Research Article Open Access

Effects of Harvest and Post-Harvest Processing Methods on Quality of Beche-de-mer in Fiji Islands

Ravinesh Ram1*, Roveena Vandana Chand2 and Paul C. Southgate1

1Centre for Sustainable Tropical Fisheries and Aquaculture, College of Marine & Environmental Sciences, James Cook University, Townsville, Queensland 4811, Australia

2School of Biological and Chemical Sciences, Faculty of Science Technology and Environment, University of the South Pacific, Suva, Fiji Islands

- *Corresponding Author:

- Ravinesh Ram

Centre for Sustainable Tropical Fisheries and Aquaculture

College of Marine & Environmental Sciences

James Cook University, Townsville

Queensland 4811, Australia

Tel: +6799362543

E-mail: ravinesh.ram@my.jcu.edu.au, ravineshram@gmail.com

Received date: September 10, 2014; Accepted date: October 27, 2014; Published date: October 29, 2014

Citation: Ram R, Chand RV, Southgate PC (2014) Effect of Harvest and Post-Harvest Processing Methods on Quality of Bêche-De-Mer in Fiji Islands. J Marine Sci Res Dev 4:153. doi:10.4172/2155-9910.1000153

Copyright: © 2014 Ram R, et al. This is an open-access article distributed under the terms of the Creative Commons Attribution License, which permits unrestricted use, distribution, and reproduction in any medium, provided the original author and source are credited.

Visit for more related articles at Journal of Marine Science: Research & Development

Abstract

The sea cucumber fishery and processing of sea cucumbers into bêche-de-mer (BDM) supports livelihoods and generates significant export income in Fiji. Harvesting and processing of sea cucumbers has been done in Fiji for over two centuries and the processing technique has changed little over this time. Processing of sea cucumbers involves a number of steps: first boiling, slitting and gutting, smoke drying and sun drying. This study investigated the effects of harvesting and post-harvest handling techniques on the quality of BDM produced in Fiji and documented difficulties faced by the BDM processors in producing a good quality product. Our results show that to generate income as soon as possible, sea cucumber fishers in Fiji hastened BDM processing by eradicating or shortening necessary processing steps. This resulted in production of lower quality product with lower value and reduced acceptance. The first boiling and smoking steps of processing were particularly problematic for fishers. A well processed BDM product has good odour, appearance, shape, color and size and has moisture content appropriate for storage without spoilage. Processed BDM sold by fishers to the main exporters in Fiji were generally of low quality because of a number of consistent characteristics that greatly impacted on quality and product value. Common problems with product quality included improper cleaning, contamination with sand, peeling skin resulting from over-boiling and burning resulting from an inappropriate smoking technique. The results of our study have prompted immediate awareness and education activities for sea cucumber fishers and processors in Fiji supporting improvements in product quality and improved income from this important coastal livelihood.

Keywords

Bêche-de-mer; Processing; Quality; Harvest; Postharvest processing

Introduction

Sea cucumbers have been harvested and utilized commercially for at least 1000 years in the Indo – Pacific region [1]. It is a product that is consumed in many tropical and subtropical countries [2,3] and in Fiji was first exploited for commercial purposes by Chinese exporters in the early 1820’s [4]. Sea cucumbers are processed into a dried and nonperishable product known as ’bêche-de-mer’ (BDM), and processing of BDM offered a source of income for Fijian communities subsequent to the collapse of the sandalwood trade in the early 1800’s [4]. Still today, harvesting and producing appropriately processed and presented BDM offers good income opportunities for fishers in Fiji. Consumption of BDM is considered to be beneficial for human health as it is a good source of animal protein, vitamins, minerals, micronutrients and essential fatty acids [5-8].

