Review Article Open Access

Effect of Food Processing Industries Effluents on the Environment: A Case Study of MOHA Mekelle Bottling Company, Tigray, Ethiopia

Teklit Gebregiorgis Amabye*

Department of Chemistry, Mekelle University, Mekelle, Ethiopia

- *Corresponding Author:

- Teklit Gebregiorgis Amabye

Department of Chemistry, Mekelle University, Mekelle, Ethiopia

Tel: +251344407608

E-mail: teklitgeb@ gmail.com

Received: October 31, 2015 Accepted: November 19, 2015 Published: November 24, 2015

Citation: Amabye TG (2015) Effect of Food Processing Industries Effluents on the Environment: A Case Study of MOHA Mekelle Bottling Company, Tigray, Ethiopia. Ind Chem 1:110. doi: 10.4172/2469-9764.1000110

Copyright: © 2015 Amabye TG. This is an open-access article distributed under the terms of the Creative Commons Attribution License, which permits unrestricted use, distribution, and reproduction in any medium, provided the original author and source are credited.

Visit for more related articles at Industrial Chemistry

Abstract

There is an increasing awareness on the problems of environmental pollution not only in developing countries like Ethiopia but worldwide. Among the sources of this problem is effluent discharge from industries, particularly food processing industries. To determine the extent of this problem in moha soft drink company Mekelletigray Ethiopia. The effluents were collected and analyzed for solids, organics, nitrogen, pH and total coliform using standard procedure. The results showed that total solids (TS) varied 440 to 703 mg/L, total suspended solids (TSS) from 0 to 230 mg/L and total volatile solids (TVS) from 223 to 514 mg/L. The pH of the effluents varied from 6 to 8, the COD from 684 to 3,192 mg/L, the TN from 5.6 to 33.6 mg/L and the total coliform from 43 to 150 MPN/100 mL of effluent sample. Compared to the effluent limitation guidelines given by American Environmental Protection Agency, the TSS, and COD for most of the industries are well above the limits while the TKN, pH and coliform count are within the acceptable limit.

Keywords

Food processing waste; Effluents; Waste characteristics; Environmental pollution

Introduction

Man exerts many effects which directly or indirectly affects his environment. The development of industries and extensive urbanization means increased water consumption and pollution resulting from problems of waste disposal. Unfortunately, in most developing countries like Ethiopia, effluent quality standards imposed by legislation (where they exist) are sometimes easily flouted [1].

Industrial effluents are liquid wastes which are produced in the course of industrial activities. Over the years, the improper disposal of industrial effluents has been a major problem and a source of concern to both government and industrialist. In most cases the disposal or discharges of effluents, even when these are technologically and economically achievable for particular standards, do not always comply with pretreatment requirement and with applicable tonic pollutant effluent limitations or prohibitions. The consequence of these anomalies is a high degree of environmental pollution leading to serious health hazards.

Among the food processing industries commonly found in the region are beer breweries, soft drink bottling companies, vegetable oilindustries, etc. Brewery industries produce waste waters like spent cooling water, spent grain liquor, spent hop liquor, liquor from yeastrecovery system and wash down waters. In most breweries in Ethiopia, these various sources of wastewater are discharged from the industry through a common outlet. Wastes such as dry brewers grain and spent grain are used as animal feedstuff and therefore do not create disposal problems. Brewery wastewaters can be land applied after limited pretreatment (e.g., screening and equalization) if enough land area is available. This depends on which brewery streams are combined for land application, while specific quality characteristics can vary greatly [2].

The food processing plants produce oil sludge’s and other wastewaters that are normally land applied after limited pretreatment. However, considering the types and interactions of the numerous constituents of these complex waste streams and the necessity to avoid the environmental pollution problems that can result when these wastes are land applied, it is necessary that the characteristics of the effluents from breweries and other food processing industries in a developing country like Ethiopia be investigated. The purpose of this study was therefore to investigate effect effluent food processing industries in Moha soft drink industry Tigray Ethiopia.

