Research Article Open Access

Dry Sliding Tribological Behavior at Elevated Temperature of In Situ Aluminum Matrix Composites Fabricated by Al-ZrO2-C System with Different Mole Ratio of C/ZrO2

Zhu H1*, Xiaodong Sun1, Jiewen Huang1, Jianliang Li1 and Zonghan Xie21College of Materials Science and Engineering, Nanjing University of Science and Technology, Nanjing, 210094, PR China

2School of Mechanical Engineering, University of Adelaide, SA 5005, Australia

- *Corresponding Author:

- Zhu H

College of Materials Science and Engineering

Nanjing University of Science and Technology

Nanjing, 210094, PR China

Tel: +86-25-84307689

E-mail: zhg1200@sina.com

Received Date: January 04, 2017; Accepted Date: January 30, 2017; Published Date: February 14, 2017

Citation: Zhu H, Sun X, Huang J, Li J, Xie Z (2017) Dry Sliding Tribological Behavior at Elevated Temperature of In Situ Aluminum Matrix Composites Fabricated by Al- ZrO2-C System with Different Mole Ratio of C/ZrO2. J Powder Metall Min 6: 153. doi:10.4172/2168-9806.1000153

Copyright: © 2017 Zhu H, et al. This is an open-access article distributed under the terms of the Creative Commons Attribution License, which permits unrestricted use, distribution, and reproduction in any medium, provided the original author and source are credited.

Visit for more related articles at Journal of Powder Metallurgy & Mining

Abstract

The tribological behavior of the composites fabricated by an Al-ZrO2-C system with different mole ratios of C/ZrO2 at elevated temperature in air atmosphere were investigated by using a pin-on-disc wear tester. The reinforcement amounts and kinds of the composites varied with molar ratio of C/ZrO2. With the increase of the molar ratio of C/ ZrO2 from 0 to 1, the Al3Zr blocks decrease gradually and almost disappear finally. On the contrary, the ZrC particles form and increases in its amount. At elevated temperature, the composites have similar variation trend in the mass loss varied with sliding velocity and applied load, respectively. When the test temperature is at 373 K, the mass loss increases with increasing the sliding velocity, and when the sliding velocity is around 0.6 m/s, the mass loss increases to a maximum value and then decreases with further increase in sliding velocity. However, the mass loss always decreases with increasing the sliding velocity at 473 K. With the increase of C/ZrO2 molar ratio, the wear resistance of the composite increases and its friction coefficient decreases. The metal flows and adhesive wear become the main wear modes with increasing the applied load and test temperature.

Keywords

Aluminum matrix composite; Elevated temperature; Wear mechanism; Friction coefficient