Literature on the processing methods used for BDM and their effects on resulting quality is very limited. Processing BDM involves a number of steps including boiling, gutting, smoking and drying [9,10]. Each contributes to the resulting quality of the final product which determines the suitability of the processed product for Asian markets [2,9-11] and its value. Small developing nations such as Fiji are reliant on marine resources as their basis for income generation and livelihoods. Nevertheless, due to a lack of equipment required to optimize the quality of BDM, such as kerosene burners, smoking sheds and drying amenities, BDM is produced in Fiji using simple uncomplicated customary technologies principally through fire smoking and air or sun drying [9,12].

Bêche-de-mer processing entails an uncomplicated sequence of actions to accomplish a product that is non – perishable if stored in dry, dark conditions. Post-harvest steps include first boiling, slitting and gutting, second boiling, smoking and finally sun-drying [2,9,13,14]. Although these steps are uncomplicated, processing requires continuous attention to obtain a standard dry product. Failure to do so can result in reduced quality and value of the final product [9,10].

The main objectives of this study were to investigate the effects of harvesting and post-harvest handling techniques of Fijian communities and the main BDM processing agents on the quality of BDM produced in Fiji, and to identify difficulties faced by the BDM processors in producing a good quality product. The economic impacts of inadequate processing of BDM are detailed a related study (Ram et al., in press) [15].

Materials and Methods

Study site

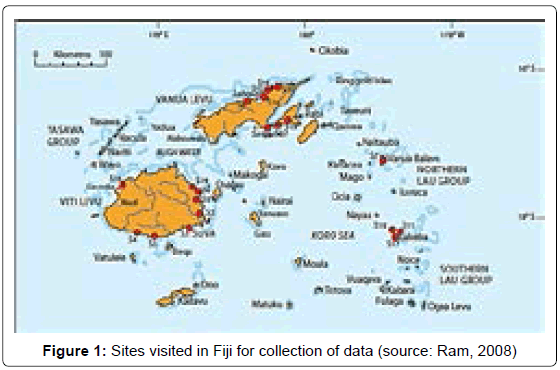

This study was conducted in the Republic of the Fiji Islands. The sites of study were eastern and western Viti Levu, northern and southern Vanua Levu and two islands from outer Lau group (Vanua Balavu and Lakeba Island). The latter two islands have two main BDM buyers who also buy product from other islands in the Lau group (Figure 1). On this basis the data from Vanua Balavu and Lakeba Island represents the Lau Group as a whole. Catch analyses and interviews with sea cucumber fishers were done when the fishers visited the main buyers on Vanua Balavu and Lakeba Island to sell their products in either fresh or dry form. However, fishers based on the main islands of Fiji (Viti Levu and Vanua Levu) were visited directly in their villages to collect data on harvesting and processing.

Data collection

Data on processing sea cucumbers was acquired through formal and informal interviews using a structured questionnaire given to fishers at the various study sites around Fiji (n=21; Figure 1). The key people targeted for interviews and collection of catch analysis data were artisanal fishers (n=86), middlemen (n=8) who purchase sea cucumbers and process them for a higher return from the exporters, the main agents for BDM exporters (n=5) located in Suva, Fiji and relevant fisheries officers at the Ministry of Fisheries and Forests, Fiji.

The questionnaire was designed to derive information about the species of sea cucumbers that were commonly harvested, total catch of each species harvested, methods used to store sea cucumbers in the sea after harvest, methods used for processing, difficult steps in the processing sequence, and sea cucumber species that were difficult to process or handle. A sea cucumber identification card and pictures of various sea cucumber species were shown to the fishers and buyers to assist with accurate sea cucumber identification [9].