Materials and Methods

Study area and scope

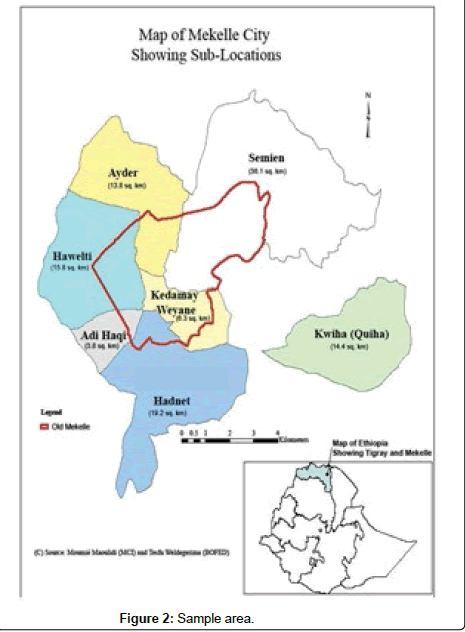

Location: Mekelle is the capital city and commercial center of the Tigray National Regional State in the northern Ethiopia (Figure 1). The town is located at 39033’E longitude and 13032’N latitude, situated in the extension of the central highlands of Ethiopia. The altitude of Mekele is between 1965 m and 2220 m above sea level. The town is bounded by mountain ranges in the east and north.

Climate

Climatically, the area is classified as “Woina Dega” (temperate) with an effective temperature between 14°C and 20°C (Ethiopian Mapping Agency, EMA, 1981), which for most of the time is comfortable. It has a moisture index (P/ET) ranging in between 0.25 and 0.5, which indicates moderately dry area. Mekelle lies between 600 mm to 700 mm rainfall region. The mean annual temperature ranges between 16°C and 20°C (Gebremedhin Berhane) [3].

Topography

The altitude varies from 2220 m at eastern side to 1965 m in the northwestern side of the town (lower reach of Illala River). The town has an overall tilt from eastern to western and northwestern side. Most streams and tributaries are controlled by this tilt while others are controlled by geological structures and underlying geology.

MOHA soft drinks Industry S.C was established on May 15, 1996 acquiring Nifas Silk Plant, Tekle Haimanot Plant, Gondar Plant, and Dessie Plant from the Ethiopian Privatization Agency with paid capital of Birr 108,654,000. The Company currently has seven operating units including Summit Plant, Bure Plant, and the recently inaugurated Hawassa Plant in the Southern Nations and Nationalities People’s Region.

The major products of MOHA Soft Drinks Industry S.C. are: Pepsi Cola, Mirinda Orange, 7-Up, Mirinda Tonic, Mirinda Apple (all Pepsi Brands), and Kool (Bure Kool and Tossa bottled water products). The Annual Turn-over of the company has reached to Birr 556 million and sales stands at an average annual growth rate of 12%.

Method of sampling

Wastewater samples were collected manually with sterilized plasticcontainers from the interception channels from where the effluent was discharged from the company’s. For each sample, grab samples were taken once a week between the months of September and December and during the peak production periods of the day. The samples were taken at about 11.30 a.m. of the day (± 0.5 hours) for all the industries throughout the study period. A total of 60 samples were collected. The containers were labeled and transported immediately in a container of ice for physiochemical and bacteriological analysis. The samples were stored in a refrigerator at 4°C to avoid biological actions until the time of analysis and after each analysis in laboratory. The samples were analyzed in the chemistry Laboratory of University of Mekelle. In the laboratory, visual analyses were made and the results recorded as the physical characteristics of the sample. Some of the samples collected were a bit clear while some looked cloudy and all contained a lot of particles. The samples are relatively dilute mixture of wastewater from different sources of varying constituents.

Method of analysis

The principal parameters used in the analysis to characterize the effluents are listed below in detail. The procedures used during the analysis are also given. Many of the parameters are interrelated.

