Electrical Energy Analysis Consumption of a CNC Lathe Machine Using Mobile Average Filter

Received: 03-Nov-2019 / Accepted Date: 16-Mar-2020 / Published Date: 23-Mar-2020 DOI: 10.4172/2576-1463.1000235

Abstract

The importance of the consumption of electric energy is substantial for any activity, in the manufacturing process excessive consumption of electrical energy has been identified and in the profitable industry the income should not exceed the expenses. Data acquisition and monitoring of manufacturing process in machine tools with CNC is common in the industry, a feature problematic with measurements is all real energy signals contain noise. The interest of the study is aimed at identifying the energy consumption of a CNC lathe machine using numerical tools.

The industry is interested in doing innovative things, in outdoing their competitors and very often uses the numeric tools for solutions problems of energy saving. The energy consumption of a CNC machine cutting is largely determined by the tool condition, in this work, the electrical energy consumed by a CNC machine is measured using mobile average filter.

In conventional energy measurements of a CNC there are some undesirable signal noises that can modify the result. The aim of this paper is to analyze, study and filter the pure signal energy consumption of the CNC machine cutting tool for a machining routine of a three-axial CNC milling machine using classic mobile average filter. The proposed methodology can be used for tool life analysis, choose a viable cooling and machine speed control.

Keywords: Electrical analysis consumption; Electrical noise; Mobile average filter; Maquine; Energy

Introduction

Highly reliable control systems are demanded for supervision, control and optimization of technical processes in energy saving [1]. The study of energy saving in industrial processes in any manufacturing sector has become a priority because industrial sector uses more energy than other end-use sectors.

Machining processes cause rising in the energy consumption of the industrial electrical circuit. It has been shown that enhancing energy efficiency of machine tools increases the environmental performance of machining systems [2]. As a result, a reliable and precise estimation model of energy consumption that can reflect the principal dynamic parameters of the electrical energy is required [3].

The main difference between the current studies and this work is the use of moving average filter. The goal of signal processing algorithms is to extract the pure signal of electrical consumption of a CNC lathe machine.

In the manufacturing industry different investigations have been carried out in order to maximize the use of resources, such as monitoring the operation of the machines while performing a machining process, such as spindle speed, cutting advances, change of cutting tool. The life of a cutting tool will also depend on the amount of material that is renewed [4].

In industrial processes the machines have variables that increase the energy expenditure, this additional consume affects the economy of the company, there are cases in which they have studied why so high expenses have become, being a clear example the energy consumption generated by a tool in a machining center, in which its variables such as speed, cutting shape, tool wear or current consumed [5].

In the industry, the electrical system overload has numerous detrimental effects, among which the following stand out: The increase in power losses in the cables, in the transformers and in the generators of the network.

The reduction in electricity consumption during mass production carried is attractive for any company that seek to reduce polluting emissions and production costs. Many efforts have been made to develop heuristic algorithms to define cutting parameters that decrease energy consumption during manufacturing [6,7].

The moving average filter, develop by Steven W. Smith, is used to minimize noise level from temporal data series as well as acting as a low pass filter, smoothing the numerical data of the real signal. Mathematically, it is similar to convolution in signal processing, thus due to its simplicity is used for time domain encoded signals.

The average mobile filter is often used to reduce the magnitude of the noise that may be present in a signal. To see how this is possible, assume that the input x[n] is given in the form x[n] =s[n] + e[n], where s[n] is the soft part of x[n], and c[n] is the erratic or noisy part of x[n]. This filter has different applications to obtain real information of numerical data applied to engineering, electrical circuits, finance, prices in the basic caste, population censuses, advanced statistics, etc. [8].

In addition, there are many works about the importance of the working speed of the machining machines through theoretical concepts, experience and laboratory experiments. Due to the inherent simplicity of this model, there exist techniques to form estimates of the parameters of the CNC current, with a numerical model during a specific work routine, however, these techniques do not have filters to reduce noise.

Electrical signals mostly contain noise caused by artifacts, additional device, interference from the network or wiring, which can hardly be eliminated by conventional analog filters. The digital filters have had great reception, but unfortunately, they induce distortions in these signals [9].

