Determination of the Iron and Zinc Contents for Teff Types in the NorthWestern part of Ethiopia

Received: 01-Jul-2024 / Manuscript No. acst-24-141033 / Editor assigned: 04-Aug-2024 / PreQC No. acst-24-141033 / Reviewed: 18-Jul-2024 / QC No. acst-24-141033 / Revised: 22-Jul-2024 / Manuscript No. acst-24-141033 / Published Date: 29-Jul-2024

Abstract

A simple and efficient method was used to determine the levels of iron and zinc in the teff flour samples. The aim of this study was to determine the concentration levels of iron and zinc in teff samples across different locations and to compare with other reported values due to different agricultural applications. The levels of Fe and Zn in the three types of teff samples collected from the three sampling areas were determined by using Micro-plasma atomic emission spectroscopy. The iron mean concentration of white teff was highest in the Bure site followed by Bahir Dar and Debre Markos sampling sites. The level of iron in the red teff was highest in the Debre Markos site followed by Bure and Bahir Dar sampling sites respectively. Similarly the iron content of the mixed teff was highest in Bahir Dar site followed by Debre Markos and Bure sampling sites. However, the amounts of Zn determined in the three types of teff samples collected from the three different locations were almost similar. The overall mean concentrations determined (mg/kg, air dry weight) for the teff samples collected from the Bure, Debre Markos and Bahir Dar sites were in the ranges of Fe (719) > Zn (86) >, Fe (728) > Zn (87) and Fe (668) > Zn (73), respectively. The one way ANOVA indicated the mean concentrations of the two studied metals found in the three types of teff samples within and between the sampling sites was not significant at 95% confidence level.

keywords

Analysis; Concentration; Determination; Digestion; Teff grains

Introduction

Teff is an annual cereal grass grown for its tiny nutritious seeds. It is a staple food in Ethiopia, consisting of two- thirds of their cereal diet and is primarily used to make injera. "Injera" is an Amharic term for Ethiopian bread similar to pan cake, made usually from teff. Injera is thin, prepared from teff flour, water and starter after successive fermentations (Neela and Fanta, 2020). Teff can also be combined with other baking flours to produce baked products, such as muffins and cookies. Teff has also been linked to other health benefits, such as anemia due to its exceptionally high Fe content (Coleman, 2012). Teff is a self-pollinated, annual, warm season cereal crop, believed to have originated in Ethiopia and have been domesticated and used throughout the world due to its excellent nutritional value as grains for human consumption and as forage for livestock (FAO, 2010). Suitable conditions of temperature, soil and water are the main growth conditions for teff. Although teff is grown for its grain, the straw is also used as forage for livestock as well as to reinforce mud or plasters in construction of houses both in rural and urban areas (Kibatu et al., 2017) [1].

Teff is a hugely important crop to Ethiopia both in terms of production and consumption (FAO/WHO, 2011). In terms of production, teff is the dominant cereal by area coverage and second only to maize in production and consumption. However, it has been historically neglected compared to other staple grain crops, yields are relatively low (around 1.26 tons/hectare) and some farmers under certain conditions sustain high losses which result in reduced quantity of grain available to consumers (Merga, 2018) [2].

Due to its best nutritional content, Ethiopian people are very comfortable with the taste of teff injera than any other food. It is the most valuable grain in Ethiopia, which is considered an excellent source of fiber, Fe and Ca than other cereal grains (Umeta et al., 2005). Recently there is a growing interest in teff grain utilization because of nutritional merits (whole grain) and free of the protein gluten that make teff an increasingly important dietary component for individuals who suffer from gluten intolerance or celiac disease (Boka et al., 2013). The color of teff can vary from white (ivory) to dark brown (black) depending on the variety. In Ethiopia three major categories can be identified, white (nech), red (quey) and mixed (sergegna) [3].

The role of minerals in food is to provide a reliable source of essential nutrients in a balanced and bio-available. There is a significant body of evidence that minerals by themselves and in proper balance to one another have important biochemical and nutritional functions. The difference in mineral content between and within teff varieties is wide ranging (Kebede, 2009) [4].

