Research Article Open Access

Effect of Cold Storage, Reheating, and Particle Sizes on In Vitro Glucose Release and Starch Digestibility among Five Rice Products in Auckland, New Zealand

Lu LW1*, Monro J2, Lu J3 and Rush E11School of Sport and Recreation, Auckland University of Technology, Auckland, New Zealand

2The New Zealand Institute for Plant and Food Research, Palmerston North, New Zealand

3School of Applied Science, Auckland University of Technology, Auckland, New Zealand

- Corresponding Author:

- Lu LW

Faculty of Health and Environmental Science

Auckland University of Technology

Private Bag 92006, Auckland 1142, New Zealand

Tel: 00 64 9 921 999, Ext: 7295

Fax: 00 64 29 921 9960

E-mail: lolu@aut.ac.nz

Received Date: March 20, 2016; Accepted Date: July 28, 2016; Published Date: August 05, 2016

Citation: Lu LW, Monro J, Lu J, Rush E (2016) Effect of Cold Storage, Reheating, and Particle Sizes on In Vitro Glucose Release and Starch Digestibility among Five Rice Products in Auckland, New Zealand. J Rice Res 4:171. doi:10.4172/2375-4338.1000171

Copyright: © 2016 Lu LW et al. This is an open-access article distributed under the terms of the Creative Commons Attribution License, which permits unrestricted use, distribution, and reproduction in any medium, provided the original author and source are credited.

Visit for more related articles at Rice Research: Open Access

Abstract

Rice provides more than 27% of daily energy intake to more than half of the world’s population. Refined and cooked rice, as a staple has been generally perceived to induce high glycaemic responses; however, it is known that cold storage of cooked rice, reheating, and mincing or chewing affects the rate and extent of starch digestion and glucose release. This in vitro experimental study aimed to investigate the effect of various combinations of these factors on the rate and extent of starch digestion of five rice products, medium grain white, medium grain brown, long grain white, basmati, and parboiled rice. Cold storage (at 4ºC) for over ten hours significantly reduced digestibility of cooked rice starch (P=0.05). The reductions in starch digestion were dependent on the type of rice product varieties (medium grain white, medium grain brown, and long grain brown about 20% (P=0.05); basmati about 30% (P=0.05); and parboiled about 40% (P<0.001). Reheating (65ºC for 15 minutes) and mincing increased starch digested by 20% (P<0.001) and 18% (P<0.001) respectively compared with the cold-stored un-minced cooked rice. The glucose released from minced freshly cooked medium grain white rice reached over 90% after 40 minutes of digestion while 24-hour cold-stored minced parboiled rice had the lowest, reaching around 40% after 180 minutes. Further study with human participants is suggested to analyse the significance of the differences between medium grain white rice and cold stored parboiled rice, for the purpose of investigating if the optimal treatment of parboiled rice (cold storage at 4ºC for 24 hours), with appropriate food safety precautions (reheating to 65ºC for at least 15 minutes), could be a public health recommendation that would improve the postprandial blood glucose response compared with the response to the more popular medium grain white rice.

Keywords

Rice starch digestion; Rapidly digested starch; Slowly digested starch; Resistant starch; Cold-store; Particle size; In vitro glucose release; Starch digestibility profile; Cooking method; Cold storage; Mincing; Reheating

Abbreviations

GI: Glycaemic Index; GL: Glycaemic Load; iAUC: Incremental Area under the Curve; RDS: Rapidly Digested Starch; RS: Resistant Starch; SDS: Slowly Digested Starch; TAS: Total Available Starch; TS: Total Starch

Introduction

As the primary carbohydrate source that supports more than half of the world population daily energy intake, rice plays an important role in meeting the energy requirement and nutrition intake. Like other dietary carbohydrates, rice products are digested and absorbed at different rates and to different extents in the human small intestine, depending on their botanical source and the physical form of the food [1]. Diets containing large amounts of rapidly digested starch (RDS i.e. starch that can be digested within 20 minutes after ingestion) may release glucose and elevate blood glucose rapidly and be detrimental to health [2], while the inclusion of foods in daily diet that have a slow release of glucose is considered beneficial. Previous studies have provided the evidence that slow starch digestion and slow glucose release are favourable for dietary management of individuals suffering from impaired blood glucose homeostasis [3-5].

Various intrinsic and extrinsic factors have been reported in a number of studies to impact on the trajectory of glucose release from rice [6-8], which is directly associated with the starch digestibility. Two important intrinsic factors are the quantity of dietary fibre present and the amylose to amylopectin ratio which depends on the botanical origin of the rice. The dietary fibre content of brown rice may significantly reduce the susceptibility to enzymatic degeneration (i.e. amylolytic attack) both in the mouth and the small intestine slowing the rate of digestion and reducing the postprandial glycaemic response [9-11]. Rice that exhibits high amylose to amylopectin ratio (e.g. long grain rice and basmati rice) tends to resist enzymatic attack longer and produce a lower postprandial glycaemic response than rice with a lower amylose to amylopectin ratio (i.e. most medium and short grain rice products). Altering rice starch structure by thermal processing, such as cooling cooked rice or storing cooked rice at low temperature, may transform gelatinized rice starch from an amorphous state to a more ordered state (i.e. crystalline state) which persists on reheating [12]. The crystallized starch form can resist enzymatic degradation in small intestine to up to 3 hours [13]. This retrogradation process may spontaneously lower the concentration of digestible starch in cooked rice and subsequently reduce the potential of postprandial glycaemic response and glycaemic index (GI) value [14]. Different degrees of particle size reduction can significantly affect rice starch digestibility [4]. It was also hypothesized that whole grain rice with outer bran intact may resist digestion longer than chopped whole grain rice and well-polished rice grain [15].