Harvesting and processing of sea cucumber

The daily harvest of the fishers was recorded by species and size. Sea cucumbers were left out of the water for approximately 5 min before length and weight were determined. The length of harvested sea cucumbers was measured using a standard ruler to the nearest 0.1 cm and their weight was measured using an analytical balance to the nearest 0.1 g. Details of the processing techniques (harvesting, boiling, gutting, smoke drying and sun drying) used by the fishers were noted through critically evaluating all steps involved. Measurements (length and weight) of individuals were taken between steps in the processing sequence to determine water loss during processing and to assess whether the processed BDM satisfied Fiji’s export size limit of 7.62 cm or 3 inches [16] before shipment. Data on processing methods were analyzed using Logistic regression analysis and a Hosmer and Lemeshow Goodness-of-Fit Test was done to determine the relationships between processing variables (harvesting, smoking, first cook, cutting and gutting) at P<0.05. The Hosmer and Lemeshow Goodness-of-Fit Test was performed on the different steps of processing methods such as harvesting, boiling, cutting and gutting, smoking and drying so that the main step of the processing step could be determined leading to major quality losses. All data were expressed as percentages plus or minus standard error and were analyzed using SPSS software.

Results

Problems with harvesting

Collection of all accessible sea cucumbers was done during low tide by communities involved in the BDM trade. A total of 19 species were captured and recorded during this study (Table 1). Daily harvests were stored in 20 litre drums that were cut in half. Our results revealed that fishers collected a large number of juvenile sea cucumber that was below the regulated minimum size limit of 7.62 cm (Table 1) [16]. The harvested species with the highest proportions of undersized individuals were Curryfish, Greenfish, Lollyfish, Sandfish (currently banned as a target species in Fiji), Curryfish ‘D’ grade (local name ‘Geci’ : Stichopus horrens) (no size limit due to its small size), Stonefish, Surf Redfish, Tigerfish and sea cucumber (local name ‘Mundra’ : Bohadschia marmorata) (Table 1). Harvesting of undersized individuals indicates over-exploitation of these sea cucumber species in Fiji. However, the Fisheries Division in Fiji lacks monitoring and a proper management plan for the sea cucumber fishery and this poses a significant threat to the future of Fiji’s BDM fishery.

| Parameter | Treatment (methionine level) (%) | |||

|---|---|---|---|---|

| 0 | 2 | 4 | 6 | |

| Initial mean weight (g) | 19.833 ± 0.218 | 19.733 ± 0.203 | 19.500 ± 0.201 | 19.267 ± 0.199 |

| Final mean weight (g) | 25.259 ± 0.807 | 24.898 ± 0.678 | 26.319 ± 0.735 | 26.136 ± 0.737 |

| Standard length (mm) | 92.298 ± 1.034 | 91.286 ± 0.840 | 93.604 ± 0.886 | 92.870 ± 0.904 |

| SGR (% day-1) | 0.336 ± 0.015a | 0.323 ± 0.014a | 0.414 ± 0.108b | 0.422 ± 0.015b |

| Mean body weight gain (g) | 5.426 ± 0.218a | 5.165 ± 0.203a | 6.819 ± 0.201b | 6.869 ± 0.199b |

| Condition factor (K) | 3.099 ± 0.046 | 3.092 ± 0.033 | 3.034 ± 0.038 | 3.051 ± 0.035 |

| GSI | 0.126 ± 0.027a | 0.162 ± 0.035a | 0.270 ± 0.092a | 0.356 ± 0.065b |

| FCE (%) | 12.905 ± 0.638a | 12.304 ± 0.583a | 16.342 ± 0.616b | 16.648 ± 0.605b |

| Ash (%) | 15.857 ± 0.996 | 13.485 ± 5.248 | 10.217 ± 0.743 | 19.274 ± 7.761 |

| Dry matter (%) | 37.861 ± 0.650 | 41.750 ± 1.983 | 63.026 ± 13.685 | 44.536 ± 4.606 |

| *Mortality (%) | 5.00 | 6.67 | 6.17 | 5.67 |

Means ± SE with different superscripts differ significantly (P<0.05) across the rows.

*No statistical significance determined since it was calculated on pooled sample.

Table 1: Growth, morphometric, feed utilisation, organ, reproductive and parameters of O.andersonii subjected to different levels of methionine.