Introduction

In situ AMCs have many excellent properties such as high specific strength and stiffness, especially in superior elevated temperature wear resistance. Up to date, they have been widely used as a light weight structural material and applied in automobile and aerospace [1-5]. It is known that the high temperature wear resistance of the in situ AMCs mainly determined by the kinds, sizes, shapes and thermodynamic stabilities of the reinforcements and their interfacial bonding strengths with the matrix at high temperature [6-8]. In situ reinforcements, such as Al2O3, TiB2, TiC, ZrC, AlB2 and ZrB2 or their compounds have been extensively used in AMCs [9-15]. Mathan Kumar et al. [16] used stir casting method to fabricate the Si3N4, AlN and ZrB2 reinforced Al 2618 alloy in situ composites and researched its wear behavior at elevated temperatures. And they have found that the composites have the higher percentage of contribution 63.84% influencing the wear rate of the Al 2618 composites and it is followed by Sliding Distance 20.2% and Temperature 5.32%, Load 4.01%, and Velocity 3.96%. Literature [17] has studied the high temperature wear properties of an in situ AMCs TiB2/Al-7Si and found that the transition of wear mode from mild to severe wear is increased to the higher loads and temperatures. Kumar et al. [18] have reported that the Al-4Cu alloy showed a transition from mild to severe wear at a load of 80 N and a sliding temperature of 373 K. But with the addition of 5 and 10 wt.% of in situ TiB2 particles to the Al-4Cu matrix, the transition temperatures are increased to 473 and 573 K and the loads are increased to 100 and 120 N, respectively. They also have found that at elevated temperature adhesion and metal flow are the predominant wear mechanisms for the Al-4Cu alloy. Whereas, oxidation, delamination and metal flow are the most dominant wear mechanisms for TiB2/Al-4Cu composites. Jerome et al. [19] have studied the effect of TiC ceramic particulate addition on the high temperature sliding wear resistance of the in situ composites produced by using a reaction mixture of K2TiF6 and graphite powder with molten metal. They have found that the wear rate increases with the increase in applied load and decreases with the increase in weight percentage of TiC. Both monolithic and composites are able to withstand thermal softening effects due to the formation of oxidative protective transfer layer. In our previous work [20-22], we have investigated that the reaction mechanism, mechanical properties and wear resistance of the in situ AMCs fabricated by an Al-ZrO2-C systems. When the molar ratio of C/ZrO2 is zero, the reinforcements of the composites are composed of particles α-Al2O3 and blocks Al3Zr. When the molar ratio of C/ZrO2 increases to 1.0, the Al3Zr almost disappears, subsequently the content of ZrC increases, which can greatly improve the wear resistance of the composites. When the wear test temperature increases, the worn surface oxidation, plastic deformation and matrix recrystallization considerably influences the wear behaviors and wear mechanisms of the composites. Up to now, there are few literatures concerning tribological behavior of this kind of in situ AMCs fabricated by Al-ZrO2-C system at elevated temperatures, which should be one of the main considerations at elevated temperature application. In order to contribute to this field, the friction and wear mechanism of the composites at elevated temperatures are investigated and the wear mechanisms are discussed in this paper.

Materials and Methods

Experimental procedures

To fabricate the aluminum matrix composites reinforced with particles of ZrC and Al2O3 and with reinforcement volume fraction of 20vol.%, the Al powders (30-50 μm average particle size, 99% purity), C powders (10-20 μm average particle size, 99% purity) and ZrO2 powders (3-5 μm average particle size, 99% purity) were selected as raw materials. Based on the following expected reaction equations: 13Al+3ZrO2 → 3Al3Zr+2Al2O3, 17Al+6ZrO2+C → 3Al3Zr+4Al2O3+ZrC and 4Al+3ZrO2+3C → 3ZrC+2Al2O3, respectively, the Al, C and ZrO2 three kind powders were proportionally weighed. The powder mixtures with the reinforcements volume fractions of 20 vol.% and the C/ZrO2 mole ratios of 0, 0.5 and 1.0 were played in a stainless steel vacuum jar for ball-milling. Processing parameters are as follows: weight ratio of ball to powder is 10:1 ball material is AISI420 stainless steel, ball diameter is 100 mm; rotating speed is 250 rotations per min and milling time is 2 hours. After milling, the mixed powders were air dried for 2 hours at temperature of 373 K and pressed into green billets in diameter of 30 mm under a pressure of 150 MPa. The billets were then played in a vacuum furnace for heating. When the temperature was increased to about 1073 K, the reaction occurred in the billet and then held at this temperature for 10 min and cooled down to environment temperature. The combusted billets were removed to their surface by grinding wheel, and then were extruded to rods in diameter of 7 mm at an extrusion rate of 10:1 at 723 K. The rods were lathed to wear test pins with 5.5 mm in diameter and 12 mm in length. The dry sliding wear tests were performed on a pin-on-disc wear machine (model MG2000, China) at 373 K and 473 K in air under relative humidity of 30-50%. The friction discs are made from of GCr15 (AISI52100) stainless steel. Its diameter, hardness and surface roughness is 70 mm, 55~60 HRC and 0.2 μm, respectively. Before the wear tests, all the end face of pins must be carefully grounded by fine metallographic sandpaper to make the counterpart surface smooth. The applied loads on pin by a lever system were 20, 30, 40 50 and 70 N, and the sliding speeds were 0.4, 0.5, 0.6 and 0.7 m/s, respectively.