In this paper a relatively new technique is presented for the filtering of signals with the minimum distortion and the maximum amount of noise eliminated using the discrete wavelet transform.

Methodology

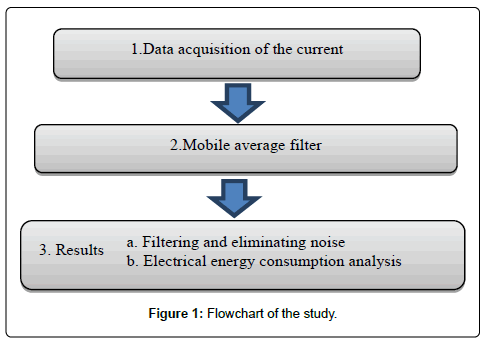

Next section describes the data acquisition, filtering method and the test system developed for its validation. Figure 1 shows the steps of the proposed process, followed by result section.

Carried out the previous procedure, the electrical current of the tool is analyzed, and the signal is filtered to eliminate unwanted information, the result of this methodology is a pure signal of the energy consumed during the manufacturing process.

Data acquisition of the current

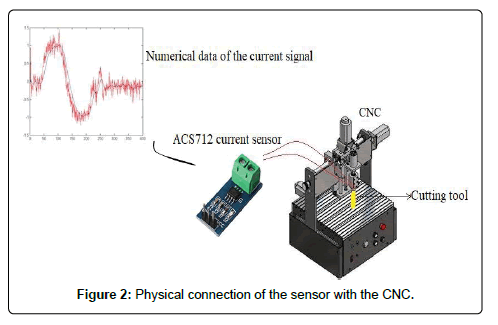

An electronic circuit that measures the current consumption of a CNC is described and analyzed. In order to convert the current signal to analog signal a commercial sensor is used, the ACS712 current sensor has been used to measure both small laboratory and large industrial type devices.

The ACS712 current sensor is a Hall Effect current sensor, which provides an economical and accurate solution for measuring AC alternating current or DC direct current. This Sensor works by transforming a magnetic field arising from the passage of current through an internal copper wire in the sensor, and converting this field into a variable voltage, the sensor has three pins, two of them supply and the third is the output which measures the flow of current [9,10].

The current sensor is in series with power supply of the tool spindle (Figure 2). For the validation of the proposed method, data readings are considered which were carried out during a machining routine of 1400 milliseconds and 1350 data. The numerical data obtained are processed in MATLAB using Mobile Average Filter.

The industrial applications of electrical drive control have sources that generate high frequency noises, namely an appropriate filter in the control will be beneficial to reduce the errors caused by the noise.

Mobile average filter

In the dynamic systems noise injection can occur anywhere, this limitation makes it difficult for any filtering method to minimize the error between the filtered signal and the original signal [11].

Noise is defined as everything in a set of data, signal, image or information in general, which

• It is not of interest.

• Degrades or distorts the signal.

• Prevents or limits the study or use of the information. Signal noise in an industrial network can cause havoc with process control systems. There may be noise in [11,12].

• The sensor, transducer or actuator with which the signal interacts.

• Poor wiring practices, the channel or in the interface measuring and sensor, and between each stage.

• The misinterpretation of a signal, in the method of analysis and modeling.

• Contamination effects on electronic products

• Long wire leads picking up radio frequency or proximity to other electrical equipment.

Even certain processing and analysis methods can introduce some noise, disturbance or collateral modification, although it may be the cost of obtaining other benefits. This noise varies depending on the circuit and may occur due to different effects, such as thermal noise, trigger noise and manufacturing quality [13].

The moving average filter is a more common filter in digital signal processing that can smooth high frequency fluctuations in the data or eliminate periodic trends of a specific frequency of the data, the filter operates by averaging a number of points of the input signal to produce each point of the output signal [14].