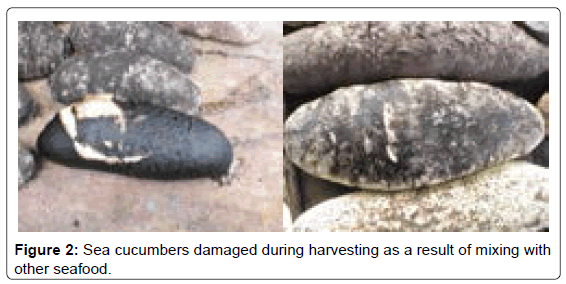

During the harvesting of sea cucumbers, villagers also targeted other species for sale or for local consumption including crabs, lobster, clams, fish and other shellfish. With the exception of Sandfish, sea cucumbers usually have a fragile and soft skin that is easily damaged as a result of improper handling [9,10]. Villagers in Fiji tend to mix sea cucumbers with other seafood’s after collection and this causes deep scratches in the sea cucumber skin [10] (Figure 2). These scratches are sometimes severe and may affect the quality of the product after final drying [9,10,12].

High value species collected by fishers in Fiji are also affected by poor storage in the sea. Instead of being kept separately, White Teatfish is mixed together with other sea cucumber species and usually also with fish and crabs. Proper storage techniques for sea cucumbers have been described previously [9,10], yet our results show that 45% of harvested White Teatfish are damaged due to poor storage (Table 1 and Figure 2). Curryfish (Stichopus hermanni) and Greenfish (S. chloronotos) also showed a high proportion of damage during harvesting (Table 1) resulting from skin deterioration (Figure 3).

Sea cucumber species with handling issues

Two species of sea cucumber, Curryfish (Stichopus hermanni) and Greenfish (Stichopus cloronotos) were determined to be the most difficult species for handling and storage in the sea by the fishers interviewed. This is because of skin and flesh deteriorated which occurs as soon as they are removed from seawater and mixed with other sea cucumber species (Figure 3). The highly fragile skin and flesh of Curryfish and Greenfish discourages fishers from harvesting these two species for processing. This is despite them being ranked as medium to high value species in Fiji and a good revenue earner. Further research on skin and flesh disintegration needs to be done to determine the causes of this problem and to provide a basis for developing more appropriate harvesting and handling methods for these species.

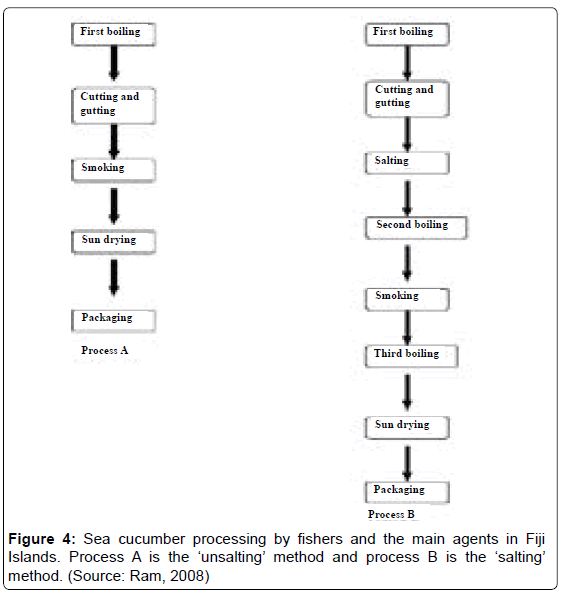

Post harvest processing

Sea cucumber processing is accomplished using two different techniques; the salting and unsalting methods (Figure 4). The salting method is generally used by the main agents of bêche-de-mer exporters in Fiji and the middlemen engaged in this trade. The simpler unsalting method is generally used by fishers in Fiji because of their lack of required processing resources. Some major product quality issues relating to production of a ‘grade A’ BDM are linked to the unsalting method of processing.

