Energy Consumption of Herbaceous Biomass Bulk Densification

Received: 19-Oct-2017 / Accepted Date: 23-Oct-2017 / Published Date: 30-Oct-2017 DOI: 10.4172/2576-1463.1000175

Abstract

In order to use biomass as an energy source, the challenge is that the original form of biomass material cost too much for handling and transporting. Densification is needed for cost effective handling, transportation, and storing. This study focuses on investigating the mechanical properties of energy crops during bulk densification. Switchgrass, corn stover, and Miscanthus samples were collected from fields and used in this study. The effects of chamber size, particle size/cut length, arrangement/orientation method, and harvesting time on specific energy of compressing bulk biomass crops were studied. Results indicated that larger compression chamber had significant lower specific energy consumption over the same volume reduction level. The particle length and particle orientation were also considered in this study. Results demonstrated that the parallel arrangement needed less compression energy; and the biomass with shorter particle sizes had higher energy consumption than those longer ones. Energy consumptions of the biomass harvested in different seasons were not significantly different for Switchgrass but found to be significant for corn stover.

Keywords: Biomass; Bulk densification; Compression; Baling; Energy consumption

23214Introduction

The cost associated with the handling and transporting of the biomass is a major concern in order to use biomass as an energy source. To reduce costs, loose biomass crops need to be densified by briquetting, pelletizing, or cubing [1]. Densification increases the bulk density of biomass from a density of 40-200 kg/m3 to a density of 600-800 kg/m3 [2-6]. Due to uniform sizes and shapes of densified biomass, the material can be easily handled with standard machines or equipment which makes the process more efficient [3,7].

For the purpose of withstanding various forces and impact during handling and transportation processes, density and durability as dependent quality index with independent variables such as, moisture content, need to be determined [8]. In order to compress the biomass efficiently, the characteristics of biomass should be understood more deeply and completely [9].

The energy consumption of biomass densification depends on applied compressing pressure and moisture content of biomass material as well as physical properties of biomass material and method of densification [10]. The energy consumption of compressing baled biomass with 170 kg/m3 initial density has been studied in previous work. However, the energy consumption performance with an initial density lower than 170 kg/m3 biomass material, which can be categorized as loose materials, is still unknown. In order to scale up the densification curve, loose biomass material needs to be studied.

Utilizing biomass to convert into energy has been studied for a number of years. Large numbers of studies were focused on the effect of physical and chemical characteristics on biomass densification. Most of these studies were concentrated on the effect of moisture content and pressure on the densification density and energy consumption. Some research activities were about the effect of particle size of chopped materials on density and energy consumption. However, study on biomass densification rarely explored physical characteristics of large sizes of biomass densification such as bales or raw material bulk densification. Large size densification commonly was referred to as initial densification which is directly relative to biomass handling, transportation, and storage especially in field.

The energy consumption of densifying biomass materials, which is a very important issue of energy crop production, has not been studied sufficiently so far. A thorough study on the mechanical properties of energy crop densification should be conducted to seek for ways to reduce the investment cost and energy consumption during densification production.

Objectives

The present work aims to investigate the mechanical properties of energy crops during bulk densification. Specific objectives of this research were to:

Determine the relationships between the specific energy of compressing bulk biomass crops with consideration of the effect of compression chamber size,

Quantify the influence of particle size and arrangement methods of particles on the energy consumption during the densification process,

Characterize the differences between compressing different types of biomass crops.

Materials And Methodology

Field crop sampling

Switchgrass, corn stover, and miscanthus samples were used and collected from farms in central Pennsylvania area. The fall switchgrass samples were manually cut at 10.2-15.2 cm from the ground surface between November and December 2013 and kept in refrigerated storage room. Switchgrass was left standing over the winter in the field, and then samples were collected in March, 2014 with the same method.

Corn was combined in October 2013 and the stover was left in field and samples were then collected by hand between November and December 2013 and stored in the same cold room as the switchgrass. The spring corn stover samples were collected in March 2014 from the same field.

Miscanthus samples were only collected in the spring. Miscanthus crops were standing in the field over the winter, and were cut in March 2014. Crop samples were also stored in the same cold storage room.

