Cross-Pinch is the next options for retrofitting with high potential of heat recovery. The cross-pinch showed that 6.606 e7 kj/h can recover from HEN, indicated that heat exchangers located on the pinch point wasted the energy, and with changing the situation of these exchangers improve energy consumption. Theses exchangers are; E-1819, E1811, E-1812, E,1824, E-1825, E-1810, E-1808 and E-1814.

Minimum approach temperature ΔTmin

To calculate the minimum approach temperature ΔTmin using the range target which illustrates the ΔTmin across the total cost. The lower of the energy costs, the lower of the ΔTmin [Linhoff, 1998]. The ΔTmin was calculated at 10˚C as indicated in. In the HEN analysis, the Δ, affected the area and energy consumption of HEN.

Targeting

Targeting provides the optimal operating condition for HEN based on the imputed data streams. Have shown the actual (design) and target utility consumption (hot and cold) and costs (operating, capital and total cost), and target for base case, respectively. These tables indicated that this isomerization unit needs to be optimized up to 19.17%.

Composite curve and grand composite curve

The energy targets are calculated using CC and GCC which are indicated in. The CC provides a counter current picture of heat transfer, and can be used to determine the minimum energy target and pinch point for the process. The pinch rang was 92-102˚C, and the pinch point is 97˚C that illustrated in CC and GCC, respectively. In CC, the blue diagram showed the heat recovery within the process decreases after the pinch rang. If we want to increase the heat recovery inside the process, the amount of energy savings will also increase. In another way, if the blue curve moved obliquely upwards or its temperatures increase, the rate of energy recovery will also increase. Also, in the red diagram, the slope of the diagram is sharpened after the pinch rang and the diagram moves upwards. If the red line is moved slowly down or the temperatures on the line be reduced, the rate of energy recovery will be increased. In the red diagram or hot stream, the temperature on this diagram has risen from 170 to 340˚C while its enthalpy is constant and equal 8 e5. So we need to increase its enthalpy up to 8 e7 to have the best energy recovery. On other hand, in the blue diagram of cold streams, if the temperature changes and increase from 80 to 120˚C, the horizontal line becomes an oblique line, and the amount of energy savings will increase. In GCC the pocket above the pinch is obvious, that should be made smaller or removed as much as possible. On pocket, where the slope of the graph is negative, the streams on the lines indicate the extra energy. These streams that showed in and 18 are numbers 905- 335-464-613-901-610-452-901-553-404-606-328. These streams are related to these heat exchangers; H-1801, E-1810 & E-1808 are related to the Feed makeup and gas drier, E-1811 & E-1812 are related to the isomerization reactor, E-1817 & E-1818 are related to the stabilizer, E-1820 is related to the DIH, E-1825 is related to the methanator. In the recovery and optimization discussion of energy consumption, we consider pinch law: 1) decrease cross-pinch, 2) don’t use hot utility in heat source part, 3) don’t use cold utility in heat sink part. For this purpose, we use methods such as changing the arrangement, replacing and adding the heat exchangers. In order to optimize energy consumption according to revise the unit, five retrofitting cases were considered and discussed below in detail. The retrofitting cases were selected according to the CC, GCC, grid diagram, and cross-pinch, and were classified according to the sections (said before). These retrofitting cases were: the first retrofitting on feed and make up gas drier, the second retrofitting on reactor exchanger circuit and isomerization reactors, the third retrofitting on methanator, the forth retrofitting on coolers exchanger, and the fifth retrofitting on column section that included DIP, DIH and Stabilizer section.