Bêche-de-mer processing and problems (post-harvest processing)

Analysis of data using logistic regression analysis and a Hosmer and Lemeshow Goodness-of-Fit Test showed that in addition to first cook (P<0.05), cutting and gutting (P<0.06) and (smoking) (P<0.04) were the major issue leading to loss of BDM quality as a result of poor processing at the fisher’s level (Table 2). Improperly smoked products have a tendency to deteriorate rapidly due to case hardening. When sold to the marine product agents these products are generally rejected or receive reduced grading with lower value.

| Stage of maturity | Sex of fish | B (Coefficient) | S. E | Wald | Exp (B) |

|---|---|---|---|---|---|

| Immature | Female | 2.672 | 0.459 | 33.843* | 0.069 |

| Small fish | 3.761 | 1.151 | 10.681* | 42.990 | |

| Medium fish | 2.205 | 1.140 | 3.737 | 9.066 | |

| Inactive | Female | -1.305 | 0.404 | 10.413* | 0.271 |

| Small fish | 1.601 | 0.744 | 4.637* | 4.959 | |

| Medium size | 0.821 | 0.720 | 1.300 | 2.272 |

*Significant different (P<0.05)

Table 2: Logistic regression on likelihood of maturity stages, sex and size of fish

The major issue affecting BDM product quality and value in Fiji is that fishers do not follow the standard procedure for processing bêchede- mer [9]. In general they process sea cucumbers with little regard for quality to obtain a quicker source of income [17]. Similar research in Madagascar revealed that, to generate quick income, sea cucumber fishers missed fundamental steps in the processing procedure which badly affected the quality of the final product [18]. If the standard processing steps for BDM are followed, good quality product will result that earns greater income for fishers and communities than poorly processed product [12].

First boiling

Our interviews revealed that 100% of fishers boil all the sea cucumber species of all sizes together without any sorting or grading before processing. Larger sizes of sea cucumber require ample time for cooking during first boil [9,10]. However, attention to this component of processing by Fijian fishers is poor and a high proportion of sea cucumbers are overcooked (Table 1). Overcooked sea cucumbers often burst affecting product quality [10].

Inappropriate cooking also results in skin peeling of high value sea cucumber species such as White Teatfish and Black Teatfish, when cooked in boiling water instead of warm water (50–65°C). In addition, Blackfish should be cooked at a high temperature (90–95°C) but not boiled. Introducing commercial sea cucumbers into boiling water results in skin peeling that affects their appearance after drying and reduces value [9,10].

Cutting and gutting

After first boiling sea cucumbers are cut and gutted to remove the viscera. The cutting methods used by fishers in Fiji are generally not of standard quality [9]. Instead of making small cuts in the anal region for species that do not require cuts in the body wall (such as Tigerfish, Stonefish, Deepwater redfish and Brownspotted sandfish) [9], very long cuts are made. These cuts are also generally not straight in the case of high value species. Chinese markets prefer BDM products with neat cuts which enhance their appearance; this is usually not considered during local processing in Fiji. Products may also be incompletely gutted resulting in a product containing gut contents that are contaminated with sand, ash and dust (Table 1). The data for cutting and gutting shown for Sandfish in Table 1 (0%) reflects the fact that this species is generally harvested and sold frozen to the main agents. Processing of Sandfish is currently banned in Fiji and our data are incomplete because the main agents are very secretive regarding Sandfish export data. There could still be significant harvesting of Sandfish in Fiji and, without monitoring and harvesting records, this could have serious consequences for the recovery of Sandfish stocks in Fiji.