Materials and Methods

In this study analytical grade reagents, Perchloric acid (70%) and nitric acid (69-72%) were used (Sigma Aldrich Steinleim, Germany). The stock standard solutions of 1000 mg L1 were prepared from the nitrate salts of the metals. The working standard solutions of the selected metals were prepared freshly from the intermediated standard solutions (100 mg L1) which were obtained by diluting stock standard solutions. Sample preparation utilized PVC flasks, polyethylene conical flasks, filter paper, 50 mL volumetric beakers, round bottom flask, ceramic mortar and pestle (USA), four digit digital analytical balance and Kjeldahl technique (England) were the materials used. All the glassware used were first kept overnight in a 10% HCl solution and then repeatedly washed with distilled water and dried in an oven for 24 h before use.

Micro-wave Plasma Atomic Emission Spectroscopy (MP-AES, 4200), with nitrogen supplied from an Agilent 4107 nitrogen generator was used to determine Fe and Zn. The sample introduction system consisted of a micro mist nebulizer and double-pass glass cyclonic spray chamber. External Gas Control Module (EGCM) accessory and auto samplers were used [5]. The MP-AES was controlled using the intuitive MP Expert software, which recommends wavelengths for the selected elements and automatically sets the nebulizer flow rate and EGCM settings. Auto background correction was used to resolve the element emission line from the organic matrix (Agilent Technologies, Inc., 2016). MP-AES consists of microwave induced plasma interfaced to an Atomic Emission Spectrophotometer (AES). It is used for simultaneous multi-analyte determination of major and minor elements. MP-AES employs microwave energy to produce a plasma discharge using nitrogen supplied from a gas cylinder or extracted from ambient air, which eliminates the need for sourcing gases in remote locations or foreign countries. Samples are typically nebulized prior to interaction with the plasma in MP-AES measurements. The atomized sample passes through the plasma and electrons are promoted to the excited state. The light emitted electrons return to the ground state light is separated into a spectrum and the intensity of each emission line measured at the detector [6].

Sample collection and preparation

White, red and mixed teff samples were collected from different teff containers from the north-western areas of Ethiopia (Bahir Dar, Bure and Debre Markos), which are one of the most teff productive regional areas in Ethiopia. From each teff sample types around 0.1 kg of sub-samples were collected from different teff containers. For each teff sample types a total of around 0.5 kg were collected through compositing. The samples were sampled by using auger sampler from the containers and unwanted materials were removed. In the laboratory the collected teff samples were washed with tap water and then with distilled water to eliminate adsorbed dust and other particulate matters. The samples were then air-dried for seven days to remove the moisture. The dried samples were ground by using a machine grinder and sieved to mesh size of 0.5 mm. Then the samples were stored in plastic bags (polyethylene) under airtight conditions until the time of digestion [7].

Digestion of samples

Applying the optimized conditions, 0.5 g of powdered each types of teff samples were transferred into a 100 mL round bottom flask. Then 6 mL of a mixture of HNO3 (69- 72%) and HClO4 (70%) with a volume ratio of 5:1 (v/v) was added and the mixture was digested on a Kjeldahl digestion apparatus fitted with a reflux condenser by setting the parameters temperature and time. The digest was allowed to cool to room temperature for 10 min without dismantling the condenser and for 10 min after removing the condenser. To the cooled solution 10 mL of distilled water was added to dissolve the precipitate formed on cooling and to minimize dissolution of filter paper by the digest residue while filtering with filter paper (Whatman 125 mm diameter, Germany) into 50 mL volumetric flask. The round bottom flask was rinsed subsequently with around 5 mL distilled water until the total volume reached around 40 mL. Then finally the solution was filled to the mark (50 mL) using distilled water. The digestion was carried out in triplicate for each sample. Digestion of the blank was also performed in parallel with the teff samples keeping all digestion parameters the same. Then the metal concentrations in the digested sample solutions were determined by using MP- AES (Agilent technologies, Inc., 2016) [8].