Previous studies of the variations in starch digestibility and absorption of glucose have largely based on the measurements of GI and estimates of the glycaemic load (GL). Englyst and Englyst [16] has introduced an in vitro definition of starch digestibility that mimics the way starch is digested in the human gastrointestinal tract. This in vitro digestion method determines nutritional starch fractions, rapidly digestible starch (RDS, can be digested within 20 minutes after ingestion), slowly digestible starch (SDS, can be digested between 20 and 180 minutes after ingestion), and resistant starch (RS, can resist digestion to up to 180 minutes), by measuring the amount of glucose released from one test food during incubation with amylase enzymes under standardized in vitro conditions over 180 minutes. The total amount of starch digested to glucose in 180 minutes is termed total available starch (TAS=RDS + SDS +RS).

The aim of this study was to obtain proof of principle that storing cooked rice at 4°C for 24 hours and reheating can reduce the rate and extent of starch digestion and glucose release and to discover the optimal combination of factors (rice type, particle size, cooking method, and storing condition) to improve the health profile of cooked rice to reduce the glycaemic load of rice consumers.

Method

Rice products tested

Five rice products (1 kg each) were purchased from a New Zealand local high-turnover supermarket (Pak’n’save): medium grain white rice (Sun Rice®), pure white basmati rice (King’s Choice®), medium grain brown rice (Sun Rice®), long grain brown rice (Sun Rice®), and parboiled rice (Real Rice®). All rice products were produced within one year and in good condition. The selection of rice products was based on empirical information gathered from an Auckland Indian community nutritionist and shelf space for these products in supermarkets frequented by Indian and Chinese customers.

Comparison of treatments

Two series of twelve experiments were applied to each of the five rice products to investigate 1. the effect of time of cold storage at 4°C for 4, 8, 10, 12, and 24 hours and 2. the combination of the effects of mincing the freshly cooked or 24 h cold stored rice to 2.5 mm in diameter on the glucose release trajectory and starch digestibility profile (i.e. the proportions of RDS, SDS, and RS) of each cooked rice product (Table 1).

| Group 1: Investigate the cold storage time effect on rice starch digestibility | |

| 1 | Freshly cooked rice |

| 2 | Cooked rice stored at 4°C for 4 hours |

| 3 | Cooked rice stored at 4°C for 8 hours |

| 4 | Cooked rice stored at 4°C for 10 hours |

| 5 | Cooked rice stored at 4°C for 12 hours |

| 6 | Cooked rice stored at 4°C for 24 hours |

| Group 2: Investigate the effect of mincing and cold storage on rice starch digestibility profile | |

| 7 | Freshly cooked rice at 37°C, minced grain structure |

| 8 | Freshly cooked rice at 37°C, intact grain structure |

| 9 | Cooked rice stored at 4°C for 24 hours, reheated to 65°C for 15 minutes, minced grain |

| 10 | Cooked rice stored at 4°C for 24 hours, reheated to 65°C for 15 minutes, intact grain |

| 11 | Cooked rice stored at 4°C for 24 hours, minced grain structure |

| 12 | Cooked rice stored at 4°C for 24 hours, intact grain structure |

| Samples 1âÂ?Â?6: grains reheated to 65ºC and minced before digesting | |

Table 1: Summary of treatments and mincing used in testing the effects of rice processing on starch fractions in five types of rice (medium grain white rice, basmati rice, medium grain brown rice, long grain brown rice, and parboiled long grain white rice).

Each experiment was duplicated so all results and statistical analyses were from the average of duplicated samples.

Rice cooking

Each raw rice product (100.0 g) and 110 mL of distilled water was weighed into a 60 mL glass beaker (KIMAX, USA). All beakers were tightly sealed and immersed in boiling water in a large cooking pan and covered during cooking. Basmati, parboiled and medium-grain white rice samples were boiled for 25 minutes; and, medium-grain and long-grain brown rice samples were boiled for 45 minutes to achieve complete gelatinisation. Freshly cooked rice (at 100°C) was removed from large cooking pan and rapidly cooled by running cold tap water around the glass beaker until the centre of the rice was cooled to 37°C.

Mincing

Mincing was achieved by rubbing the rice grains gently through a 2 mm sieve on cooking paper. The minced particles (2.5 mm in diameter) of each rice product (5.0 g) were quickly collected into 10 separate plastic pots (70 mL; Lab Serve LBS 30002) and tightly capped to prevent moisture loss.

Cold storage

Tightly capped pots containing intact or minced cooked rice grains were immediately placed in the refrigerator at 4°C. The temperature of the refrigerator was monitored every two hours during the storage time.

Reheating

At the end of each cold storage time period (4-hour, 8-hour, 10- hour, 12-hour and 24-hour), two plastic pots for each of the five rice products (5.0 g) were taken out of the refrigerator and kept tightly capped to prevent moisture loss. The pots were put into a warm water bath at 65°C for at least 15 minutes until the rice was completely heated to 65°C.

Starch digestion

Total starch and moisture content: The total starch (TS) content was determined by the Megazyme TS enzymatic procedure (AA/AMG) AACC Method 76-12 [17,18]. The moisture content (%) was determined as the moisture removed from intact uncooked rice grains by drying for 24-hr in a vaccum oven at 60°C attached to a freezedrier.