Smoking

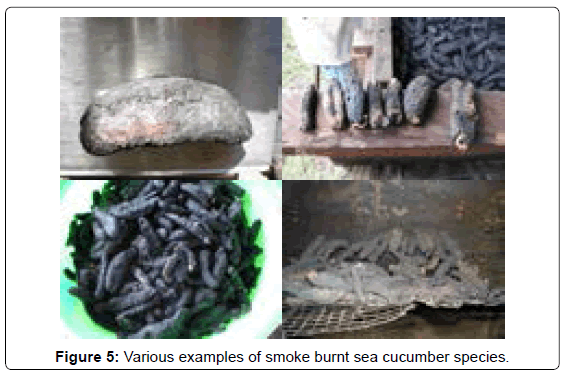

Smoking is performed after cutting and gutting (Figure 4). In the salting procedure (Fiji’s current standard procedure), after cutting and gutting, the products are usually salted in grade 11 coarse solar salt for 2-3 days before they are boiled again and smoked (Figure 4). Instead of producing a gentle smoke for the smoking step, fishers in Fiji generate fire that either roasts the products (Figure 5) or generates a hard skin on the product known as “case – hardening” [19]. “Case – hardening” is described as burnt skin resulting from high temperature that prevents moisture loss from the product resulting in spoilage. The proportion of burnt product resulting from smoke drying during sea cucumber processing by fishers in Fiji is shown for all harvested species in Table 1.

Usually the smoking process is done for 24 – 48 hours and the resulting product is sun dried for four to five days to accomplish a ‘grade A’ product [9,10]. However, to generate rapid income, village processors in Fiji generally perform the smoking and sun drying process together for a day and sell the product to middlemen or the main agents. The products contain 25-35% moisture and due to poor storage, a high proportion of the product may spoil as a result of insufficient drying (Table 1). Insufficient drying is a major issue in local processing of BDM in Fiji. This problem results because sea cucumbers are generally piled on top of each other during processing which hinders moisture loss. The products are kept like this for days and this result in spoilage (Table 1).

Bêche-de-mer quality standard at the main buyer’s warehouse before export

The main BDM exporters in Fiji either process sea cucumbers themselves to a marketable standard before exporting to Asian markets, or purchase product processed by local fishers and reprocess prior to export. Reprocessed product is given a low grade and has reduced value. Data generated from the main agent’s warehouse revealed that nearly all the bêche-de-mer (all species) exported from Fiji to Asian markets were of poor quality (Table 3). Factors that influenced this grading included:

| Parameter | Treatment (methionine level) (%) | |||

|---|---|---|---|---|

| 0 | 2 | 4 | 6 | |

| Water Temperature (°C) | 17.292 ± 0.101 | 17.353 ± 0.104 | 17.344 ± 0.103 | 17.4 ± 0.1 |

| Electrical conductivity (µS/cm) | 91.341 ± 1.416 | 91.111 ± 1.435 | 91.211 ± 1.422 | 91.791 ± 1.462 |

| Dissolved Oxygen (mg/L) | 5.048 ± 0.257 | 5.407 ± 0.224 | 4.935 ± 0.267 | 5.012 ± 0.275 |

| Chlorophyll a (mg/L) | 0.02 ± 0.007 | 0.048 ± 0.056 | 0.051 ± 0.038 | 0.098 ± 0.111 |

Table 3: Water quality parameters determined in hapas with O. andersonii.

Undersized (less than 7.62 cm) (Table 1)

Damaged (skin damage, flesh ripped, skin peeled and holes in the tissue)

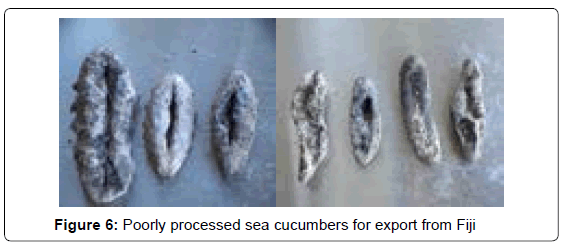

Product had poor appearance (shape distorted, gut cavity contaminated with sand, dust and remaining gut contents, poorly cut for gutting) (Figure 6)

Products were over-dried (Table 3) and burnt as a result of smoking at higher temperatures.