Compression chamber

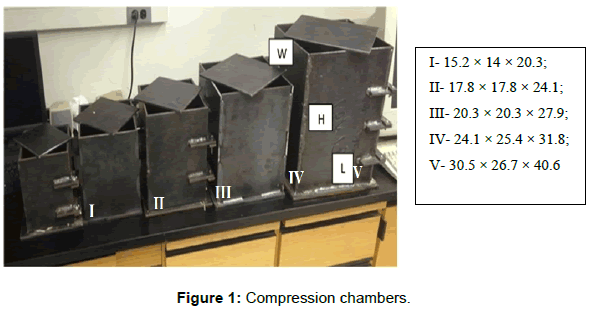

To evaluate the effect of chamber size on specific energy consumption, five compression chambers with different sizes were made as shown in Figure 1. The bottom area of those chambers were 1/2, 3/8, 1/4, 3/16 and 1/8 of the compression chamber of a small square baler (14 by 18 in, or 1625.8 cm2). The height of a chamber was proportional to the bottom area. Chambers were built with carbon steel plate to ensure the strength. Each chamber had its matched compression platen, and the chamber body was welded. Five cross sections of these chambers were (L×W×H, cm) as shown in Figure 1.

Sample preparation

For each compression chamber, the raw crop samples were cut into two lengths. One length was 5.1 cm (2 in), and the other was the same with the chamber width (W). Three chamber widths, 14 cm (5.5 in), 19.1 cm (7.5 in), and 25.4 cm (10 in), were used for compressing all crops. For switchgrass and miscanthus, two more chamber widths, 16.5 cm (6.5 in) and 22.9 cm (9 in) were added to the tests. Crops were cut using an electric band saw.

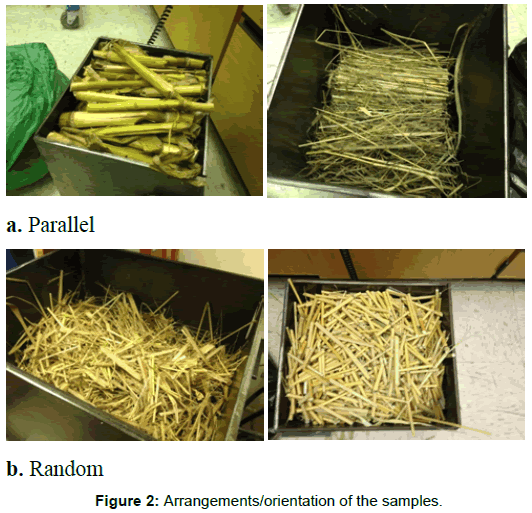

The arrangements of crop samples in a compression chamber included two methods, parallel and random (Figure 2). Parallel arrangement means that all the crop stems were set horizontal nearly in the same direction and parallel to one of the sidewalls of the chamber (Figure 2a). Real parallel arrangement was hard to achieve due to leafs and nodes etc. on the stem. While filling the chamber, attempts were made to minimize mass scatter loss and stem-leave destructive disturbance. These were other reasons that non-parallel particles existed in the chamber. In random arrangement, crop samples were randomly placed inside the chamber as shown in Figure 2b. The term “random” used here is quasi-random due to (1) the limited space inside a chamber; (2) attempt to distribute all sample pieces uniformly; and (3) minimize mass scatter loss and leave-stem proportional and structural changes.

All crop samples were weighed before filling them into the compression chamber to maintain the same initial bulk density. For both arrangements, samples were placed into the chamber gently and no vertical load was applied during sample placement process. When the chamber was full and had more sample to be filled in, a preloading process was applied. Basically, the pre-loading was a gentle compression and vertical compression force and displacement applied were recorded.

The starting density of loose switchgrass material was around 37-42 kg/m3. This starting density was obtained by arranging the loose material in the chamber gradually and applying an appropriate pre-load. The pre-loading process was also recorded as an initial compression process. For loose corn material, the starting density was in a range of 41 to 43 kg/m3. Due to the relatively high plant density and large stem size, the initial density of Miscanthus was from 75 to 85 kg/m3 for all parallel arrangements and 2-in (50 mm) long random arrangement. The starting density was between 40 and 45 kg/m3 in random arrangement treatments with long sizes (5.5 in, 6.5 in, 7.5 in, 9 in and 10 in).