The mass loss was measured by an electronic balance with the resolution of 0.01 mg. The wear surface was observed under a scanning electron microscope (SEM, Quanta 2000) equipped with an energy dispersive X-ray spectroscope (EDS) in order to indicate the wear mechanism.

Results and Discussion

Wear characteristics

The wear properties of the composites are affected by their microstructures. As in our previous published paper, the microstructures of the composites vary with the C/ZrO2 mole ratios. When the C/ZrO2 mole ratio is 0, the reinforcements of the composite are composed of Al3Zr blocks and α-Al2O3 fine particles. As the C/ZrO2 mole ratio increases to 0.5, the amount of the Al3Zr phase reduces and another new phase ZrC forms. When the C/ZrO2 mole ratio reaches 1.0, the Al3Zr phase almost disappears and the α-Al2O3 and ZrC particles are the final reinforcements of the composite (Figure 1a).

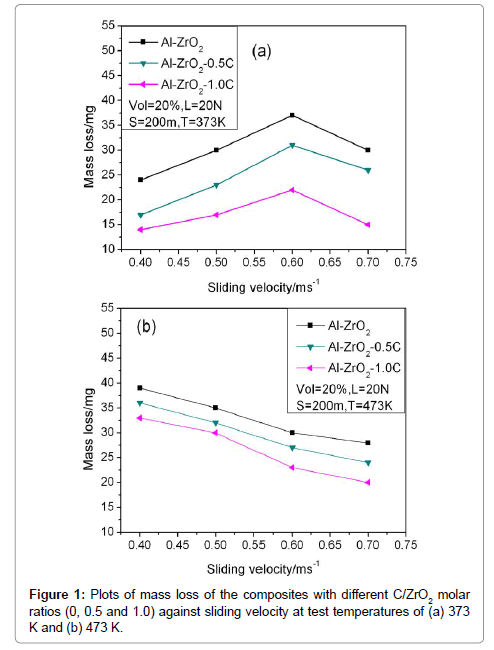

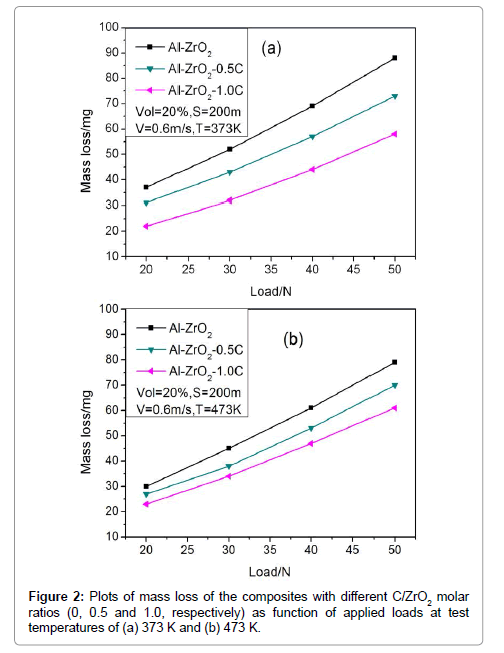

Figure 1 shows the wear mass losses of the composites varied with the sliding velocity under an applied load 20 N and a sliding distance of 200 m at temperatures of 373 K and 473 K. It can be seen from Figure 1a that the wear mass losses of the composites increase with the rising of sliding velocity. When the sliding velocity increases to 0.6 ms-1, the wear mass loss increases to a maximum value. When the sliding velocity increases further, the wear mass loss decreases. However, when the test temperature increases to 473 K, the wear mass losses of the composites always decrease with the rising of sliding velocity as shown in Figure 1b. From Figure 1, it can be seen that the wear resistances of the composites increase with the increase of C/ZrO2 molar ratios (Figure 2). The variations of wear mass loss with applied load under a sliding velocity of 0.6 m/s and a sliding distance of 200 m for the composites are shown in Figure 2. From Figure 2, it is obvious that the wear mass losses increase linearly with increasing