Solids: Solids determination was carried out following the procedure outlined in Standard Method [4]. The total solid (TS) was determined gravimetrically by evaporating a known volume of the effluent sample to dryness at 104°C in a ventilated oven until a constant weight was achieved. Total volatile solids (TVS) were determined by firing the residue at 600°C for 1 hour in a muffle furnace and determining the loss in weight of the residue. Total suspended solids (TSS) were determined gravimetrically by filtering a known volume of the effluent sample using a vacuum filtration apparatus and Whatman No. 40 filter paper, drying the residue and the filter paper at 104°C and determining the mass of residue left on the filter paper.

pH: This was determined using a portable pH meter (HACH Senson 3). The Chemical Oxygen Demand (COD) of the samples were determined by refluxing a known volume of each sample with a known amount of potassium dichromate (K2Cr2O7) in the presence of sulphuric acid (H2SO4), silver sulphate (AgSO4) and mercuric sulphate (HgSO4). The amount of dichromate left after the reflux was determined by titration against ferrous ammonium sulphate [Fe(NH4)2(SO4)2.6H2O], using ferrroin as indicator as described by Standard Methods [4]. Similar volume of blank sample consisting of distilled water was equally refluxed and titrated. The COD was computed from:

Where, A=mL of [Fe(NH4)2(SO4)2.6H2O] in a blank sample, B=mL of [Fe(NH4)2(SO4)2.6H2O] in the effluent sample, N=normality of the titrant and Vs=the mL of sample.

Total Kjedahl Nitrogen (TN): This was determined by digesting a known volume of the effluent samples in the presence of H2SO4, K2SO4 and CuSO4 until the ejection of SO3 stopped and the solution became colourless or pale straw. The solution was then distilled after addition of phenolphthaline indicator and hydroxide thiosulphate reagents and the distillate collected and titrated with standard 0.02N H2SO4. A blank consisting of ammonia free water was equally digested, distilled and titrated and the TKN determined as described in Standard Method [4].

Coliform count: Multiple Tube Fermentation technique was employed to statistically estimate the number of coliform bacteria in a given volume of the samples following the method outlined in Ref. [4]. A three-fold dilution series was prepared for each sample using Lauryl Tryptose Broth (LTB) tubes for the presumptive test and Brilliant Green Bile broth (BGB) for the confirmatory test. After incubation at 37°C for 12-48 ± 3 hours, the pattern of positives and negatives were noted and a standardized MPN table consulted to determine the most probable number of organisms (causing the positive results) per 100 mL of each of the effluent samples.

Results and Discussion

The results of the analysis are summarized in Table 1 which also shows a comparison of the result with the Nigerian Federal Environmental Protection Agency (FEPA) effluent limitation guidelines for all industrial wastes [5,6] together with the general standard for discharge of effluents into inland surface water [7].