Retrofitting cases

The first retrofitting case on the Feed and make up gas drier

HEN investigation of grid diagram shows that 613 and 610 streams have been located on the pinch position. According to the PFD, stream 613 is the output stream from the Feed Drier equipment at 304˚C temperature, which enters to the AC E-1808 for cooling, and reach 60˚C temperature. The output stream from the AC E-1808 was sent to a SW E-1809 to reach 40˚C temperature. Another stream with number 606 and 40˚C temperature, first, enters the E-1810, which is heated by MPS and reached 146˚C temperature, Then send to the H-1801 electric heater and reaches 316˚C temperature. To optimize energy, first, we simulate the plane by Aspen HYSYS V9, illustrated in. Stream 613 with 304˚C temperature (hot stream) and stream 606 with 40˚C temperature (cold stream), were heat transferred in E-1810-new process-to-process heat exchanger. So far, both hot and cold streams have not reached their desired temperature. Therefore, the temperature of 610 stream in H-1801 electric heater increases from 300 to 316˚C, and stream 615 in the AC E-1808 reaches 40˚C. The SW E-1809 and MPS in E-1810 were removed and saved utility. This retrofitting case changes the utility consumption and total cost that indicated in Table 1. By down this case, the E-1809 heat exchanger was eliminated which included a cooling water heat exchanger and, MPS in E-1810 were removed and replaced by the process stream. The duties of the H-1801 electric heat exchanger and E-1808 AC heat exchanger were reduced by 90.78% and 72.1%, respectively. The cross- pinch has been reduced by 1.282 e7 kj/h or 19.4%. Table 1 compares the use of hot and cold utility in the base case and the first retrofitting case. Thus the total utility consumption was reduced by 3.61%. Also, consumption of hot and cold utility decreased by 1.31 e7 kj and 1.2 e7 kj, respectively. The first retrofitting case have saved $3784 per year.

The second retrofitting case on reactor exchanger circuit and reaction section

Output stream number is 327 from the second reactor, first, heated in the E-1811, then heated by the E- 1812, and after that send to the E-1813 that heated by MPS to reach 146˚C, which is shown in. Another stream number is 348, first, enters to E-1815, and then send to the AC to reaches 53˚C. By studying the second retrofitting case, the energy consumption has been changed. By simulation this case and designing a plan for saved energy consumption, stream 327, first, heat exchanged with stream 348 by E-1811-n as indicated in. Then send to the E-1812- nn and after that send to the E-1813-nn to reached 167˚C temperature. By the second retrofitting case, the E-1815 has been removed, and MPS used in the E-1813 has also been eliminated. The results shown that by carrying out this case, the cross-pinch has been reduced by 3.5 e7 kj, and hot and cold utility has been reduced by 7.5%. Also, consumption of cold and hot utility has decreased by 3.8 e7 kj and 1.48 e7 kj, respectively, that illustrated in Table 1 and compare with the base case in Table 1.

The third retrofitting case on methanatore

In the third retrofitting, illustrated in, the stream number 905 and 213˚C temperature first, enters the E-8125 to cool down up to 60˚C, and then, was sent to the SW heat exchanger E-1827 to reach 40˚C temperature. Another stream, with stream number 901 and temperature of 32˚C first, enters the E-1825 and reach 186˚C temperature, and then, enters to the E-1826 to reach 210˚C using HPS. With simulation, to optimize the energy consumption, we changed the direction of the stream. The stream number 905 with 213˚C (hot stream), that the output of R-1803, First send to the E-1826-new and exchanged with the stream number 902 with 186˚C (cold stream), and then send to the E-1825-new. The E-1827 was eliminated due to reaching to the desired temperature, that illustrated in. The stream number 901 with 32˚C (hydrogen stream) exchanged in the E-1825- new with stream number 906 with 189˚C. In this retrofitting case, one heat exchanger was removed, and E-1826 which used HPS changed to the process-to-process heat exchanger. Also, E-1827 that used cold utility was removed. By the third retrofitting case, utility consumption and cost were decreased, as summarized in Table 1. The cross-pinch has been reduced by 0.06 e7 kj and saved 0.19% of energy consumption. Table 1 compares the base case and the third retrofitting case in utility consumption and costs. The results show consumption of hot and cold utility has decreased by 5 e5 kj and 7.2 e5 kj, respectively, or 0.44% in total.

The fourth retrofitting case on coolers Exchanger

Since, most of the cooling exchangers in this research were AC types, that use high energy consumption. AC, by electric utilities gives the energy from hot stream and send it to the air, that make a lot of waste. PGSOC is located in hot and humid area in the bandar abas, that closest to the Persian Gulf sea. Water from the sea was treated with chlorine chemicals, to prevent corrosion, and send to the pond. SW for heat exchangers is used from the pond, and after being exchanged in the SW heat exchanger, sea water recycled to the pond. The fourth retrofitting case studied using SW instead of an AC. In this case, the AC E-1803, ACE-1818, and AC E-1821 which were the DIP, Stabilizer, and DIH condenser, respectively, were replaced with SW. Water in the SW heat exchangers can be recovered and recycled in the process. Utility consumption and costs are shown in Table 1 and compared with the base case in Table 1. The results shown that, in this case, the amount of total cost has been significantly reduced by 22.5% and $53243 per/year.