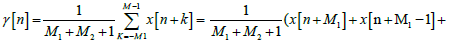

The filter was mathematically expressed as:

(1)

(1)

Where:

γn: Input signal

xk: Output signal

M: Number of pints in the middle and smoothing signal

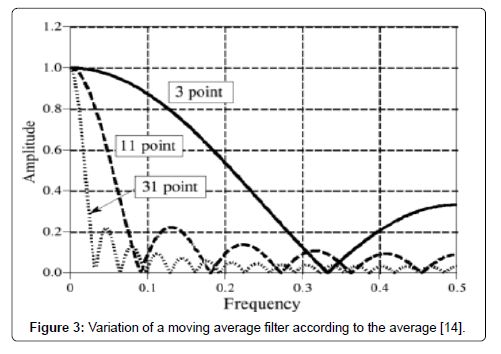

In the Figure 3, shows the variation of a moving average filter according to the average.

Figure 3: Variation of a moving average filter according to the average [14].

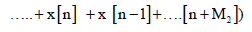

Given a positive integer N, the moving average filter at point N is a discrete time system given by the input / output.

(2)

(2)

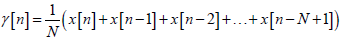

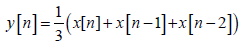

Where x[n] the input is applied to the filter, and γ[n] is the resulting output response. For example, if N = 3, the moving average filter at point 3 is given by the input / output.

(3)

(3)

Thus, the term "point N" refers to the number of input values used when calculating the filter output. The filter is known as the "moving average filter", because we calculate the following value and [n-1] of the output, moving the time point interval over which the filter output is calculated.

The moving average filter modifies the simulation program in which your filtered data is implemented, this filter can use the signal values to calculate the average. The filtering characteristics are not affected, the only drawback being that the filtered signal is slightly delayed. This filter can be implemented as a single point filter function that receives an unfiltered value and returns its filtered version. Such a function is implemented in MATLAB to filter signals [15].

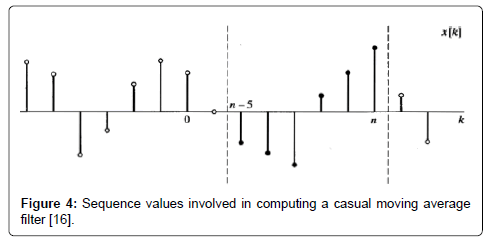

Figure 4 shows an input sequence plotted as a function of a dummy index k and samples involved in the computation of the output sample γn for n=7, M1=0, M2=5 ,the output sample γ [7] is equal to one-sixth of the sum of call the samples between the vertical dotted lines. To computeγ [8], both dotted lines would move one sample to the right [16].

Figure 4: Sequence values involved in computing a casual moving average filter [16].

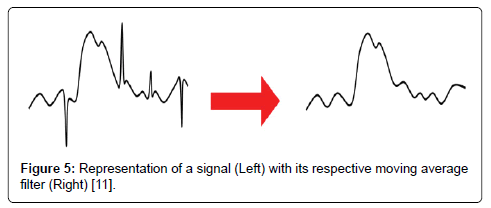

The following Figure 5 shows the representation of an improved signal after applying a mobile average filter, after that it is noted that the noise was eliminated (unwanted information).

Figure 5: Representation of a signal (Left) with its respective moving average filter (Right) [11].

Results

The results section is divided in two sub-sections, where the first describes the filtering technique of the current consumption. The second sub-section presents the electrical energy consumption analysis using a numerical method. In order to test the accuracy of the technique a specific CNC machine routine is evaluated using well stabilized techniques.

Filtering and eliminating noise

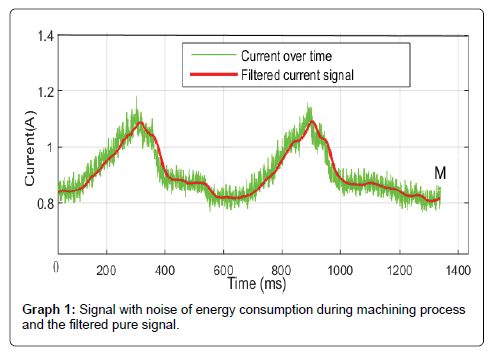

Graph 1 represent the current consumption for a specific machining of process in CNC which last 1300 ms (M), material is removed for a solid block using a cutting tool to produce a part based on G-code. As shown in green color in Graph 1 the current consumption of the tool at the time of the machining routine is affected by unwanted information (noise) which presents unstable positions within the real signal, this is due to that there are internal components of the system that cause the signal to be affected when doing the numerical survey of the current flow.