In vitro digestion and glucose analysis: The in vitro digestion adopted a timed digesta sampling procedure (20, 40, 60, 120, 180 min) to show the relatively susceptibility of starch digestibility [2,19]. This starch digestion method and the glucose analysis method (dinitrosalicylic acid colorimetric method) used were based on the methods published by Mishra et al. [20].

Starch calculation: The proportion of RDS was expressed as the reducing sugar measured in the 20 minutes aliquots as a proportion of TS, and SDS as reducing sugar released between 20 and 180 minutes as a proportion of TS. The proportion of RS was estimated by (TS -RDSSDS)/ TS * 100%.

Statistics

Summary of glucose release over time (g/100 g rice dry weight basis) and starch digestibility profiles (proportions of RDS, SDS, and RS) were subjected to repeated measures one-way analysis of variance (ANOVA) followed by a T-test for independent samples. The significance concentration was P<0.05. All analyses were performed using Excel for Windows XP, version 2010 (Microsoft, USA) and Statistical Package for the Social Science (SPSS) for Windows XP, version 2.0 (IBM, USA).

Results

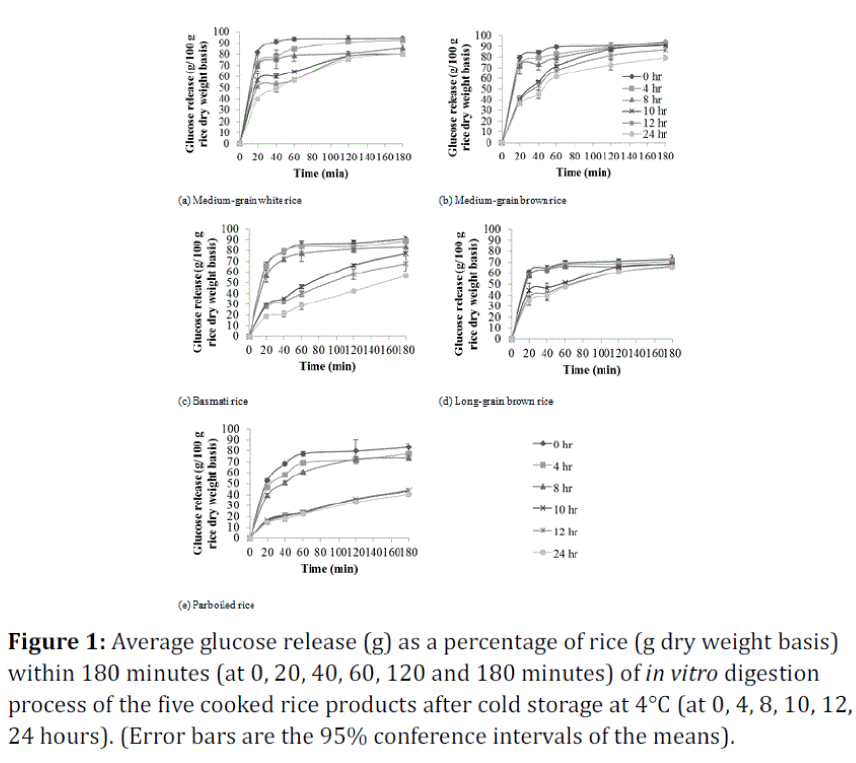

Effects of cold storage time on glucose release

The extent and rate of glucose release decreased with cold storage (Figure 1). For minced medium-grain white, medium-grain brown and basmati rice the glucose release rate was higher than that of long-grain brown and parboiled rice for the same cold storage time. More than 10 hours of cold storage reduced glucose release around 30% (P=0.05). For parboiled rice, the glucose release was less than for other rice product varieties at every time point (Figure 1) and the proportional reduction with cold treatment was greater (40%, P<0.001). No further reduction was observed after 12 hours and 24 hours of cold storage (Figure 1e).

Figure 1: Average glucose release (g) as a percentage of rice (g dry weight basis) within 180 minutes (at 0, 20, 40, 60, 120 and 180 minutes) of in vitro digestion process of the five cooked rice products after cold storage at 4°C (at 0, 4, 8, 10, 12, 24 hours). (Error bars are the 95% conference intervals of the means).