The fifth retrofitting case on the DIP, DIH and Stabilizer columns section

Columns are the main equipment’s in the LNI unit. Due to condenser and reboiler at top and bottom of column, consumption of hot and cold utility has been increased. Therefore, columns are one of the equipment that should be studied. In columns, energy consumption reduces in three ways that include: column pressure changes, condenser and reboiler change, preheating of feed, and use of a condenser or auxiliary reboiler. In this work we studied the column pressure changes, condenser and reboiler change, and preheating of feed, that were discussed in detail at blow.

DIP

First, we studied the DIP column. The condenser temperature at the top of the DIP was 56˚C, and the reboiler temperature at the bottom of the column was 101˚C. The pinch point was 97˚C, and the reboiler temperature was closed to the pinch point. Thus we can consider reboiler and condenser were located in the below pinch. Therefore, it is not expected to recover substantial amount of energy waste. Nevertheless, we investigation to see if reduction in pressure could result in energy saving. pressure reduction in the feed, reboiler and condenser reduce the column operation temperature and resulting heat duty. Hence, in this study we attempted, the decrease in pressure on feed from 4.8 to 3 barg, (considering the operating pressure of reboiler and condenser) while the pressure of the reboiler and condenser were keep constant. By simulation with Aspen HYSYS V9, the results shown in Table 1. The results indicated that the little significant change in duties of condenser and reboiler, because the these duties related to the operating pressure and composition. Also no significant in the product composition was obtained. In another scenario, maintain the feed inlet pressure and reduced the condenser from 1.4 to 1 and reboiler pressure from 3.1 to 2.7, at Aspen HYSYS v9, that showed in Table 1. The results showed that, by reducing the pressure of the condenser and reboiler, the total duty of the reboiler and condenser has reduced by 6.01 e6 kj or 3.05%. By decrease the pressure of condenser and reboiler the temperature of condenser and reboiler were decreased. Then the duty of condenser and reboiler in order to changing the temperature of composition, were decrease. Also the product composition of DIP product was constant and the yield of tower was not changed. In this case the IC5 in product is the key component that determines the Top of DIP pressure. Due to the total condenser were designed, the total of IC5 should be convert to the liquid. In operation condition the temperature of IC5 that is liquid were determine the pressure of condenser. In DIP column the pressure of Top DIP could decreased up to 1.5 barg that the IC5 were liquid. More decreasing the of Top DIP to cause the increase of Flare.

DIH

In DIH column the condenser temperature at the top of the DIH was 58˚C, and the reboiler temperature at the bottom of the column was 132˚C. Thus, the condenser and the reboiler of DIH column were on the both side of the pinch point (97˚C). The DIH column has waste energy according to the pinch point position. Therefore, we studied the pressure of DIH column to change the occasion of condenser and reboiler in order to improve energy consumption. One way to improve the energy of the column is reduce the pressure at the top and bottom of the column. In the DIH column, the top and bottom pressure of the column, were decreased by 0.1-0.1 step. Also the pressure of condenser was reduced from 0.7 to 0.5 barg, and the Pressure of reboiler were decreased from 2.2 to 2.0 barg. To consideration of these changes we used Aspen HYSYS v9. By changing the top pressure of the column from 1.3 to 1.1 barg and the bottom pressure of the column from 2 to 1.8 barg, the heat duty of the condenser and reboiler has also been reduced, which is given in Table 17. As we say in above, by decrease the pressure in the top and bottom of column, the temperatures of top and bottom of column were decreased, and in result the duty of condenser and reboiler were reduced. These changes saved the 0.2 e 7 kj or 2.75% of energy in the column. Also the product composition showed that there are a little changed in product composition and yield, that we consider constant. Since, in this case the RON and the pressure of 2-2DMB and 2-3DMB in top of DIH is the major, then C5’s and di-methyl butanes in isomer is the key components that determine the Top of DIH pressure. For total condenser, in operating condition the temperature of C5’s and di-methyl butanes that is liquid were determine the pressure of condenser. Also the operating condition were changed in summer and winter.