The red signal in Graph 1 shows the same signal as the green, but now the moving average filter that eliminates the noise is applied, resulting in the pure signal of the power consumption of the tool. The Filtered current signal was calculated using equation 1, 2 and 3.

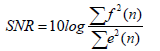

An important parameter in signal processing to analyze performance is the Signal to Noise Ratio (SNR). It relates and calculates the average powers of both the signal and the noise, where mathematically it is represented as follows [17].

(4)

(4)

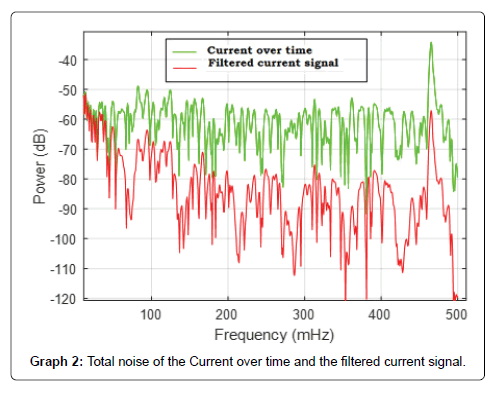

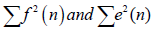

Where  are the powers of the signal and noise averages. Graph 2 shows the total noise of the real signal marked in green and the signal filtered using Mobile average filter in red. Electrical energy consumption analysis

are the powers of the signal and noise averages. Graph 2 shows the total noise of the real signal marked in green and the signal filtered using Mobile average filter in red. Electrical energy consumption analysis

Elemental analysis and observation of Graph 2 indicates high frequency reduction when filtering technique is applied. As a result of this technique, the Electrical energy consumption analysis can be assessed using numerical method.

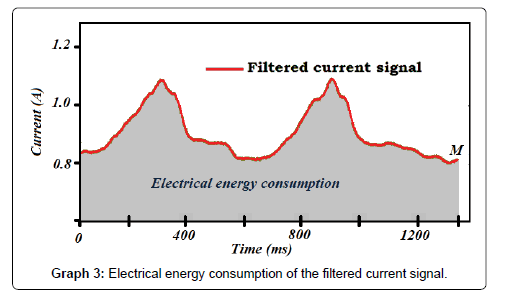

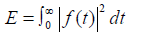

A direct way of estimating the electrical energy consumption is developed in this research through the use of the integration of the filtered current signal of the Graph 1.

(5)

(5)

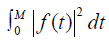

Where f(t) is the filtered current signal. Equation (5) can be used in the following way which calculates the area under the curve of a signal in a range of 0 to M (1300 ms).

(6)

(6)

Graph 3 shows the electrical energy consumption for a specific routine of the CNC machine, in order to further identify the area under the signal Mat lab tool box is used.

ε = 0.9032e + 03A/ms (7)

The above numerical implementation of the method can be used for optimization cutting conditions of the routines of a material, tool life, choose a viable cooling system and optimize the energy expenditure of the numerical control machine. The proposed method can be replicated in other analysis of energy consumption, that use an electronic device monitor system with undesirable noise.

Conclusion

The paper proposes to combine conventional energy consumption analysis of a CNC machine with a low-pass filter, to assess the contribution and impact of the research a specific CNC machine routine is evaluated. The results showed the effectiveness of this method in the high frequency noise reduction.

The mobile media filter for signal filtering is an effective tool for engineering and research, as well as for various applications such as industrial energy consumption. Many recent investigations have examined the electrical consumption, this interest arises from an electric energy saving measure nevertheless, the signal noisy is a common problem of the actual techniques. In this article, a filtering technique is applied to an energy consumption signal of a cutting tool of a CNC machine.

The basic procedure is examined by analyzing the filtering characteristics of red signal in Graph 1 using mobile media filter. The Graph 1 shows how noise was eliminated as unwanted information from the pure signal.