the applied load, which is attributed to the uniform distribution of the reinforcements in the aluminum matrix and the steady properties of the composites. It also can be seen in Figure 2 that when the test temperature increases, the mass losses decrease under the same test conditions. This is because the oxidation layer on the wear surface becomes thicker and stronger at test temperature of 473 K and it can effectively reduce the friction between the pin and disc.

Friction coefficients

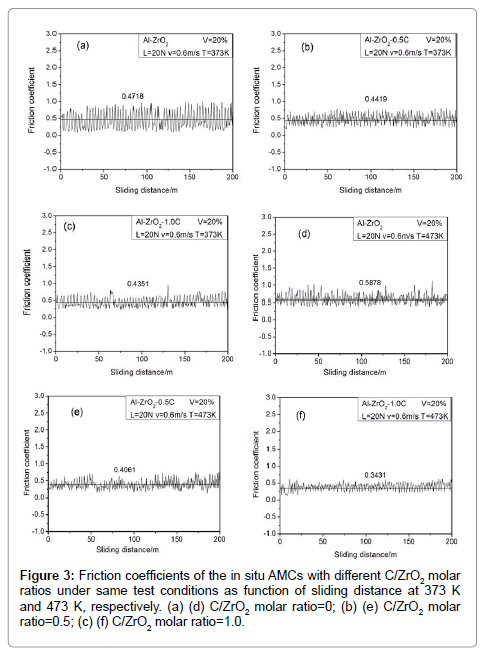

The friction coefficient is an important factor on the wear property of the composite. When the test temperature is at 373 K, the variations of the friction coefficients varied with sliding distance under a sliding velocity of 0.6 m/s and an applied load of 20 N are shown in Figure 3. From Figure 3, it can be seen that when the C/ZrO2 molar ratios increase from 0 to 1.0, the friction coefficients have a slightly decrease in their varied ranges and their values. While when the test temperature increases to 473 K, the friction coefficients decrease obviously in their values and decrease slightly in their varied ranges as shown in Figure 4. When the test temperature is at 473 K, the recrystallization takes place in the wear surface and the hardness of the wear surface decreases, which will lead to the increase of the friction coefficient in its value and its varied range. While the oxidation layer forms on the wear surface simultaneously at the test temperature of 473 K. The oxidation layer cannot be cracked due to the light applied load e.g. 20 N and it can effectively reduce the roughness of the wear surface and leads to the decrease in friction coefficient. In addition, with the increase of the C/ZrO2 molar ratio, the amount of Al3Zr blocks decreases and the ZrC fine particles increases. The amount of the contact points between the pin and disc considerable increases, which can also result in the decrease of the friction coefficient in its varied range and its value.