Moisture contents of the crop samples were determined using methods recommended in ASAE standards for forage [11]. The average moisture content of switchgrass was 7.95 ± 0.44% (w.b.). The average moisture content of October and December harvested corn stover were 19.62 ± 4.02% (w.b.) and 21.02 ± 2.81% (w.b.), respectively. The average moisture content of miscanthus was 11.2 ± 0.55% (w.b.).

Universal testing machine

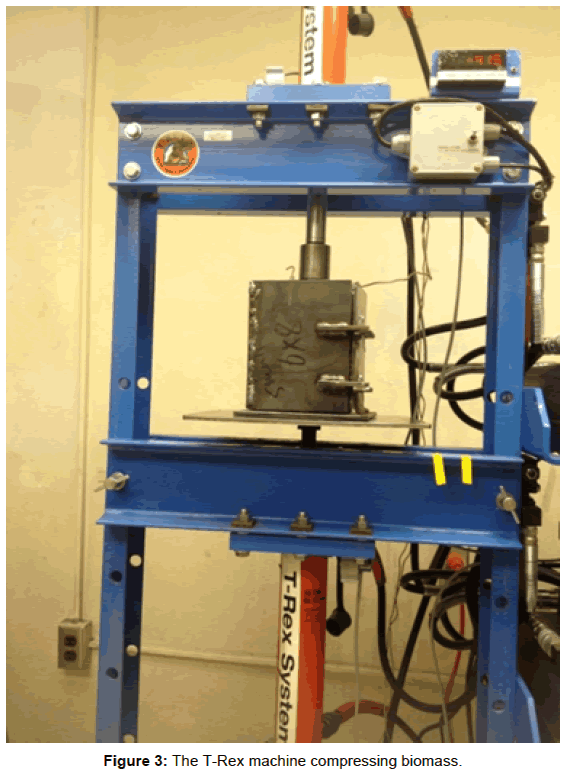

The universal testing machine (Cooper Instruments and Systems) located in Agricultural and Biological Engineering building was used in this study (Figure 3). The loading capacity of this machine was 89,000 N (20,000 lb) which was limited by the maximum pressure of its hydraulic cylinders. Two identical hydraulic cylinders were in opposite direction to apply vertical loading force. The upper cylinder extends downward and the lower cylinder extends upward. Each cylinder could be controlled separately. The stroke of each cylinder was 25.4 cm (10 in). The hydraulic system didn’t have a speed control valve. Hence, the hydraulic cylinders had a constant speed of 1.946 cm/s (0.766 in/s) for all compression tests. The speed is not adjustable due to the design of the machine.

There was a load cell mounted at the rod end of the upper cylinder. This load cell was connected to a data logger to record the vertical load. Two potentiometers were also mounted on the rod end of each cylinder to collect the vertical displacement.

To perform the pre-loading progress precisely, a secondary load cell (model #, Transduce Techniques) was mounted on the loading system. The secondary load cell had a load range of 0-500 lbs. To receive higher resolutions during preloading process. This load cell was placed manually between the platen of the chamber and the rod end of upper cylinder each time. After all samples for this chamber was loaded into the chamber, this secondary load cell was removed and the main load cell was then used to record the rest of compression process.

The universal testing machine could be operated manually in preloading stage. While in compression tests, it was operated automatically and the loading process stopped when the platen reached to the set maximum vertical displacement.

Experimental design

As shown in Table 1, chamber size, particle size, the harvesting season/date, were considered as factors that may affect energy consumption. Crop types included Switchgrass, Corn stover, and Mithcanthus. The all experiments were distributed into groups due to their different particle sizes and arrangement methods:

| Crop type | Harvesting date | Arrangement | Groups | Chambers | ||||

|---|---|---|---|---|---|---|---|---|

| Switchgrass | 2013-Oct | Parallel | Parallel-long | I | III | V | ||

| 2014-March | Parallel | Parallel-long | I | II | III | IV | V | |

| Random | Random-long | I | II | III | IV | V | ||

| Random-5.1cm | I | II | III | IV | V | |||

| Cornstover | 2013-Oct | Parallel | Parallel-long | I | III | V | ||

| Random | Random-5.1 cm | I | III | V | ||||

| 2013-Dec | Parallel | Parallel-long | I | III | V | |||

| Random | Random-5.1 | I | III | V | ||||

| Miscanthus | 2014-March | Parallel | Parallel-long | I | II | III | IV | V |

| Random | Random-long | I | II | III | IV | V | ||

| Random-5.1 cm | I | II | III | IV | V | |||

Table 1: Details of experimental design for Switchgrass (S), Miscanthus (M), and Corn Stover (C).