For a company that has numerical control machines integrated into its manufacturing processes, the present method can be applied, future research will be carried out to determine best practice and energy saving conditions of the CNC in manufacturing processes.

References

- Sirodz MPN, Purwanto TS, Hermanto A, Barata I, Taufiqullah (2017) Electric Speed Governor for 1kw Micro hydro Generator. Innovative Energy & Research 6: 174.

- Hu S, Liu F, He Y, Hu T (2012) An on-line approach for energy efficiency monitoring of machine tools. Journal of Cleaner Production.

- Jiang Z, Gao D, Lu Y (2019) Electrical energy consumption of CNC machine tools based on empirical modeling. Int J Adv Manuf Technol 100: 2255–2267.

- Qian Q, Zhong RT (2016) Evaluation on models of calculating energy consumption in metal. Int J Adv Manufacturing Techno, pp. 2087-2099

- Kumar Patil AI (2016) Measurement and analysis of cutting forces. International Journal of Structural, 359-369.

- MarÃn R, Juárez C, MartÃnez Y, Irma (2018) Análisis del consumo energético a través de la medición de corriente para determinar la vida útil de la herramienta de corte de un torno usando integración numérica.Revista de IngenierÃa Eléctrica, 5: 10-17.

- Liu N, Zhang YF, Lu WF (2015) A hybrid approach to energy consumption modelling based on cutting power: a milling case, Journal of Cleaner Production, 104: 264-272.

- Congbo L, Xingzheng CA, Ying T, Li L (2017) Selection of optimum parameters in multi-pass face milling for máximum energy efficiency and minimum production cost, Journal of Cleaner Production, 140:1805-18.

- Ballesteros L, Dora M (2004) Aplicación de la transformada wavelet discreta en el filtrado de señales bioeléctricas Umbral CientÃfico, núm. 5, diciembre, Universidad Manuela Beltrán Bogotá, Colombia. pp. 92-98.

- Wang L, Chai S, Yoo D, Gan L, Ng K (2014) PID and Predictive Control of Electrical Drives and Power Converters using MATLAB / Simulink, IEEE Press, Wiley, 116-126.

- Lipec K, Bruce E (1967) Reducing Electrical Noise in Instrument Circuits, IEEE Trans. Ind. Gen. Appl.

- Rojas HE, Cortés CA, Forero MC (2018) Local polynomial approximation and intersection of confident intervals for removing noise of lightning electric field measurements. 205: 264-273.

- SantamarÃa F, Cortés C, Román F (2012) Uso de la Transformada de On deletas (Wavelet Transform) en la Reducción de Ruidos en las Señales de Campo Eléctrico producidas por Rayos, Bogotá – Colombia 1: 65-78

- Alonso A, GilNegrete N, Nieto J, Giménez JG (2013) Development of rubber component model suitable for being implemented in railway dynamic simulation programs, Journal of Sound and Vibration, 332: 3032-3048.

- Kendall, Maurice G, Alan Stuar Y, Keith Ord J (1983) TheAdvanced Theory of Statistics, Vol. 3: Design and Analysis, and Time-Series 4º Ed. Londres: Macmillan.

- Oppenheim A, Schafer R, Buck J (1998) Discrete-Time Signal Proccessing. Upper Saddle River, Nueva Jersey, Prentice Hall.

- Proakis JG, Manolakis DG (1996) Digital Signal Processing. 3th ed, USA: Prentice Hall 36-39

Citation: Miguel H, Carlos J, Irma M (2020) Electrical Energy Analysis Consumption of a CNC Lathe Machine Using Mobile Average Filter. Innov Ener Res 9: 235 DOI: 10.4172/2576-1463.1000235

Copyright: © 2020 Miguel H, et al. This is an open-access article distributed under the terms of the Creative Commons Attribution License, which permits unrestricted use, distribution, and reproduction in any medium, provided the original author and source are credited

Select your language of interest to view the total content in your interested language

Share This Article

Recommended Journals

Open Access Journals

Article Tools

Article Usage

- Total views: 5471

- [From(publication date): 0-2020 - Nov 13, 2025]

- Breakdown by view type

- HTML page views: 4550

- PDF downloads: 921