Wear surfaces and wear mechanisms

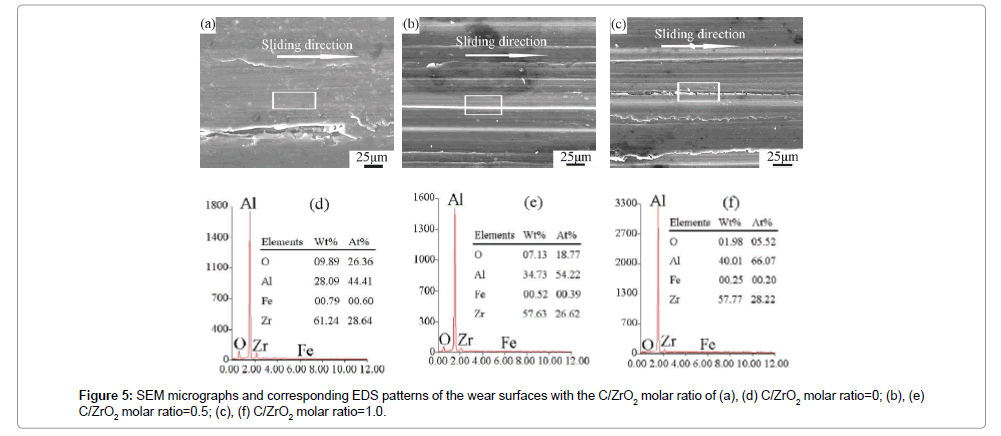

Wear mechanisms of the aluminum matrix composites are highly dependent on their surface microstructure and test temperature [23]. The wear surfaces of samples with C/ZrO2 mole ratios at 0, 0.5, and 1.0 are characterized by SEM micrographs in Figure 5a, respectively. The corresponding EDS patterns from the selected area are shown in Figure 5a. When the C/ZrO2 mole ratios are 0, the reinforcements of the composites are composed of Al3Zr blocks and α-Al2O3 particles. The wear debris are embedded into the wear surface and there are some shallow furrows on the wear surface in Figure 5a, which is resulted from the breaking of the brittle phase Al3Zr by the shear force and compressive stress. As compared with the ambient wear test results in our previous literature, the amount of debris on the wear surface decreases considerably. When the test temperature increases to 473 K, the recrystallization takes place on the wear surface during the repeating wear test. Thus, the hardness of the wear surface decreases. As a result, the debris caused by the broken brittle Al3Zr blocks is embedded into the aluminum matrix under the external applied load. It is indicate that the Al3Zr phase is disadvantageous to the wear resistance of the aluminum matrix composite. But the α-Al2O3 particles can effectively become the supporting points due to their high bonding strengths with the matrix. And they are beneficial to the increase of the wear resistance of the composites. Simultaneously, with the increase of test temperature, the oxidation layer is formed and become thinker on the wear surface, which can remarkably improve the wear properties of the composite. When the C/ZrO2 mole ratio increases to 0.5, the amount of the brittle phase Al3Zr decreases and a new phase ZrC simultaneously forms. As a result, the amount of the supporting points between the pin and disc further increases, which leads to the decrease in the friction coefficient of the composite. Its corresponding wear surface in Figure 5b shows that there are some sharp and straight furrows on the wear surface. Here, it is clear that the abrasive wear decreases and the other wear modes (i.e. oxidation wear and adhesive wear) increase relatively.

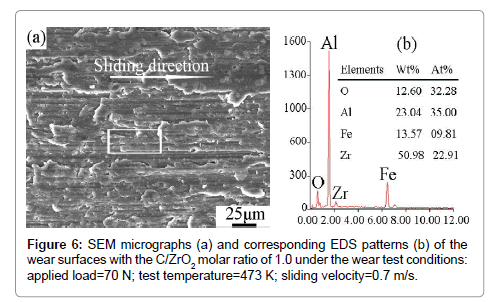

The wear test conditions: applied load=20 N, test temperature=473 K, sliding velocity=0.7 m/s and sliding distance=200 m. As the C/ZrO2 mole ratio increases to 1.0, the Al3Zr blocks are completely replaced by the ZrC particles. The α-Al2O3 and ZrC particles are the final reinforcements of the composite and they uniformly distribute in the aluminum matrix (Figure 5c). Its worn surface as shown in Figure 5c indicates that the amount of the straight furrows increases. During the wear test at high temperature, the hardness of the aluminum matrix decreases due to the recrystallization and then the aluminum will be removed by the counterpart disc. The reinforcements distributed uniformly in the aluminum matrix have high bonding strengths with the matrix and can effectively sustain the external applied load, which enhances the wear resistance of the composites. While the strong particles e.g. α-Al2O3 and ZrC separated from the matrix, they act as debris in the wear surface. Therefore, there are some obvious furrows on the wear surfaces (Figure 5d-5f). From Figure 5d-5f, it is concluded that when the C/ZrO2 molar ratio increases, the contents of the iron slightly decrease, which indicates that the adhesive resistance of the composites slightly decrease and the oxidation wear becomes the important mode in the complex wear mechanisms. However, when the applied load increases to 70 N, there are metal follows on the wear surface as shown in Figure 6a. Its corresponding EDS pattern in Figure 6b also indicates that many iron elements have transferred from the counterpart disc to the wear surface and that the content of oxygen increases greatly, which shows the adhesion and oxidation increase significantly. Therefore, when the temperature is at 473 K and the applied load increases to 70 N, the friction between the pin and disc becomes unstable and even cannot be able to be tested. It is demonstrated that the adhesive wear becomes a dominate wear mode of the hybrid wear mechanisms of the composites.