Stabilizer

In Stabilizer the condenser temperature at the top of column is 53˚C, and the reboiler temperature at the bottom of the column is 177˚C. Therefore, the condenser and the reboiler of stabilizer column were on the both side of the pinch point (97˚C), and the stabilizer column should be studied in energy consumption according to pinch point position. Therefore, we investigation the pressure of column to change of the condenser and reboiler situation in order to improve energy consumption. In Stabilizer column used the PA for pressure of column because the pinch point was in the middle of top and bottom temperatures. By changing the top pressure of the column from 14.2 to 12.4 barg and the bottom pressure of the column from 14.4 to 12.6 barg, the heat duty of the reboiler has also been decreased, which is given in the Table 1. As we say in above, with decreasing the pressure of top and bottom column, the temperature as well as decreasing. As we expect the duty of reboiler decreased. These changes saved 0.2 e 7 kj or 3.7% of energy consumption in the Stabilizer column. Also changed the operating condition in top of the Stabilizer is related to the key component of product.

Total saving of energy consumption

In this research, we studied five retrofitting cases on HEN of the LNI unit that discussed above.

The first retrofitting case was on the Feed and make-up gas drier. By doing this case, the E-1809 heat exchanger was eliminated which included a SW heat exchanger and, MPS in E-1810 were removed and replaced by the process stream. The duties of the H-1801 electric heat exchanger and E-1808 AC heat exchanger were reduced by 90.78% and 72.1%, respectively. Also, cross-pinch has been reduced by 1.282 e7 kj/h or 19.4%. The total utility consumption was reduced by 3.65%. The second retrofitting case was on the Reactor Exchanger circuit and Reaction section. By doing the second retrofitting case, the E-1815, the AC heat exchanger, has been removed, and MPS used in the E- 1813 has also been eliminated. The results show that by carrying out this case, the cross-pinch has been reduced by 3.5 e7 kj, and hot and cold utility has been reduced by 7.5%. The third retrofitting case was on the methanator. In this retrofitting case, with changed in the direction of the stream, the E-1826 which used hot utility consumption HPS changed to the process-to-process heat exchanger. Also, E-1827 used the cold utility consumption was removed and cold utility consumption was saved. The results show that the hot and cold utility consumption was reduced by 0.18%. Also, the cross- pinch has been reduced by 0.06 e7 kj and saved 0.19%. The fourth correction case was studied SW instead of an AC. In this case, the E-1803, E-1818, and E-1821 which were the DIP, Stabilizer, and DIH condenser, respectively, were replaced with SW. The results show that, in this case, the energy consumption is constant and the amount of total cost has been significantly reduced by 22.5%. The fifth retrofitting case studied the pinch point position on the DIP, DIH and Stabilizer columns. For change the pinch point and decrease the energy consumption of columns we studied the pressure of column, condenser and reboiler. The result showed that by decreasing the pressure of column, the duty of condenser and reboiler were decreased. Then, by carrying out this retrofitting case on the DIP, DIH and Stabilizer columns, the total utility consumption has been reduced. Table 1, were summarized the utility consumption (Heating and Cooling) and costs (capital cost, operating cost, and total cost) of cases (base case, retrofitting cases). Table 2 showed different percentages of utility consumption and costs between each case and base case. The results showed that, these cases saved 14.15 MW in cold utility and 7.75 MW in hot utility, and crosspinch has been significantly reduced by 70%, that showed in. In total, energy consumption of LNI unit reduced by 21.74 MW or by 11.3%, and have been saved 858.685 e9 kj/h energy per year. Showed the grid diagram after retrofitting cases, and indicated the most cross-pinch were removed. CC and the GCC were shown in and 25. As be seen in the CC, the red diagram has shifted to the blue diagram. In fact, this diagram shows that the horizontal distance between the two diagrams, which represent QHmin and QCmin, is closer to each other, or reduced. In GCC, the amount of pocket and compared with the GCC of base case quite obviously reduced. Therefore, as the heat pocket in this retrofitting case becomes smaller, the amount of heat or energy lost is reduced. Costs were the most important issue in designing retrofitting cases, that showed in Table 2 and comparison total of all retrofitting cases with the base case. The results show that costs be reduced by 3.7%, and saved $8830.08 $/year. Table 2, indicated the comparison of energy consumption and cost between the target and retrofitting cases. Table 2 showed that only 9.7% difference between target and retrofitting case. Then, by modification on HEN of LNI, the unit can achieve the optimization of energy consumption.