Results and Discussion

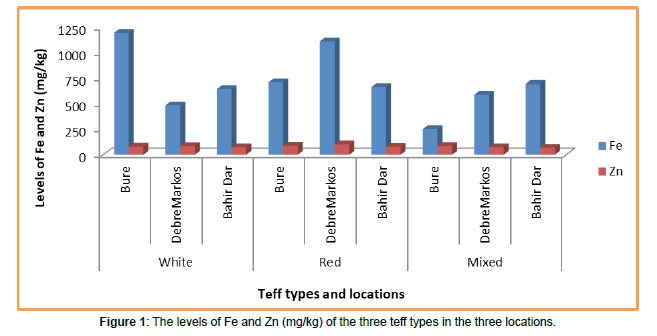

As shown in Figure 1, the iron mean concentration of white teff was highest in the Bure site followed by Bahir Dar and Debre Markos sampling sites. The level of iron in the red teff was highest in the Debre Markos site followed by Bure and Bahir Dar sampling sites respectively. Similarly the iron content of the mixed teff was highest in Bahir Dar site followed by Debre Markos and Bure sampling sites. However, the amounts of Zn determined in the three types of teff samples collected from the three different locations were almost similar (Figure 1).

As shown in Table 1 the overall mean concentrations determined (mg/kg, dry weight) for the teff samples collected from the Bure site were, Fe (719) > Zn (86). The overall mean concentrations determined (mg/kg, dry weight) for the teff samples collected from the Debre Markos site, Fe (728) > Zn (87). Similarly the overall mean concentrations determined (mg/kg, dry weight) for the teff samples collected from the Bahir Dar site were, Fe (668) > Zn (73). The concentrations of the metals were carried out by using MP-AES and mean values were determined from triplicate analysis of each sample and triplicate samples were used for each sample. The results were expressed in terms of mean values ± SD. All the results obtained from the MP-AES that were expressed in terms of (mg/L) were converted into (mg/kg) (Table 1).

| Concentrations (Mean ± SD) in mg/kg | |||

|---|---|---|---|

| Sampling sites | Teff types | Fe | Zn |

| Bure | White | 1195±1 | 80±1 |

| Red | 709±1 | 90±1 | |

| Mixed | 252±2 | 87±3 | |

| Overall mean | 719 | 86 | |

| Debre Markos | White | 485±1 | 85±1 |

| Red | 1110±2 | 102±2 | |

| Mixed | 588±3 | 73±3 | |

| Overall mean | 728 | 87 | |

| Bahir Dar | White | 645±1 | 73±1 |

| Red | 664±2 | 77±1 | |

| Mixed | 694±4 | 69±3 | |

| Overall mean | 668 | 73 | |

Table 1: Mean concentrations (mean ± SD, n = 3, mg kg-1 (air dry weight) of Fe and Zn in each samples.

As shown on Table 2 the concentrations of Fe and Zn in this study were higher than the concentrations of the other studied reports. The level of Fe in the white teff was higher than that of the red and mixed teff samples collected from the Bure site and the level of Fe in the red teff was higher than that of the white and mixed teff samples collected from the Debre Markos site. The amount of Fe determined in the three types of teff samples collected from the Bahir Dar site were almost similar. The concentrations of Zn determined in the three types of teff samples were also similar within each sampling sites. The differences in the concentration of the studied metals across different locations are due to the difference of agricultural practices and usage of different fertilizers like urea and others (Table 2) [9].