Conclusion

The influences of C/ZrO2 molar ratio, sliding velocity and applied load on the tribological behavior of the composites made by reaction method in an Al-ZrO2-C system were investigated by pin-on-disc dry sliding wear tests at elevated temperatures. Some conclusions are as follows:

• The mass losses of the composites increase linearly with the applied loads. At a test temperature of 373 K, the mass losses of the composites slightly increase with the increase of sliding velocity, whereas when the sliding velocity is higher than 0.6 m/s, the mass losses decrease gradually. When the test temperature reaches 473 K, the mass losses always decrease with the increase of the sliding velocity. With the increase of C/ZrO2 molar ratios, the friction coefficients of the composites decrease and their wear resistances increase.

• The wear mechanisms of the composite are composed of adhesive wear, abrasive wear and oxidation wear. With the increase of the C/ZrO2 molar ratios, the abrasive wear decreases. When the C/ ZrO2 molar ratio is 1.0 and the applied load increases to 70 N, the metal flow and adhesive wear become the dominate wear modes of the hybrid wear mechanisms.

Acknowledgement

This work was supported by the National Natural Science Foundations of China (grant no. 51371098 and 51571118) and the Natural Science Foundations of Jiangsu Province, China (grant no. BK20141308).

References

- Dinaharan I, Murugan N, Thangarasu A (2016)Development of empirical relationships for prediction of mechanical and wear properties of AA6082 aluminum matrix composites produced using friction stir processing.Engineering Science and Technology19: 1132-1144.

- JiménezAE, BermúdezMD, CintasJ, HerreraEJ (2009) Dry wear of NiAl3-reinforced mechanically alloyed aluminum with different microstructure.Wear 266: 255-265.

- TjongSC, MaZY(2000) Microstructural and mechanical characteristic of in situ metal matrix composites.MaterSciEngR29: 49-113.

- RosenbergerMR, ForlererE, SchvezovCE (2009) Wear behavior of AA1060 reinforced with alumina under different loads. Wear266(2009) 356-359.

- Humberto MelgarejoZ, Marcelo SuárezO, Kumar Sridharan K (2008)Microstructure and properties of functionally graded Al-Mg-B compositesfabricated by centrifugal casting.ComposPart A 39:1150-1158.

- DegnanCC, ShipwayPH, WoodJV (2001) Elevated temperature sliding wearbehavior of TiC-reinforced steel matrix composites. Wear251: 1444-1451.

- PrassadSV, AsthanaR (2004)Aluminum metal-matrix composites for automotive applications: tribological considerations.TribolLett17: 445-452.

- KumarS, BalasubramanianV (2008)Developing a mathematical model to evaluate wear rate of Al7075/SiCp powder metallurgy composites.Wear264: 1026-1034.

- MindivanH, TekmenC, DikiciB, TsunekawaY, GavgaliM (2009) Wear behavior of plasma sprayed composite coatings with in situ formed Al2O3.MaterDes30:4516-4520.

- ZhaoDG, LiuXF, PanYC, BianXF, LiuXJ (2007)Microstructure and mechanical properties of in situ synthesized (TiB2+Al2O3)/Al-Cu composites.JMaterProc Technol 189:237-241.