When BDM products are traded by village processors to the main agents or exporters, they are sometimes rejected due to extremely bad odour resulting from spoilage, insufficient drying and burning during the smoking process. Buyers however, do purchase the product but when graded by size and quality, extremely poor quality products that cannot be reprocessed for the market are rejected or discarded as waste (Table 3). High value species such as White Teatfish, Black Teatfish are not rejected if they are processed by the fishers but instead purchased and reprocessed as a low grade product (e.g. ‘Grade D’) and exported to Asian markets for low value. Because populations of the high value species of sea cucumbers are declining rapidly in Fiji [20], buyers tend to purchase the product in perishable state from the fishers for little value and process themselves to obtain a higher return from Asian markets (Table 3). The results in Table 3 show that 43% of White Teatfish (a high value species) is exported as damaged product that was processed by fishers. As a result, processors now prevent fishers from processing the higher value species.

The percentages of damaged individuals are high for higher value species (Table 3) due to flesh and skin damage caused during harvesting and processing. In addition, high value species are generally purchased raw from the villages and extended exposure of the sea cucumbers to the air or to sun may result death or very poor condition. The skin may also peel as a result of the drying effect from the air or sun [9]. Data for the percentage of damaged individuals shown in Table 3 also includes smoke burnt products that were processed by village processors.

The proportion of over-dried product for the major exported species is also shown in Table 3. Over-dried BDM has reduced nutritive value [21,22] and, especially after over boiling, may have skin and flesh that is fragile and may easily break leading to serious product quality issues [9,10]. Greenfish, Amberfish, Surf Redfish and Curryfish, in particular, show a high proportion of damaged product (Table 3) because of the fragility of their skin and flesh and their susceptibility to damage during harvesting.

Conclusion

Bêche-de-mer processing in Fiji is generally done rapidly to obtain income as soon as possible. As a result essential processing steps are shortened or missed completely and this has serious consequences for the quality of the final product. Processing steps in Fiji involved first boil after harvest, slitting and gutting, followed by salting (main agents only), smoke drying and finally sun-drying. Fishers found smoke drying and first boiling to be difficult steps during processing and this result in poor quality products being produced in the Fiji. The final dried product generally has poor exterior appearance, distorted or twisted shape, and particulate matter present in the gut cavities and, perhaps of most importance, a high rate of spoilage due to improper storage. These factors reduce the grade of the final product from ‘A’ to ‘B-D’ grade. Further research is required into the impacts of processing methods on the quality of BDM produced in the Fiji and to develop ways to add value to BDM exported from Fiji. The results of our study have prompted immediate awareness and education activities for sea cucumber fishers and processors in Fiji supporting improvements in product quality and improved income from this important coastal livelihood.

Acknowledgements

The authors wish to thank the main buyers and village people in Fiji for their assistance with data gathering and provision of information. Involvement of officials from the Ministry of Fisheries and Forest of Fiji is also thankfully acknowledged.

References

- Bumrasarinpai R (2006) Overview of issues on concerned aquatic species under the convention on international trade in endangered species of wild fauna and flora (CITES), in Regional technical consultation on international fisheries related issues: WP03.

- Conand C (1990) The fishing resources of the Pacific Island Countries. Part 2: Holothuria, in Overview of Bêche-de-mer industry in Milne Bay Province, Papua New Guinea, J. Kinch, Editor. SPC Bêche-de-mer information bulletin. p. 2-15.

- Anon (1994) Sea cucumbers and Bêche-de-mer of the tropical Pacific: a handbook for fishers, no 18, in Bêche-de-mer production in Tuvalu, K. Belhadjali, Editor. 1994, SPC Bêche-de-mer information bulletin. p. 2-3.

- Ward P (1972) The Pacific Bêche-de-mer with special reference to Fiji. In Pp 2 – 15. , in Bêche-de-mer and sandalwood trade in Fiji. Master’s Thesis, M. Dough, Editor. 1972: Macquarie University. Department of History. School of general studies: 2-15.

- James D (1988) Production, Consumption, and Demand in Fish Drying and Smoking; production and quality, P.E. Doe, Editor Technomic Publishing Co Inc.1-4.