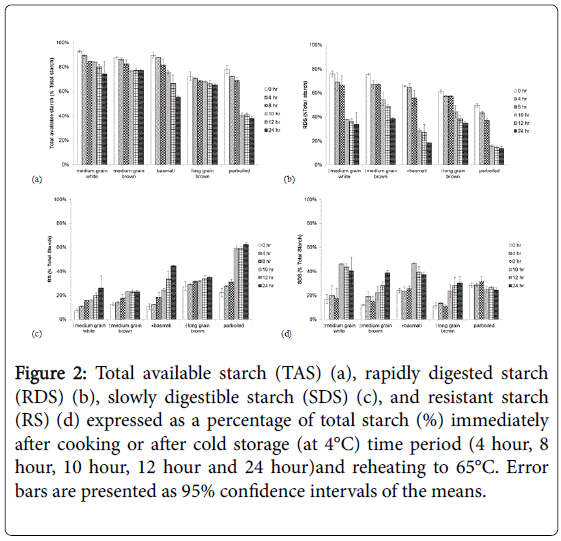

Effects of cold storage time on starch digestibility profiles

Increasing cold storage time from 0 hour to 10 hours gradually reduced the TAS and RDS whereas increased SDS and RS. The most significant change in digestibility was found in minced parboiled rice, of which both TAS and RDS dropped by around 50% (P<0.001) (Figures 2a and 2b) and RS almost doubled (P<0.001) after 10 hours of cold storage. Minced medium grain white and basmati rice had a more significant reduction in TAS (by average 20%, P<0.001) and RDS (by average 25%, P<0.001) compared with whole grain rice (medium-grain and long-grain brown rice, average 5% reduction in both TAS and RDS, P=0.1) following more than 10 hours of cold storage. Both medium-grain white and basmati rice had an average 20% increase to around 40% of SDS after 10 hours of cold storage (P<0.001), and both whole grain rice (medium-grain and long-grain brown rice) had around 10% increase (P<0.001) (Figure 2c). An insignificant but steady increase of RS among medium-grain white rice, medium-grain brown rice, basmati rice and long-grain brown rice was observed (from 5% to 10%, P=0.1) (Figure 2d).

Figure 2: Total available starch (TAS) (a), rapidly digested starch (RDS) (b), slowly digestible starch (SDS) (c), and resistant starch (RS) (d) expressed as a percentage of total starch (%) immediately after cooking or after cold storage (at 4°C) time period (4 hour, 8 hour, 10 hour, 12 hour and 24 hour)and reheating to 65°C. Error bars are presented as 95% confidence intervals of the means.

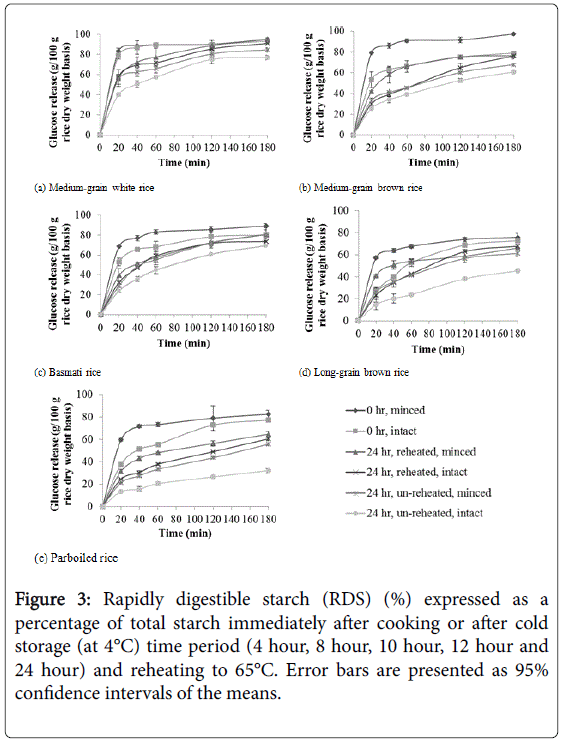

Effect of various combined treatments (rice product varieties, 24-hr cold storage, reheating and rice grain particle size interruption) on glucose release

Cold storage over 24 hours without reheating treatment significantly reduced glucose release from all rice products by up to 40% (p<0.001) (Figure 3). Reheating to 65°C after 24 hours of cold storage treatment reversed around 20% the effect of cold storage i.e., increased RDS and SDS in all five rice products (p<0.001). Mincing also increased the rate and extent (RDS + SDS) of glucose release. The increase was larger in whole grain rice products (medium-grain brown by around 10%, P<0.001; long-grain brown by around 18%, P<0.001) compared with refined grain (medium-grain white and basmati by approximately 4%, P<0.001; Figure 3).

When the same combination of treatments applied, both parboiled rice and long-grain brown rice had significantly lower (around 10%, P<0.001) overall rates and extents of glucose release than the other three rice products (Figure 3). Between parboiled and long-grain brown rice, when reheating was applied, parboiled rice had a similar glucose release trajectory to that of long-grain brown; however, when no reheating was applied, parboiled rice had a slightly lower (around 5%, p<0.001) rate and extent of glucose release (Figures 3d and 3e).

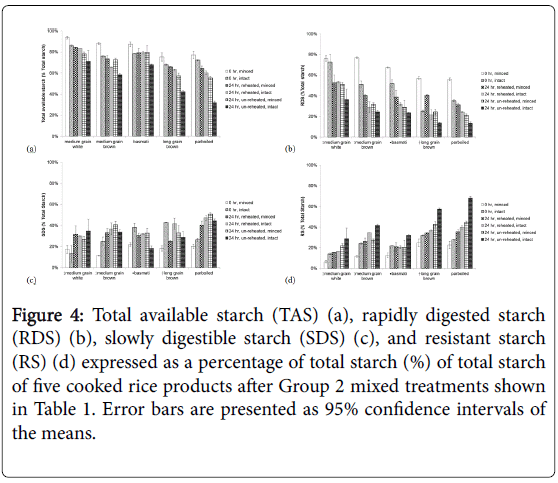

Effects of rice product variety, cold storage, reheating and mincing on starch digestibility

Between un-reheated and reheated rice: Twenty-four hours cold storage promoted the formation of starch retrogradation (i.e., increase in RS by up to 40%, P<0.001) and the reduction of TAS (by around 25%, P<0.001) and RDS (by up to 40%, P<0.001), while reheating reversed the starch retrogradation and increased the proportion of TAS (by up to 20%, P=0.01) and RDS (by up to 10%, P<0.001), depending on rice types and the structure of cooked rice grains (Figures 4a-4c).