- Naveen KumarG, NarayanasamyR, NatarajanS, Kumaresh BabuSP, SivaprasadK,et al. (2010) Dry sliding wear behavior of AA 6351-ZrB2 in situ composite at room temperature.Mater Des31:1526-1532.

- ZhangSL, ZhaoYT, ChenG, ChengXN (2007)Microstructures and dry slidingwearproperties of in situ (Al3Zr + ZrB2)/Al composites.J MaterProc Technol184:201-208.

- ZhuHG, WangHZ, GeLQ, XuWJ, YuanYZ (2008) Study of the microstructure and mechanical properties of composites fabricated by the reaction method in an Al-TiO2-B2O3 system.Mater Sci EngA 478: 87-92.

- NatarajanS, NarayanasamyR, Kumaresh BabuSP, DineshG, Anil KumarB, et al. (2009)Sliding wear behavior of Al 6063/TiB2 in situ composites at elevated temperaturesMater Des30:2521-2531.

- Yuan L, Han J, Liu J, Jiang Z (2016) Mechanical properties and tribological behavior of aluminum matrix composites reinforced with in-situ AlB2 particles. TribologyInternational98: 41-47.

- Kumar NM, Kumaran S, Kumaraswamidhas LA (2016)2_in_situ_composites_at_elevated_temperatures' title='Click here'> Wear behaviour of Al 2618 alloy reinforcedwith Si3N4, AlN and ZrB2 in situ compositesat elevated temperatures.Alexandria Engineering Journal55: 19-36.

- KumarS, Subramanya SarmaV, MurtyBS (2009)Effect of temperature on the wearbehavior of Al-7Si-TiB2 in-situ composites. Metall Mater TransA40: 223-231.

- KumarS, Subramanya SarmaV, MurtyBS (2010) Hightemperature wear behavior of Al-4Cu-TiB2 in situ compositesWear26: 1266-1274.

- Jerome S, RavisankarB, Pranab Kumar M, NatarajanS (2010)Synthesis and evaluation of mechanical and high temperature tribologicalproperties of in-situ Al-TiC composites.Tribo Inter43: 2029-2036.

- ZhuHG, MinJ, AiYL, ChuD, WangH, et al. (2010) The reaction mechanism and mechanical properties of the composite fabricated in an Al-ZrO2-C system.MaterSciEngA527:6178-6183.

- Zhu HG, Min J, LiJL, AiYL, GeLQ, et al. (2010)In situ fabrication of (α-Al2O3+Al3Zr)/Al composites in an Al-ZrO2 system.ComposSci Technol70 : 2183-2189.

- ZhuHG, AiYL, MinJ, WuQ,WangHZ (2010)Dry sliding wear behavior of Al-based composites fabricated by exothermic dispersion reaction in an Al-ZrO2-C system.Wear 268: 1465-1471.

- Koraman E, Baydo─?an M, Say─▒lgan S, Kalkanl─▒ A (2015) Dry slidingwearbehaviorofAl-Fe-Si-V alloys at elevatedtemperatures. Wear323: 101-107.

Relevant Topics

- Additive Manufacturing

- Coal Mining

- Colloid Chemistry

- Composite Materials Fabrication

- Compressive Strength

- Extractive Metallurgy

- Fracture Toughness

- Geological Materials

- Hydrometallurgy

- Industrial Engineering

- Materials Chemistry

- Materials Processing and Manufacturing

- Metal Casting Technology

- Metallic Materials

- Metallurgical Engineering

- Metallurgy

- Mineral Processing

- Nanomaterial

- Resource Extraction

- Rock Mechanics

- Surface Mining

Recommended Journals

Article Tools

Article Usage

- Total views: 3721

- [From(publication date):

April-2017 - Apr 05, 2025] - Breakdown by view type

- HTML page views : 2860

- PDF downloads : 861