| Symbol | Parameter | Concentration | |

|---|---|---|---|

| Before digestion | WHO Standard | ||

| - | pH | 7.21 | 6.0-9.0 |

| NTU | Turbidity | 280.00 | - |

| ms/cm | Conductivity | 46.70 | 1000.00 |

| mg/l | Water hardness/Bicarbonate | 76.00 | - |

| oC | Temperature | 27.00 | 37.00 |

| mg/l | Alkalinity | 75.00 | - |

| mg/l | Chloride | 140.00 | 250.00 |

| mg/l | Total Dissolved Solid (TDS) | 74.00 | 50.00 |

| mg/l | Total Suspended Solid (TSS) | 63.10 | 30.00 |

| mg/l | Sulphate | 200.00 | 200.00 |

| mg/l | Phosphate | 1.28 | - |

| mg/l | Total Solid (TS) | 137.10 | 500.00 |

| mg/l | Total Nitrogen | 1.07 | 4.00 |

| mg/l | Chemical Oxygen Demand (COD) | 418.67 | 200.00 |

| mg/l | Dissolved Oxygen (DO) | 21.20 | - |

| % | Oil and Grease | 20.00 | - |

| mg/l | Total Hardness | 40.00 | - |

| cfu/100ml | Total Viable Count (Fecal Coliform) | 58 × 107 | 400.00 |

| BOD5 | Biological Oxygen Demand | 33.50 | 30.00 |

| mg/l | Acidity | 125.00 | - |

| % | Volatile Solid | 10.0(0.2g) | - |

| ppm | Nickel | 0.00 | 0.02 |

| ppm | Manganese | 0.00 | 0.10 |

| ppm | Magnesium | 3.11 | - |

| ppm | Calcium | 3.68 | 75.00 |

| ppm | Lead | 0.02 | 0.10 |

| ppm | Zinc | 0.02 | 1.00 |

| ppm | Iron | 0.00 | 0.30 |

| ppm | Silver | 0.00 | - |

| ppm | Sodium | 21.62 | 75.00 |

| ppm | Selenium | 21.65 | - |

| ppm | Copper | 0.10 | 2.00 |

| ppm | Cadmium | 0.00 | 0.003 |

| ppm | Cobalt | 22.86 | 0.02 |

| ppm | Chromium | 0.00 | 0.05 |

| ppm | Potassium | 4.25 | - |

| ppm | Aluminium | 5.26 | - |

| ppm | Mercury | 0.80 | - |

Table 1: Comparison of result with the Nigerian Federal Environmental Protection Agency (FEPA) effluent.

Solids concentration

Suspended solids are a direct indication of the solids removable by plain sedimentation and also are an index of the sludge forming characteristics. The range of values of suspended solids in the analyzed samples ranged from 0 for AVOP to 30 mg/L for every food industry. The value for Mekelle moha plant (42 mg/L) is also higher than the value of 0.53 mg/L reported for the Nigerian Bottling Company plant in Maidugri, Nigeria by Ref. [8]. Except for AVOP, the suspended solids concentrations are also higher than the value of 30 mg/L given by Ethiopian guidelines for discharge of industrial effluents into surface water.

All these indicate the need for treatment before the discharge of these effluents into surface streams. The total solids concentration ranged from 440 mg/L for Premier Brewery to 703 mg/L for soft drinks Company. They are all below the value of 2,030 mg/L given in the Ethiopian FEPA guideline. The volatile solids concentrations ranged from 223 to 514 mg/L.

Organics

COD is generally defined as the total quantity of oxygen required for complete oxidation of organic compound to carbon dioxide and water. It is an important rapidly measured parameter to determine the degree of pollution in an effluent [9]. From the analysis, the COD values ranged from 684 mg/L for Coca-Cola Bottling Company These values were all higher than the value of 14.8 mg/L reported for Ethiopians soft industry [10], the FEPA guideline of 80 mg/L and the 250 mg/L given by General standards. The COD value of the effluent from moha plant is very much smaller than the value of the other samples just like in the case of suspended solids but all of them signifies the need for treatment before disposal.

pH

The pH values ranged from 6 to 8. The effluents from most of the breweries were slightly acidic or neutral while those of the non breweries were either neutral or slightly alkaline. The recorded pH values fell within the effluent limitation guidelines and discharge standard.

Nitrogen

Organic nitrogen and ammonia are essential nutrient for growth. Their oxygen content reduction potential and the fact that they can be toxic to aquaticlife make them not desirable in drinking or recreational water. Their presence in the effluent in substantial amount, just like other tested parameter, signifies the need for treatment to avoid the associated adverse effects. The value of total kjeldahl nitrogen (TKN) concentrations ranged from 5.6 mg/L to 33.6 mg/L. The values for most of the industries are well within the value of 20 mg/L given by Ref. [5]. Also, all of the values are well below the value of 100 mg/L given by General Standard.

Pathogenic bacteria

The samples tested gave the coliform bacteria concentrations ranging from 43 to 150 MPN/100 mL (Figure 2). This shows that all the samples are capable of causing pollution and probably contains human wastes which are the primary sources. FEPA guideline gave a maximum value of 400 MPN/100 mL while for the general standard the values ranged from 50 to 5000 MPN/100 mL depending on the envisaged treatment and use of the surface water to which the effluent is discharged. Although the coliform counts for the industrial effluents are below the guidelines and standards, there is still the need for treatment to ensure that the surface water is pathogen free.