Figure 4: Total available starch (TAS) (a), rapidly digested starch (RDS) (b), slowly digestible starch (SDS) (c), and resistant starch (RS) (d) expressed as a percentage of total starch (%) of total starch of five cooked rice products after Group 2 mixed treatments shown in Table 1. Error bars are presented as 95% confidence intervals of the means.

The most significant change in starch digestibility profile following 24-hour cold storage was observed in long-grain brown rice and parboiled rice. TAS reduced by 25% (P<0.001) and RDS reduced by up to 40% (P<0.001), and RS increased by around 40% (P<0.001; Figures 4a-4c). The cold storage also promoted the formation of SDS; however, the increase was not consistent. Among these five rice products, parboiled rice had the highest proportion of SDS (around 40%) (Figure 4c). The largest effect of reheating was observed for intact parboiled rice (around 30% increase in TAS and RDS, P<0.001), and the smallest change was observed in minced basmati rice (around 2% increase in TAS and RDS, P=0.5; Figures 4a and 4b). However, the reversion did not bring the TAS and RDS to the freshly cooked values. Still around 10% of starch retained the retrogradation status in all rice products (Figure 4a).

Between intact and minced rice: Minced rice, compared with their intact counterparts, had overall a higher proportion of TAS (around 15% higher, P<0.001) and RDS (around 40% higher, P<0.001) and lower proportion of RS (around 20% lower, P<0.001; Figures 4a, 4b and 4d). The impact of mincing on the increase of TAS content was more significant in un-reheated whole grain rice (medium-grain and longgrain brown rice) and parboiled rice (around 20% increase after mincing, P<0.001; Figure 4a). Similarly, mincing had a more significant impact on the reduction of RS content among un-reheated whole grain rice and parboiled rice (around 20% decrease after mincing, P<0.001; Figure 4d). A large increase in RDS and SDS following mincing treatment was again observed among whole grain rice and parboiled rice (more than 20% RDS increase after mincing, P<0.001; around 10% SDS decrease after mincing, P<0.001; Figures 4b and 4c). However, the change of SDS between minced and intact medium-grain white rice was statistically insignificant (P=0.37; Figure 4c).

Effects of combined factors: Cold storage strongly promoted starch retrogradation in long-grain brown rice and parboiled rice, both of which had a larger decrease in TAS and RDS and a larger increase in RS compared with medium-grain white rice, basmati rice and medium-grain brown rice. Mincing and reheating, however, reduced the difference. As a result, the reheated minced long-grain brown rice and parboiled rice had a similar proportion of TAS (around 60%; Figure 4a).

The increase of TAS in minced rice was related to an increase of RDS. The mincing of brown rice almost doubled the RDS concentration and significantly reduced the SDS concentration in long- and medium-grain brown rice. Compared with the starch fractions in long-grain brown rice, the RDS, SDS and RS concentrations in parboiled rice were only slightly affected by the mincing process. (Figures 4a and 4b).

The effect of mincing also varied among different rice types. After the cold storage and reheating cycle, minced long-grain brown rice had much less RS than the intact rice. Compared with long-grain brown rice, the effect was much less significant in well-polished rice and medium-grain brown rice. The particle size did not affect the RS proportion in parboiled rice.

Discussion

This study has demonstrated that rice product variety, larger particle size (extent of mincing or chewing rice grains), 24-hour cold storage at 4°C and reheating to 65°C might also substantially lower the rate and extent of starch digestion observed by others for rice [4,21,22]. The two rice products that were most different were the widely consumed medium-grain white rice (SunRice®) and Real Rice® parboiled rice. Medium grain white rice had the highest TAS and RDS compared and 24-hour cold storage the least impact on TAS and in vitro glucose release reduction compared with parboiled. Generally speaking, whole grain rice products (medium-grain brown rice and long-grain brown rice) were more responsive to cold storage and mincing treatments than refined grain rice (medium-grain white rice and basmati). The main source of these differences was in the proportions of RS and SDS, which were both directly affected by parboiling treatment (pre-cooked) and milling and polishing processes (refined vs. encapsulated whole grains).

Twenty four hour cold storage at 4°C substantially reduced in vitro glucose release in all rice products which is consistent with previous research findings [23,24]. The slowdown of rice starch digestion (i.e., hydrolysis) and thus the in vitro starch digestibility due to cold storage has been shown by others to be caused by retrogradation or recrystallisation of previously gelatinised starch [8,12,13,25].

Parboiling could also induce irreversible retrogradation of amylose, which could lead to the formation of type 3 RS (RS3) and SDS [10]. The slower in vitro glucose release and higher RS and lower TAS and RDS of parboiled rice confirms the previous observation that parboiling (i.e., pre-cooking, drying, cooling, and then polishing) can increase starch retrogradation and alter the chemical structures of starch in ways that limit the rate of enzyme action. Furthermore, the gelatinisation of long-grain rice starch (i.e., high amylose starch) followed by hydrothermal processing (i.e., parboiling) can result in recrystallisation of starch and significantly rearranges the retrograded starch chain, thus increasing the proportion of RS [12,25,26].

Differences in starch digestibility can also be explained by the proportion of amylose-amylopectin present which depends largely on the botanical source, the rice grain particle size and the storage conditions [13,27,28]. Long-grain rice has a relatively higher proportion of amylose, of which the irreversible retrogradation reaches peak limit after 48 hours [23] but cold storage (over 48 hours) may further induce the formation of RS and impacts on rice sensory properties making the rice unacceptable for consumption.