• Parallel-long: parallel arrangement and long particle size,

• Random-long: random arrangement method and long particle size, and

• Random-5.1 cm: random arrangement and 5.1 cm particle size.

Chambers I, II, III, IV, and V represent different chamber sizes 14 cm (5.5 in), 16.5 cm (6.5 in), 19.1 cm (7.5 in), 22.9 cm (9 in), and 25.4 cm (10 in). Each test was repeated five times.

Data collection and analysis

The data logger had a sampling rate of 10 data per second. Recorded data included time, displacement of the upper and the lower cylinders, vertical loading forces of two load cells over the course of each test. A LabVIEW program was used to program the data logger. After tests, the vertical displacement vs. loading force curve was plotted in Excel. Using the displacement as horizontal coordinate, the area under the vertical load would be the energy consumption during compression.

The calculation of energy consumption included both the preloading and loading processes. ANOVA was used to test the significant differences, and establish desired regression relationships between density and volume reduction.

Results

Switchgrass compression

All switchgrass compression tests started from an approximately the same density of 40 kg/m3. Loading or compressing process was stopped at 88% volume reduction. The specific energy consumptions were calculated.

Overall specific energy requirements for switchgrass harvested in 2014 is shown in Figure 4. Statistical analysis results showed arrangement groups and chamber size had significant effect on specific energy consumption of switchgrass compression (p=0.023, F=4.03, df=2 for arrangement group and p<0.001, F=13.707, df=4 for chamber size for 88% volume reduction). Random-long arrangements of switchgrass required least energy for compression followed by parallellong and random-5.1 cm. As the chamber size increases the specific energy requirements decreased. The interaction of chamber size and arrangement type was not statistically significant (p>0.05).

Fall 2013 harvested switchgrass with Chambers I, III, and V were compared with spring 2014 harvested switchgrass (Table 2). Chamber size significantly change the specific energy consumption in 2013 and 2014 harvested switchgrass for all volume reduction percentages (p<0.005). In general, increased chamber size decreased the specific energy consumption (Table 2).

| Harvest Time | Chambers | Particle size (cm) | Arrangement | Volume Reduction | |||

|---|---|---|---|---|---|---|---|

| 60% | 70% | 80% | 88% | ||||

| Fall 2013 | I | 14 | parallel | 0.100 a | 0.218 a | 0.638 a | 1.870 a |

| III | 19.1 | parallel | 0.085 ab | 0.212 a | 0.555 ab | 1.659 ab | |

| V | 25.4 | parallel | 0.067 b | 0.149 b | 0.449 b | 1.324 b | |

| Spring 2014 | I | 14 | parallel | 0.097 a | 0.216 a | 0.582 a | 1.963 a |

| III | 19.1 | parallel | 0.084 a | 0.224 a | 0.661 a | 2.064 b | |

| V | 25.4 | parallel | 0.056 a | 0.184 a | 0.504 a | 1.427 c | |

Table 2: Specific Energy Consumption of 2013 and 2014 Harvested Switchgrass.

It was seen that there was no significant difference in specific energy consumption for different harvest dates (p>0.005) for all volume reduction percentages except 88% volume reduction. At 88% volume reduction, the average specific energy consumption in 2014-March was significantly higher than in 2013-October harvest switchgrass. The interaction effect of harvest date and chamber size also was not significant for all volume reduction percentages (p>0.005) except 88% volume reduction (p=0.047).

Study of corn stover compression

Two adjacent corn fields were selected to collect stove samples in this study. Both these fields have the similar soil, illumination, and weather conditions. The only difference was that one field was combined in October 2013, and the other one was combined in December 2013. Both of the fields were covered by snow from October to December. For the field combined in December, corn plants were standing in the field; but the field combined in October corn stover had two months laid under the snow.

October and December harvested corn stovers were used in this study. All tests were distributed into two groups: parallel-long and random-5.1 cm. The initial densities of all groups were around 40 kg/m3.