Conclusions and Recommendations

Conclusion

The results showed as follows:

(a) The COD values ranged from 2,166 to 3,192 mg/L WHO guidelines gave an acceptable range of 2,166 to 3,192 indicating that based on COD values alone the effluents can be discharged into surface streams without any negative impact.

(b) The TS ranged from 440 to 703 mg/L, TVS ranged from 223 to 514 mg/L while the TSS ranged 0 to 230 mg/L. While the value for the TSS was higher than the maximum limit set in WHO Guidelines, the total solids concentration was well within the limit.

(c) The pH ranges from 6 to 7.5 for breweries and 7 to 8 for food processing. WHO guidelines gave an acceptable range of 6-9 indicating that based on pH values alone the effluents can be discharged into surface streams without any negative impact.

(d) The coliform count, measured as MPN/100 mL ranged from 43 to 150 while the value for the TKN ranged from 5.6 to 33.6 mg/L.

Recommendations

The basic responsibility for pollution control in Ethiopia lies with the federal state Environmental Protection Agencies. To ensure that our surface waters are safe from the negative impacts of effluent discharge from industries, the following recommendations are made as a way of solving pollution problem caused by the increased industrialization.

The FEPA guidelines should be reviewed to include effluent and other limitations for such specific industries like breweries, vegetable oil and other food processing industries not already covered by the guidelines. Also limitations for many other relevant pollution parameters should be included.

Federal and State Environmental Protection Agencies should carry out routine checks on industries especially food processing industries with a view to ensuring compliance.

Finally, in the absence of standards for some certain pollution parameters, industries should set up their own in-house quality limits for these parameters as reported for the east Africa bolting company,

Anaerobic digestion

Acknowledgements

The authors are grateful to Asmel Abdu who was very useful and to the Department of Earth Science and Chemistry, Mekelle University for the Analysis of the sample the collection of samples for this study.

References

- Okereke CD (2007) Environmental Pollution Control. 1st edn. Barloz Publication, Owerri, Nigeria.

- Otta JW, Cable JK (1987) Land application of wastes from brewing and distilling. In proc. of the 1987 food processing waste conference. Georgia Tech Research Institute, Atlanta, Georgia.

- Proceedings of the 1987 Food Processing Waste Conference (1987) Georgia Tech Research Institute, Atlanta, Georgia. pp. 129-144.

- Greenberg AE, Clesceri LS, Eaton AD (1985) Standard Method for the Examination of Water and Wastewater. 16th edn. American Public Health Association (APHA), Washington, USA.

- FEPA (1988) Effluent Limitation Guidelines in Nigeria for all Industries. Federal Environmental Protection Act. Second Schedule (Regulation 3). Government Press, Lagos.

- FEPA (1991) Guidelines and Standard for Environmental Control in Nigeria. Federal Environmental Protection Agency (FEPA).

- Chaterjee AK (2010) Water Supply, Waste Disposal and Environmental Engineering. 8th edn. Khanna Publishers, New Delhi, India.

- Arku AY, Musa SM, Maoke ALE, Dibal JM (2012) Re-examining raw effluents from Nigerian Bottling Company, Maidugri for Crop Irrigation. Journal of Applied Hytotechnology in Environmental Sanitation 1: 43-49.

- Tchobanoglous G, Burton FL, Stensel HD, Metcalf E (2003) Wastewater Engineering: Treatment and Reuse. TATA McGraw-Hill Publishing Company, New York, USA.

- Egwuonwu CC, Uzoije AP, Okafor VC, Ezeanya NC, Nwachukwu MU (2012) Evaluation of the effects of industrial wastewater discharge on surface water (A case study of Nigeria Breweries Plc Enugu). Greener Journal of Physical Sciences 2: 056-063.

Relevant Topics

Recommended Journals

Article Tools

Article Usage

- Total views: 20061

- [From(publication date):

December-2015 - Apr 02, 2025] - Breakdown by view type

- HTML page views : 18514

- PDF downloads : 1547