Particle size is inversely correlated with the accessibility of the digestive enzymes such as amylase. Previous studies have cited particle size reduction as a factor reducing retrogradation and increasing digestibility of rice starch [23]. We have shown that the effect of particle size reduction was greater for whole grain rice than wellpolished rice. The bran or the whole grain outer layer acts to encapsulate the starch and protect it from enzymatic attack in the small intestine. When the encapsulation is broken down by chewing or mincing, the amylase penetrates and initiates the digestion more quickly.

Feri et al. [23] and Eerlingen et al. [27] both found a high concentration of RS in retrograded waxy maize starch after 120 minutes of in vitro enzymatic incubation but did not extend their studies beyond this time. This study has also shown that the digestion of rice starch was not complete at 120 minutes and for some rice varieties was still not complete at 180 minutes. Previous studies have recommended 4°C as the optimal and safe storage temperature that is compatible with our daily life. However, reheating to 65°C is required to prevent the growth of Bacillus cereus, a bacterium that has often been associated with food poisoning in cooked rice products.

The strength of this study is that it followed precise and valid starch digestion techniques [20]. This group of experiments extended the research by for the first time, simulating a series of rice consumption scenarios: cold storage times, reheating before consumption and chewing. The potential alternative cooking, cold-storage and reheating procedure in this study was demonstrated to be effective in reducing the rate and extent of the glucose release during the in vitro digestion of cooked rice products, and thus may be effective in reducing the rate and extent of postprandial glycaemic response in humans. It is particularly relevant for individuals suffering from problematic carbohydrate metabolism. These findings should be further consolidated through GI measurement and chewing tests with human participants. Moreover, as slow digestion of starch may be associated with a reduced sensation of hunger [12] this cooking procedure may help reduce total daily food intake, increase the chewing length of each mouthful and prolong the intervals between food intake [15,29,30]. Further studies on the satiety of reheated rice and viscosity within the gastrointestinal tract are recommended.

The limitation is that this study is restricted to the in vitro laboratory experimental conditions. The inter-and intra- individual variations, including glucose disposal rate, chewing rate, chewed particle size distributions, etc., could not be considered as covariant variables in starch digestibility profile analysis. This study used mincing to simulate the average disruption of food achieved by chewing. Mincing broke down the outer layer of brown rice and disrupted the physical form, which directly affected the extent and rate of starch digestion in vitro. However, the disruption of cooked rice grains by the mincer pan gave a rice particle size less than or equal to 2.5 mm in diameter, which could be significantly different in human trials. Future study could use the samples masticated by participants till the point at which they felt the need to swallow [15]. Furthermore, further study is required to investigate the rate and extent to which the starch of optimal rice choice is digested and absorbed in the human gastrointestinal tract and released into the bloodstream as free glucose. The inter-and intra-individual variations need to be investigated in order to provide a more constructive recommendation on the optimal combination of rice choice and cooking and preparation method.

Conclusion

This study has demonstrated that the rate and extent of the starch digestibility of common rice products in New Zealand can be suppressed by reducing the physical form of the cooked rice grain and by prolonged cold storage (at 4°C for 24 hours). Reheating (to 65°C for 15 minutes) after cold storage can slightly increase the starch digestibility of cold-stored rice. The formation of RS and SDS in cooked rice products after cold storage or reheating does appear to be affected by the physical form of the rice grain. Minced brown rice with interrupted bran structure becomes more susceptible to digestion than intact brown rice grain. The physical form interruption appears to have less impact on white rice. Among these four New Zealand popular rice products (medium-grain white rice, basmati rice, medium-grain brown rice and long-grain brown rice), parboiled long-grain white rice had the lowest overall concentration of available starch over the time course after in vitro digestion starts. The findings suggest that replacing freshly cooked medium-grain white rice with cold-stored and reheated cooked parboiled rice should be encouraged as it has the potential to offer significant nutritional benefits to people in New Zealand who have rice in their main diet.

Acknowledgements

Chemicals and experimental equipment were supported by Plant and Food Research, Palmerston North, and Auckland University of Technology, Auckland, New Zealand.

Contributions of the Authors

Louise W Lu, who designed and conducted the research and wrote the article; Elaine Rush, who helped with study development, edited the article and added knowledge; John A Monro, who helped design the experiment and kindly contributed time and resource to all the experiments; Jun Lu, who helped with editing.

References

- Palfai TP, Monti PM, Ostafin B, Hutchison K (2000) Effects of nicotine deprivation on alcohol-related information processing and drinking behavior. J Abnorm Psychol 109: 96-105.

- Harrison EL, Hinson RE, McKee SA (2009) Experimenting and daily smokers: episodic patterns of alcohol and cigarette use. Addict Behav 34: 484-486.

- Howell A, Leyro T, Hogan J, Buckner J, Zvolensky M (2010) Anxiety sensitivity, distress tolerance, and discomfort intolerance in relation to coping and conformity motives for alcohol use and alcohol use problems among young adult drinkers. Addictive Behaviors 35:1144-1147.

- Krukowski RA, Solomon LJ, Naud S (2005) Triggers of heavier and lighter cigarette smoking in college students. J Behav Med 28: 335-345.

- Reed MB, Wang R, Shillington AM, Clapp JD, Lange JE (2007) The relationship between alcohol use and cigarette smoking in a sample of undergraduate college students. Addictive Behaviors 32: 449-464.