Conclusion

To produce gasoline with higher quality and according to environmental issues, the LNI process has been considering, and investigated on HEN to decrease the energy consumption necessary. In this research, the modification of the LNI process to optimize energy consumption and reduction costs has been studied using PA. Data were extracted to calculate actual and target utility consumption, CC, GCC, ΔTmin , QHmin, QCmin, hot and cold utility consumption, and pinch point by using AEA. The target showed that, HEN of LNI can be optimized up to 19.17%, then five retrofitting cases were studied on HEN of LNI. Results shown that, by modifications, E-1809, E-1815 and E-1827 heat exchangers were removed. E-1810, E-1813 and E-1826 heat exchangers were changed to process-to-process heat exchanger. MPS in E-1810 and E-1813 heat exchanger, HPS in E-1826 heat exchanger, and two SW in E-1809 and E-1827, were saved. Three AC heat exchanger, that are E-1803, E-1818 and E-1821 replaced with SW heat exchanger. The duties of H-1801 electric heater and AC E-1808 were decreased. The hot and cold utility consumption decreased by 2.78 e7 Kj and 5.08 e7 Kj, respectively. Also difference between target and retrofitting case was 9.7%, cross-pinch was decreased by 70% and, the utility consumption and total cost 11.3% and 3.7% decreased, in order.

References

- Serfidan AC, Türkay M (2021) Octane Optimization with a Combined Machine Learning and Optimization Approach. In Computer Aided Chemical Engineering 50:221-226.

- Alwi SRW, Abd Manan Z (2016) Simultaneous energy targeting, placement of utilities with flue gas, and design of heat recovery networks. Applied Energy 161:605-610.

- Wolf HU, Lang W, Zander R (1984) Alkaline haematin D-575, a new tool for the determination of haemoglobin as an alternative to the cyanhaemiglobin method. II. Standardisation of the method using pure chlorohaemin. Clin Chim Acta 136: 95-104.

- Shah VB, Shah BS, Puranik GV (2011) Evaluation of non cyanide methods for hemoglobin estimation. Indian J Pathol Micr 54: 764-768.

- Karakochuk CD, Hess SY, Moorthy D, Namaste S, Parker ME, et al. (2019) Measurement and interpretation of hemoglobin concentration in clinical and field settings: a narrative review. Ann NY Acad Sci 1450: 126-146.

- Kang SH, Kim HK, Ham CK, Lee DS, Cho HI (2008) Comparison of four hematology analyzers, CELL-DYN Sapphire, ADVIA 120, Coulter LH 750, and Sysmex XE-2100, in terms of clinical usefulness. Int J Lab Hem 30: 480-486.

- Whitehead Jr RD, Zhang M, Sternberg MR, Schleicher RL, Drammeh B, et al. (2017) Effects of preanalytical factors on hemoglobin measurement: A comparison of two HemoCue point-of-care analyzers. Clin Biochem 50: 513-520.

- Mohamed MF, Shehata WM, Halim AA, Gad FK (2017) Improving gasoline quality produced from MIDOR light naphtha isomerization unit. Egyptian Journal of Petroleum 26:111-124.

- Tarighaleslami AH, Walmsley TG, Atkins MJ, Walmsley MR, Liew PY, et al. (2017) A Unified Total Site Heat Integration targeting method for isothermal and non-isothermal utilities. Energy 119:10-25.

Indexed at, Google Scholar, Crossref

Indexed at, Google Scholar, Crossref

Indexed at, Google Scholar, Crossref

Indexed at, Google Scholar, Crossref

Citation: Somayeh H, Reza MM (2023) Energy Optimization of Light Naphtha Isomerization Unit at PGSOC1 Using by Pinch Analysis. J Anal Bioanal Tech 14: 506.

Copyright: © 2023 Somayeh H, et al. This is an open-access article distributed under the terms of the Creative Commons Attribution License, which permits unrestricted use, distribution, and reproduction in any medium, provided the original author and source are credited.