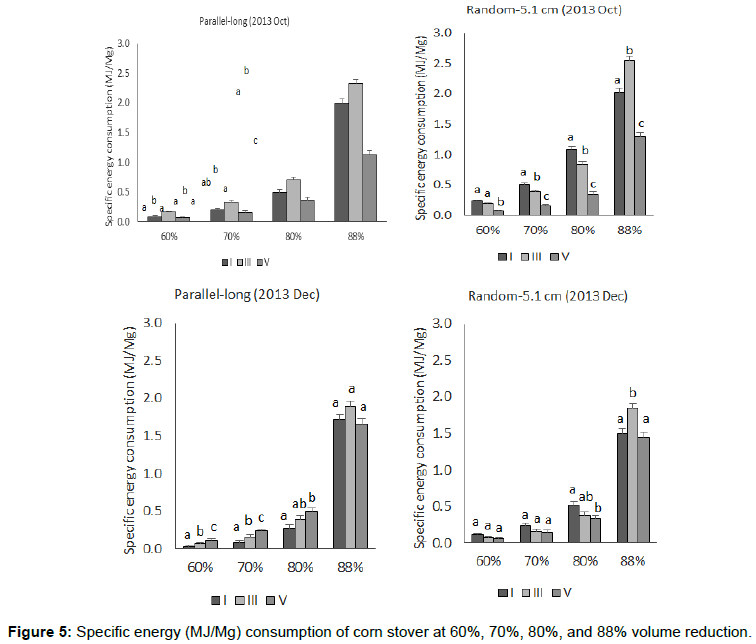

Two-way Anova of all corn stover data showed that significant effect of harvest date on specific energy consumption for 88% volume reduction compression (p=0.000, F=27.86, df=1). December harvested corn stover required significantly less specific energy for compression than the October harvested corn stover (Figure 5). Overall the arrangement type had no significant effect on specific energy consumption for compression (p=0.754, F=0.100, df=1). The effect of chamber size was also significant (F=0.000, F=121.26, df=2).

The interactions between harvest date* arrangement type (p=0.001, F=13.73, df=1) and harvest date*chamber size (p=0.000, F=48.43, df=2) had significant effect on specific energy consumptions for 88% volume reduction. While parallel arrangement required lower energy in October, random arrangement required less energy for December harvested corn stover. Even though the harvest date*chamber size interaction effects was significant, Chamber 5 required least energy in both October and December harvested corn stover. However the difference between the chambers in December was not significant (p>0.05).

In sum, the harvested time could impact the effect of chamber size on energy consumption. Additional two months under snow condition made the stovers, leaves, and rods softer, which could save energy consumption in compression.

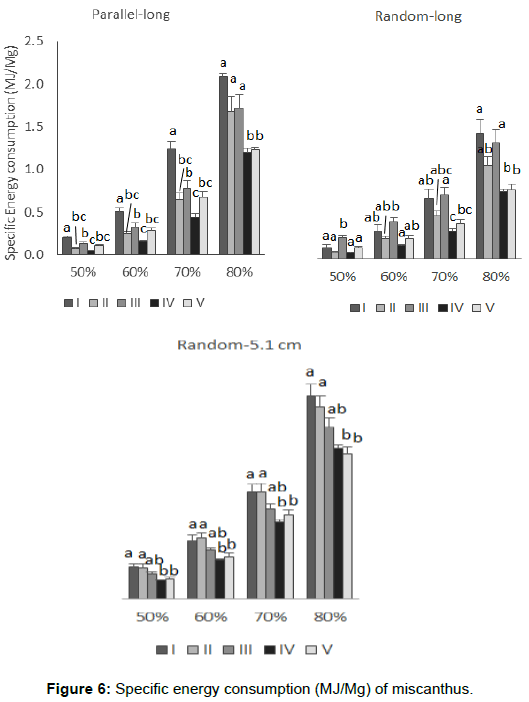

Study of miscanthus compression

In the experiments of miscanthus, chamber size, particle size, and arrangement method were the factors to be tested. Due to the hardness of miscanthus and the capacity of the compressor, the limitation of volume reduction was set at 80%. The results of energy consumption are shown as following in Figure 6.

The all 15 treatments were divided into 3 groups due to their different particle sizes and arrangement methods: parallel-long, random-long, and random-5.1 cm. The initial densities of randomlong and random-5.1 cm were around 40 kg/m3. However, the initial density of parallel-long arrangement of mischantus was about 80 kg/m3 because of the smaller gap between the particles.