Teff type |

Fe | Zn | Method | Reference |

|---|---|---|---|---|

| White | 95-377 | 24-68 | - | Baye et al. (2014) |

| White | 160±2 | 30±0.12 | FAAS | Kebede (2009) |

| White | 189 | - | - | do Nascimento et al. (2018) |

| White | 161±2 | 27±0.0 | PTXRF | Kibatu et al. (2017) |

| White | 89.5-146 | - | ICP-OES | Girma and Meareg (2017) |

| White | 485-1195 | 73-85 | MP-AES | This study |

| Red | 116->1500 | 23-67 | - | Baye et al. (2014) |

| Red | 246±1. | 48±11 | FAAS | Kebede (2009) |

| Red | 664-1110 | 77-102 | MP-AES | This study |

| Mixed | 115->1500 | 38-39 | - | Baye et al. (2014) |

| Mixed | 201±1 | 38±0.1 | FAAS | Kebede (2009) |

| Mixed | 589 | - | - | do Nascimento et al. (2018) |

| Mixed | 226±0.02 | 34±0.1 | PTXRF | Kibatu et al. (2017) |

| Mixed | 76 | 36 | - | Yilmaz and Arslan (2018) |

| Mixed | 443 | - | - | Kibatu et al., 2017) |

| Mixed | 252-694 | 69-87 | MP-AES | This study |

Table 2: Comparison of the concentration of teff samples with other reported values

Conclusion

In this study, effective method was used for the determination of the mean concentration levels of iron and zinc in the three types of teff flours collected from the North-Western parts of Ethiopia. The overall mean concentrations determined (mg/kg, air dry weight) for the teff samples collected from the Bure site were Fe (719) > Zn (86). The overall mean concentrations determined (mg/kg, dry weight) for the teff samples collected from the Debre Markos site were Fe (728) > Zn (87). Similarly the overall mean concentrations determined (mg/kg, dry weight) for the teff samples collected from the Bahir Dar site were Fe (668) > Zn (73). The statistical analysis indicated that there was no significant difference between the mean concentrations of the studied iron and zinc found in the three types of teff samples within and between the sampling sites at 95% confidence level.

References

- Boka B, Woldegiorgis AZ, Haki GD (2013) Antioxidant properties of Ethiopian traditional bread (Injera) as affected by processing techniques and tef grain (Eragrostis tef (Zucc.) varieties. Canadian Chemical Transactions1: 7-24.

- Baye K., Mouquet‐Rivier C, Icard‐Vernière C, Picq C, Guyot JP, et al. (2014) Changes in mineral absorption inhibitors consequent to fermentation of E thiopian injera: implications for predicted iron bioavailability and bio accessibility. International journal of food science & technology 49: 174-180.

- do Nascimento KDO, Paes SDND, de Oliveira IR, Reis IP, Augusta IM, et al. (2018) Teff: suitability for different food applications and as a raw material of gluten-free, a literature reviews. Journal of Food and Nutrition Research 6: 74-81.

- Kebede Z (2009) Levels of essential elements in three teff [Eragrostis tef (Zucc.) Trotter] varieties. Addis Ababa University.

- Kibatu G, Chacha R, Kiende R (2017) Determination of major, minor and trace elements in Tef using portable total x-ray fluorescence (TXRF) spectrometer. EC Nutrition 9: 51-59.

- Merga, M. (2018) Progress, achievements and challenges of tef breeding in Ethiopia. Journal of Agricultural Science and Food Research 9:1-8.

- Neela S, Fanta SW (2020) Injera (An ethnic, traditional staple food of Ethiopia): A review on traditional practice to scientific developments. Journal of Ethnic Foods 7: 1-15.

- Umeta M, West CE, Fufa H (2005) Content of zinc, iron, calcium and their absorption inhibitors in foods commonly consumed in Ethiopia . Journal of Food Composition and Analysis 18: 803-817.

- Yilmaz HO, Arslan M (2018) Teff: Nutritional compounds and effects on human health. Acta Scientific Medical Sciences 2: 15-18.

Indexed at, Google Scholar, Crossref

Indexed at, Google Scholar, Crossref

Citation: Abraha G (2024) Determination of the Iron and Zinc Contents for TeffTypes in the North-Western part of Ethiopia. Adv Crop Sci Tech 12: 717.

Copyright: © 2024 Abraha G. This is an open-access article distributed under theterms of the Creative Commons Attribution License, which permits unrestricteduse, distribution, and reproduction in any medium, provided the original author andsource are credited.

Share This Article

Recommended Journals

Open Access Journals

Article Usage

- Total views: 541

- [From(publication date): 0-2024 - Apr 02, 2025]

- Breakdown by view type

- HTML page views: 368

- PDF downloads: 173