- Hughes JR, Kalman D (2006) Do smokers with alcohol problems has more difficulty quitting? Drug Alcohol Depend 82: 91-102.

- Hurt RD, Offord KP, Croghan IT, Gomez-Dahl L, Kottke TE, et al. (1996) Mortality following inpatient addictions treatment: Role of tobacco use in a community-based cohort. JAMA: Journal of the American Medical Association 275: 1097-1103.

- Lisha NE, Carmody TP2, Humfleet GL2, Delucchi KL2 (2014) Reciprocal effects of alcohol and nicotine in smoking cessation treatment studies. Addict Behav 39: 637-643.

- Taylor B, Rehm J (2006) When risk factors combine: The interaction between alcohol and smoking for aerodigestive cancer, coronary heart disease, and traffic and fire injury. Addictive Behaviors 31: 1522-1535.

- Jarvis CM, Hayman LL, Braun LT, Schwertz DW, Ferrans CE, et al. (2007) Cardiovascular risk factors and metabolic syndrome in alcohol- and nicotine-dependent men and women. J CardiovascNurs 22: 429-435.

- Joseph AM, Willenbring ML, Nugent SM, Nelson DB (2004) A randomized trial of concurrent versus delayed smoking intervention for patients in alcohol dependence treatment. Journal of Studies on Alcohol, 65: 681-691.

- Kodl M, Fu SS, Joseph AM (2006) Tobacco cessation treatment for alcohol-dependent smokers: when is the best time? Alcohol Res Health 29: 203-207.

- Fu S, Kodl M, Willenbring M, Nelson D, Nugent S, et al. (2008) Ethnic differences in alcohol treatment outcomes and the effect of concurrent smoking cessation treatment. Drug and Alcohol Dependence 92: 61-68.

- Holt LJ, Litt MD, Cooney NL (2012) Prospective analysis of early lapse to drinking and smoking among individuals in concurrent alcohol and tobacco treatment. Psychology of Addictive Behaviors 26:561-572.

- Centers for Disease Control and Prevention (CDC) (2009) Cigarette smoking among adults and trends in smoking cessation - United States, 2008. MMWR Morb Mortal Wkly Rep 58: 1227-1232.

- Irving LM, Seidner AL, Burling TA, Thomas RG, Brenner GF (1994) Drug and alcohol abuse inpatients' attitudes about smoking cessation. J Subst Abuse 6: 267-278.

- Macnee CL, Talsma A (1995) Development and testing of the barriers to cessation scale. Nurs Res 44: 214-219.

- Orleans CT, Rimer BK, Cristinzio S, Keintz MK, Fleisher L (1991) A national survey of older smokers: treatment needs of a growing population. Health Psychol 10: 343-351.

- Kristeller JL (1994) Treatment of hard-core, high-risk smokers using FDA approved pharmaceutical agents: An oral health team perspective. Health Values 18: 25-32.

- Asher MK, Martin RA, Rohsenow DJ, MacKinnon S, Traficante R, et al. (2003) Perceived barriers to quitting smoking among alcohol dependent patients in treatment. Journal of Substance Abuse Treatment 24: 169-174.

- Martin RA, Rohsenow DJ, MacKinnon SV, Abrams DB, Monti PM (2006) Correlates of motivation to quit smoking among alcohol dependent patients in residential treatment. Drug Alcohol Depend 83: 73-78.

- Marlatt GA, Gordon JR (1985) Relapse prevention. New York: Guilford Press.

- Velicer WF, DiClemente CC, Prochaska JO, Brandenburg N (1985) Decisional balance measure for assessing and predicting smoking status. J PersSoc Psychol 48: 1279-1289.

- DiClemente CC, Prochaska JO (1982) Self-change and therapy change of smoking behavior: a comparison of processes of change in cessation and maintenance. Addict Behav 7: 133-142.

- Curry SJ, Grothaus L, McBride C (1997) Reasons for quitting: intrinsic and extrinsic motivation for smoking cessation in a population-based sample of smokers. Addict Behav 22: 727-739.

- Baha M, Le Faou AL (2010) Smokers' reasons for quitting in an anti-smoking social context. Public Health 124: 225-231.

- Curry SJ, McBride C, Grothaus LC, Louie D, Wagner EH (1995) A randomized trial of self-help materials, personalized feedback, and telephone counseling with nonvolunteer smokers. J Consult Clin Psychol 63: 1005-1014.

- Saunders JB, Aasland OG, Babor TF, de la Fuente JR, Grant M (1993) Development of the Alcohol Use Disorders Identification Test (AUDIT): WHO Collaborative Project on Early Detection of Persons with Harmful Alcohol Consumption--II. Addiction 88: 791-804.

- First MB, Williams JB, Spitzer RL, Gibbon M (2002) Structured Clinical Interview for DSM-IV-TR Axis I Disorders, Clinical Trials Version (SCID-CT). New York: Biometrics Research, New York State Psychiatric Institute.

- Brown RA, Lejuez CW, Kahler CW, Strong DR (2002) Distress tolerance and duration of past smoking cessation attempts. J Abnorm Psychol 111: 180-185.

- Heatherton TF, Kozlowski LT, Frecker RC, Fagerström KO (1991) The Fagerström Test for Nicotine Dependence: a revision of the Fagerström Tolerance Questionnaire. Br J Addict 86: 1119-1127.

- Pomerleau CS, Carton SM, Lutzke ML, Flessland KA, Pomerleau OF (1994) Reliability of the Fagerstrom Tolerance Questionnaire and the Fagerstrom Test for Nicotine Dependence. Addict Behav 19: 33-39.