Overall, the effects of chamber size and arrangement type on specific energy consumption for compression were found to be significant for all levels of volume reduction percentages. The specific energy consumption decreased by the increasing chamber size (p<0.001, F=28.86, df=4 for 88% volume reduction). Random arrangement method with long particle size required the least amount of energy for compression (p<0.001, F=78.24, df=2 for 88% volume reduction). Chamber size*arrangement method interaction was also found to be significant except 80% volume reduction meaning that the effect of chamber size is not same for different arrangement methods. However the interaction effect of chamber size and arrangement method was not significant for 80% volume reduction of mischantus compression.

Discussions

This study indicated that the specific energy requirements for compressing bulk switchgrass, corn stover, and mischantus samples were related to the chamber size and the orientation of crop stems. In another word, the size of the compression chamber had significant effect on energy consumption, or larger compression chamber will have smaller boundary effect. Larger compression chamber required significant lower specific energy. This indicated that the larger the chamber was more efficient when compressing these crops especially for higher volume reduction percentages.

The parallelly arranged crops could reduce the compression energy for corn stover and mischantus. Making stems in the same direction while baling the grass could be a good choice, but not easy to achieve in practice. For corn stover particle size had less influence on compression energy compared to switchgrass and Miscanthus due to its relatively complicated composition and initial low bulk density. In most cases, the chopped biomass with shorter particle sizes had higher specific energy consumption than longer particle sizes, but not significant.

Switchgrass harvested in fall and spring seasons had no signification differences in compression energy consumption when the moisture contents were similar. However, there was significant difference in specific energy consumption between corn stover collected in October and December. These two additional months from October to December standing in snow reduced the specific energy consumption for 11%- 44%. The more volume reduction, the more energy consumption could be saved.

References

- Kaliyan N, Morey RV (2006a) Factors affecting strength and durability of densified products. ASABE Paper No. 066077. St. Joseph, ASAE Annual Meeting, Michigan.

- Holley CA (1983) The densification of biomass by roll briquetting. Proc Institute for Briquetting and Agglomeration (IBA) 18: 95-102.

- Mani S, Tabil LG, Sokhansanj S (2003) An overview of compaction of biomass grinds. Powder Handl Process 15: 160-168.

- Obernberger I, Thek G (2004) Physical characterisation and chemical composition of densified biomass fuels with regard to their combustion behavior. Biomass Bioenergy 27: 653-669.

- McMullen J, Fasina OO, Wood CW, Feng Y (2005) Storage and handling characteristics of pellets from poultry litter. Applied Eng in Agric 21: 645-651.

- Adapa PK, Schoenau GJ, Tabil LG, Arinze EA, Singh A, et al. (2007) Customized and value-added high quality alfalfa products- a new concept. Agricultural Engineering International 6: 1-28.

- Kaliyan N, Morey RV (2006b) Densification characteristics of corn stover and switchgrass. ASABE Paper No. 066174. St. Joseph, ASAE Annual Meeting, Michigan.

- Adapa P, Tabil L (2009) Compaction characteristics of barley, canola, oat and wheat straw. Biosyst Eng 104: 335-344.

- Sokhansanj S, Turhollow AF (2004) Biomass densification - cubing operations and costs for corn stover. Appl Eng Agric 20: 495-499.

- Mani S, Tabil LG, Sokhansanj S (2006) Specific energy requirement for compacting corn stover. Bioresour Technol 30: 648-654.

- ASAE Standards S358.2. (2003) Moisture measurement-forages. American Society of Agricultural Engineers, St. Joseph, ASAE Annual Meeting, Michigan.

Citation: Wang T, Liu J (2017) Energy Consumption of Herbaceous Biomass Bulk Densification. Innov Ener Res 6: 175. DOI: 10.4172/2576-1463.1000175

Copyright: ©2017 Wang T, et al. This is an open-access article distributed under the terms of the Creative Commons Attribution License, which permits unrestricted use, distribution, and reproduction in any medium, provided the original author and source are credited.

Share This Article

Recommended Journals

Open Access Journals

Article Tools

Article Usage

- Total views: 2464

- [From(publication date): 0-2017 - Nov 21, 2024]

- Breakdown by view type

- HTML page views: 1770

- PDF downloads: 694