- Sikorski Z, Haard N, Motohiro T, Pan BS (1998) Quality, in Fish Drying and Smoking; production and quality, P.E. Doe, Editor., Technomic Publishing Co Inc:88-116

- Ferdouse F (1999) Bêche-de-mer markets and utilisation. SPC Bêche-de-mer information bulletin,11: 3-9.

- Bordbar S, Anwar F, Saari N (2011) High-value components and bioactives from sea cucumbers for functional foods--a review. Mar Drugs 9: 1761-1805.

- SPC (1994) Sea cucumbers and beche-de-mer of the tropical pacific. Handbook No. 18 Noumea: SPC. 51.

- Sachithananthan K, Osman SS, Mlay M, Schoemaker R n (1985) Report on the national workshop on fish handling in Zanzibar, in United Republic of Tanzania and report on the Tanzania/ SWIOP national workshop on Bêche-de-mer processing. 1985, National workshop on fish handling. 45-83.

- Purcell SW (2014) Value, market preferences and trade of Beche-de-mer from Pacific Island sea cucumbers. PLoS One 9: e95075.

- Seeto J (1999) Bêche-de-mer processing – a little more effort to get much more money while saving precious resources. SPC Bêche-de-mer information bulletin, 11: 2-3.

- Schoppe S (2000) Sea cucumber fishery in Philippines. SPC Bêche-de-mer information bulletin, 13:10-12.

- Jun A (2002) Trepang exploitation in the Philippines: updated information. SPC Bêche-de-mer information bulletin, 17:17-21.

- Ram R, Chand R.V, Southgate PC (2014) Effects of Processing Methods on the value of bêche-de-mer from the Fiji Islands. Journal of Marine Science: Research and Development ,in press.

- Bruckner AW, Johnson KA, Field JD (2003) Conservation strategies for sea cucumbers: Can a CITES appendix II listing promote sustainable international trade. SPC Bêche-de-mer information bulletin, 18: 24-33.

- Kinch J (2002) Overview of Bêche-de-mer industry in Milne Bay Province, Papua New Guinea. SPC Bêche-de-mer information bulletin, 2002. 17:2-15.

- Irwing MA (1994) Fishing Bêche-de-mer in Madagascar. SPC Bêche-de-mer information bulletin, 6:10-11.

- Venugopal V (2006) Seafood processing: adding value through quick freezing, retortable packaging, and cook – chilling. United States of America, CRC press, Taylor and Francis group.

- Pakoa K, Saladrau W, Lalavanua W, Valotu D, Tuinasavusavu I et al, (2013) The status of sea cucumber resources and fisheries management in Fiji. SPC :51.

- Chen J (2001) Present status and prospects of sea cucumber industry in China, in Advances in sea cucumber aquaculture and management .A. Lovatelli et al, FAO Fisheries Technical Paper. No. 463: Rome; FAO:25-38.

- Ram R (2008) Impacts of harvest and post-harvest processing methods on quality and value of bêche-de-mer in Fiji Islands. Master of Science Thesis, University of the South Pacific. 191.

Relevant Topics

- Algal Blooms

- Blue Carbon Sequestration

- Brackish Water

- Catfish

- Coral Bleaching

- Coral Reefs

- Deep Sea Fish

- Deep Sea Mining

- Ichthyoplankton

- Mangrove Ecosystem

- Marine Engineering

- Marine Fisheries

- Marine Mammal Research

- Marine Microbiome Analysis

- Marine Pollution

- Marine Reptiles

- Marine Science

- Ocean Currents

- Photoendosymbiosis

- Reef Biology

- Sea Food

- Sea Grass

- Sea Transportation

- Seaweed

Recommended Journals

Article Tools

Article Usage

- Total views: 18390

- [From(publication date):

December-2014 - Apr 02, 2025] - Breakdown by view type

- HTML page views : 13692

- PDF downloads : 4698