- Fagerstrom KO, Heatherton TF, Kozlowski LT (1990) Nicotine addiction and its assessment. Ear Nose Throat J 69: 763-765.

- Filbey FM, Claus E, Audette AR, Niculescu M, Banich MT, et al. (2007) Exposure to the taste of alcohol elicits activation of the mesocorticolimbicneurocircuitry. Neuropsychopharmacology 33: 1391-1401.

- Fleming MF, Barry KL, MacDonald R (1991) The alcohol use disorders identification test (AUDIT) in a college sample. Int J Addict 26: 1173-1185.

- Cherpitel CJ (1995) Analysis of cut points for screening instruments for alcohol problems in the emergency room. J Stud Alcohol 56: 695-700.

- Macnee CL, Talsma A (1995) Predictors of progress in smoking cessation. Public Health Nurs 12: 242-248.

- Curry S, Wagner EH, Grothaus LC (1990) Intrinsic and extrinsic motivation for smoking cessation. J Consult Clin Psychol 58: 310-316.

- McBride CM, Pollak KI, Bepler G, Lyna P, Lipkus IM, et al. (2001) Reasons for quitting smoking among low-income African American smokers. Health Psychol 20: 334-340.

- Bonn-Miller MO, Zvolensky MJ (2009) An evaluation of the nature of marijuana use and its motives among young adult active users. Am J Addict 18: 409-416.

- Buckner JD, Zvolensky MJ, Schmidt NB (2012) Cannabis-related impairment and social anxiety: the roles of gender and cannabis use motives. Addict Behav 37: 1294-1297.

- Agrawal A, Budney AJ, Lynskey MT (2012) The co-occurring use and misuse of cannabis and tobacco: a review. Addiction 107: 1221-1233.

- Degenhardt L, Hall W, Lynskey M (2001) The relationship between cannabis use and other substance use in the general population. Drug Alcohol Depend 64: 319-327.

- Cohen J, Cohen P (1983) Applied multiple regression/correlation analysis for the behavioral sciences. Hillsdale, NJ: Lawrence Erlbaum.

- Cohen J, Cohen P, West SG, Aiken LS (2003) Applied multiple regression/correlation analysis for the behavioral sciences (3rd ed.). Mahwah, NJ US: Lawrence Erlbaum Associates Publishers.

- Lipkus IM, Feaganes JR, Green JD, Sedikides C (2001) The Relationship Between Attitudinal Ambivalence and Desire to Quit Smoking Among College Smokers. Journal of Applied Social Psychology, 31: 113-133.

- Wilson SJ, Creswell KG, Sayette MA, Fiez JA (2013) Ambivalence about smoking and cue-elicited neural activity in quitting-motivated smokers faced with an opportunity to smoke. Addict Behav 38: 1541-1549.

- Festinger LA (1957) A theory of cognitive dissonance. Evanston, IL: Row, Peterson.

- Markowitz LJ (2000) Smoker's perceived self-exemption from health risks. Psi Chi Journal of Undergraduate Research 5: 119-124.

- Jamieson P, Romer D (2001)What do young people think they know about the risks of smoking? In P. Slovic (Ed.), Smoking: Risk, perception, and policy (pp. 51-63). Thousand Oaks, CA US: Sage Publications, Inc.

- Schane RE, Glantz SA, Ling PM (2009) Social smoking implications for public health, clinical practice, and intervention research. American Journal of Preventive Medicine 37: 124-131.

- DaniJA, De Biasi M (2001) Cellular mechanisms of nicotine addiction. PharmacolBiochemBehav 70: 439-446.

- Nestler EJ (2005) Is there a common molecular pathway for addiction? Nat Neurosci 8: 1445-1449.

- Ehrman RN, Robbins SJ, Bromwell MA, Lankford ME, Monterosso JR, et al. (2002) Comparing attentional bias to smoking cues in current smokers, former smokers, and non-smokers using a dot-probe task. Drug Alcohol Depend 67: 185-191.

- Kerst WF, Waters AJ (2014)Attentional retraining administered in the field reduces smokers’ attentional bias and craving.

- Wiers RW, Rinck M, Kordts R, Houben K, Strack F (2010) Retraining automatic action-tendencies to approach alcohol in hazardous drinkers. Addiction 105: 279-287.

- Raupach T, West R, Brown J (2013) The most "successful" method for failing to quit smoking is unassisted cessation. Nicotine Tob Res 15: 748-749.

- Korte KJ, Capron DW, Zvolensky M, Schmidt NB (2013) The Fagerström test for nicotine dependence: do revisions in the item scoring enhance the psychometric properties? Addict Behav 38: 1757-1763.

Relevant Topics

- Basmati Rice

- Drought Tolerence

- Golden Rice

- Leaf Diseases

- Long Grain Rice

- Par Boiled Rice

- Raw Rice

- Rice

- Rice and Aquaculture

- Rice and Nutrition

- Rice Blast

- Rice Bran

- Rice Diseases

- Rice Economics

- Rice Genome

- Rice husk

- Rice production

- Rice research

- Rice Yield

- Sticky Rice

- Stress Resistant Rice

- Unpolished Rice

- White Rice

Recommended Journals

Article Tools

Article Usage

- Total views: 15004

- [From(publication date):

August-2016 - Apr 04, 2025] - Breakdown by view type

- HTML page views : 13917

- PDF downloads : 1087